Chamfer Corner . They are created for mainly for protecting the. a chamfered corner. Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. A chamfer is an angle on the edge of a workpiece. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. Bevel and chamfer are terms addressed as sloped edges yet they differ in angle and use. chamfering is the process in developing that edge and what one could argue, a unique yet very common application. Depending on component size, this may seem like a simple adjustment, but its implications are profound. a newly machined metal part can end up with edges that are sharper than desired for the end user unless the. chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut diagonally. A bevel is usually cut at. chamfering removes sharp corners and edges, reducing the risk of injuries caused by accidental bumps or collisions.

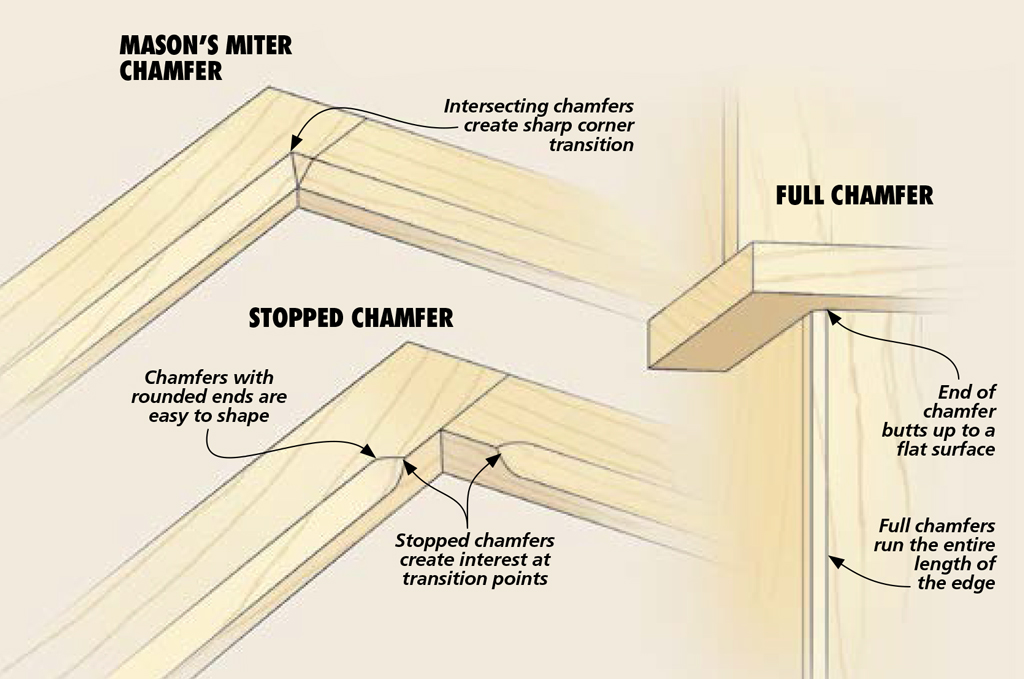

from www.woodsmith.com

chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut diagonally. chamfering is the process in developing that edge and what one could argue, a unique yet very common application. A bevel is usually cut at. They are created for mainly for protecting the. chamfering removes sharp corners and edges, reducing the risk of injuries caused by accidental bumps or collisions. Bevel and chamfer are terms addressed as sloped edges yet they differ in angle and use. Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. A chamfer is an angle on the edge of a workpiece. Depending on component size, this may seem like a simple adjustment, but its implications are profound. a chamfered corner.

The Versatile Chamfer Woodsmith

Chamfer Corner A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. chamfering removes sharp corners and edges, reducing the risk of injuries caused by accidental bumps or collisions. a chamfered corner. Depending on component size, this may seem like a simple adjustment, but its implications are profound. A bevel is usually cut at. Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. A chamfer is an angle on the edge of a workpiece. Bevel and chamfer are terms addressed as sloped edges yet they differ in angle and use. chamfering is the process in developing that edge and what one could argue, a unique yet very common application. chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut diagonally. They are created for mainly for protecting the. a newly machined metal part can end up with edges that are sharper than desired for the end user unless the.

