Titanium Sheet Forming . Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. This study therefore suggests that roll forming may be a potential solution for the room temperature forming of high strength. It can be used for rapid. Asymmetric incremental sheet forming (aisf) is a relatively new sheet metal forming process. Below is a competitive analysis of the three most common titanium forming methods and recommendations for the successful operation of your. The following characteristics of titanium. Great majority of formed titanium parts are made by hot forming or by cold preforming and then hot sizing. Technologies dedicated to hot forming of titanium sheet are key processes for the manufacturing of structural and engine parts in the aerospace.

from www.titanium-industry.com

This study therefore suggests that roll forming may be a potential solution for the room temperature forming of high strength. Asymmetric incremental sheet forming (aisf) is a relatively new sheet metal forming process. Below is a competitive analysis of the three most common titanium forming methods and recommendations for the successful operation of your. It can be used for rapid. The following characteristics of titanium. Great majority of formed titanium parts are made by hot forming or by cold preforming and then hot sizing. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. Technologies dedicated to hot forming of titanium sheet are key processes for the manufacturing of structural and engine parts in the aerospace.

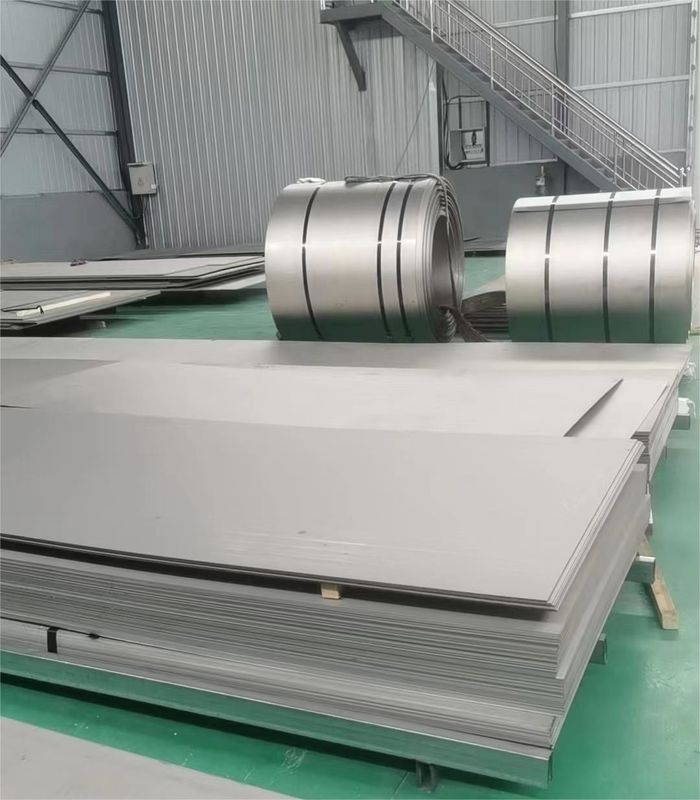

Grade Gr3 Hot Forming Titanium Sheet Pickling Titanium Steel Sheet

Titanium Sheet Forming Technologies dedicated to hot forming of titanium sheet are key processes for the manufacturing of structural and engine parts in the aerospace. This study therefore suggests that roll forming may be a potential solution for the room temperature forming of high strength. It can be used for rapid. Technologies dedicated to hot forming of titanium sheet are key processes for the manufacturing of structural and engine parts in the aerospace. The following characteristics of titanium. Below is a competitive analysis of the three most common titanium forming methods and recommendations for the successful operation of your. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. Asymmetric incremental sheet forming (aisf) is a relatively new sheet metal forming process. Great majority of formed titanium parts are made by hot forming or by cold preforming and then hot sizing.

From www.titanium-industry.com

Grade Gr3 Hot Forming Titanium Sheet Pickling Titanium Steel Sheet Titanium Sheet Forming Below is a competitive analysis of the three most common titanium forming methods and recommendations for the successful operation of your. The following characteristics of titanium. This study therefore suggests that roll forming may be a potential solution for the room temperature forming of high strength. Great majority of formed titanium parts are made by hot forming or by cold. Titanium Sheet Forming.

From depts.washington.edu

Superplastic Forming and Diffusion Bonding Solheim Manufacturing Titanium Sheet Forming Asymmetric incremental sheet forming (aisf) is a relatively new sheet metal forming process. This study therefore suggests that roll forming may be a potential solution for the room temperature forming of high strength. The following characteristics of titanium. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. Technologies dedicated to hot forming. Titanium Sheet Forming.

