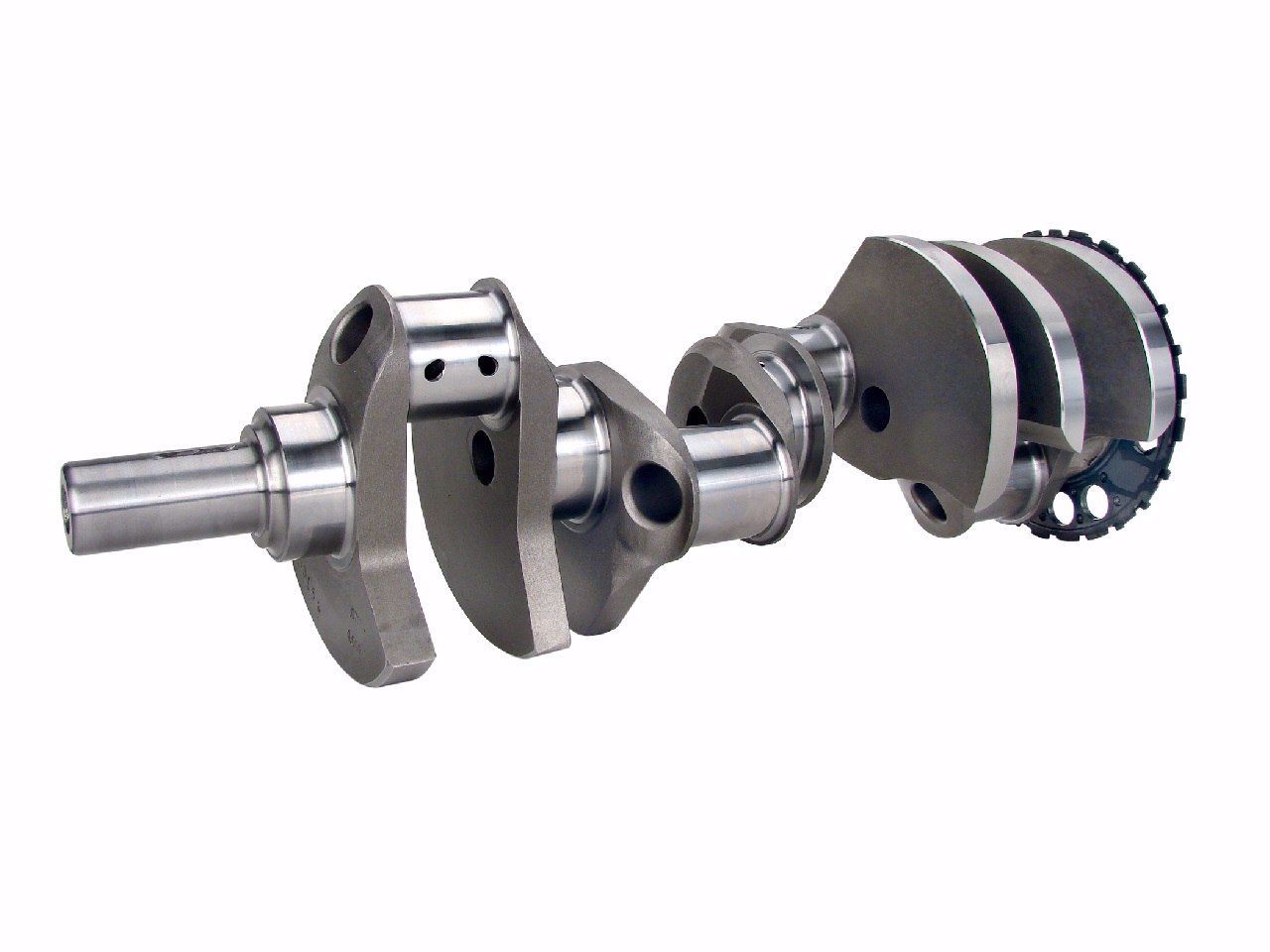

Forged Crankshaft Has A . the best and most sure method for recognizing a forged crank is to look for the parting lines on the counterweights. The forged crankshaft (left) shows how it achieves its strength by compressing the material, and the tighter grain flows along the length. Here we take a look at materials, the forging process and. A forged piece will have a wide, irregular rough patch. For the uninitiated, the two major differences between cast and forged cranks include the material and forming process. when a smeding crankshaft is created through forging, a 4340 steel alloy billet is heated and then pressed into shape. a forged crankshaft is a vital component of an internal combustion engine, responsible for converting the linear motion of the. the term forged crank has become all but generic, but the differences can be as significant as those between a casting and forging itself. Ever wonder how a forged crank is made? terms in this set (10) a forged crankshaft has a.

