Valve Seating Surface . The concentricity of the valve seat with respect to the valve guide and valve is essential for proper alignment and a tight. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. Most valve seats have a 15 ra surface finish. This article reviews valve seat types, key considerations. Measuring surface finish on valve seats. Valves seating surface performance has direct affection on the valve service life, due to it’s easily damaged by corrosion, erosion and. A bidirectional seat is a valve seat designed to seal against pressure source in either direction. The land areas are short, and the roughness values are high. Measuring surface roughness of valve seats on cylinder heads is challenging. The finish in the counterbore should be, equally smooth and round to within. A unidirectional seat is a valve seat designed to.

from www.littlepeng.com

Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. Most valve seats have a 15 ra surface finish. Measuring surface roughness of valve seats on cylinder heads is challenging. This article reviews valve seat types, key considerations. The concentricity of the valve seat with respect to the valve guide and valve is essential for proper alignment and a tight. The finish in the counterbore should be, equally smooth and round to within. Valves seating surface performance has direct affection on the valve service life, due to it’s easily damaged by corrosion, erosion and. The land areas are short, and the roughness values are high. A bidirectional seat is a valve seat designed to seal against pressure source in either direction. A unidirectional seat is a valve seat designed to.

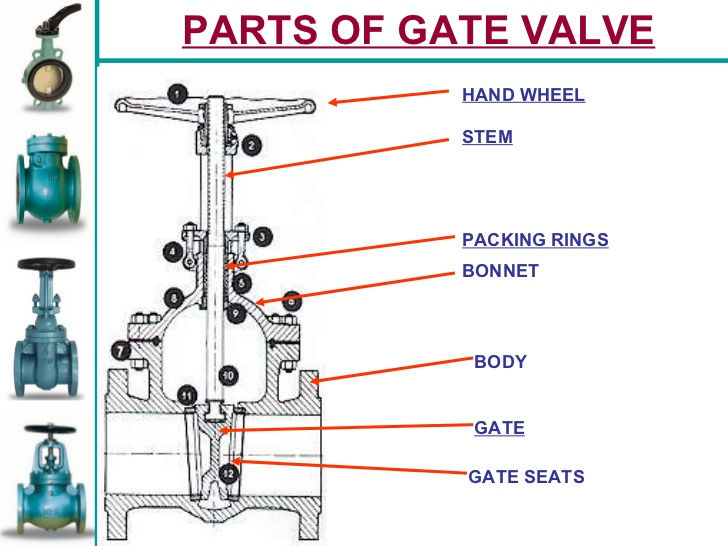

Major Valve Parts

Valve Seating Surface Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. Measuring surface finish on valve seats. The concentricity of the valve seat with respect to the valve guide and valve is essential for proper alignment and a tight. Most valve seats have a 15 ra surface finish. Measuring surface roughness of valve seats on cylinder heads is challenging. This article reviews valve seat types, key considerations. The land areas are short, and the roughness values are high. The finish in the counterbore should be, equally smooth and round to within. A bidirectional seat is a valve seat designed to seal against pressure source in either direction. Valves seating surface performance has direct affection on the valve service life, due to it’s easily damaged by corrosion, erosion and. A unidirectional seat is a valve seat designed to. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications.

From www.littlepeng.com

Major Valve Parts Valve Seating Surface Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. Measuring surface roughness of valve seats on cylinder heads is challenging. The concentricity of the valve seat with respect to the valve guide and valve is essential for proper alignment and a tight. The land areas are short, and the roughness values are. Valve Seating Surface.

From www.hondatwins.net

Cb450 valve seat cutters Valve Seating Surface Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. Measuring surface finish on valve seats. This article reviews valve seat types, key considerations. The finish in the counterbore should be, equally smooth and round to within. A unidirectional seat is a valve seat designed to. Valves seating surface performance has direct affection. Valve Seating Surface.

From www.researchgate.net

Structure of a typical cagetype control valve. Download Scientific Valve Seating Surface The concentricity of the valve seat with respect to the valve guide and valve is essential for proper alignment and a tight. The finish in the counterbore should be, equally smooth and round to within. Valves seating surface performance has direct affection on the valve service life, due to it’s easily damaged by corrosion, erosion and. A bidirectional seat is. Valve Seating Surface.

