Ceramic Plate Test Solderability . The ceramic plate was used to. 100 x 100mm (4 x 4 inches); Cut down on assembly issues, including misapplications of solder mask; With the help of the must system 3 wetting balance, solderability tests can be performed on almost all components and pcbs. 1.1 scope this standard prescribes test methods, defect definitions, acceptance criteria, and illustrations for assessing the solderability of. Improve likelihood of reliable solder joints; The ceramic plate test (cpt) or surface mount process simulation test (1) has been used in the industry since the early 1990s to evaluate. The unique solder globule testing. Approximately 0.8mm thick without test pads on the surface. Not everyone accepts that the wetting balance test is suited for determining the solderability of plating materials. This paper addresses several testing protocols and methods to enhance solderability including: The ceramic plate test (cpt),.

from www.stannol.de

With the help of the must system 3 wetting balance, solderability tests can be performed on almost all components and pcbs. The ceramic plate was used to. The unique solder globule testing. This paper addresses several testing protocols and methods to enhance solderability including: 1.1 scope this standard prescribes test methods, defect definitions, acceptance criteria, and illustrations for assessing the solderability of. Improve likelihood of reliable solder joints; Not everyone accepts that the wetting balance test is suited for determining the solderability of plating materials. Cut down on assembly issues, including misapplications of solder mask; The ceramic plate test (cpt),. 100 x 100mm (4 x 4 inches);

