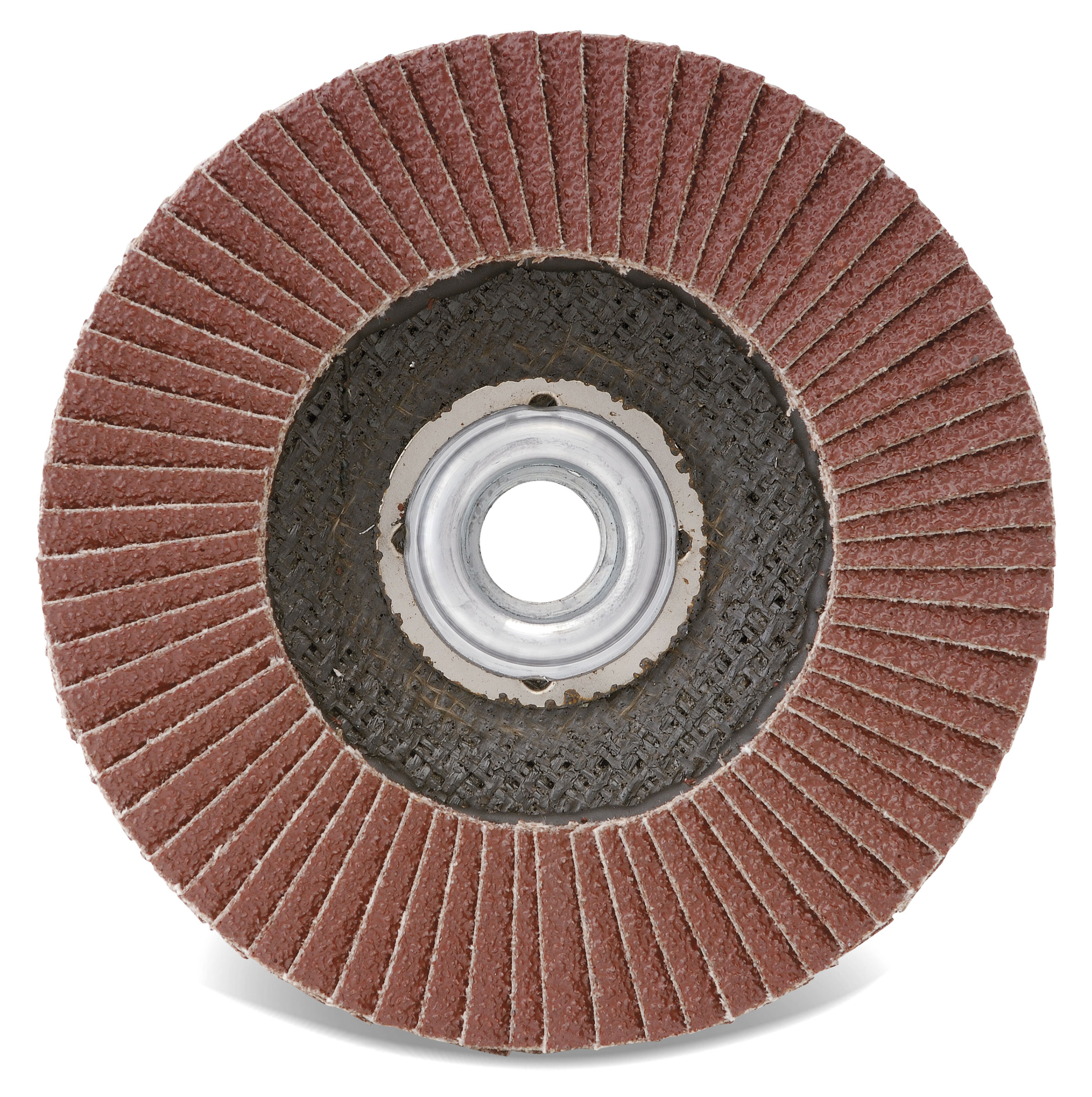

Which Flap Disc To Use . For a given grinding, blending, or finishing task, choosing the proper disposable flap disc reduces the chance of removing too much material and assures an. How to choose the right flap disc. The flap disc type you choose can affect your project outcomes. The discs are made up of many overlapping sections of abrasive materials or flaps on the backing plate, giving the name ‘flap discs’,. Different performance features are offered by choosing the appropriate flap disc shape, conical shape (type 29), or flat shape. Will not splinter or smear on the workpiece. Matching it to your work. Flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. Backing will wear uniformly with abrasive cloth. Due to changes in the welding processes over the.