From brandxmetals.com

Chamfered Corner Brand X Metals Chamfer Corner A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. chamfering removes sharp corners and edges, reducing the risk of injuries caused by accidental bumps or collisions. a chamfered corner. A bevel is usually cut at. a newly machined metal part can end up with edges that are sharper. Chamfer Corner.

From www.trim-tex.com

Chamfer Bead Molded Corners for Drywall TrimTex Chamfer Corner a newly machined metal part can end up with edges that are sharper than desired for the end user unless the. Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. A chamfer is an angle on the edge of a workpiece. chamfering is the process in developing that edge and. Chamfer Corner.

From www.youtube.com

Solid Edge How to dimension chamfer with corner intersection? YouTube Chamfer Corner a chamfered corner. chamfering removes sharp corners and edges, reducing the risk of injuries caused by accidental bumps or collisions. A bevel is usually cut at. They are created for mainly for protecting the. A chamfer is an angle on the edge of a workpiece. Depending on component size, this may seem like a simple adjustment, but its. Chamfer Corner.

From www.trim-tex.com

Chamfer Bead Molded Corners for Drywall TrimTex Chamfer Corner Bevel and chamfer are terms addressed as sloped edges yet they differ in angle and use. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. a newly machined metal part can end up with edges that are sharper than desired for the end user unless the. chamfering refers to. Chamfer Corner.

From plasterart.com.au

Corner Beads Chamfer Finish PlasterArt Chamfer Corner Depending on component size, this may seem like a simple adjustment, but its implications are profound. chamfering removes sharp corners and edges, reducing the risk of injuries caused by accidental bumps or collisions. a newly machined metal part can end up with edges that are sharper than desired for the end user unless the. Bevel and chamfer are. Chamfer Corner.

From www.decoist.com

Maximizing Chamfered Corners Home Renovation in Barcelona’s Eixample Chamfer Corner Bevel and chamfer are terms addressed as sloped edges yet they differ in angle and use. chamfering removes sharp corners and edges, reducing the risk of injuries caused by accidental bumps or collisions. Depending on component size, this may seem like a simple adjustment, but its implications are profound. A chamfer is an angle on the edge of a. Chamfer Corner.

From giosnrxwn.blob.core.windows.net

Chamfer Drywall Corner Bead at Thomas Moll blog Chamfer Corner a chamfered corner. chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut diagonally. Bevel and chamfer are terms addressed as sloped edges yet they differ in angle and use. A bevel is usually cut at. Depending on component size, this may seem like. Chamfer Corner.

From www.decoist.com

Maximizing Chamfered Corners Home Renovation in Barcelona’s Eixample Chamfer Corner Depending on component size, this may seem like a simple adjustment, but its implications are profound. Bevel and chamfer are terms addressed as sloped edges yet they differ in angle and use. chamfering removes sharp corners and edges, reducing the risk of injuries caused by accidental bumps or collisions. A chamfer edge improves visual properties, but it is also. Chamfer Corner.

From www.precastconcretemagnet.com

The Complete Guide to Chamfering Concrete Edges Knowledge Chamfer Corner They are created for mainly for protecting the. a chamfered corner. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. A bevel is usually cut at. chamfering removes sharp corners and edges, reducing the risk of injuries caused by accidental bumps or collisions. chamfering refers to a processing. Chamfer Corner.

From h-o-m-e.org

What Does A Chamfered Edge Look Like? Chamfer Corner They are created for mainly for protecting the. Bevel and chamfer are terms addressed as sloped edges yet they differ in angle and use. chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut diagonally. A bevel is usually cut at. A chamfer edge improves. Chamfer Corner.

From plasterart.com.au

32mm Chamfer 90º Corner Bead 3.0m TrimTex PlasterArt Chamfer Corner A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. Bevel and chamfer are terms addressed as sloped edges yet they differ in angle and use. a chamfered corner. A chamfer is an angle on the edge of a workpiece. chamfering is the process in developing that edge and what. Chamfer Corner.