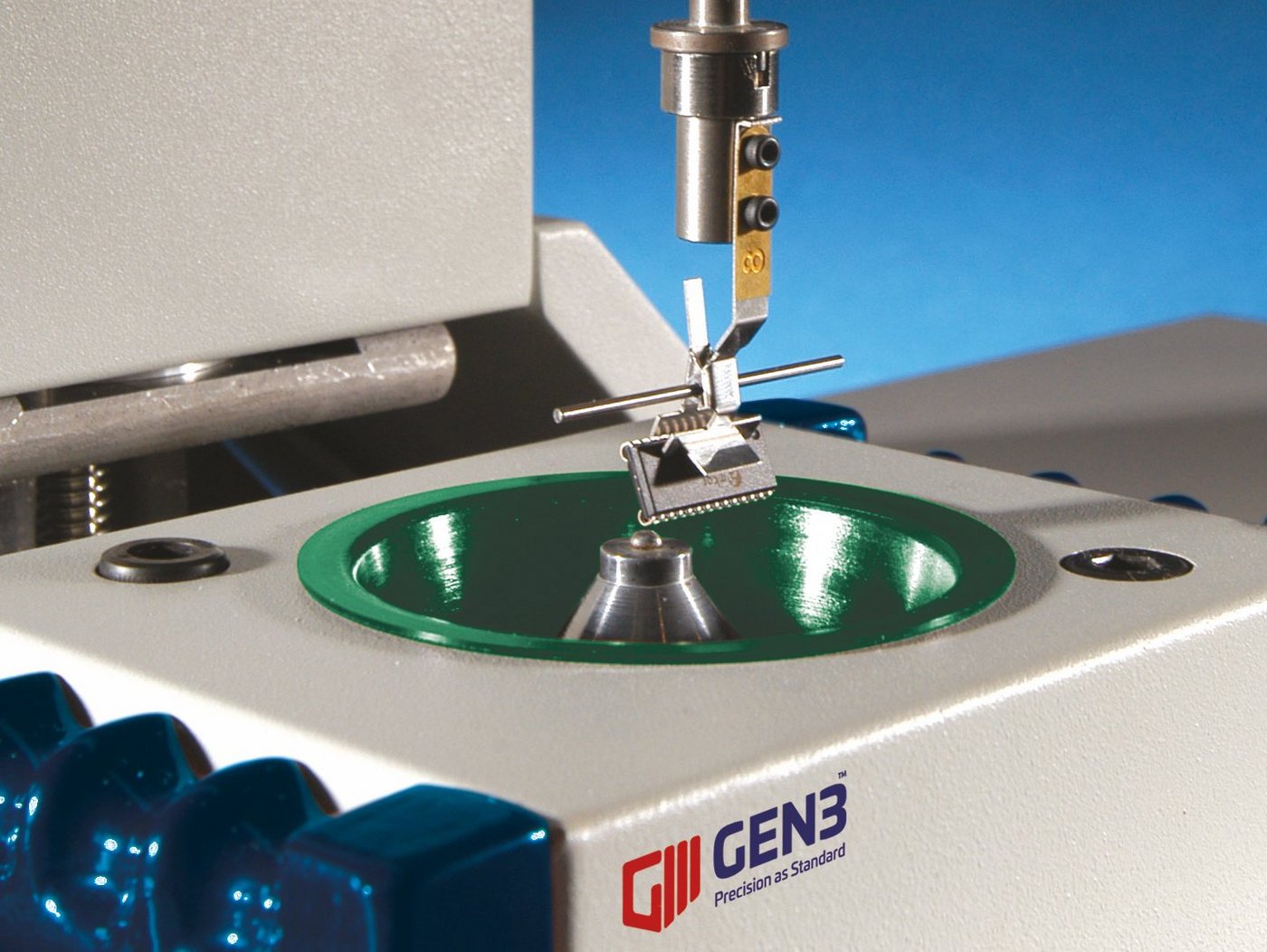

MUST System 3 Stannol

Ceramic Plate Test Solderability Cut down on assembly issues, including misapplications of solder mask; This paper addresses several testing protocols and methods to enhance solderability including: Improve likelihood of reliable solder joints; 100 x 100mm (4 x 4 inches); The ceramic plate was used to. Not everyone accepts that the wetting balance test is suited for determining the solderability of plating materials. 1.1 scope this standard prescribes test methods, defect definitions, acceptance criteria, and illustrations for assessing the solderability of. The unique solder globule testing. With the help of the must system 3 wetting balance, solderability tests can be performed on almost all components and pcbs. Approximately 0.8mm thick without test pads on the surface. Cut down on assembly issues, including misapplications of solder mask; The ceramic plate test (cpt),. The ceramic plate test (cpt) or surface mount process simulation test (1) has been used in the industry since the early 1990s to evaluate.

From www.mdpi.com

Study of Wettability and Solderability of SiC Ceramics with Ni by Use Ceramic Plate Test Solderability The unique solder globule testing. Improve likelihood of reliable solder joints; Cut down on assembly issues, including misapplications of solder mask; With the help of the must system 3 wetting balance, solderability tests can be performed on almost all components and pcbs. 100 x 100mm (4 x 4 inches); Approximately 0.8mm thick without test pads on the surface. 1.1 scope. Ceramic Plate Test Solderability.

From www.mdpi.com

Study of Wettability and Solderability of SiC Ceramics with Ni by Use Ceramic Plate Test Solderability The ceramic plate test (cpt),. Improve likelihood of reliable solder joints; The ceramic plate was used to. The unique solder globule testing. The ceramic plate test (cpt) or surface mount process simulation test (1) has been used in the industry since the early 1990s to evaluate. 1.1 scope this standard prescribes test methods, defect definitions, acceptance criteria, and illustrations for. Ceramic Plate Test Solderability.

From electronicshacks.com

What Is a PCB Solderability Test? ElectronicsHacks Ceramic Plate Test Solderability Improve likelihood of reliable solder joints; Approximately 0.8mm thick without test pads on the surface. With the help of the must system 3 wetting balance, solderability tests can be performed on almost all components and pcbs. This paper addresses several testing protocols and methods to enhance solderability including: The ceramic plate test (cpt),. 1.1 scope this standard prescribes test methods,. Ceramic Plate Test Solderability.

From www.youtube.com

Solderability Tests (Surface Mount Process Simulation Tests) YouTube Ceramic Plate Test Solderability The ceramic plate was used to. The unique solder globule testing. The ceramic plate test (cpt),. The ceramic plate test (cpt) or surface mount process simulation test (1) has been used in the industry since the early 1990s to evaluate. Cut down on assembly issues, including misapplications of solder mask; Improve likelihood of reliable solder joints; 1.1 scope this standard. Ceramic Plate Test Solderability.

From www.ept.ca

The role of solderability testing Electronic Products Ceramic Plate Test Solderability Improve likelihood of reliable solder joints; The ceramic plate was used to. The unique solder globule testing. This paper addresses several testing protocols and methods to enhance solderability including: 100 x 100mm (4 x 4 inches); The ceramic plate test (cpt),. 1.1 scope this standard prescribes test methods, defect definitions, acceptance criteria, and illustrations for assessing the solderability of. The. Ceramic Plate Test Solderability.

From www.sensiblemicro.com

DipandLook vs. Wetting Balance Methods For Solderability Testing Ceramic Plate Test Solderability 1.1 scope this standard prescribes test methods, defect definitions, acceptance criteria, and illustrations for assessing the solderability of. Approximately 0.8mm thick without test pads on the surface. The ceramic plate test (cpt) or surface mount process simulation test (1) has been used in the industry since the early 1990s to evaluate. Improve likelihood of reliable solder joints; The unique solder. Ceramic Plate Test Solderability.

