Conveyor Belt Width Chart . This eliminates the need for extensive calculations. One of the very first decisions facing an owner, engineer or contractor is to ‘standardize’ on belt widths and design criteria as defined by cema — conveyor equipment manufacturers. Conveyor belt is normally referred to as the carcass. in a sense, the carcass is the heart of the conveyor belt since it must: Our top seven are described below. Understanding a basic conveyor belt calculation will ensure your conveyor design is accurate and is not putting too many demands on your system. There are many different belts available. Many conveying timing belts operate at low speeds and minimal loads. Mrf muscleflex belts are designed to denote the full thickness breaking strength in kilo newtons / metre width and the number of plies. The belt conveyor design guide offers a comprehensive manual on power demands, belt curves, transitions, and industry.

from www.mknorthamerica.com

Many conveying timing belts operate at low speeds and minimal loads. Conveyor belt is normally referred to as the carcass. in a sense, the carcass is the heart of the conveyor belt since it must: The belt conveyor design guide offers a comprehensive manual on power demands, belt curves, transitions, and industry. Mrf muscleflex belts are designed to denote the full thickness breaking strength in kilo newtons / metre width and the number of plies. Our top seven are described below. There are many different belts available. This eliminates the need for extensive calculations. One of the very first decisions facing an owner, engineer or contractor is to ‘standardize’ on belt widths and design criteria as defined by cema — conveyor equipment manufacturers. Understanding a basic conveyor belt calculation will ensure your conveyor design is accurate and is not putting too many demands on your system.

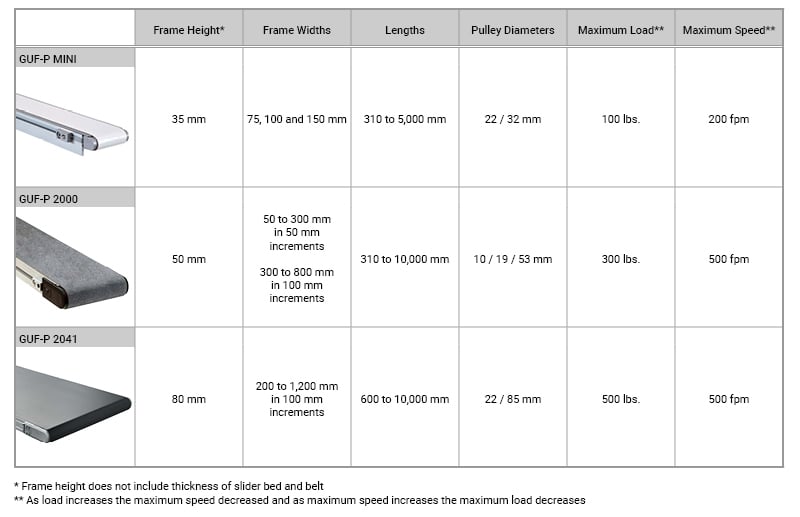

Belt Conveyor Types mk

Conveyor Belt Width Chart The belt conveyor design guide offers a comprehensive manual on power demands, belt curves, transitions, and industry. Our top seven are described below. Understanding a basic conveyor belt calculation will ensure your conveyor design is accurate and is not putting too many demands on your system. Conveyor belt is normally referred to as the carcass. in a sense, the carcass is the heart of the conveyor belt since it must: Mrf muscleflex belts are designed to denote the full thickness breaking strength in kilo newtons / metre width and the number of plies. There are many different belts available. Many conveying timing belts operate at low speeds and minimal loads. This eliminates the need for extensive calculations. The belt conveyor design guide offers a comprehensive manual on power demands, belt curves, transitions, and industry. One of the very first decisions facing an owner, engineer or contractor is to ‘standardize’ on belt widths and design criteria as defined by cema — conveyor equipment manufacturers.