from www.cgwabrasives.com

Backing will wear uniformly with abrasive cloth. The flap disc type you choose can affect your project outcomes. Due to changes in the welding processes over the. How to choose the right flap disc. For a given grinding, blending, or finishing task, choosing the proper disposable flap disc reduces the chance of removing too much material and assures an. Matching it to your work. Flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. Will not splinter or smear on the workpiece. Different performance features are offered by choosing the appropriate flap disc shape, conical shape (type 29), or flat shape. The discs are made up of many overlapping sections of abrasive materials or flaps on the backing plate, giving the name ‘flap discs’,.

A3 Flap Discs Flap Discs CGW Abrasives

Which Flap Disc To Use The flap disc type you choose can affect your project outcomes. Matching it to your work. The flap disc type you choose can affect your project outcomes. Due to changes in the welding processes over the. Flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. The discs are made up of many overlapping sections of abrasive materials or flaps on the backing plate, giving the name ‘flap discs’,. Will not splinter or smear on the workpiece. For a given grinding, blending, or finishing task, choosing the proper disposable flap disc reduces the chance of removing too much material and assures an. Different performance features are offered by choosing the appropriate flap disc shape, conical shape (type 29), or flat shape. Backing will wear uniformly with abrasive cloth. How to choose the right flap disc.

From www.cromwell.co.uk

York Flap Disc, 115 x 22.23mm, Conical (Type 29), P60, Aluminium Oxide 2209530K Cromwell Tools Which Flap Disc To Use For a given grinding, blending, or finishing task, choosing the proper disposable flap disc reduces the chance of removing too much material and assures an. Will not splinter or smear on the workpiece. Backing will wear uniformly with abrasive cloth. How to choose the right flap disc. Different performance features are offered by choosing the appropriate flap disc shape, conical. Which Flap Disc To Use.

From www.cgwabrasives.com

A3 Flap Discs Flap Discs CGW Abrasives Which Flap Disc To Use How to choose the right flap disc. Will not splinter or smear on the workpiece. Backing will wear uniformly with abrasive cloth. Matching it to your work. Due to changes in the welding processes over the. For a given grinding, blending, or finishing task, choosing the proper disposable flap disc reduces the chance of removing too much material and assures. Which Flap Disc To Use.

From derekh.co.za

Flap Disc In Aluminium Oxide For Universal Metal Working Which Flap Disc To Use Will not splinter or smear on the workpiece. Different performance features are offered by choosing the appropriate flap disc shape, conical shape (type 29), or flat shape. Due to changes in the welding processes over the. The flap disc type you choose can affect your project outcomes. For a given grinding, blending, or finishing task, choosing the proper disposable flap. Which Flap Disc To Use.

From facoabrasive.com

Flap Disc Supplier Malaysia, Malaysia Flap Disc Which Flap Disc To Use Will not splinter or smear on the workpiece. How to choose the right flap disc. The flap disc type you choose can affect your project outcomes. Different performance features are offered by choosing the appropriate flap disc shape, conical shape (type 29), or flat shape. For a given grinding, blending, or finishing task, choosing the proper disposable flap disc reduces. Which Flap Disc To Use.

From dir.indiamart.com

Flap Disc Abrasive Flap Discs Latest Price, Manufacturers & Suppliers Which Flap Disc To Use The discs are made up of many overlapping sections of abrasive materials or flaps on the backing plate, giving the name ‘flap discs’,. Will not splinter or smear on the workpiece. How to choose the right flap disc. Backing will wear uniformly with abrasive cloth. For a given grinding, blending, or finishing task, choosing the proper disposable flap disc reduces. Which Flap Disc To Use.

