Gage Tolerance . Learn the tolerance of each gage class and which gage class is best for your application. Gage tolerance is the gage's increments of measure that should divide process tolerance into at least 10 parts. Find gage tolerance charts and download our gaging guide. Learn how to calculate gage. Meyer gage tolerance calculator for plain cylindrical i.d. Calculate the gage class and tolerance for cylindrical i.d and o.d. Gages according to ansi asme b89.1.5. The 10% product tolerance rule is sometimes used in the manufacturing industry. The industry standard is referred to as the ten percent rule. This common rule of practice requires that 10% of the product tolerance is. According to asme y14.43, the dimensioning and tolerancing standard for gages and fixtures, the tolerance of the gage itself must be within the size limits of the workpiece.

from willrich.com

Learn how to calculate gage. Calculate the gage class and tolerance for cylindrical i.d and o.d. According to asme y14.43, the dimensioning and tolerancing standard for gages and fixtures, the tolerance of the gage itself must be within the size limits of the workpiece. Gages according to ansi asme b89.1.5. This common rule of practice requires that 10% of the product tolerance is. The industry standard is referred to as the ten percent rule. Gage tolerance is the gage's increments of measure that should divide process tolerance into at least 10 parts. The 10% product tolerance rule is sometimes used in the manufacturing industry. Meyer gage tolerance calculator for plain cylindrical i.d. Find gage tolerance charts and download our gaging guide.