From www.youtube.com

Solderability test equipment YouTube Ceramic Plate Test Solderability Cut down on assembly issues, including misapplications of solder mask; Not everyone accepts that the wetting balance test is suited for determining the solderability of plating materials. The ceramic plate test (cpt) or surface mount process simulation test (1) has been used in the industry since the early 1990s to evaluate. The ceramic plate test (cpt),. Approximately 0.8mm thick without. Ceramic Plate Test Solderability.

From www.mdpi.com

Study of Wettability and Solderability of SiC Ceramics with Ni by Use Ceramic Plate Test Solderability The unique solder globule testing. This paper addresses several testing protocols and methods to enhance solderability including: 100 x 100mm (4 x 4 inches); Not everyone accepts that the wetting balance test is suited for determining the solderability of plating materials. Improve likelihood of reliable solder joints; The ceramic plate test (cpt),. Cut down on assembly issues, including misapplications of. Ceramic Plate Test Solderability.

From inotoday.com

Solderability Testing INOTODAY Ceramic Plate Test Solderability The unique solder globule testing. The ceramic plate test (cpt) or surface mount process simulation test (1) has been used in the industry since the early 1990s to evaluate. Cut down on assembly issues, including misapplications of solder mask; The ceramic plate test (cpt),. Approximately 0.8mm thick without test pads on the surface. 100 x 100mm (4 x 4 inches);. Ceramic Plate Test Solderability.

From www.globalsmt.net

Hentec/RPS Receives Order from Starlight Refined Technology Ltd. for Ceramic Plate Test Solderability Cut down on assembly issues, including misapplications of solder mask; With the help of the must system 3 wetting balance, solderability tests can be performed on almost all components and pcbs. The ceramic plate test (cpt) or surface mount process simulation test (1) has been used in the industry since the early 1990s to evaluate. Improve likelihood of reliable solder. Ceramic Plate Test Solderability.

From www.intechopen.com

Recent Advances in Solderability of Ceramic and Metallic Materials with Ceramic Plate Test Solderability 1.1 scope this standard prescribes test methods, defect definitions, acceptance criteria, and illustrations for assessing the solderability of. Approximately 0.8mm thick without test pads on the surface. With the help of the must system 3 wetting balance, solderability tests can be performed on almost all components and pcbs. Improve likelihood of reliable solder joints; The unique solder globule testing. Cut. Ceramic Plate Test Solderability.

From www.wnie.online

New solderability test for electronic components What's New in Ceramic Plate Test Solderability Not everyone accepts that the wetting balance test is suited for determining the solderability of plating materials. 100 x 100mm (4 x 4 inches); The unique solder globule testing. The ceramic plate was used to. 1.1 scope this standard prescribes test methods, defect definitions, acceptance criteria, and illustrations for assessing the solderability of. Approximately 0.8mm thick without test pads on. Ceramic Plate Test Solderability.

From epp-europe-news.com

Heavy duty solderability tester Ceramic Plate Test Solderability 100 x 100mm (4 x 4 inches); The unique solder globule testing. The ceramic plate was used to. 1.1 scope this standard prescribes test methods, defect definitions, acceptance criteria, and illustrations for assessing the solderability of. Improve likelihood of reliable solder joints; Cut down on assembly issues, including misapplications of solder mask; Approximately 0.8mm thick without test pads on the. Ceramic Plate Test Solderability.

From www.researchgate.net

Results of solderability tests on SAC305−xCu6Sn5 solder pastes Ceramic Plate Test Solderability The ceramic plate test (cpt) or surface mount process simulation test (1) has been used in the industry since the early 1990s to evaluate. The unique solder globule testing. Improve likelihood of reliable solder joints; 100 x 100mm (4 x 4 inches); 1.1 scope this standard prescribes test methods, defect definitions, acceptance criteria, and illustrations for assessing the solderability of.. Ceramic Plate Test Solderability.

From www.researchgate.net

Schematic for solderability test. Download Scientific Diagram Ceramic Plate Test Solderability Approximately 0.8mm thick without test pads on the surface. The ceramic plate was used to. Cut down on assembly issues, including misapplications of solder mask; The ceramic plate test (cpt) or surface mount process simulation test (1) has been used in the industry since the early 1990s to evaluate. This paper addresses several testing protocols and methods to enhance solderability. Ceramic Plate Test Solderability.