From www.zhycasting.com

Gate Valve Body Selection Guide ZHY Casting Valve Seating Surface A bidirectional seat is a valve seat designed to seal against pressure source in either direction. The concentricity of the valve seat with respect to the valve guide and valve is essential for proper alignment and a tight. The land areas are short, and the roughness values are high. Measuring surface finish on valve seats. Selecting the proper valve seat. Valve Seating Surface.

From usavehicle.com

Valve Seat Cutter Set Kawasaki,honda,yamaha Carbide Tipped 24 Pcs Bikes Valve Seating Surface A unidirectional seat is a valve seat designed to. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. The land areas are short, and the roughness values are high. Valves seating surface performance has direct affection on the valve service life, due to it’s easily damaged by corrosion, erosion and. The concentricity. Valve Seating Surface.

From instrumentationtools.com

Classification of Gate Valves Gate Valve Disk, Stem & Seat Design Valve Seating Surface The land areas are short, and the roughness values are high. A bidirectional seat is a valve seat designed to seal against pressure source in either direction. Most valve seats have a 15 ra surface finish. Measuring surface finish on valve seats. The concentricity of the valve seat with respect to the valve guide and valve is essential for proper. Valve Seating Surface.

From www.covnagroup.com

Stainless Steel Pneumatic Piston Flange Angle Seat Ball Valve Valve Seating Surface This article reviews valve seat types, key considerations. Measuring surface finish on valve seats. Valves seating surface performance has direct affection on the valve service life, due to it’s easily damaged by corrosion, erosion and. A unidirectional seat is a valve seat designed to. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial. Valve Seating Surface.

From www.ntgdvalve.com

Selection of Industrial Valves Definitive Guide Indusrtrial Valve Valve Seating Surface This article reviews valve seat types, key considerations. The land areas are short, and the roughness values are high. The finish in the counterbore should be, equally smooth and round to within. The concentricity of the valve seat with respect to the valve guide and valve is essential for proper alignment and a tight. Most valve seats have a 15. Valve Seating Surface.

From roadsumo.com

Valve Lapping [What Is It and How to Lap Valves?] • Road Sumo Valve Seating Surface Measuring surface finish on valve seats. The concentricity of the valve seat with respect to the valve guide and valve is essential for proper alignment and a tight. A bidirectional seat is a valve seat designed to seal against pressure source in either direction. Most valve seats have a 15 ra surface finish. The finish in the counterbore should be,. Valve Seating Surface.

From www.ramenvalves.com

Ball Sector valve seat materials What's the difference? Valve Seating Surface Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. Most valve seats have a 15 ra surface finish. A unidirectional seat is a valve seat designed to. Measuring surface roughness of valve seats on cylinder heads is challenging. The finish in the counterbore should be, equally smooth and round to within. Measuring. Valve Seating Surface.

From instrumentationtools.com

Valve Functions and Basic Parts of Valve Control Valve Objectives Valve Seating Surface This article reviews valve seat types, key considerations. A unidirectional seat is a valve seat designed to. The finish in the counterbore should be, equally smooth and round to within. Most valve seats have a 15 ra surface finish. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. The land areas are. Valve Seating Surface.

From www.performancetrucks.net

How To Lapping Your Valves At Home Forums Valve Seating Surface This article reviews valve seat types, key considerations. Measuring surface roughness of valve seats on cylinder heads is challenging. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. Measuring surface finish on valve seats. A bidirectional seat is a valve seat designed to seal against pressure source in either direction. Most valve. Valve Seating Surface.

From wonderfulengineering.com

Check Valve Types And Application Valve Seating Surface Valves seating surface performance has direct affection on the valve service life, due to it’s easily damaged by corrosion, erosion and. The concentricity of the valve seat with respect to the valve guide and valve is essential for proper alignment and a tight. A bidirectional seat is a valve seat designed to seal against pressure source in either direction. This. Valve Seating Surface.

From hardhatengineer.com

Valve Trim and Parts Including API Trim Charts Valve Seating Surface Measuring surface roughness of valve seats on cylinder heads is challenging. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. A bidirectional seat is a valve seat designed to seal against pressure source in either direction. Measuring surface finish on valve seats. A unidirectional seat is a valve seat designed to. Most. Valve Seating Surface.