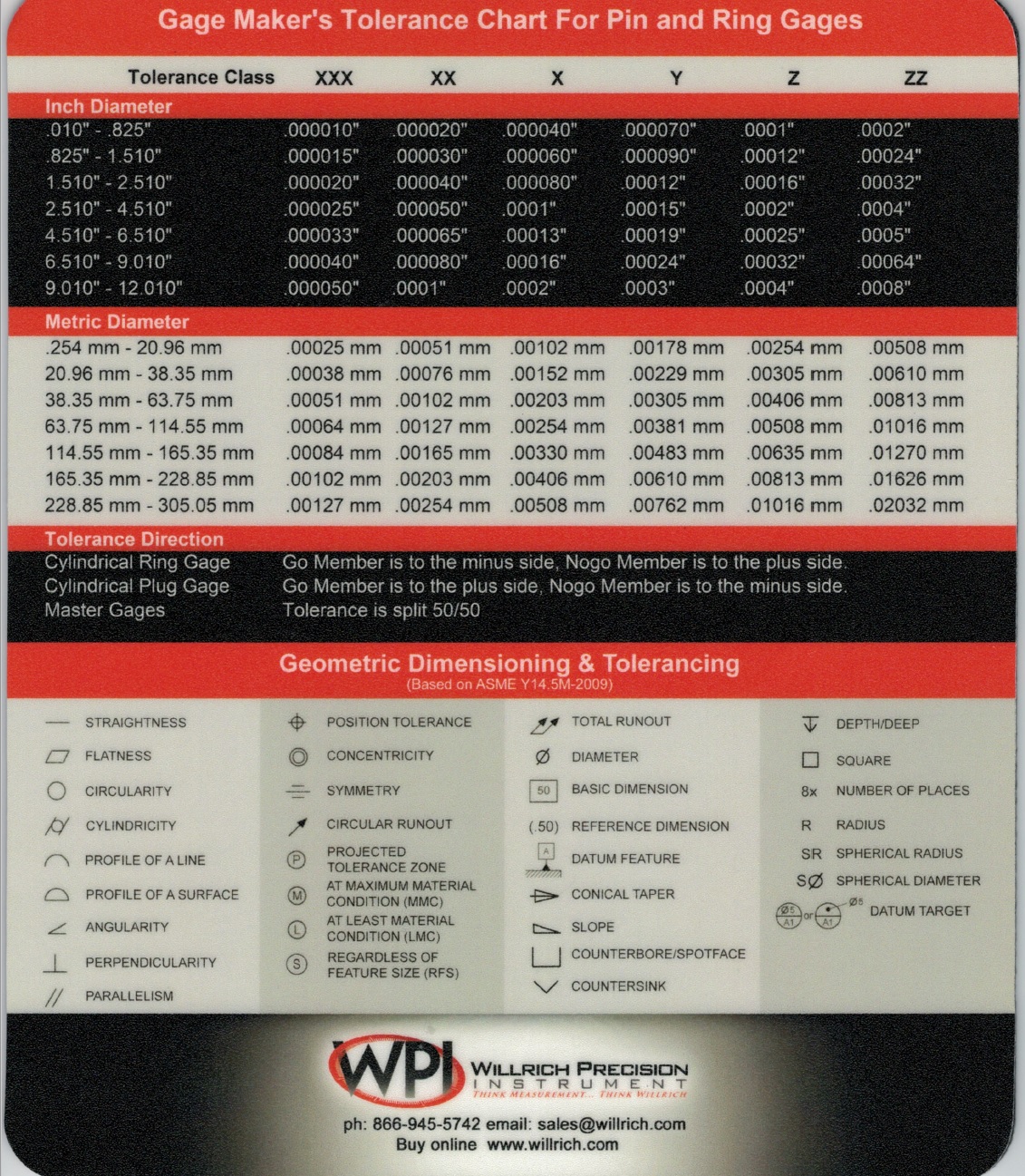

Gagemakers Tolerance Chart Willich Precision Instruments

Gage Tolerance Learn how to calculate gage. This common rule of practice requires that 10% of the product tolerance is. Gages according to ansi asme b89.1.5. Meyer gage tolerance calculator for plain cylindrical i.d. Learn how to calculate gage. Calculate the gage class and tolerance for cylindrical i.d and o.d. According to asme y14.43, the dimensioning and tolerancing standard for gages and fixtures, the tolerance of the gage itself must be within the size limits of the workpiece. The 10% product tolerance rule is sometimes used in the manufacturing industry. Gage tolerance is the gage's increments of measure that should divide process tolerance into at least 10 parts. Find gage tolerance charts and download our gaging guide. The industry standard is referred to as the ten percent rule. Learn the tolerance of each gage class and which gage class is best for your application.

From mungfali.com

Gage Block Tolerance Chart Gage Tolerance The 10% product tolerance rule is sometimes used in the manufacturing industry. Learn how to calculate gage. Find gage tolerance charts and download our gaging guide. The industry standard is referred to as the ten percent rule. This common rule of practice requires that 10% of the product tolerance is. According to asme y14.43, the dimensioning and tolerancing standard for. Gage Tolerance.

From exogszodf.blob.core.windows.net

Plug Gauge Tolerance Standards at Tracy Benedetti blog Gage Tolerance The 10% product tolerance rule is sometimes used in the manufacturing industry. According to asme y14.43, the dimensioning and tolerancing standard for gages and fixtures, the tolerance of the gage itself must be within the size limits of the workpiece. Learn how to calculate gage. This common rule of practice requires that 10% of the product tolerance is. Find gage. Gage Tolerance.

From vermontgage.com

Product and Technical Support Resources Vermont Gage Gage Tolerance The industry standard is referred to as the ten percent rule. Learn how to calculate gage. Gage tolerance is the gage's increments of measure that should divide process tolerance into at least 10 parts. Learn the tolerance of each gage class and which gage class is best for your application. This common rule of practice requires that 10% of the. Gage Tolerance.

From www.ebay.com

Vermont Gage Steel NoGo Pin Gage Set Black Oxide Tolerance Class ZZ 0. Gage Tolerance The industry standard is referred to as the ten percent rule. Calculate the gage class and tolerance for cylindrical i.d and o.d. According to asme y14.43, the dimensioning and tolerancing standard for gages and fixtures, the tolerance of the gage itself must be within the size limits of the workpiece. This common rule of practice requires that 10% of the. Gage Tolerance.

From mungfali.com

Metric Thread Gage Chart Gage Tolerance According to asme y14.43, the dimensioning and tolerancing standard for gages and fixtures, the tolerance of the gage itself must be within the size limits of the workpiece. Meyer gage tolerance calculator for plain cylindrical i.d. This common rule of practice requires that 10% of the product tolerance is. Gages according to ansi asme b89.1.5. Calculate the gage class and. Gage Tolerance.

From mavink.com

Gdt Tolerances Gage Tolerance Gage tolerance is the gage's increments of measure that should divide process tolerance into at least 10 parts. Find gage tolerance charts and download our gaging guide. The industry standard is referred to as the ten percent rule. This common rule of practice requires that 10% of the product tolerance is. The 10% product tolerance rule is sometimes used in. Gage Tolerance.