From baktisurabaya.com

10 Tipe Belt Conveyor Dan Material Belt Conveyor CV BAKTI Conveyor Belt Width Chart This eliminates the need for extensive calculations. There are many different belts available. Mrf muscleflex belts are designed to denote the full thickness breaking strength in kilo newtons / metre width and the number of plies. Understanding a basic conveyor belt calculation will ensure your conveyor design is accurate and is not putting too many demands on your system. Conveyor. Conveyor Belt Width Chart.

From heimedt.com

Conveyor belt & small conveyor belt Heim EDT GmbH Conveyor Belt Width Chart Understanding a basic conveyor belt calculation will ensure your conveyor design is accurate and is not putting too many demands on your system. The belt conveyor design guide offers a comprehensive manual on power demands, belt curves, transitions, and industry. This eliminates the need for extensive calculations. There are many different belts available. One of the very first decisions facing. Conveyor Belt Width Chart.

From easy-systems.eu

Incline belt conveyor Belt conveyors Conveyor Belt Width Chart Mrf muscleflex belts are designed to denote the full thickness breaking strength in kilo newtons / metre width and the number of plies. Understanding a basic conveyor belt calculation will ensure your conveyor design is accurate and is not putting too many demands on your system. Conveyor belt is normally referred to as the carcass. in a sense, the carcass. Conveyor Belt Width Chart.

From www.youtube.com

Belt conveyor Power calculation YouTube Conveyor Belt Width Chart The belt conveyor design guide offers a comprehensive manual on power demands, belt curves, transitions, and industry. Many conveying timing belts operate at low speeds and minimal loads. Mrf muscleflex belts are designed to denote the full thickness breaking strength in kilo newtons / metre width and the number of plies. Understanding a basic conveyor belt calculation will ensure your. Conveyor Belt Width Chart.

From www.mknorthamerica.com

Belt Conveyor Types mk Conveyor Belt Width Chart One of the very first decisions facing an owner, engineer or contractor is to ‘standardize’ on belt widths and design criteria as defined by cema — conveyor equipment manufacturers. Conveyor belt is normally referred to as the carcass. in a sense, the carcass is the heart of the conveyor belt since it must: The belt conveyor design guide offers a. Conveyor Belt Width Chart.

From enginelibfrenetical.z13.web.core.windows.net

Mtd Belt Sizes Chart Conveyor Belt Width Chart There are many different belts available. The belt conveyor design guide offers a comprehensive manual on power demands, belt curves, transitions, and industry. Mrf muscleflex belts are designed to denote the full thickness breaking strength in kilo newtons / metre width and the number of plies. This eliminates the need for extensive calculations. Our top seven are described below. Conveyor. Conveyor Belt Width Chart.

From www.indiamart.com

PVC Conveyor Belt, Belt Width 03000 mm, Belt Thickness 18 mm, Rs Conveyor Belt Width Chart Many conveying timing belts operate at low speeds and minimal loads. The belt conveyor design guide offers a comprehensive manual on power demands, belt curves, transitions, and industry. Our top seven are described below. One of the very first decisions facing an owner, engineer or contractor is to ‘standardize’ on belt widths and design criteria as defined by cema —. Conveyor Belt Width Chart.

From www.texam.co.uk

Modular Belt Conveyor Systems Conveyor Manufacturer Connectaveyor Conveyor Belt Width Chart This eliminates the need for extensive calculations. Mrf muscleflex belts are designed to denote the full thickness breaking strength in kilo newtons / metre width and the number of plies. The belt conveyor design guide offers a comprehensive manual on power demands, belt curves, transitions, and industry. Our top seven are described below. There are many different belts available. One. Conveyor Belt Width Chart.

From news.thomasnet.com

mk® Automation Introduces Modular Belt Conveyors Conveyor Belt Width Chart One of the very first decisions facing an owner, engineer or contractor is to ‘standardize’ on belt widths and design criteria as defined by cema — conveyor equipment manufacturers. Conveyor belt is normally referred to as the carcass. in a sense, the carcass is the heart of the conveyor belt since it must: Mrf muscleflex belts are designed to denote. Conveyor Belt Width Chart.

