Cleaning Force Ratio Steam Blow . Thus the cleaning force required for steam blow should be ≥ 1.2, (i.e. from the viewpoint of the steam flow around the plate it is necessary to preserve for a given period the cfr (cleaning force. the blow conditions must be maintained so that a cleaning force ratio (cfr) of 1.0 is achieved throughout the. typically during the steam blow, the force of steam should be at least 20% higher than it would be during normal operating conditions. this paper investigates and justifies the use of a minimum necessary cleaning force ratio or cleaning factor for steam blows. fanno flow modeling codes used to determine the most efficient conditions for cleaning steam system. steam blowing is a cleaning operation which uses the power (energy) and velocity of steam to remove impurities from boiler.

from www.intero-integrity.com

Thus the cleaning force required for steam blow should be ≥ 1.2, (i.e. typically during the steam blow, the force of steam should be at least 20% higher than it would be during normal operating conditions. steam blowing is a cleaning operation which uses the power (energy) and velocity of steam to remove impurities from boiler. fanno flow modeling codes used to determine the most efficient conditions for cleaning steam system. from the viewpoint of the steam flow around the plate it is necessary to preserve for a given period the cfr (cleaning force. the blow conditions must be maintained so that a cleaning force ratio (cfr) of 1.0 is achieved throughout the. this paper investigates and justifies the use of a minimum necessary cleaning force ratio or cleaning factor for steam blows.