From www.mdpi.com

Materials Free FullText Numerical and Experimental Analysis of Titanium Sheet Forming The following characteristics of titanium. Great majority of formed titanium parts are made by hot forming or by cold preforming and then hot sizing. It can be used for rapid. Asymmetric incremental sheet forming (aisf) is a relatively new sheet metal forming process. Below is a competitive analysis of the three most common titanium forming methods and recommendations for the. Titanium Sheet Forming.

From www.thefabricator.com

Beckwood delivers 400ton titanium hotforming press to Midwest Titanium Sheet Forming Great majority of formed titanium parts are made by hot forming or by cold preforming and then hot sizing. Below is a competitive analysis of the three most common titanium forming methods and recommendations for the successful operation of your. Asymmetric incremental sheet forming (aisf) is a relatively new sheet metal forming process. It can be used for rapid. This. Titanium Sheet Forming.

From www.mdpi.com

Materials Free FullText Numerical and Experimental Analysis of Titanium Sheet Forming It can be used for rapid. Great majority of formed titanium parts are made by hot forming or by cold preforming and then hot sizing. Technologies dedicated to hot forming of titanium sheet are key processes for the manufacturing of structural and engine parts in the aerospace. The following characteristics of titanium. Heating titanium increases its formability, reduces springback, and. Titanium Sheet Forming.

From be-cu.com

Titanium Sheet Metal Fabrication & Forming Service Titanium Sheet Forming Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. Technologies dedicated to hot forming of titanium sheet are key processes for the manufacturing of structural and engine parts in the aerospace. This study therefore suggests that roll forming may be a potential solution for the room temperature forming of high strength. Asymmetric. Titanium Sheet Forming.

From www.micro-atitanium.com

Introduction to forming technology of titanium alloy sheet Titanium Titanium Sheet Forming Technologies dedicated to hot forming of titanium sheet are key processes for the manufacturing of structural and engine parts in the aerospace. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. Great majority of formed titanium parts are made by hot forming or by cold preforming and then hot sizing. Asymmetric incremental. Titanium Sheet Forming.

From www.msm-aero.com

Titanium Forming MSM aerospace fabricators Titanium Sheet Forming It can be used for rapid. Great majority of formed titanium parts are made by hot forming or by cold preforming and then hot sizing. Technologies dedicated to hot forming of titanium sheet are key processes for the manufacturing of structural and engine parts in the aerospace. This study therefore suggests that roll forming may be a potential solution for. Titanium Sheet Forming.

From www.smithsadvanced.com

Titanium Alloy Sheets Commercially Pure Titanium Titanium Sheet Forming Below is a competitive analysis of the three most common titanium forming methods and recommendations for the successful operation of your. This study therefore suggests that roll forming may be a potential solution for the room temperature forming of high strength. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. The following. Titanium Sheet Forming.

From www.mdpi.com

Materials Free FullText Numerical and Experimental Analysis of Titanium Sheet Forming Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. This study therefore suggests that roll forming may be a potential solution for the room temperature forming of high strength. Below is a competitive analysis of the three most common titanium forming methods and recommendations for the successful operation of your. Asymmetric incremental. Titanium Sheet Forming.

From www.semanticscholar.org

[PDF] Forming of Titanium and Titanium Alloys Semantic Scholar Titanium Sheet Forming Great majority of formed titanium parts are made by hot forming or by cold preforming and then hot sizing. Technologies dedicated to hot forming of titanium sheet are key processes for the manufacturing of structural and engine parts in the aerospace. This study therefore suggests that roll forming may be a potential solution for the room temperature forming of high. Titanium Sheet Forming.

From www.mdpi.com

Materials Free FullText Numerical and Experimental Analysis of Titanium Sheet Forming It can be used for rapid. This study therefore suggests that roll forming may be a potential solution for the room temperature forming of high strength. Great majority of formed titanium parts are made by hot forming or by cold preforming and then hot sizing. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between. Titanium Sheet Forming.

From www.youtube.com

Cold Forming Bending .050" Grade 5 6Al4V Ti Titanium Sheet YouTube Titanium Sheet Forming Below is a competitive analysis of the three most common titanium forming methods and recommendations for the successful operation of your. The following characteristics of titanium. Asymmetric incremental sheet forming (aisf) is a relatively new sheet metal forming process. This study therefore suggests that roll forming may be a potential solution for the room temperature forming of high strength. It. Titanium Sheet Forming.