From www.scribd.com

CEMA 6 Belt Conveyors Belt Widths.pdf PDF Conveyor Belt Width Chart The belt conveyor design guide offers a comprehensive manual on power demands, belt curves, transitions, and industry. One of the very first decisions facing an owner, engineer or contractor is to ‘standardize’ on belt widths and design criteria as defined by cema — conveyor equipment manufacturers. Our top seven are described below. Mrf muscleflex belts are designed to denote the. Conveyor Belt Width Chart.

From nomis.hr

CL inclined conveyor belt Nomis Conveyor Belt Width Chart Conveyor belt is normally referred to as the carcass. in a sense, the carcass is the heart of the conveyor belt since it must: The belt conveyor design guide offers a comprehensive manual on power demands, belt curves, transitions, and industry. One of the very first decisions facing an owner, engineer or contractor is to ‘standardize’ on belt widths and. Conveyor Belt Width Chart.

From www.automatedconveyors.com

Automated Conveyor Systems, Inc. Product Catalog MODEL "HPB Conveyor Belt Width Chart Our top seven are described below. The belt conveyor design guide offers a comprehensive manual on power demands, belt curves, transitions, and industry. There are many different belts available. Understanding a basic conveyor belt calculation will ensure your conveyor design is accurate and is not putting too many demands on your system. Conveyor belt is normally referred to as the. Conveyor Belt Width Chart.

From www.monk-conveyors.com

Medium Duty Belt Conveyors Monk Conveyors Conveyor Belt Width Chart Conveyor belt is normally referred to as the carcass. in a sense, the carcass is the heart of the conveyor belt since it must: Many conveying timing belts operate at low speeds and minimal loads. Our top seven are described below. Mrf muscleflex belts are designed to denote the full thickness breaking strength in kilo newtons / metre width and. Conveyor Belt Width Chart.

From storageequipmentsystems.com

How Does a Conveyor Belt Works? Storage Equipment Systems Conveyor Belt Width Chart Conveyor belt is normally referred to as the carcass. in a sense, the carcass is the heart of the conveyor belt since it must: Many conveying timing belts operate at low speeds and minimal loads. Our top seven are described below. There are many different belts available. Mrf muscleflex belts are designed to denote the full thickness breaking strength in. Conveyor Belt Width Chart.

From mavink.com

Conveyor Belt Weight Chart Conveyor Belt Width Chart The belt conveyor design guide offers a comprehensive manual on power demands, belt curves, transitions, and industry. Our top seven are described below. One of the very first decisions facing an owner, engineer or contractor is to ‘standardize’ on belt widths and design criteria as defined by cema — conveyor equipment manufacturers. Mrf muscleflex belts are designed to denote the. Conveyor Belt Width Chart.

From www.researchgate.net

Basic components of a conveyor belt. Download Scientific Diagram Conveyor Belt Width Chart There are many different belts available. Mrf muscleflex belts are designed to denote the full thickness breaking strength in kilo newtons / metre width and the number of plies. Our top seven are described below. Many conveying timing belts operate at low speeds and minimal loads. The belt conveyor design guide offers a comprehensive manual on power demands, belt curves,. Conveyor Belt Width Chart.

From www.grainger.com

30 in Belt Wd, 2,525 lb Max Load Capacity, Belt Conveyor 42X879RB190 Conveyor Belt Width Chart Conveyor belt is normally referred to as the carcass. in a sense, the carcass is the heart of the conveyor belt since it must: One of the very first decisions facing an owner, engineer or contractor is to ‘standardize’ on belt widths and design criteria as defined by cema — conveyor equipment manufacturers. Understanding a basic conveyor belt calculation will. Conveyor Belt Width Chart.

From www.iqsdirectory.com

Conveyor System What Is It? How Does It Work? Types Of Conveyor Belt Width Chart One of the very first decisions facing an owner, engineer or contractor is to ‘standardize’ on belt widths and design criteria as defined by cema — conveyor equipment manufacturers. Many conveying timing belts operate at low speeds and minimal loads. Conveyor belt is normally referred to as the carcass. in a sense, the carcass is the heart of the conveyor. Conveyor Belt Width Chart.