from www.dsperformance.net

For the uninitiated, the two major differences between cast and forged cranks include the material and forming process. Here we take a look at materials, the forging process and. a forged crankshaft is a vital component of an internal combustion engine, responsible for converting the linear motion of the. Ever wonder how a forged crank is made? when a smeding crankshaft is created through forging, a 4340 steel alloy billet is heated and then pressed into shape. the best and most sure method for recognizing a forged crank is to look for the parting lines on the counterweights. terms in this set (10) a forged crankshaft has a. The forged crankshaft (left) shows how it achieves its strength by compressing the material, and the tighter grain flows along the length. A forged piece will have a wide, irregular rough patch. the term forged crank has become all but generic, but the differences can be as significant as those between a casting and forging itself.

K1 Tecnologies LS Crankshaft Driven Speed Performance

Forged Crankshaft Has A For the uninitiated, the two major differences between cast and forged cranks include the material and forming process. Here we take a look at materials, the forging process and. the term forged crank has become all but generic, but the differences can be as significant as those between a casting and forging itself. A forged piece will have a wide, irregular rough patch. when a smeding crankshaft is created through forging, a 4340 steel alloy billet is heated and then pressed into shape. terms in this set (10) a forged crankshaft has a. a forged crankshaft is a vital component of an internal combustion engine, responsible for converting the linear motion of the. The forged crankshaft (left) shows how it achieves its strength by compressing the material, and the tighter grain flows along the length. Ever wonder how a forged crank is made? the best and most sure method for recognizing a forged crank is to look for the parting lines on the counterweights. For the uninitiated, the two major differences between cast and forged cranks include the material and forming process.

From www.scatcrankshafts.com

LS1 6Bolt LS Series Competition 4340 Crankshaft SCAT Crankshafts Forged Crankshaft Has A For the uninitiated, the two major differences between cast and forged cranks include the material and forming process. the best and most sure method for recognizing a forged crank is to look for the parting lines on the counterweights. the term forged crank has become all but generic, but the differences can be as significant as those between. Forged Crankshaft Has A.

From www.speedwaymotors.com

Scat 435040006000 Chevy 4340 Crankshaft4 Stroke, 350 Main Forged Crankshaft Has A a forged crankshaft is a vital component of an internal combustion engine, responsible for converting the linear motion of the. For the uninitiated, the two major differences between cast and forged cranks include the material and forming process. The forged crankshaft (left) shows how it achieves its strength by compressing the material, and the tighter grain flows along the. Forged Crankshaft Has A.

From www.usaperform.com

Lunati SBC 3.750” Lightweight Voodoo 4340 Crankshaft 6.000” 2. Forged Crankshaft Has A Here we take a look at materials, the forging process and. The forged crankshaft (left) shows how it achieves its strength by compressing the material, and the tighter grain flows along the length. terms in this set (10) a forged crankshaft has a. the best and most sure method for recognizing a forged crank is to look for. Forged Crankshaft Has A.

From dieselcranks.com

New Crankshaft Cummins 6C, 6CT, 6CTA 8.3L Replaces 3917320, 3917443 Forged Crankshaft Has A terms in this set (10) a forged crankshaft has a. Here we take a look at materials, the forging process and. For the uninitiated, the two major differences between cast and forged cranks include the material and forming process. a forged crankshaft is a vital component of an internal combustion engine, responsible for converting the linear motion of. Forged Crankshaft Has A.

From www.carid.com

Eagle Specialty® Ford F150 / Lobo 4.6L 2005 Crankshaft Forged Crankshaft Has A Ever wonder how a forged crank is made? The forged crankshaft (left) shows how it achieves its strength by compressing the material, and the tighter grain flows along the length. Here we take a look at materials, the forging process and. A forged piece will have a wide, irregular rough patch. a forged crankshaft is a vital component of. Forged Crankshaft Has A.