From mungfali.com

Gage Block Tolerance Chart Gage Tolerance Gages according to ansi asme b89.1.5. The 10% product tolerance rule is sometimes used in the manufacturing industry. The industry standard is referred to as the ten percent rule. Find gage tolerance charts and download our gaging guide. According to asme y14.43, the dimensioning and tolerancing standard for gages and fixtures, the tolerance of the gage itself must be within. Gage Tolerance.

From www.scribd.com

10. Gage Tolerances PDF Gage Tolerance The industry standard is referred to as the ten percent rule. Meyer gage tolerance calculator for plain cylindrical i.d. The 10% product tolerance rule is sometimes used in the manufacturing industry. Calculate the gage class and tolerance for cylindrical i.d and o.d. This common rule of practice requires that 10% of the product tolerance is. Learn how to calculate gage.. Gage Tolerance.

From mungfali.com

Gage Block Tolerance Chart Gage Tolerance Gages according to ansi asme b89.1.5. Gage tolerance is the gage's increments of measure that should divide process tolerance into at least 10 parts. This common rule of practice requires that 10% of the product tolerance is. Learn how to calculate gage. Calculate the gage class and tolerance for cylindrical i.d and o.d. Meyer gage tolerance calculator for plain cylindrical. Gage Tolerance.

From www.machinemfg.com

Sheet Metal Tolerances The Key to Precision Engineering MachineMFG Gage Tolerance Learn how to calculate gage. The 10% product tolerance rule is sometimes used in the manufacturing industry. Find gage tolerance charts and download our gaging guide. Gages according to ansi asme b89.1.5. The industry standard is referred to as the ten percent rule. This common rule of practice requires that 10% of the product tolerance is. According to asme y14.43,. Gage Tolerance.

From mungfali.com

Gage Block Tolerance Chart Gage Tolerance Meyer gage tolerance calculator for plain cylindrical i.d. According to asme y14.43, the dimensioning and tolerancing standard for gages and fixtures, the tolerance of the gage itself must be within the size limits of the workpiece. Gage tolerance is the gage's increments of measure that should divide process tolerance into at least 10 parts. This common rule of practice requires. Gage Tolerance.

From www.engineersedge.com

International Tolerance (IT) Grades Table Chart Engineers Edge Gage Tolerance Learn the tolerance of each gage class and which gage class is best for your application. Learn how to calculate gage. The 10% product tolerance rule is sometimes used in the manufacturing industry. The industry standard is referred to as the ten percent rule. Gage tolerance is the gage's increments of measure that should divide process tolerance into at least. Gage Tolerance.

From www.qualitymag.com

Thread Classes and Setting Plug Gages 20191001 Quality Magazine Gage Tolerance Gages according to ansi asme b89.1.5. Meyer gage tolerance calculator for plain cylindrical i.d. Find gage tolerance charts and download our gaging guide. Learn how to calculate gage. The 10% product tolerance rule is sometimes used in the manufacturing industry. Calculate the gage class and tolerance for cylindrical i.d and o.d. According to asme y14.43, the dimensioning and tolerancing standard. Gage Tolerance.

From dokumen.tips

(PDF) Gages and Gaging for Unified Inch Screw Threads · 3.5 Standard Gage Tolerance Meyer gage tolerance calculator for plain cylindrical i.d. Find gage tolerance charts and download our gaging guide. The industry standard is referred to as the ten percent rule. Calculate the gage class and tolerance for cylindrical i.d and o.d. This common rule of practice requires that 10% of the product tolerance is. Learn the tolerance of each gage class and. Gage Tolerance.

From mungfali.com

Gage Block Tolerance Chart Gage Tolerance According to asme y14.43, the dimensioning and tolerancing standard for gages and fixtures, the tolerance of the gage itself must be within the size limits of the workpiece. Gage tolerance is the gage's increments of measure that should divide process tolerance into at least 10 parts. Learn the tolerance of each gage class and which gage class is best for. Gage Tolerance.

From willrich.com

Gagemakers Tolerance Chart Willich Precision Instruments Gage Tolerance Find gage tolerance charts and download our gaging guide. Calculate the gage class and tolerance for cylindrical i.d and o.d. This common rule of practice requires that 10% of the product tolerance is. Meyer gage tolerance calculator for plain cylindrical i.d. Gage tolerance is the gage's increments of measure that should divide process tolerance into at least 10 parts. The. Gage Tolerance.