From www.iqsdirectory.com

Conveyor Belts What Is It? How Does It Work? Types, Parts Conveyor Belt Width Chart Mrf muscleflex belts are designed to denote the full thickness breaking strength in kilo newtons / metre width and the number of plies. There are many different belts available. Conveyor belt is normally referred to as the carcass. in a sense, the carcass is the heart of the conveyor belt since it must: Our top seven are described below. This. Conveyor Belt Width Chart.

From www.engineeringtoolbox.com

Conveyors Capacities Conveyor Belt Width Chart There are many different belts available. Conveyor belt is normally referred to as the carcass. in a sense, the carcass is the heart of the conveyor belt since it must: Many conveying timing belts operate at low speeds and minimal loads. This eliminates the need for extensive calculations. Mrf muscleflex belts are designed to denote the full thickness breaking strength. Conveyor Belt Width Chart.

From flexibleconveyorsystems.com

Some of the Type of Conveyors offered by Flexible Conveyor Systems, Inc. Conveyor Belt Width Chart This eliminates the need for extensive calculations. Mrf muscleflex belts are designed to denote the full thickness breaking strength in kilo newtons / metre width and the number of plies. Conveyor belt is normally referred to as the carcass. in a sense, the carcass is the heart of the conveyor belt since it must: Understanding a basic conveyor belt calculation. Conveyor Belt Width Chart.

From www.ultimationinc.com

Belt Conveyor Buy Online 28" W x 11' L Conveyor Belt Conveyor Belt Width Chart There are many different belts available. This eliminates the need for extensive calculations. The belt conveyor design guide offers a comprehensive manual on power demands, belt curves, transitions, and industry. Our top seven are described below. One of the very first decisions facing an owner, engineer or contractor is to ‘standardize’ on belt widths and design criteria as defined by. Conveyor Belt Width Chart.

From www.indiamart.com

Packing Conveyor Belts, Belt Thickness 16 mm at Rs 1000/unit in Conveyor Belt Width Chart Many conveying timing belts operate at low speeds and minimal loads. Mrf muscleflex belts are designed to denote the full thickness breaking strength in kilo newtons / metre width and the number of plies. Understanding a basic conveyor belt calculation will ensure your conveyor design is accurate and is not putting too many demands on your system. One of the. Conveyor Belt Width Chart.

From library3dengineer.blogspot.com

Modular Curve Conveyor Belt width 600mm Download free 3D cad Conveyor Belt Width Chart The belt conveyor design guide offers a comprehensive manual on power demands, belt curves, transitions, and industry. Conveyor belt is normally referred to as the carcass. in a sense, the carcass is the heart of the conveyor belt since it must: Many conveying timing belts operate at low speeds and minimal loads. Our top seven are described below. One of. Conveyor Belt Width Chart.

From mavink.com

Conveyor Belt Types Conveyor Belt Width Chart One of the very first decisions facing an owner, engineer or contractor is to ‘standardize’ on belt widths and design criteria as defined by cema — conveyor equipment manufacturers. This eliminates the need for extensive calculations. Mrf muscleflex belts are designed to denote the full thickness breaking strength in kilo newtons / metre width and the number of plies. There. Conveyor Belt Width Chart.

From www.indiamart.com

Rubber Heavy Duty Conveyor Belts, Belt Width 500 1000 mm, Belt Conveyor Belt Width Chart The belt conveyor design guide offers a comprehensive manual on power demands, belt curves, transitions, and industry. Understanding a basic conveyor belt calculation will ensure your conveyor design is accurate and is not putting too many demands on your system. One of the very first decisions facing an owner, engineer or contractor is to ‘standardize’ on belt widths and design. Conveyor Belt Width Chart.