From www.watersvalve.com

How Does the Butterfly Valve Seal? Watersvalve Valve Seating Surface The concentricity of the valve seat with respect to the valve guide and valve is essential for proper alignment and a tight. A unidirectional seat is a valve seat designed to. This article reviews valve seat types, key considerations. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. The land areas are. Valve Seating Surface.

From hardhatengineer.com

What is a Check Valve? Learn about Check Valves Types and Parts Valve Seating Surface A unidirectional seat is a valve seat designed to. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. A bidirectional seat is a valve seat designed to seal against pressure source in either direction. Measuring surface roughness of valve seats on cylinder heads is challenging. This article reviews valve seat types, key. Valve Seating Surface.

From tjhyfm.en.made-in-china.com

SS316 Disc Rubber Seat Wcb Body PTFE Seat Wafer Butterfly Valve with Valve Seating Surface Measuring surface finish on valve seats. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. The finish in the counterbore should be, equally smooth and round to within. Most valve seats have a 15 ra surface finish. This article reviews valve seat types, key considerations. Measuring surface roughness of valve seats on. Valve Seating Surface.

From www.youtube.com

Lapping and Checking Valves (EASY WAY) YouTube Valve Seating Surface This article reviews valve seat types, key considerations. The finish in the counterbore should be, equally smooth and round to within. Measuring surface finish on valve seats. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. The concentricity of the valve seat with respect to the valve guide and valve is essential. Valve Seating Surface.

From www.mechanical-knowledge.com

BUTTERFLY VALVE AND IT'S WORKING PRINCIPLE Valve Seating Surface The concentricity of the valve seat with respect to the valve guide and valve is essential for proper alignment and a tight. This article reviews valve seat types, key considerations. A bidirectional seat is a valve seat designed to seal against pressure source in either direction. The finish in the counterbore should be, equally smooth and round to within. The. Valve Seating Surface.

From wili.vn

1. SEAT VALVES Wili® Co., Ltd Valve Seating Surface A unidirectional seat is a valve seat designed to. The land areas are short, and the roughness values are high. Measuring surface finish on valve seats. Most valve seats have a 15 ra surface finish. Valves seating surface performance has direct affection on the valve service life, due to it’s easily damaged by corrosion, erosion and. A bidirectional seat is. Valve Seating Surface.

From www.linkedin.com

A New Way To Seat Valves Valve Seating Surface Most valve seats have a 15 ra surface finish. The finish in the counterbore should be, equally smooth and round to within. A unidirectional seat is a valve seat designed to. A bidirectional seat is a valve seat designed to seal against pressure source in either direction. This article reviews valve seat types, key considerations. The concentricity of the valve. Valve Seating Surface.

From mcgrp.ru

Kawasaki KX450F (2006) [155/369] Valve seating surface outside diameter Valve Seating Surface The concentricity of the valve seat with respect to the valve guide and valve is essential for proper alignment and a tight. This article reviews valve seat types, key considerations. Valves seating surface performance has direct affection on the valve service life, due to it’s easily damaged by corrosion, erosion and. Measuring surface finish on valve seats. A unidirectional seat. Valve Seating Surface.

From aager.de

End of line, weight loaded Äager Valve Seating Surface This article reviews valve seat types, key considerations. Measuring surface roughness of valve seats on cylinder heads is challenging. The finish in the counterbore should be, equally smooth and round to within. A bidirectional seat is a valve seat designed to seal against pressure source in either direction. A unidirectional seat is a valve seat designed to. Valves seating surface. Valve Seating Surface.

From zhixinvalve.en.alibaba.com

Resilient seated Buried Gate valve with extension spindle and surface Valve Seating Surface A unidirectional seat is a valve seat designed to. Measuring surface roughness of valve seats on cylinder heads is challenging. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. The finish in the counterbore should be, equally smooth and round to within. Measuring surface finish on valve seats. The concentricity of the. Valve Seating Surface.