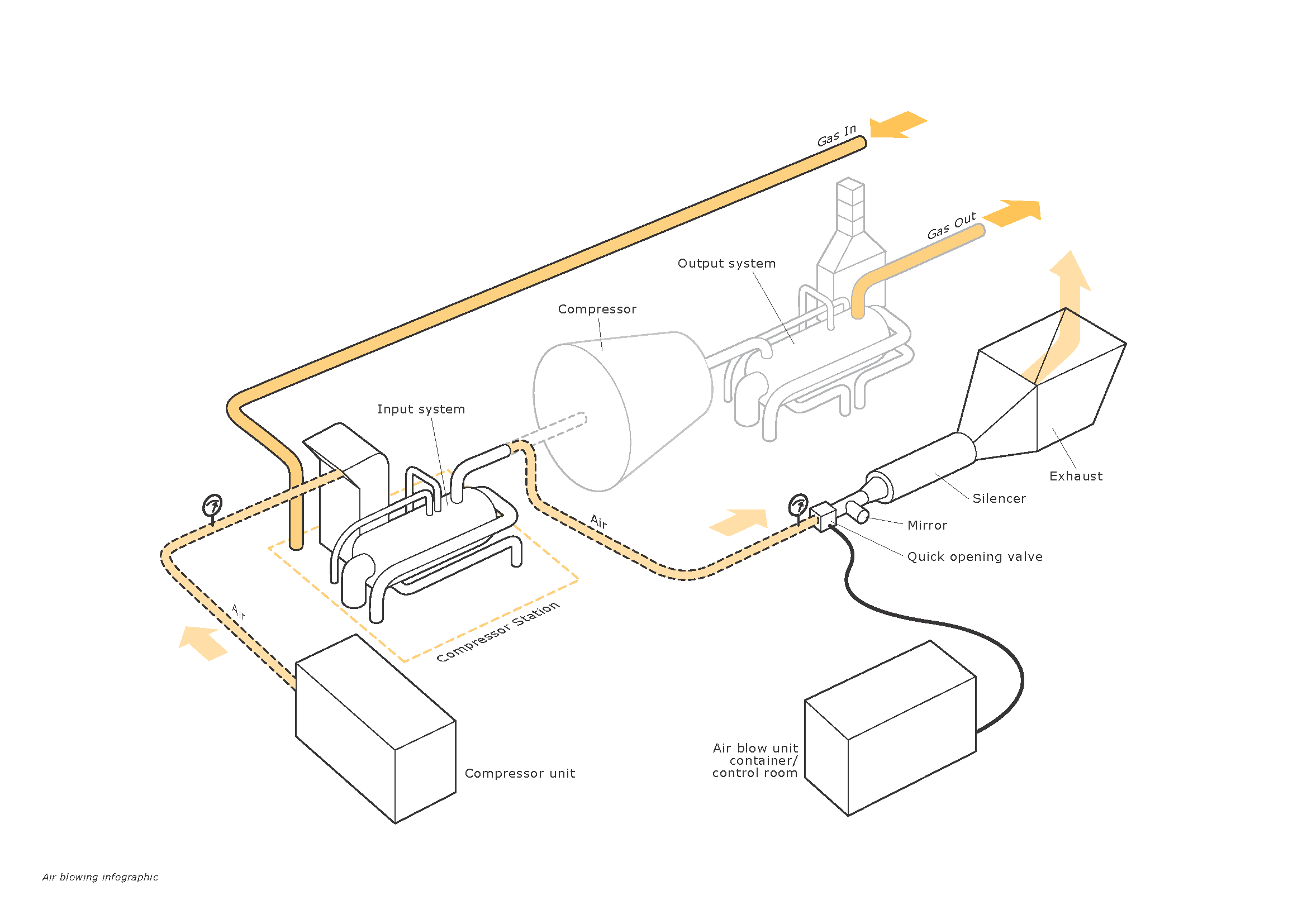

Air blowing Cleaning Services Intero Integrity Services

Cleaning Force Ratio Steam Blow fanno flow modeling codes used to determine the most efficient conditions for cleaning steam system. from the viewpoint of the steam flow around the plate it is necessary to preserve for a given period the cfr (cleaning force. Thus the cleaning force required for steam blow should be ≥ 1.2, (i.e. the blow conditions must be maintained so that a cleaning force ratio (cfr) of 1.0 is achieved throughout the. typically during the steam blow, the force of steam should be at least 20% higher than it would be during normal operating conditions. this paper investigates and justifies the use of a minimum necessary cleaning force ratio or cleaning factor for steam blows. fanno flow modeling codes used to determine the most efficient conditions for cleaning steam system. steam blowing is a cleaning operation which uses the power (energy) and velocity of steam to remove impurities from boiler.

From www.slideserve.com

PPT PowerPoint Presentation, free download ID6635468 Cleaning Force Ratio Steam Blow typically during the steam blow, the force of steam should be at least 20% higher than it would be during normal operating conditions. the blow conditions must be maintained so that a cleaning force ratio (cfr) of 1.0 is achieved throughout the. this paper investigates and justifies the use of a minimum necessary cleaning force ratio or. Cleaning Force Ratio Steam Blow.

From dguha1952.blogspot.com

ABC OF THERMAL POWER PLANT Cleaning Force Ratio Steam Blow typically during the steam blow, the force of steam should be at least 20% higher than it would be during normal operating conditions. fanno flow modeling codes used to determine the most efficient conditions for cleaning steam system. this paper investigates and justifies the use of a minimum necessary cleaning force ratio or cleaning factor for steam. Cleaning Force Ratio Steam Blow.

From www.campbell-sevey.com

Boiler Blowdown Procedure & Tips to Minimize blowdown in Boiler Cleaning Force Ratio Steam Blow this paper investigates and justifies the use of a minimum necessary cleaning force ratio or cleaning factor for steam blows. the blow conditions must be maintained so that a cleaning force ratio (cfr) of 1.0 is achieved throughout the. steam blowing is a cleaning operation which uses the power (energy) and velocity of steam to remove impurities. Cleaning Force Ratio Steam Blow.

From joinpipingknowledge.blogspot.com

Air Blowing in Piping Systems. Cleaning Force Ratio Steam Blow typically during the steam blow, the force of steam should be at least 20% higher than it would be during normal operating conditions. from the viewpoint of the steam flow around the plate it is necessary to preserve for a given period the cfr (cleaning force. fanno flow modeling codes used to determine the most efficient conditions. Cleaning Force Ratio Steam Blow.

From verchem.com.sg

SilentSteam Blow VERChem Cleaning Force Ratio Steam Blow from the viewpoint of the steam flow around the plate it is necessary to preserve for a given period the cfr (cleaning force. the blow conditions must be maintained so that a cleaning force ratio (cfr) of 1.0 is achieved throughout the. steam blowing is a cleaning operation which uses the power (energy) and velocity of steam. Cleaning Force Ratio Steam Blow.

From www.fourquest.com

Steam Blowing MP Steam Header Cleaning Force Ratio Steam Blow fanno flow modeling codes used to determine the most efficient conditions for cleaning steam system. from the viewpoint of the steam flow around the plate it is necessary to preserve for a given period the cfr (cleaning force. Thus the cleaning force required for steam blow should be ≥ 1.2, (i.e. the blow conditions must be maintained. Cleaning Force Ratio Steam Blow.