From www.monk-conveyors.com

Medium Duty Belt Conveyors Monk Conveyors Conveyor Belt Width Chart Our top seven are described below. Understanding a basic conveyor belt calculation will ensure your conveyor design is accurate and is not putting too many demands on your system. Conveyor belt is normally referred to as the carcass. in a sense, the carcass is the heart of the conveyor belt since it must: Many conveying timing belts operate at low. Conveyor Belt Width Chart.

From conveyorbeltguide.com

Designation Conveyor Belt Width Chart Our top seven are described below. Many conveying timing belts operate at low speeds and minimal loads. The belt conveyor design guide offers a comprehensive manual on power demands, belt curves, transitions, and industry. Mrf muscleflex belts are designed to denote the full thickness breaking strength in kilo newtons / metre width and the number of plies. This eliminates the. Conveyor Belt Width Chart.

From www.indiamart.com

Nylon Conveyor Belts, Belt Width 2000 mm, For Industrial Purposes at Conveyor Belt Width Chart Mrf muscleflex belts are designed to denote the full thickness breaking strength in kilo newtons / metre width and the number of plies. Understanding a basic conveyor belt calculation will ensure your conveyor design is accurate and is not putting too many demands on your system. Our top seven are described below. One of the very first decisions facing an. Conveyor Belt Width Chart.

From www.iqsdirectory.com

Conveyor Belts What Is It? How Does It Work? Types, Parts Conveyor Belt Width Chart The belt conveyor design guide offers a comprehensive manual on power demands, belt curves, transitions, and industry. Conveyor belt is normally referred to as the carcass. in a sense, the carcass is the heart of the conveyor belt since it must: There are many different belts available. One of the very first decisions facing an owner, engineer or contractor is. Conveyor Belt Width Chart.

From in.pinterest.com

Know About Belt Conveyor or Conveyor Belts Conveyor belt, Conveyors Conveyor Belt Width Chart One of the very first decisions facing an owner, engineer or contractor is to ‘standardize’ on belt widths and design criteria as defined by cema — conveyor equipment manufacturers. Conveyor belt is normally referred to as the carcass. in a sense, the carcass is the heart of the conveyor belt since it must: There are many different belts available. The. Conveyor Belt Width Chart.

From www.ultimationinc.com

Belt Conveyor 28" W x 16' L 24" W Belt Ultimation Conveyor Belt Width Chart Mrf muscleflex belts are designed to denote the full thickness breaking strength in kilo newtons / metre width and the number of plies. Our top seven are described below. Conveyor belt is normally referred to as the carcass. in a sense, the carcass is the heart of the conveyor belt since it must: This eliminates the need for extensive calculations.. Conveyor Belt Width Chart.

From www.iqsdirectory.com

Belt Conveyors Components, Types, Design, and Applications Conveyor Belt Width Chart Understanding a basic conveyor belt calculation will ensure your conveyor design is accurate and is not putting too many demands on your system. Many conveying timing belts operate at low speeds and minimal loads. This eliminates the need for extensive calculations. One of the very first decisions facing an owner, engineer or contractor is to ‘standardize’ on belt widths and. Conveyor Belt Width Chart.

From www.indiamart.com

Rubber Cleated Conveyor Belt, Belt Width 100 500 mm, Belt Thickness Conveyor Belt Width Chart This eliminates the need for extensive calculations. Mrf muscleflex belts are designed to denote the full thickness breaking strength in kilo newtons / metre width and the number of plies. Conveyor belt is normally referred to as the carcass. in a sense, the carcass is the heart of the conveyor belt since it must: The belt conveyor design guide offers. Conveyor Belt Width Chart.

From sautec.co

Construction belt conveyor SAUTEC Conveyor Belt Width Chart The belt conveyor design guide offers a comprehensive manual on power demands, belt curves, transitions, and industry. Many conveying timing belts operate at low speeds and minimal loads. One of the very first decisions facing an owner, engineer or contractor is to ‘standardize’ on belt widths and design criteria as defined by cema — conveyor equipment manufacturers. Conveyor belt is. Conveyor Belt Width Chart.