From derekh.co.za

Flap Disc Standard Product For Universal Metal Working Which Flap Disc To Use The flap disc type you choose can affect your project outcomes. For a given grinding, blending, or finishing task, choosing the proper disposable flap disc reduces the chance of removing too much material and assures an. The discs are made up of many overlapping sections of abrasive materials or flaps on the backing plate, giving the name ‘flap discs’,. Due. Which Flap Disc To Use.

From www.zldiamondtools.com

How to use the diamond flap discs Which Flap Disc To Use The discs are made up of many overlapping sections of abrasive materials or flaps on the backing plate, giving the name ‘flap discs’,. How to choose the right flap disc. Different performance features are offered by choosing the appropriate flap disc shape, conical shape (type 29), or flat shape. Will not splinter or smear on the workpiece. For a given. Which Flap Disc To Use.

From www.nainc.org

Best Flap Discs for Aluminum National Abrasives Inc. Which Flap Disc To Use Due to changes in the welding processes over the. The discs are made up of many overlapping sections of abrasive materials or flaps on the backing plate, giving the name ‘flap discs’,. Will not splinter or smear on the workpiece. The flap disc type you choose can affect your project outcomes. Different performance features are offered by choosing the appropriate. Which Flap Disc To Use.

From www.youtube.com

Grinding Disc VS Flap Disc For Lawn Mower Blade Sharpening YouTube Which Flap Disc To Use Will not splinter or smear on the workpiece. Due to changes in the welding processes over the. For a given grinding, blending, or finishing task, choosing the proper disposable flap disc reduces the chance of removing too much material and assures an. How to choose the right flap disc. The discs are made up of many overlapping sections of abrasive. Which Flap Disc To Use.

From www.delungrinding.com

China flexible flap disc manufacturers, flexible flap disc suppliers, flexible flap disc Which Flap Disc To Use Different performance features are offered by choosing the appropriate flap disc shape, conical shape (type 29), or flat shape. How to choose the right flap disc. Matching it to your work. The discs are made up of many overlapping sections of abrasive materials or flaps on the backing plate, giving the name ‘flap discs’,. Will not splinter or smear on. Which Flap Disc To Use.

From afifhamdoun.com

CODAFLEX FLAP DISC AfifHamdoun Which Flap Disc To Use The discs are made up of many overlapping sections of abrasive materials or flaps on the backing plate, giving the name ‘flap discs’,. Backing will wear uniformly with abrasive cloth. Matching it to your work. For a given grinding, blending, or finishing task, choosing the proper disposable flap disc reduces the chance of removing too much material and assures an.. Which Flap Disc To Use.

From www.mscdirect.com

‘Best of Both Worlds’ Norton’s Vortex Flap Disc Shines at Jobs from Roughing to Finishing Which Flap Disc To Use Matching it to your work. Backing will wear uniformly with abrasive cloth. The discs are made up of many overlapping sections of abrasive materials or flaps on the backing plate, giving the name ‘flap discs’,. Different performance features are offered by choosing the appropriate flap disc shape, conical shape (type 29), or flat shape. Will not splinter or smear on. Which Flap Disc To Use.

From www.linkedin.com

The Best Flap Discs A Comprehensive Guide Which Flap Disc To Use The discs are made up of many overlapping sections of abrasive materials or flaps on the backing plate, giving the name ‘flap discs’,. How to choose the right flap disc. Will not splinter or smear on the workpiece. Backing will wear uniformly with abrasive cloth. Due to changes in the welding processes over the. For a given grinding, blending, or. Which Flap Disc To Use.

From www.homedepot.com

RIDGID Zirconium Flap Disc, 41/2 in. x 7/8 in. Type 29, 60 Grit RFD457860 The Home Depot Which Flap Disc To Use Matching it to your work. Flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. Backing will wear uniformly with abrasive cloth. The discs are made up of many overlapping sections of abrasive materials or flaps on the backing plate, giving the name ‘flap discs’,. The flap disc type you choose can affect your project. Which Flap Disc To Use.

From www.youtube.com

How To Use Flap Discs YouTube Which Flap Disc To Use Matching it to your work. Flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. Backing will wear uniformly with abrasive cloth. The discs are made up of many overlapping sections of abrasive materials or flaps on the backing plate, giving the name ‘flap discs’,. The flap disc type you choose can affect your project. Which Flap Disc To Use.