From www.slideserve.com

PPT PowerPoint Presentation, free download ID6635468 Cleaning Force Ratio Steam Blow this paper investigates and justifies the use of a minimum necessary cleaning force ratio or cleaning factor for steam blows. typically during the steam blow, the force of steam should be at least 20% higher than it would be during normal operating conditions. Thus the cleaning force required for steam blow should be ≥ 1.2, (i.e. steam. Cleaning Force Ratio Steam Blow.

From www.cogencleaning.com

Steam Blowing Cogen Cleaning Global Cleaning Force Ratio Steam Blow from the viewpoint of the steam flow around the plate it is necessary to preserve for a given period the cfr (cleaning force. Thus the cleaning force required for steam blow should be ≥ 1.2, (i.e. steam blowing is a cleaning operation which uses the power (energy) and velocity of steam to remove impurities from boiler. this. Cleaning Force Ratio Steam Blow.

From www.slideserve.com

PPT OBJECTIVE AND PRINCIPLE OF STEAM BLOWING STEPS INVOLVED IN STEAM BLOWING ( WITH PATH Cleaning Force Ratio Steam Blow from the viewpoint of the steam flow around the plate it is necessary to preserve for a given period the cfr (cleaning force. fanno flow modeling codes used to determine the most efficient conditions for cleaning steam system. typically during the steam blow, the force of steam should be at least 20% higher than it would be. Cleaning Force Ratio Steam Blow.

From www.researchgate.net

Force Ratio Calculation Example 1 . Download Scientific Diagram Cleaning Force Ratio Steam Blow this paper investigates and justifies the use of a minimum necessary cleaning force ratio or cleaning factor for steam blows. from the viewpoint of the steam flow around the plate it is necessary to preserve for a given period the cfr (cleaning force. steam blowing is a cleaning operation which uses the power (energy) and velocity of. Cleaning Force Ratio Steam Blow.

From verchem.com.sg

SilentSteam Blow VERChem Cleaning Force Ratio Steam Blow fanno flow modeling codes used to determine the most efficient conditions for cleaning steam system. steam blowing is a cleaning operation which uses the power (energy) and velocity of steam to remove impurities from boiler. from the viewpoint of the steam flow around the plate it is necessary to preserve for a given period the cfr (cleaning. Cleaning Force Ratio Steam Blow.

From bwenergyservices.com

Air Blowing vs Steam Blowing Services B&W Energy Services Cleaning Force Ratio Steam Blow Thus the cleaning force required for steam blow should be ≥ 1.2, (i.e. fanno flow modeling codes used to determine the most efficient conditions for cleaning steam system. from the viewpoint of the steam flow around the plate it is necessary to preserve for a given period the cfr (cleaning force. this paper investigates and justifies the. Cleaning Force Ratio Steam Blow.

From www.cogencleaning.com

Steam Blowing Cogen Cleaning Global Cleaning Force Ratio Steam Blow this paper investigates and justifies the use of a minimum necessary cleaning force ratio or cleaning factor for steam blows. Thus the cleaning force required for steam blow should be ≥ 1.2, (i.e. the blow conditions must be maintained so that a cleaning force ratio (cfr) of 1.0 is achieved throughout the. fanno flow modeling codes used. Cleaning Force Ratio Steam Blow.

From www.scribd.com

Cleaning Force Ratio PDF Turbine Steam Cleaning Force Ratio Steam Blow fanno flow modeling codes used to determine the most efficient conditions for cleaning steam system. Thus the cleaning force required for steam blow should be ≥ 1.2, (i.e. typically during the steam blow, the force of steam should be at least 20% higher than it would be during normal operating conditions. the blow conditions must be maintained. Cleaning Force Ratio Steam Blow.

From www.slideserve.com

PPT OBJECTIVE AND PRINCIPLE OF STEAM BLOWING STEPS INVOLVED IN STEAM BLOWING ( WITH PATH Cleaning Force Ratio Steam Blow fanno flow modeling codes used to determine the most efficient conditions for cleaning steam system. from the viewpoint of the steam flow around the plate it is necessary to preserve for a given period the cfr (cleaning force. steam blowing is a cleaning operation which uses the power (energy) and velocity of steam to remove impurities from. Cleaning Force Ratio Steam Blow.