From www.competitionproducts.com

Scat, 4340 Steel Crankshaft, Ford SB 302 Main, 3.250" Stroke, 5. Forged Crankshaft Has A the best and most sure method for recognizing a forged crank is to look for the parting lines on the counterweights. For the uninitiated, the two major differences between cast and forged cranks include the material and forming process. Ever wonder how a forged crank is made? terms in this set (10) a forged crankshaft has a. . Forged Crankshaft Has A.

From www.dsperformance.net

K1 Technologies Crankshaft for Chevrolet LS 3.622 Stroke with 58 Forged Crankshaft Has A Here we take a look at materials, the forging process and. the term forged crank has become all but generic, but the differences can be as significant as those between a casting and forging itself. when a smeding crankshaft is created through forging, a 4340 steel alloy billet is heated and then pressed into shape. a forged. Forged Crankshaft Has A.

From www.dropforging.net

Cast vs Crankshaft Forged Crankshaft Has A the term forged crank has become all but generic, but the differences can be as significant as those between a casting and forging itself. Here we take a look at materials, the forging process and. For the uninitiated, the two major differences between cast and forged cranks include the material and forming process. The forged crankshaft (left) shows how. Forged Crankshaft Has A.

From www.exportersindia.com

Polished Steel Crankshaft at Rs 40,000 / Piece in Kolkata ID Forged Crankshaft Has A Ever wonder how a forged crank is made? terms in this set (10) a forged crankshaft has a. Here we take a look at materials, the forging process and. a forged crankshaft is a vital component of an internal combustion engine, responsible for converting the linear motion of the. when a smeding crankshaft is created through forging,. Forged Crankshaft Has A.

From www.onallcylinders.com

Parts Bin Build a Strong Bottom End by Starting with a Summit Racing Forged Crankshaft Has A when a smeding crankshaft is created through forging, a 4340 steel alloy billet is heated and then pressed into shape. the term forged crank has become all but generic, but the differences can be as significant as those between a casting and forging itself. For the uninitiated, the two major differences between cast and forged cranks include the. Forged Crankshaft Has A.

From www.competitionproducts.com

Eagle 4340 Steel Crankshaft, Chrysler 360 Main, 4.000" Stroke, 6 Forged Crankshaft Has A Ever wonder how a forged crank is made? A forged piece will have a wide, irregular rough patch. The forged crankshaft (left) shows how it achieves its strength by compressing the material, and the tighter grain flows along the length. the best and most sure method for recognizing a forged crank is to look for the parting lines on. Forged Crankshaft Has A.

From dieselcranks.com

Detroit Diesel 6V92 New Crankshaft Forged Crankshaft Has A Ever wonder how a forged crank is made? the best and most sure method for recognizing a forged crank is to look for the parting lines on the counterweights. terms in this set (10) a forged crankshaft has a. the term forged crank has become all but generic, but the differences can be as significant as those. Forged Crankshaft Has A.

From hanshin-imports.ch

Tomei EJ26 Strengthened Fullcounter Crankshaft By Hanshin Forged Crankshaft Has A Here we take a look at materials, the forging process and. terms in this set (10) a forged crankshaft has a. A forged piece will have a wide, irregular rough patch. when a smeding crankshaft is created through forging, a 4340 steel alloy billet is heated and then pressed into shape. the best and most sure method. Forged Crankshaft Has A.

From www.competitionproducts.com

Eagle 4340 Steel Crankshaft, Ford 460 Main, 4.500" Stroke, 6.700 Forged Crankshaft Has A when a smeding crankshaft is created through forging, a 4340 steel alloy billet is heated and then pressed into shape. A forged piece will have a wide, irregular rough patch. The forged crankshaft (left) shows how it achieves its strength by compressing the material, and the tighter grain flows along the length. Ever wonder how a forged crank is. Forged Crankshaft Has A.

From www.scatcrankshafts.com

F43 Series Lighweight Competition 4340 Crankshaft SCAT Forged Crankshaft Has A Ever wonder how a forged crank is made? Here we take a look at materials, the forging process and. the term forged crank has become all but generic, but the differences can be as significant as those between a casting and forging itself. A forged piece will have a wide, irregular rough patch. the best and most sure. Forged Crankshaft Has A.