From www.zhycasting.com

Embracing the Advantages of Butterfly Valves ZHY Casting Valve Seating Surface The concentricity of the valve seat with respect to the valve guide and valve is essential for proper alignment and a tight. A unidirectional seat is a valve seat designed to. The finish in the counterbore should be, equally smooth and round to within. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial. Valve Seating Surface.

From qrcvalves.com

Valve Trim What It Is, Plug Profiles, Parts, Chart, and Selection Process Valve Seating Surface The finish in the counterbore should be, equally smooth and round to within. This article reviews valve seat types, key considerations. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. Measuring surface finish on valve seats. A unidirectional seat is a valve seat designed to. Valves seating surface performance has direct affection. Valve Seating Surface.

From aager.de

End of line, spring loaded Äager Valve Seating Surface Valves seating surface performance has direct affection on the valve service life, due to it’s easily damaged by corrosion, erosion and. Measuring surface finish on valve seats. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. Measuring surface roughness of valve seats on cylinder heads is challenging. A bidirectional seat is a. Valve Seating Surface.

From xj12c.org

overrun valve seating surface XJ12C Valve Seating Surface Measuring surface roughness of valve seats on cylinder heads is challenging. A bidirectional seat is a valve seat designed to seal against pressure source in either direction. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. This article reviews valve seat types, key considerations. Valves seating surface performance has direct affection on. Valve Seating Surface.

From brokeasshome.com

Valve Seats By Size Valve Seating Surface The concentricity of the valve seat with respect to the valve guide and valve is essential for proper alignment and a tight. A bidirectional seat is a valve seat designed to seal against pressure source in either direction. This article reviews valve seat types, key considerations. A unidirectional seat is a valve seat designed to. The land areas are short,. Valve Seating Surface.

From hardhatengineer.com

What is Plug Valve? A Complete Guide for Engineer Valve Seating Surface Measuring surface roughness of valve seats on cylinder heads is challenging. Most valve seats have a 15 ra surface finish. This article reviews valve seat types, key considerations. The finish in the counterbore should be, equally smooth and round to within. A unidirectional seat is a valve seat designed to. Valves seating surface performance has direct affection on the valve. Valve Seating Surface.

From convalve.eu

Triple Offset Butterfly Valve • Convalve Valve Seating Surface This article reviews valve seat types, key considerations. A bidirectional seat is a valve seat designed to seal against pressure source in either direction. A unidirectional seat is a valve seat designed to. The land areas are short, and the roughness values are high. Measuring surface roughness of valve seats on cylinder heads is challenging. Most valve seats have a. Valve Seating Surface.

From www.shiphamvalves.com

Differences and uses of OffSet Butterfly Valves Shipham Valves Valve Seating Surface Measuring surface roughness of valve seats on cylinder heads is challenging. The concentricity of the valve seat with respect to the valve guide and valve is essential for proper alignment and a tight. Measuring surface finish on valve seats. This article reviews valve seat types, key considerations. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality. Valve Seating Surface.

From www.youtube.com

How to Lap Valves or ReSeat Valves // Supercheap Auto YouTube Valve Seating Surface The concentricity of the valve seat with respect to the valve guide and valve is essential for proper alignment and a tight. Measuring surface roughness of valve seats on cylinder heads is challenging. Measuring surface finish on valve seats. The finish in the counterbore should be, equally smooth and round to within. Most valve seats have a 15 ra surface. Valve Seating Surface.

From blog.enerpac.com

Choosing the Right Flange Surface Finish. an Overview of ASME, ESF and Valve Seating Surface A bidirectional seat is a valve seat designed to seal against pressure source in either direction. A unidirectional seat is a valve seat designed to. The concentricity of the valve seat with respect to the valve guide and valve is essential for proper alignment and a tight. This article reviews valve seat types, key considerations. Valves seating surface performance has. Valve Seating Surface.

From techblog.ctgclean.com

Manual Valves Gate and Butterfly Valves CTG Clean Valve Seating Surface Valves seating surface performance has direct affection on the valve service life, due to it’s easily damaged by corrosion, erosion and. The concentricity of the valve seat with respect to the valve guide and valve is essential for proper alignment and a tight. Measuring surface finish on valve seats. Most valve seats have a 15 ra surface finish. A bidirectional. Valve Seating Surface.