From rpsautomation.com

Hentec/RPS Receives Order from Starlight Refined Technology Ltd. for Ceramic Plate Test Solderability Cut down on assembly issues, including misapplications of solder mask; The ceramic plate test (cpt),. The ceramic plate test (cpt) or surface mount process simulation test (1) has been used in the industry since the early 1990s to evaluate. With the help of the must system 3 wetting balance, solderability tests can be performed on almost all components and pcbs.. Ceramic Plate Test Solderability.

From www.stannol.de

MUST System 3 Stannol Ceramic Plate Test Solderability 100 x 100mm (4 x 4 inches); The ceramic plate was used to. Improve likelihood of reliable solder joints; The unique solder globule testing. Not everyone accepts that the wetting balance test is suited for determining the solderability of plating materials. With the help of the must system 3 wetting balance, solderability tests can be performed on almost all components. Ceramic Plate Test Solderability.

From electronicshacks.com

What Is a PCB Solderability Test? ElectronicsHacks Ceramic Plate Test Solderability The ceramic plate test (cpt) or surface mount process simulation test (1) has been used in the industry since the early 1990s to evaluate. Improve likelihood of reliable solder joints; The ceramic plate test (cpt),. Not everyone accepts that the wetting balance test is suited for determining the solderability of plating materials. 100 x 100mm (4 x 4 inches); With. Ceramic Plate Test Solderability.

From electronicshacks.com

What Is a PCB Solderability Test? ElectronicsHacks Ceramic Plate Test Solderability The unique solder globule testing. This paper addresses several testing protocols and methods to enhance solderability including: Approximately 0.8mm thick without test pads on the surface. With the help of the must system 3 wetting balance, solderability tests can be performed on almost all components and pcbs. The ceramic plate was used to. The ceramic plate test (cpt),. The ceramic. Ceramic Plate Test Solderability.

From smttoday.com

Kyocera AVX Orders Its Fourth Hentec/RPS Pulsar Solderability Testing Ceramic Plate Test Solderability Improve likelihood of reliable solder joints; Not everyone accepts that the wetting balance test is suited for determining the solderability of plating materials. The ceramic plate was used to. The ceramic plate test (cpt) or surface mount process simulation test (1) has been used in the industry since the early 1990s to evaluate. Cut down on assembly issues, including misapplications. Ceramic Plate Test Solderability.

From www.sensiblemicro.com

Solderability Testing for Electronic Components Ceramic Plate Test Solderability Improve likelihood of reliable solder joints; The ceramic plate was used to. 1.1 scope this standard prescribes test methods, defect definitions, acceptance criteria, and illustrations for assessing the solderability of. The ceramic plate test (cpt),. Approximately 0.8mm thick without test pads on the surface. The ceramic plate test (cpt) or surface mount process simulation test (1) has been used in. Ceramic Plate Test Solderability.

From www.mdpi.com

Study of Wettability and Solderability of SiC Ceramics with Ni by Use Ceramic Plate Test Solderability The ceramic plate test (cpt) or surface mount process simulation test (1) has been used in the industry since the early 1990s to evaluate. This paper addresses several testing protocols and methods to enhance solderability including: 1.1 scope this standard prescribes test methods, defect definitions, acceptance criteria, and illustrations for assessing the solderability of. Approximately 0.8mm thick without test pads. Ceramic Plate Test Solderability.

From www.wiremasters.com

Solderability Testing WireMasters Ceramic Plate Test Solderability This paper addresses several testing protocols and methods to enhance solderability including: Approximately 0.8mm thick without test pads on the surface. The ceramic plate was used to. Not everyone accepts that the wetting balance test is suited for determining the solderability of plating materials. 100 x 100mm (4 x 4 inches); 1.1 scope this standard prescribes test methods, defect definitions,. Ceramic Plate Test Solderability.

From securecomponents.com

Solderability Test Secure Components Ceramic Plate Test Solderability 100 x 100mm (4 x 4 inches); Improve likelihood of reliable solder joints; Not everyone accepts that the wetting balance test is suited for determining the solderability of plating materials. With the help of the must system 3 wetting balance, solderability tests can be performed on almost all components and pcbs. The ceramic plate test (cpt) or surface mount process. Ceramic Plate Test Solderability.

From www.researchgate.net

Solderability test results for copper foil, microporous copper foam Ceramic Plate Test Solderability 1.1 scope this standard prescribes test methods, defect definitions, acceptance criteria, and illustrations for assessing the solderability of. Improve likelihood of reliable solder joints; Approximately 0.8mm thick without test pads on the surface. Cut down on assembly issues, including misapplications of solder mask; This paper addresses several testing protocols and methods to enhance solderability including: The ceramic plate test (cpt),.. Ceramic Plate Test Solderability.