From equipmentparts.co.za

CRANKSHAFT F3L912 D4152646 Forged Crankshaft Has A the term forged crank has become all but generic, but the differences can be as significant as those between a casting and forging itself. Ever wonder how a forged crank is made? the best and most sure method for recognizing a forged crank is to look for the parting lines on the counterweights. The forged crankshaft (left) shows. Forged Crankshaft Has A.

From maxtorqueperformance.com

vs Billet Callies Explains Crankshaft Choices Forged Crankshaft Has A the term forged crank has become all but generic, but the differences can be as significant as those between a casting and forging itself. Ever wonder how a forged crank is made? The forged crankshaft (left) shows how it achieves its strength by compressing the material, and the tighter grain flows along the length. A forged piece will have. Forged Crankshaft Has A.

From www.hotrod.com

How To Tell A Cast Crank From A Crank Hot Rod Hot Rod Network Forged Crankshaft Has A The forged crankshaft (left) shows how it achieves its strength by compressing the material, and the tighter grain flows along the length. the best and most sure method for recognizing a forged crank is to look for the parting lines on the counterweights. the term forged crank has become all but generic, but the differences can be as. Forged Crankshaft Has A.

From www.scatcrankshafts.com

LS1 SSeries 6Bolt LS Series Competition 4340 Crankshaft SCAT Forged Crankshaft Has A Ever wonder how a forged crank is made? terms in this set (10) a forged crankshaft has a. The forged crankshaft (left) shows how it achieves its strength by compressing the material, and the tighter grain flows along the length. the best and most sure method for recognizing a forged crank is to look for the parting lines. Forged Crankshaft Has A.

From www.competitionproducts.com

Manley,4340 Steel Crankshaft, Chevrolet 350 Main, 3.480" Stroke Forged Crankshaft Has A the best and most sure method for recognizing a forged crank is to look for the parting lines on the counterweights. The forged crankshaft (left) shows how it achieves its strength by compressing the material, and the tighter grain flows along the length. A forged piece will have a wide, irregular rough patch. a forged crankshaft is a. Forged Crankshaft Has A.

From socalautoparts.com

Crankshaft, 4340 Chromoly, Nitrided, 76mm Counterweight, VW Forged Crankshaft Has A a forged crankshaft is a vital component of an internal combustion engine, responsible for converting the linear motion of the. terms in this set (10) a forged crankshaft has a. the term forged crank has become all but generic, but the differences can be as significant as those between a casting and forging itself. when a. Forged Crankshaft Has A.

From prorace-engineering.co.uk

OEM 2.0 TFSI Crankshaft (1.8t Stroker Crank) ProRace Engineering Forged Crankshaft Has A A forged piece will have a wide, irregular rough patch. terms in this set (10) a forged crankshaft has a. Here we take a look at materials, the forging process and. The forged crankshaft (left) shows how it achieves its strength by compressing the material, and the tighter grain flows along the length. For the uninitiated, the two major. Forged Crankshaft Has A.

From www.disenparts.com

Steel Crankshaft Cummins Forged Crankshaft Has A The forged crankshaft (left) shows how it achieves its strength by compressing the material, and the tighter grain flows along the length. Here we take a look at materials, the forging process and. A forged piece will have a wide, irregular rough patch. when a smeding crankshaft is created through forging, a 4340 steel alloy billet is heated and. Forged Crankshaft Has A.

From forgedcrankshaftmanufacturers.blogspot.com

Crankshaft Manufacturers Tractor Crankshaft Suppliers Forged Crankshaft Has A A forged piece will have a wide, irregular rough patch. when a smeding crankshaft is created through forging, a 4340 steel alloy billet is heated and then pressed into shape. Here we take a look at materials, the forging process and. the best and most sure method for recognizing a forged crank is to look for the parting. Forged Crankshaft Has A.

From www.dsperformance.net

K1 Tecnologies LS Crankshaft Driven Speed Performance Forged Crankshaft Has A Ever wonder how a forged crank is made? Here we take a look at materials, the forging process and. For the uninitiated, the two major differences between cast and forged cranks include the material and forming process. the term forged crank has become all but generic, but the differences can be as significant as those between a casting and. Forged Crankshaft Has A.