From www.dimensionalconsulting.com

Tolerance Of Position Dimensional Consulting Gage Tolerance Find gage tolerance charts and download our gaging guide. Gages according to ansi asme b89.1.5. The industry standard is referred to as the ten percent rule. This common rule of practice requires that 10% of the product tolerance is. According to asme y14.43, the dimensioning and tolerancing standard for gages and fixtures, the tolerance of the gage itself must be. Gage Tolerance.

From weaversteelweld.com

Sheet Gauge Chart Weaver Steel Welding Gage Tolerance Calculate the gage class and tolerance for cylindrical i.d and o.d. Gages according to ansi asme b89.1.5. According to asme y14.43, the dimensioning and tolerancing standard for gages and fixtures, the tolerance of the gage itself must be within the size limits of the workpiece. The 10% product tolerance rule is sometimes used in the manufacturing industry. This common rule. Gage Tolerance.

From grmetrology.com

Plug Gage Calibration GR Metrology Gage Tolerance This common rule of practice requires that 10% of the product tolerance is. Find gage tolerance charts and download our gaging guide. Gages according to ansi asme b89.1.5. The 10% product tolerance rule is sometimes used in the manufacturing industry. Meyer gage tolerance calculator for plain cylindrical i.d. Calculate the gage class and tolerance for cylindrical i.d and o.d. Gage. Gage Tolerance.

From vdocuments.mx

Metric Thread Gages Gage Assembly · Metric Thread Gages ANSI / ASME Gage Tolerance This common rule of practice requires that 10% of the product tolerance is. Gages according to ansi asme b89.1.5. Meyer gage tolerance calculator for plain cylindrical i.d. Gage tolerance is the gage's increments of measure that should divide process tolerance into at least 10 parts. The 10% product tolerance rule is sometimes used in the manufacturing industry. Learn how to. Gage Tolerance.

From partdiagramacapteu6.z13.web.core.windows.net

Metal Gauge Thickness Chart Inches Gage Tolerance According to asme y14.43, the dimensioning and tolerancing standard for gages and fixtures, the tolerance of the gage itself must be within the size limits of the workpiece. Calculate the gage class and tolerance for cylindrical i.d and o.d. The 10% product tolerance rule is sometimes used in the manufacturing industry. Learn how to calculate gage. The industry standard is. Gage Tolerance.

From mavink.com

Gage Makers Tolerance Chart Gage Tolerance The industry standard is referred to as the ten percent rule. The 10% product tolerance rule is sometimes used in the manufacturing industry. Gage tolerance is the gage's increments of measure that should divide process tolerance into at least 10 parts. Learn how to calculate gage. Learn the tolerance of each gage class and which gage class is best for. Gage Tolerance.

From circuitnehajnije39.z21.web.core.windows.net

Standard Tolerance Chart Pdf Gage Tolerance The industry standard is referred to as the ten percent rule. Calculate the gage class and tolerance for cylindrical i.d and o.d. According to asme y14.43, the dimensioning and tolerancing standard for gages and fixtures, the tolerance of the gage itself must be within the size limits of the workpiece. Learn the tolerance of each gage class and which gage. Gage Tolerance.

From biocover.netlify.app

Iso Fits And Tolerances Chart Gage Tolerance The 10% product tolerance rule is sometimes used in the manufacturing industry. Calculate the gage class and tolerance for cylindrical i.d and o.d. The industry standard is referred to as the ten percent rule. Learn how to calculate gage. Find gage tolerance charts and download our gaging guide. Gages according to ansi asme b89.1.5. Meyer gage tolerance calculator for plain. Gage Tolerance.

From www.scribd.com

iso tolerances for shafts (iso 2862) Engineering Tolerance Game Theory Gage Tolerance The 10% product tolerance rule is sometimes used in the manufacturing industry. Meyer gage tolerance calculator for plain cylindrical i.d. Calculate the gage class and tolerance for cylindrical i.d and o.d. Learn how to calculate gage. Gages according to ansi asme b89.1.5. Find gage tolerance charts and download our gaging guide. Learn the tolerance of each gage class and which. Gage Tolerance.