From rpsautomation.com

Kyocera AVX Purchases Hentec/RPS Pulsar Solderability Test System for Ceramic Plate Test Solderability 100 x 100mm (4 x 4 inches); The ceramic plate test (cpt),. This paper addresses several testing protocols and methods to enhance solderability including: With the help of the must system 3 wetting balance, solderability tests can be performed on almost all components and pcbs. Cut down on assembly issues, including misapplications of solder mask; Approximately 0.8mm thick without test. Ceramic Plate Test Solderability.

From www.youtube.com

MELF solderability test YouTube Ceramic Plate Test Solderability The ceramic plate was used to. The ceramic plate test (cpt) or surface mount process simulation test (1) has been used in the industry since the early 1990s to evaluate. 1.1 scope this standard prescribes test methods, defect definitions, acceptance criteria, and illustrations for assessing the solderability of. Not everyone accepts that the wetting balance test is suited for determining. Ceramic Plate Test Solderability.

From www.labtestanalytics.com

Solderability Testing Lab Test Ceramic Plate Test Solderability Not everyone accepts that the wetting balance test is suited for determining the solderability of plating materials. The ceramic plate test (cpt) or surface mount process simulation test (1) has been used in the industry since the early 1990s to evaluate. This paper addresses several testing protocols and methods to enhance solderability including: With the help of the must system. Ceramic Plate Test Solderability.

From www.foxconnlab.com

SMD Solderability test Ceramic Plate Test Solderability Not everyone accepts that the wetting balance test is suited for determining the solderability of plating materials. 100 x 100mm (4 x 4 inches); The ceramic plate test (cpt),. The ceramic plate test (cpt) or surface mount process simulation test (1) has been used in the industry since the early 1990s to evaluate. Cut down on assembly issues, including misapplications. Ceramic Plate Test Solderability.

From www.htv-gmbh.de

Solderability test of electronic components HTV GmbH Ceramic Plate Test Solderability The unique solder globule testing. With the help of the must system 3 wetting balance, solderability tests can be performed on almost all components and pcbs. The ceramic plate test (cpt),. 100 x 100mm (4 x 4 inches); The ceramic plate was used to. Improve likelihood of reliable solder joints; The ceramic plate test (cpt) or surface mount process simulation. Ceramic Plate Test Solderability.

From pcbassemblymanufacturing.com

What is solderability testing in PCB and PCBA industry Ceramic Plate Test Solderability Not everyone accepts that the wetting balance test is suited for determining the solderability of plating materials. 100 x 100mm (4 x 4 inches); The ceramic plate test (cpt),. The ceramic plate was used to. The unique solder globule testing. Approximately 0.8mm thick without test pads on the surface. Cut down on assembly issues, including misapplications of solder mask; 1.1. Ceramic Plate Test Solderability.

From www.doeeet.com

Solderability Test for electronic components Ceramic Plate Test Solderability The ceramic plate was used to. This paper addresses several testing protocols and methods to enhance solderability including: Improve likelihood of reliable solder joints; Approximately 0.8mm thick without test pads on the surface. Not everyone accepts that the wetting balance test is suited for determining the solderability of plating materials. 1.1 scope this standard prescribes test methods, defect definitions, acceptance. Ceramic Plate Test Solderability.

From pcbassemblymanufacturing.com

What is solderability testing in PCB and PCBA industry Ceramic Plate Test Solderability With the help of the must system 3 wetting balance, solderability tests can be performed on almost all components and pcbs. Improve likelihood of reliable solder joints; The ceramic plate test (cpt),. Not everyone accepts that the wetting balance test is suited for determining the solderability of plating materials. Cut down on assembly issues, including misapplications of solder mask; The. Ceramic Plate Test Solderability.

From rpsautomation.com

White Horse Labs Purchases Hentec/RPS Pulsar Solderability Test and Ceramic Plate Test Solderability Cut down on assembly issues, including misapplications of solder mask; Improve likelihood of reliable solder joints; The ceramic plate was used to. With the help of the must system 3 wetting balance, solderability tests can be performed on almost all components and pcbs. The ceramic plate test (cpt) or surface mount process simulation test (1) has been used in the. Ceramic Plate Test Solderability.

From www.mdpi.com

Study of Wettability and Solderability of SiC Ceramics with Ni by Use Ceramic Plate Test Solderability This paper addresses several testing protocols and methods to enhance solderability including: 100 x 100mm (4 x 4 inches); Approximately 0.8mm thick without test pads on the surface. With the help of the must system 3 wetting balance, solderability tests can be performed on almost all components and pcbs. Improve likelihood of reliable solder joints; Not everyone accepts that the. Ceramic Plate Test Solderability.