From www.scatcrankshafts.com

Excalibur Lightweight 4340 Crankshaft SCAT Crankshafts Forged Crankshaft Has A a forged crankshaft is a vital component of an internal combustion engine, responsible for converting the linear motion of the. For the uninitiated, the two major differences between cast and forged cranks include the material and forming process. terms in this set (10) a forged crankshaft has a. Ever wonder how a forged crank is made? The forged. Forged Crankshaft Has A.

From www.heritagepartscentre.com

SSP Counterweighted Crankshaft 69mm VW Journal Heritage Parts Forged Crankshaft Has A the best and most sure method for recognizing a forged crank is to look for the parting lines on the counterweights. Ever wonder how a forged crank is made? terms in this set (10) a forged crankshaft has a. For the uninitiated, the two major differences between cast and forged cranks include the material and forming process. . Forged Crankshaft Has A.

From www.cnleotrade.com

Crankshaft Steel Forged Crankshaft Has A terms in this set (10) a forged crankshaft has a. when a smeding crankshaft is created through forging, a 4340 steel alloy billet is heated and then pressed into shape. a forged crankshaft is a vital component of an internal combustion engine, responsible for converting the linear motion of the. The forged crankshaft (left) shows how it. Forged Crankshaft Has A.

From www.jalopyjournal.com

455 olds steel crankshaft The H.A.M.B. Forged Crankshaft Has A The forged crankshaft (left) shows how it achieves its strength by compressing the material, and the tighter grain flows along the length. the best and most sure method for recognizing a forged crank is to look for the parting lines on the counterweights. Ever wonder how a forged crank is made? a forged crankshaft is a vital component. Forged Crankshaft Has A.

From oespeed.com

EAGLE 4.6L 4340 CHROMOLY STEEL CRANKSHAFT (.011″ LONGER STROKE Forged Crankshaft Has A Ever wonder how a forged crank is made? a forged crankshaft is a vital component of an internal combustion engine, responsible for converting the linear motion of the. The forged crankshaft (left) shows how it achieves its strength by compressing the material, and the tighter grain flows along the length. the best and most sure method for recognizing. Forged Crankshaft Has A.

From www.epartrade.com

EAGLE SPECIALTY PRODUCTS, INC. Chrysler modern hemi crankshafts Forged Crankshaft Has A For the uninitiated, the two major differences between cast and forged cranks include the material and forming process. a forged crankshaft is a vital component of an internal combustion engine, responsible for converting the linear motion of the. the term forged crank has become all but generic, but the differences can be as significant as those between a. Forged Crankshaft Has A.

From aapistons.com

4140 Counterweighted Crankshaft Chevy Journal AA Performance Forged Crankshaft Has A Here we take a look at materials, the forging process and. The forged crankshaft (left) shows how it achieves its strength by compressing the material, and the tighter grain flows along the length. Ever wonder how a forged crank is made? the term forged crank has become all but generic, but the differences can be as significant as those. Forged Crankshaft Has A.

From www.summitracing.com

K1 Technologies Crankshafts 3503750BB6F57 Free Shipping on Forged Crankshaft Has A when a smeding crankshaft is created through forging, a 4340 steel alloy billet is heated and then pressed into shape. a forged crankshaft is a vital component of an internal combustion engine, responsible for converting the linear motion of the. terms in this set (10) a forged crankshaft has a. A forged piece will have a wide,. Forged Crankshaft Has A.

From tinindianperformance.com

Tin Indian Performance Pontiac Crankshaft Forged Crankshaft Has A A forged piece will have a wide, irregular rough patch. For the uninitiated, the two major differences between cast and forged cranks include the material and forming process. the term forged crank has become all but generic, but the differences can be as significant as those between a casting and forging itself. terms in this set (10) a. Forged Crankshaft Has A.

From www.coolairvw.co.uk

76mm Counterweighted Crankshaft 4340 Cool Air VW Forged Crankshaft Has A when a smeding crankshaft is created through forging, a 4340 steel alloy billet is heated and then pressed into shape. For the uninitiated, the two major differences between cast and forged cranks include the material and forming process. a forged crankshaft is a vital component of an internal combustion engine, responsible for converting the linear motion of the.. Forged Crankshaft Has A.