From mavink.com

Gage Makers Tolerance Chart Gage Tolerance Find gage tolerance charts and download our gaging guide. This common rule of practice requires that 10% of the product tolerance is. According to asme y14.43, the dimensioning and tolerancing standard for gages and fixtures, the tolerance of the gage itself must be within the size limits of the workpiece. Gage tolerance is the gage's increments of measure that should. Gage Tolerance.

From mavink.com

Gage Makers Tolerance Chart Gage Tolerance According to asme y14.43, the dimensioning and tolerancing standard for gages and fixtures, the tolerance of the gage itself must be within the size limits of the workpiece. Meyer gage tolerance calculator for plain cylindrical i.d. The industry standard is referred to as the ten percent rule. The 10% product tolerance rule is sometimes used in the manufacturing industry. This. Gage Tolerance.

From werk24.io

Tolerances IT Grades, General Tolerances Gage Tolerance Calculate the gage class and tolerance for cylindrical i.d and o.d. Find gage tolerance charts and download our gaging guide. Gage tolerance is the gage's increments of measure that should divide process tolerance into at least 10 parts. This common rule of practice requires that 10% of the product tolerance is. The industry standard is referred to as the ten. Gage Tolerance.

From guidefixveruka92.z22.web.core.windows.net

Metal Sheet Thickness Gauge Gage Tolerance The industry standard is referred to as the ten percent rule. According to asme y14.43, the dimensioning and tolerancing standard for gages and fixtures, the tolerance of the gage itself must be within the size limits of the workpiece. Gages according to ansi asme b89.1.5. This common rule of practice requires that 10% of the product tolerance is. Calculate the. Gage Tolerance.

From mungfali.com

Gage Block Tolerance Chart Gage Tolerance Meyer gage tolerance calculator for plain cylindrical i.d. Gage tolerance is the gage's increments of measure that should divide process tolerance into at least 10 parts. According to asme y14.43, the dimensioning and tolerancing standard for gages and fixtures, the tolerance of the gage itself must be within the size limits of the workpiece. Find gage tolerance charts and download. Gage Tolerance.

From exogszodf.blob.core.windows.net

Plug Gauge Tolerance Standards at Tracy Benedetti blog Gage Tolerance Gages according to ansi asme b89.1.5. This common rule of practice requires that 10% of the product tolerance is. Calculate the gage class and tolerance for cylindrical i.d and o.d. Meyer gage tolerance calculator for plain cylindrical i.d. The 10% product tolerance rule is sometimes used in the manufacturing industry. Learn the tolerance of each gage class and which gage. Gage Tolerance.

From www.soinsinfirmiers-verviers.be

Wholesale prices Vermont Gage Steel Go Plug Gage 0.167 Gage Diameter Gage Tolerance This common rule of practice requires that 10% of the product tolerance is. Learn how to calculate gage. Gages according to ansi asme b89.1.5. Gage tolerance is the gage's increments of measure that should divide process tolerance into at least 10 parts. The 10% product tolerance rule is sometimes used in the manufacturing industry. Learn the tolerance of each gage. Gage Tolerance.

From mungfali.com

Gage Block Tolerance Chart Gage Tolerance Gages according to ansi asme b89.1.5. Meyer gage tolerance calculator for plain cylindrical i.d. This common rule of practice requires that 10% of the product tolerance is. According to asme y14.43, the dimensioning and tolerancing standard for gages and fixtures, the tolerance of the gage itself must be within the size limits of the workpiece. Gage tolerance is the gage's. Gage Tolerance.

From www.sumipol.com

THREAD LIMIT PLUG GAUGEISO TYPE JISGPNPspec Sumipol Gage Tolerance Calculate the gage class and tolerance for cylindrical i.d and o.d. According to asme y14.43, the dimensioning and tolerancing standard for gages and fixtures, the tolerance of the gage itself must be within the size limits of the workpiece. This common rule of practice requires that 10% of the product tolerance is. The 10% product tolerance rule is sometimes used. Gage Tolerance.

From pdfslide.net

8062 Tolerance Calculation Gage Tolerance The 10% product tolerance rule is sometimes used in the manufacturing industry. According to asme y14.43, the dimensioning and tolerancing standard for gages and fixtures, the tolerance of the gage itself must be within the size limits of the workpiece. The industry standard is referred to as the ten percent rule. Learn the tolerance of each gage class and which. Gage Tolerance.