From www.clarkdietrich.com

Chamfered Corner Bead ClarkDietrich Building Systems Chamfer Corner chamfering removes sharp corners and edges, reducing the risk of injuries caused by accidental bumps or collisions. chamfering is the process in developing that edge and what one could argue, a unique yet very common application. A chamfer is an angle on the edge of a workpiece. Depending on component size, this may seem like a simple adjustment,. Chamfer Corner.

From www.steinkebrothers.com

Chamforcor CFC Steinke Brothers Inc. Chamfer Corner A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. A chamfer is an angle on the edge of a workpiece. chamfering is the process in developing that edge and what one could argue,. Chamfer Corner.

From www.finepowertools.com

Bevel vs Chamfer Difference Between the Edges Demystified. Chamfer Corner a chamfered corner. A chamfer is an angle on the edge of a workpiece. chamfering removes sharp corners and edges, reducing the risk of injuries caused by accidental bumps or collisions. A bevel is usually cut at. Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. chamfering is the. Chamfer Corner.

From www.madearia.com

Chamfer vs BevelExplained And Their Difference Aria Chamfer Corner Bevel and chamfer are terms addressed as sloped edges yet they differ in angle and use. Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. Depending on component size, this may seem like a simple adjustment, but its implications are profound. A bevel is usually cut at. chamfering is the process. Chamfer Corner.

From www.trim-tex.com

Chamfer Bead Molded Corners for Drywall TrimTex Chamfer Corner A chamfer is an angle on the edge of a workpiece. Depending on component size, this may seem like a simple adjustment, but its implications are profound. They are created for mainly for protecting the. chamfering removes sharp corners and edges, reducing the risk of injuries caused by accidental bumps or collisions. A bevel is usually cut at. . Chamfer Corner.

From www.dreamstime.com

Chamfered Corner Of Decorative Brick Wall Stock Photo Image of corner Chamfer Corner A chamfer is an angle on the edge of a workpiece. chamfering removes sharp corners and edges, reducing the risk of injuries caused by accidental bumps or collisions. chamfering is the process in developing that edge and what one could argue, a unique yet very common application. a chamfered corner. Depending on component size, this may seem. Chamfer Corner.

From www.woodsmith.com

The Versatile Chamfer Woodsmith Chamfer Corner chamfering is the process in developing that edge and what one could argue, a unique yet very common application. A bevel is usually cut at. Bevel and chamfer are terms addressed as sloped edges yet they differ in angle and use. A chamfer is an angle on the edge of a workpiece. Depending on component size, this may seem. Chamfer Corner.

From www.woodsmith.com

The Versatile Chamfer Woodsmith Chamfer Corner Bevel and chamfer are terms addressed as sloped edges yet they differ in angle and use. chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut diagonally. a newly machined metal part can end up with edges that are sharper than desired for the. Chamfer Corner.

From www.decoist.com

Maximizing Chamfered Corners Home Renovation in Barcelona’s Eixample Chamfer Corner Depending on component size, this may seem like a simple adjustment, but its implications are profound. They are created for mainly for protecting the. chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut diagonally. a newly machined metal part can end up with. Chamfer Corner.

From www.homehardware.ca

TrimTex 7/8"x7/8"x8' Chamfer Vinyl Corner Bead Home Hardware Chamfer Corner Depending on component size, this may seem like a simple adjustment, but its implications are profound. Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. chamfering refers to a processing method in which. Chamfer Corner.

From www.rmcspl.co.za

construction formwork chamfers & corner fillets from Rebar, Mesh and Chamfer Corner chamfering removes sharp corners and edges, reducing the risk of injuries caused by accidental bumps or collisions. a newly machined metal part can end up with edges that are sharper than desired for the end user unless the. chamfering is the process in developing that edge and what one could argue, a unique yet very common application.. Chamfer Corner.

From www.hickorychair.com

Artisan Chamfered Corner Dining TableMahogany Chamfer Corner Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. a newly machined metal part can end up with edges that are sharper than desired for the end user unless the. A bevel is usually cut at. They are created for mainly for protecting the. A chamfer is an angle on the. Chamfer Corner.