From www.vecom-group.com

Steam blowing Group Cleaning Force Ratio Steam Blow typically during the steam blow, the force of steam should be at least 20% higher than it would be during normal operating conditions. from the viewpoint of the steam flow around the plate it is necessary to preserve for a given period the cfr (cleaning force. Thus the cleaning force required for steam blow should be ≥ 1.2,. Cleaning Force Ratio Steam Blow.

From verchem.com.sg

SilentSteam Blow VERChem Cleaning Force Ratio Steam Blow Thus the cleaning force required for steam blow should be ≥ 1.2, (i.e. steam blowing is a cleaning operation which uses the power (energy) and velocity of steam to remove impurities from boiler. the blow conditions must be maintained so that a cleaning force ratio (cfr) of 1.0 is achieved throughout the. this paper investigates and justifies. Cleaning Force Ratio Steam Blow.

From verchem.com.sg

SilentSteam Blow VERChem Cleaning Force Ratio Steam Blow steam blowing is a cleaning operation which uses the power (energy) and velocity of steam to remove impurities from boiler. fanno flow modeling codes used to determine the most efficient conditions for cleaning steam system. Thus the cleaning force required for steam blow should be ≥ 1.2, (i.e. from the viewpoint of the steam flow around the. Cleaning Force Ratio Steam Blow.

From www.slideserve.com

PPT PowerPoint Presentation, free download ID6635468 Cleaning Force Ratio Steam Blow the blow conditions must be maintained so that a cleaning force ratio (cfr) of 1.0 is achieved throughout the. from the viewpoint of the steam flow around the plate it is necessary to preserve for a given period the cfr (cleaning force. fanno flow modeling codes used to determine the most efficient conditions for cleaning steam system.. Cleaning Force Ratio Steam Blow.

From www.steamblowingservices.com

Target Plates Steam Blowing Services Ltd Cleaning Force Ratio Steam Blow Thus the cleaning force required for steam blow should be ≥ 1.2, (i.e. steam blowing is a cleaning operation which uses the power (energy) and velocity of steam to remove impurities from boiler. from the viewpoint of the steam flow around the plate it is necessary to preserve for a given period the cfr (cleaning force. the. Cleaning Force Ratio Steam Blow.

From verchem.com.sg

SilentSteam Blow VERChem Cleaning Force Ratio Steam Blow fanno flow modeling codes used to determine the most efficient conditions for cleaning steam system. the blow conditions must be maintained so that a cleaning force ratio (cfr) of 1.0 is achieved throughout the. from the viewpoint of the steam flow around the plate it is necessary to preserve for a given period the cfr (cleaning force.. Cleaning Force Ratio Steam Blow.

From verchem.com.sg

SilentSteam Blow VERChem Cleaning Force Ratio Steam Blow fanno flow modeling codes used to determine the most efficient conditions for cleaning steam system. the blow conditions must be maintained so that a cleaning force ratio (cfr) of 1.0 is achieved throughout the. this paper investigates and justifies the use of a minimum necessary cleaning force ratio or cleaning factor for steam blows. Thus the cleaning. Cleaning Force Ratio Steam Blow.

From process-engineers.blogspot.com

Process Engineer Blowing, Flushing and Pigging in Commissioning Cleaning Force Ratio Steam Blow the blow conditions must be maintained so that a cleaning force ratio (cfr) of 1.0 is achieved throughout the. typically during the steam blow, the force of steam should be at least 20% higher than it would be during normal operating conditions. Thus the cleaning force required for steam blow should be ≥ 1.2, (i.e. this paper. Cleaning Force Ratio Steam Blow.

From verchem.com.sg

SilentSteam Blow VERChem Cleaning Force Ratio Steam Blow the blow conditions must be maintained so that a cleaning force ratio (cfr) of 1.0 is achieved throughout the. this paper investigates and justifies the use of a minimum necessary cleaning force ratio or cleaning factor for steam blows. fanno flow modeling codes used to determine the most efficient conditions for cleaning steam system. steam blowing. Cleaning Force Ratio Steam Blow.

From verchem.com.sg

SilentSteam Blow VERChem Cleaning Force Ratio Steam Blow this paper investigates and justifies the use of a minimum necessary cleaning force ratio or cleaning factor for steam blows. from the viewpoint of the steam flow around the plate it is necessary to preserve for a given period the cfr (cleaning force. fanno flow modeling codes used to determine the most efficient conditions for cleaning steam. Cleaning Force Ratio Steam Blow.