From www.youtube.com

Titanium Sheet Manufacturers, Suppliers, and Industry Information YouTube Titanium Sheet Forming It can be used for rapid. Below is a competitive analysis of the three most common titanium forming methods and recommendations for the successful operation of your. Great majority of formed titanium parts are made by hot forming or by cold preforming and then hot sizing. Asymmetric incremental sheet forming (aisf) is a relatively new sheet metal forming process. The. Titanium Sheet Forming.

From www.mdpi.com

Materials Free FullText Tailoring Titanium Sheet Metal Using Laser Titanium Sheet Forming The following characteristics of titanium. Great majority of formed titanium parts are made by hot forming or by cold preforming and then hot sizing. Asymmetric incremental sheet forming (aisf) is a relatively new sheet metal forming process. This study therefore suggests that roll forming may be a potential solution for the room temperature forming of high strength. It can be. Titanium Sheet Forming.

From www.metalstitanium.com

Forming Titanium Sheet ASTM B381 Square Shape Polished GR7 GR9 GR12 Titanium Sheet Forming Asymmetric incremental sheet forming (aisf) is a relatively new sheet metal forming process. Below is a competitive analysis of the three most common titanium forming methods and recommendations for the successful operation of your. Technologies dedicated to hot forming of titanium sheet are key processes for the manufacturing of structural and engine parts in the aerospace. It can be used. Titanium Sheet Forming.

From www.mdpi.com

Materials Free FullText Tribological Aspects of Sheet Titanium Forming Titanium Sheet Forming Great majority of formed titanium parts are made by hot forming or by cold preforming and then hot sizing. Below is a competitive analysis of the three most common titanium forming methods and recommendations for the successful operation of your. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. It can be. Titanium Sheet Forming.

From www.mdpi.com

Materials Free FullText Numerical and Experimental Analysis of Titanium Sheet Forming It can be used for rapid. Great majority of formed titanium parts are made by hot forming or by cold preforming and then hot sizing. The following characteristics of titanium. Below is a competitive analysis of the three most common titanium forming methods and recommendations for the successful operation of your. Heating titanium increases its formability, reduces springback, and permits. Titanium Sheet Forming.

From www.mdpi.com

Materials Free FullText Numerical and Experimental Analysis of Titanium Sheet Forming Asymmetric incremental sheet forming (aisf) is a relatively new sheet metal forming process. Great majority of formed titanium parts are made by hot forming or by cold preforming and then hot sizing. Technologies dedicated to hot forming of titanium sheet are key processes for the manufacturing of structural and engine parts in the aerospace. The following characteristics of titanium. Heating. Titanium Sheet Forming.

From www.metalstitanium.com

Forming Titanium Sheet ASTM B381 Square Shape Polished GR7 GR9 GR12 Titanium Sheet Forming The following characteristics of titanium. This study therefore suggests that roll forming may be a potential solution for the room temperature forming of high strength. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. Below is a competitive analysis of the three most common titanium forming methods and recommendations for the successful. Titanium Sheet Forming.

From www.msm-aero.com

Titanium Forming MSM aerospace fabricators Titanium Sheet Forming Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. Technologies dedicated to hot forming of titanium sheet are key processes for the manufacturing of structural and engine parts in the aerospace. The following characteristics of titanium. Below is a competitive analysis of the three most common titanium forming methods and recommendations for. Titanium Sheet Forming.

From www.msm-aero.com

Titanium Forming MSM aerospace fabricators Titanium Sheet Forming Asymmetric incremental sheet forming (aisf) is a relatively new sheet metal forming process. It can be used for rapid. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. Technologies dedicated to hot forming of titanium sheet are key processes for the manufacturing of structural and engine parts in the aerospace. Below is. Titanium Sheet Forming.

From www.metalstitanium.com

Forming Titanium Sheet ASTM B381 Square Shape Polished GR7 GR9 GR12 Titanium Sheet Forming It can be used for rapid. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. Asymmetric incremental sheet forming (aisf) is a relatively new sheet metal forming process. This study therefore suggests that roll forming may be a potential solution for the room temperature forming of high strength. Technologies dedicated to hot. Titanium Sheet Forming.

From www.mdpi.com

Materials Free FullText Numerical and Experimental Analysis of Titanium Sheet Forming Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. Great majority of formed titanium parts are made by hot forming or by cold preforming and then hot sizing. It can be used for rapid. Technologies dedicated to hot forming of titanium sheet are key processes for the manufacturing of structural and engine. Titanium Sheet Forming.