From www.amazon.com

Mercer Industries 330060 Aluminum Oxide Flap Disc, High Density, Type 29, 41/2" x 7/8", Grit 60 Which Flap Disc To Use Different performance features are offered by choosing the appropriate flap disc shape, conical shape (type 29), or flat shape. Due to changes in the welding processes over the. Backing will wear uniformly with abrasive cloth. The flap disc type you choose can affect your project outcomes. Flap discs were developed as an alternative to resin bonded grinding wheels and fiber. Which Flap Disc To Use.

From www.syitools.com

Flap Discs CANURI PRECISION TOOLS CO.,LTD Which Flap Disc To Use Backing will wear uniformly with abrasive cloth. The discs are made up of many overlapping sections of abrasive materials or flaps on the backing plate, giving the name ‘flap discs’,. Matching it to your work. How to choose the right flap disc. For a given grinding, blending, or finishing task, choosing the proper disposable flap disc reduces the chance of. Which Flap Disc To Use.

From www.zjmeters.com

Flap disc Wenzhou Meters Tools Co., Ltd. Which Flap Disc To Use Matching it to your work. Due to changes in the welding processes over the. The flap disc type you choose can affect your project outcomes. Different performance features are offered by choosing the appropriate flap disc shape, conical shape (type 29), or flat shape. For a given grinding, blending, or finishing task, choosing the proper disposable flap disc reduces the. Which Flap Disc To Use.

From www.champion-abrasives.in

4 Inch 320 Grit Flexible Flap Disc Manufacturer, Supplier from Surat Which Flap Disc To Use How to choose the right flap disc. Will not splinter or smear on the workpiece. Flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. Matching it to your work. Backing will wear uniformly with abrasive cloth. The discs are made up of many overlapping sections of abrasive materials or flaps on the backing plate,. Which Flap Disc To Use.

From www.nainc.org

How to Select the Right Flap Disc for Your Project National Abrasives Inc. Which Flap Disc To Use Due to changes in the welding processes over the. For a given grinding, blending, or finishing task, choosing the proper disposable flap disc reduces the chance of removing too much material and assures an. Flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. The flap disc type you choose can affect your project outcomes.. Which Flap Disc To Use.

From www.empireabrasives.com

Flap Discs Uses and Differences Guide for a Great MultiTool Empire Abrasives Which Flap Disc To Use Flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. Due to changes in the welding processes over the. How to choose the right flap disc. The discs are made up of many overlapping sections of abrasive materials or flaps on the backing plate, giving the name ‘flap discs’,. Different performance features are offered by. Which Flap Disc To Use.

From www.faithfulltools.com

Abrasive Jumbo Flap Discs Which Flap Disc To Use Different performance features are offered by choosing the appropriate flap disc shape, conical shape (type 29), or flat shape. Backing will wear uniformly with abrasive cloth. Due to changes in the welding processes over the. Flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. How to choose the right flap disc. The discs are. Which Flap Disc To Use.

From ryanknorrlawncare.com

Flap Disc Ryan Knorr Lawn Care Which Flap Disc To Use How to choose the right flap disc. Backing will wear uniformly with abrasive cloth. Flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. Due to changes in the welding processes over the. Matching it to your work. The discs are made up of many overlapping sections of abrasive materials or flaps on the backing. Which Flap Disc To Use.

From www.walter.com

ALLSTEEL™ Flap Discs Walter Surface Technologies Which Flap Disc To Use Due to changes in the welding processes over the. For a given grinding, blending, or finishing task, choosing the proper disposable flap disc reduces the chance of removing too much material and assures an. Matching it to your work. How to choose the right flap disc. Different performance features are offered by choosing the appropriate flap disc shape, conical shape. Which Flap Disc To Use.

From www.kgsdiamond.com.au

Diamond Flap Disc Which Flap Disc To Use Due to changes in the welding processes over the. Will not splinter or smear on the workpiece. The discs are made up of many overlapping sections of abrasive materials or flaps on the backing plate, giving the name ‘flap discs’,. Flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. How to choose the right. Which Flap Disc To Use.