From gionxmqqw.blob.core.windows.net

Chamfered Corner Design at Lawrence Alvarez blog Chamfer Corner A bevel is usually cut at. a chamfered corner. chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut diagonally. chamfering is the process in developing that edge and what one could argue, a unique yet very common application. a newly machined. Chamfer Corner.

From www.trim-tex.com

Chamfer Bead Molded Corners for Drywall TrimTex Chamfer Corner a newly machined metal part can end up with edges that are sharper than desired for the end user unless the. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. Bevel and chamfer are terms addressed as sloped edges yet they differ in angle and use. chamfering refers to. Chamfer Corner.

From gionxmqqw.blob.core.windows.net

Chamfered Corner Design at Lawrence Alvarez blog Chamfer Corner Depending on component size, this may seem like a simple adjustment, but its implications are profound. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance. A chamfer is an angle on the edge of a workpiece. a newly machined metal part can end up with edges that are sharper than. Chamfer Corner.

From autocadtip.com

How to make Chamfer corner in AutoCAD? AutoCAD Tips Chamfer Corner chamfering removes sharp corners and edges, reducing the risk of injuries caused by accidental bumps or collisions. chamfering is the process in developing that edge and what one could argue, a unique yet very common application. a newly machined metal part can end up with edges that are sharper than desired for the end user unless the.. Chamfer Corner.

From gionxmqqw.blob.core.windows.net

Chamfered Corner Design at Lawrence Alvarez blog Chamfer Corner Depending on component size, this may seem like a simple adjustment, but its implications are profound. Bevel and chamfer are terms addressed as sloped edges yet they differ in angle and use. A bevel is usually cut at. chamfering is the process in developing that edge and what one could argue, a unique yet very common application. a. Chamfer Corner.

From formandbuild.com

Wood Chamfer 3/4" x 10' Length — Form and Build Supply Inc. Chamfer Corner They are created for mainly for protecting the. Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. chamfering removes sharp corners and edges, reducing the risk of injuries caused by accidental bumps or collisions. a chamfered corner. a newly machined metal part can end up with edges that are. Chamfer Corner.

From www.clarkdietrich.com

Chamfered Corner Bead ClarkDietrich Building Systems Chamfer Corner A bevel is usually cut at. They are created for mainly for protecting the. Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. Depending on component size, this may seem like a simple adjustment, but its implications are profound. A chamfer is an angle on the edge of a workpiece. chamfering. Chamfer Corner.

From forums.sketchup.com

How to chamfer in 3d Corner Pro SketchUp Community Chamfer Corner a newly machined metal part can end up with edges that are sharper than desired for the end user unless the. Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. They are created for mainly for protecting the. chamfering refers to a processing method in which the edges of materials. Chamfer Corner.

From www.bopha.co.za

construction formwork chamfers & plastic corner fillets from Rebar Chamfer Corner chamfering removes sharp corners and edges, reducing the risk of injuries caused by accidental bumps or collisions. a newly machined metal part can end up with edges that are sharper than desired for the end user unless the. a chamfered corner. Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered. Chamfer Corner.

From www.youtube.com

Pro E Creo Chamfer Corner Chamfer Tutorial GRS YouTube Chamfer Corner a newly machined metal part can end up with edges that are sharper than desired for the end user unless the. A bevel is usually cut at. Depending on component size, this may seem like a simple adjustment, but its implications are profound. chamfering removes sharp corners and edges, reducing the risk of injuries caused by accidental bumps. Chamfer Corner.

From www.artofit.org

Quick corner chamfers Artofit Chamfer Corner Bevel and chamfer are terms addressed as sloped edges yet they differ in angle and use. a newly machined metal part can end up with edges that are sharper than desired for the end user unless the. chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole. Chamfer Corner.

From www.trim-tex.com

Chamfer Bead Molded Corners for Drywall TrimTex Chamfer Corner A bevel is usually cut at. a chamfered corner. Bevel and chamfer are terms addressed as sloped edges yet they differ in angle and use. chamfering refers to a processing method in which the edges of materials such as metals and resins and corners of hole openings are cut diagonally. A chamfer is an angle on the edge. Chamfer Corner.