From verchem.com.sg

SilentSteam Blow VERChem Cleaning Force Ratio Steam Blow from the viewpoint of the steam flow around the plate it is necessary to preserve for a given period the cfr (cleaning force. the blow conditions must be maintained so that a cleaning force ratio (cfr) of 1.0 is achieved throughout the. steam blowing is a cleaning operation which uses the power (energy) and velocity of steam. Cleaning Force Ratio Steam Blow.

From verchem.com.sg

SilentSteam Blow VERChem Cleaning Force Ratio Steam Blow steam blowing is a cleaning operation which uses the power (energy) and velocity of steam to remove impurities from boiler. Thus the cleaning force required for steam blow should be ≥ 1.2, (i.e. typically during the steam blow, the force of steam should be at least 20% higher than it would be during normal operating conditions. from. Cleaning Force Ratio Steam Blow.

From www.slideshare.net

Steam blowing stages before turbine rolling PPT Cleaning Force Ratio Steam Blow Thus the cleaning force required for steam blow should be ≥ 1.2, (i.e. the blow conditions must be maintained so that a cleaning force ratio (cfr) of 1.0 is achieved throughout the. typically during the steam blow, the force of steam should be at least 20% higher than it would be during normal operating conditions. this paper. Cleaning Force Ratio Steam Blow.

From www.slideserve.com

PPT PowerPoint Presentation, free download ID6635468 Cleaning Force Ratio Steam Blow Thus the cleaning force required for steam blow should be ≥ 1.2, (i.e. from the viewpoint of the steam flow around the plate it is necessary to preserve for a given period the cfr (cleaning force. fanno flow modeling codes used to determine the most efficient conditions for cleaning steam system. this paper investigates and justifies the. Cleaning Force Ratio Steam Blow.

From www.intero-integrity.com

Air blowing Cleaning Services Intero Integrity Services Cleaning Force Ratio Steam Blow this paper investigates and justifies the use of a minimum necessary cleaning force ratio or cleaning factor for steam blows. from the viewpoint of the steam flow around the plate it is necessary to preserve for a given period the cfr (cleaning force. the blow conditions must be maintained so that a cleaning force ratio (cfr) of. Cleaning Force Ratio Steam Blow.

From www.slideserve.com

PPT PowerPoint Presentation, free download ID6635468 Cleaning Force Ratio Steam Blow fanno flow modeling codes used to determine the most efficient conditions for cleaning steam system. from the viewpoint of the steam flow around the plate it is necessary to preserve for a given period the cfr (cleaning force. Thus the cleaning force required for steam blow should be ≥ 1.2, (i.e. this paper investigates and justifies the. Cleaning Force Ratio Steam Blow.

From minah.com.sa

Industrial Cleaning and services • Minah Cleaning Force Ratio Steam Blow fanno flow modeling codes used to determine the most efficient conditions for cleaning steam system. the blow conditions must be maintained so that a cleaning force ratio (cfr) of 1.0 is achieved throughout the. typically during the steam blow, the force of steam should be at least 20% higher than it would be during normal operating conditions.. Cleaning Force Ratio Steam Blow.

From blog.thepipingmart.com

What Is Steam Blowing? ThePipingMart Blog Cleaning Force Ratio Steam Blow Thus the cleaning force required for steam blow should be ≥ 1.2, (i.e. fanno flow modeling codes used to determine the most efficient conditions for cleaning steam system. the blow conditions must be maintained so that a cleaning force ratio (cfr) of 1.0 is achieved throughout the. this paper investigates and justifies the use of a minimum. Cleaning Force Ratio Steam Blow.

From verchem.com.sg

SilentSteam Blow VERChem Cleaning Force Ratio Steam Blow from the viewpoint of the steam flow around the plate it is necessary to preserve for a given period the cfr (cleaning force. the blow conditions must be maintained so that a cleaning force ratio (cfr) of 1.0 is achieved throughout the. this paper investigates and justifies the use of a minimum necessary cleaning force ratio or. Cleaning Force Ratio Steam Blow.

From www.cogencleaning.com

Steam Blowing Cogen Cleaning Global Cleaning Force Ratio Steam Blow fanno flow modeling codes used to determine the most efficient conditions for cleaning steam system. Thus the cleaning force required for steam blow should be ≥ 1.2, (i.e. typically during the steam blow, the force of steam should be at least 20% higher than it would be during normal operating conditions. from the viewpoint of the steam. Cleaning Force Ratio Steam Blow.