From www.mdpi.com

Materials Free FullText Numerical and Experimental Analysis of Titanium Sheet Forming The following characteristics of titanium. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. Technologies dedicated to hot forming of titanium sheet are key processes for the manufacturing of structural and engine parts in the aerospace. Asymmetric incremental sheet forming (aisf) is a relatively new sheet metal forming process. This study therefore. Titanium Sheet Forming.

From www.researchgate.net

(PDF) Tribological Aspects of Sheet Titanium Forming Titanium Sheet Forming Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. Great majority of formed titanium parts are made by hot forming or by cold preforming and then hot sizing. It can be used for rapid. Below is a competitive analysis of the three most common titanium forming methods and recommendations for the successful. Titanium Sheet Forming.

From www.mdpi.com

Materials Free FullText Numerical and Experimental Analysis of Titanium Sheet Forming The following characteristics of titanium. This study therefore suggests that roll forming may be a potential solution for the room temperature forming of high strength. Asymmetric incremental sheet forming (aisf) is a relatively new sheet metal forming process. Below is a competitive analysis of the three most common titanium forming methods and recommendations for the successful operation of your. Heating. Titanium Sheet Forming.

From www.alamy.com

Closeup of a section of the titanium sheets which form the skin of the Titanium Sheet Forming Technologies dedicated to hot forming of titanium sheet are key processes for the manufacturing of structural and engine parts in the aerospace. The following characteristics of titanium. This study therefore suggests that roll forming may be a potential solution for the room temperature forming of high strength. Great majority of formed titanium parts are made by hot forming or by. Titanium Sheet Forming.

From www.titanium-industry.com

Grade Gr3 Hot Forming Titanium Sheet Pickling Titanium Steel Sheet Titanium Sheet Forming The following characteristics of titanium. Below is a competitive analysis of the three most common titanium forming methods and recommendations for the successful operation of your. Great majority of formed titanium parts are made by hot forming or by cold preforming and then hot sizing. Asymmetric incremental sheet forming (aisf) is a relatively new sheet metal forming process. It can. Titanium Sheet Forming.

From www.mdpi.com

Materials Free FullText Numerical and Experimental Analysis of Titanium Sheet Forming Great majority of formed titanium parts are made by hot forming or by cold preforming and then hot sizing. Below is a competitive analysis of the three most common titanium forming methods and recommendations for the successful operation of your. It can be used for rapid. Technologies dedicated to hot forming of titanium sheet are key processes for the manufacturing. Titanium Sheet Forming.

From www.mdpi.com

Materials Free FullText Numerical and Experimental Analysis of Titanium Sheet Forming The following characteristics of titanium. This study therefore suggests that roll forming may be a potential solution for the room temperature forming of high strength. Great majority of formed titanium parts are made by hot forming or by cold preforming and then hot sizing. Asymmetric incremental sheet forming (aisf) is a relatively new sheet metal forming process. It can be. Titanium Sheet Forming.

From www.titaniumprocessingcenter.com

Titanium Sheet Titanium Processing Center Titanium Sheet Forming Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. Asymmetric incremental sheet forming (aisf) is a relatively new sheet metal forming process. This study therefore suggests that roll forming may be a potential solution for the room temperature forming of high strength. It can be used for rapid. Below is a competitive. Titanium Sheet Forming.

From www.metalstitanium.com

Forming Titanium Sheet ASTM B381 Square Shape Polished GR7 GR9 GR12 Titanium Sheet Forming It can be used for rapid. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. Below is a competitive analysis of the three most common titanium forming methods and recommendations for the successful operation of your. Asymmetric incremental sheet forming (aisf) is a relatively new sheet metal forming process. Great majority of. Titanium Sheet Forming.

From develop3d.com

Figur G15 launched for sheet metal forming by Desktop Metal DEVELOP3D Titanium Sheet Forming This study therefore suggests that roll forming may be a potential solution for the room temperature forming of high strength. The following characteristics of titanium. Asymmetric incremental sheet forming (aisf) is a relatively new sheet metal forming process. Technologies dedicated to hot forming of titanium sheet are key processes for the manufacturing of structural and engine parts in the aerospace.. Titanium Sheet Forming.

From www.metalstitanium.com

Forming Titanium Sheet ASTM B381 Square Shape Polished GR7 GR9 GR12 Titanium Sheet Forming Great majority of formed titanium parts are made by hot forming or by cold preforming and then hot sizing. Asymmetric incremental sheet forming (aisf) is a relatively new sheet metal forming process. Technologies dedicated to hot forming of titanium sheet are key processes for the manufacturing of structural and engine parts in the aerospace. Below is a competitive analysis of. Titanium Sheet Forming.