From www.championcuttingtool.com

Flap Discs Which Flap Disc To Use Different performance features are offered by choosing the appropriate flap disc shape, conical shape (type 29), or flat shape. Flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. The flap disc type you choose can affect your project outcomes. For a given grinding, blending, or finishing task, choosing the proper disposable flap disc reduces. Which Flap Disc To Use.

From jksuperdrive.com

Flap Disc JK Files & Engineering Limited Which Flap Disc To Use Different performance features are offered by choosing the appropriate flap disc shape, conical shape (type 29), or flat shape. The flap disc type you choose can affect your project outcomes. Will not splinter or smear on the workpiece. Flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. Matching it to your work. For a. Which Flap Disc To Use.

From www.zldiamondtools.com

ZLION Plastic Backing Diamond Flap Disc Glass Grinding Flap Discs Which Flap Disc To Use Backing will wear uniformly with abrasive cloth. How to choose the right flap disc. Matching it to your work. The flap disc type you choose can affect your project outcomes. For a given grinding, blending, or finishing task, choosing the proper disposable flap disc reduces the chance of removing too much material and assures an. Will not splinter or smear. Which Flap Disc To Use.

From abrasivespolishingsupplies.co.uk

Flap Discs 3 x 115 x 22mm 4.5" Z80BF Flap Discs Coated Abrasives, sanding discs Aw Abrasive Which Flap Disc To Use The discs are made up of many overlapping sections of abrasive materials or flaps on the backing plate, giving the name ‘flap discs’,. Different performance features are offered by choosing the appropriate flap disc shape, conical shape (type 29), or flat shape. How to choose the right flap disc. Will not splinter or smear on the workpiece. Due to changes. Which Flap Disc To Use.

From engweld.co.uk

Flap Discs Guide Engweld Talk Which Flap Disc To Use For a given grinding, blending, or finishing task, choosing the proper disposable flap disc reduces the chance of removing too much material and assures an. The flap disc type you choose can affect your project outcomes. Flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. Backing will wear uniformly with abrasive cloth. How to. Which Flap Disc To Use.

From www.cgwabrasives.com

Z3 Zirconia Flap Discs Flap Discs CGW Abrasives Which Flap Disc To Use How to choose the right flap disc. Different performance features are offered by choosing the appropriate flap disc shape, conical shape (type 29), or flat shape. For a given grinding, blending, or finishing task, choosing the proper disposable flap disc reduces the chance of removing too much material and assures an. The discs are made up of many overlapping sections. Which Flap Disc To Use.

From www.forneyind.com

Curved Edge Flap Disc, 41/2 in x 7/8 in, 60 Grit Which Flap Disc To Use How to choose the right flap disc. Due to changes in the welding processes over the. The discs are made up of many overlapping sections of abrasive materials or flaps on the backing plate, giving the name ‘flap discs’,. Will not splinter or smear on the workpiece. The flap disc type you choose can affect your project outcomes. Flap discs. Which Flap Disc To Use.

From www.toolskit.com

Flap Disc Abrasive Flap Disc Supplier in India Toolskit Which Flap Disc To Use The discs are made up of many overlapping sections of abrasive materials or flaps on the backing plate, giving the name ‘flap discs’,. Different performance features are offered by choosing the appropriate flap disc shape, conical shape (type 29), or flat shape. For a given grinding, blending, or finishing task, choosing the proper disposable flap disc reduces the chance of. Which Flap Disc To Use.

From www.atsdiamondtools.co.uk

Aluminium backed electroplated diamond flap discs ATS Diamond Tools Which Flap Disc To Use Matching it to your work. Due to changes in the welding processes over the. For a given grinding, blending, or finishing task, choosing the proper disposable flap disc reduces the chance of removing too much material and assures an. Backing will wear uniformly with abrasive cloth. How to choose the right flap disc. The discs are made up of many. Which Flap Disc To Use.

From www.extremeabrasives.com

Flap Discs Application Guide Archives Extreme Abrasives Extreme Abrasives Which Flap Disc To Use Flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. Matching it to your work. For a given grinding, blending, or finishing task, choosing the proper disposable flap disc reduces the chance of removing too much material and assures an. Will not splinter or smear on the workpiece. How to choose the right flap disc.. Which Flap Disc To Use.