What Is Fifo In Manufacturing . The first in, first out (fifo) method is a widely used inventory valuation technique that plays a crucial role in efficient inventory management. Fifo is predicated on the principle that the first items purchased or produced are the first to be sold or used. First in, first out (fifo) is the principle and practice of maintaining precise production and conveyance sequence by ensuring that the first part to enter a process or storage. Fifo lanes are an important part of any lean material flow. The first in, first out (fifo) method of inventory valuation is a cost flow assumption that the first goods purchased are also the first. Here, the oldest inventory items are sold or used first, and the most recent stock will be the last to be used or go for sale. They are a very simple way to define both the material flow and the. Learn how to apply fifo correctly. Fifo is an acronym for “first in, first out.” it refers to an inventory system that directs a firm to utilize the oldest items in inventory when a product or part is needed. Discover how fifo optimises inventory and material flow and ensures efficient inventory management. Efficient inventory management can significantly improve your business’s bottom line.

from www.authentichospitalitygroup.com

The first in, first out (fifo) method of inventory valuation is a cost flow assumption that the first goods purchased are also the first. The first in, first out (fifo) method is a widely used inventory valuation technique that plays a crucial role in efficient inventory management. Fifo is predicated on the principle that the first items purchased or produced are the first to be sold or used. Fifo is an acronym for “first in, first out.” it refers to an inventory system that directs a firm to utilize the oldest items in inventory when a product or part is needed. First in, first out (fifo) is the principle and practice of maintaining precise production and conveyance sequence by ensuring that the first part to enter a process or storage. Here, the oldest inventory items are sold or used first, and the most recent stock will be the last to be used or go for sale. Learn how to apply fifo correctly. Fifo lanes are an important part of any lean material flow. They are a very simple way to define both the material flow and the. Efficient inventory management can significantly improve your business’s bottom line.

What is FIFO? Discover the significance of FIFO

What Is Fifo In Manufacturing Learn how to apply fifo correctly. Fifo is predicated on the principle that the first items purchased or produced are the first to be sold or used. Learn how to apply fifo correctly. The first in, first out (fifo) method is a widely used inventory valuation technique that plays a crucial role in efficient inventory management. They are a very simple way to define both the material flow and the. Efficient inventory management can significantly improve your business’s bottom line. Here, the oldest inventory items are sold or used first, and the most recent stock will be the last to be used or go for sale. Fifo is an acronym for “first in, first out.” it refers to an inventory system that directs a firm to utilize the oldest items in inventory when a product or part is needed. The first in, first out (fifo) method of inventory valuation is a cost flow assumption that the first goods purchased are also the first. First in, first out (fifo) is the principle and practice of maintaining precise production and conveyance sequence by ensuring that the first part to enter a process or storage. Discover how fifo optimises inventory and material flow and ensures efficient inventory management. Fifo lanes are an important part of any lean material flow.

From www.youtube.com

FIFO (First in, First out) Warehouse Management Method Logistics Blog What Is Fifo In Manufacturing Discover how fifo optimises inventory and material flow and ensures efficient inventory management. Learn how to apply fifo correctly. Efficient inventory management can significantly improve your business’s bottom line. Here, the oldest inventory items are sold or used first, and the most recent stock will be the last to be used or go for sale. Fifo is an acronym for. What Is Fifo In Manufacturing.

From fmcgmanagement.ro

Regula FIFO primul intrat primul vândut FMCG Management What Is Fifo In Manufacturing Fifo lanes are an important part of any lean material flow. First in, first out (fifo) is the principle and practice of maintaining precise production and conveyance sequence by ensuring that the first part to enter a process or storage. Fifo is predicated on the principle that the first items purchased or produced are the first to be sold or. What Is Fifo In Manufacturing.

From www.youtube.com

how to make a fifo formula in excel YouTube What Is Fifo In Manufacturing Here, the oldest inventory items are sold or used first, and the most recent stock will be the last to be used or go for sale. The first in, first out (fifo) method of inventory valuation is a cost flow assumption that the first goods purchased are also the first. Efficient inventory management can significantly improve your business’s bottom line.. What Is Fifo In Manufacturing.

From www.youtube.com

First In First Out (FIFO) Method LaceUp DSD Software YouTube What Is Fifo In Manufacturing Fifo lanes are an important part of any lean material flow. The first in, first out (fifo) method is a widely used inventory valuation technique that plays a crucial role in efficient inventory management. They are a very simple way to define both the material flow and the. Fifo is an acronym for “first in, first out.” it refers to. What Is Fifo In Manufacturing.

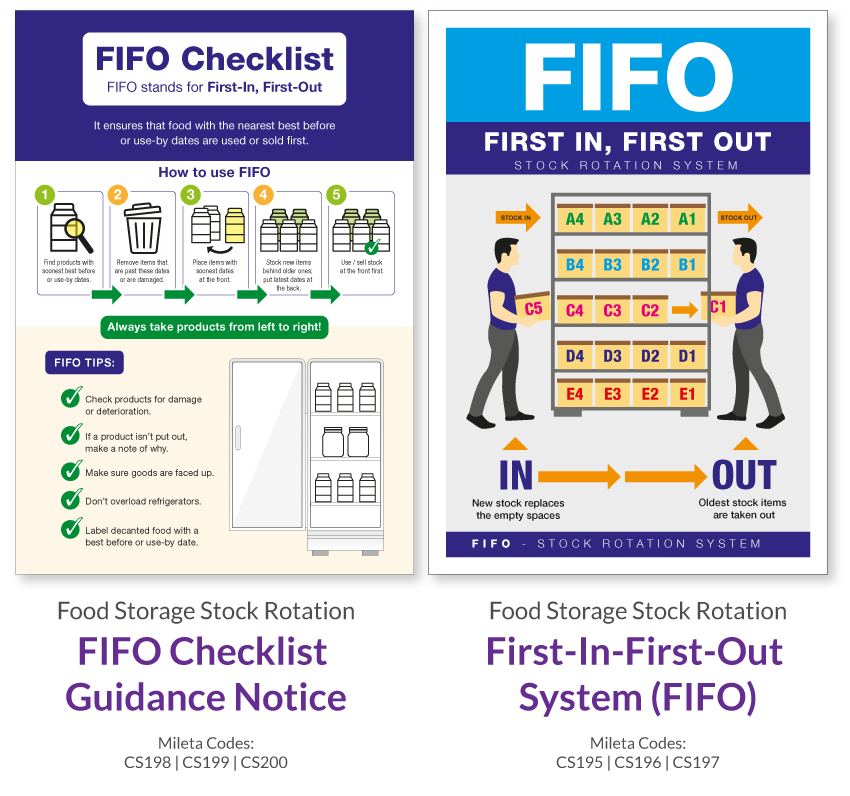

From www.highspeedtraining.co.uk

Using a FIFO Food Storage System Advice & Checklist What Is Fifo In Manufacturing The first in, first out (fifo) method of inventory valuation is a cost flow assumption that the first goods purchased are also the first. Learn how to apply fifo correctly. The first in, first out (fifo) method is a widely used inventory valuation technique that plays a crucial role in efficient inventory management. First in, first out (fifo) is the. What Is Fifo In Manufacturing.

From pharmastate.academy

SOP For Raw Material FIFO And FEFO Procedure What Is Fifo In Manufacturing Here, the oldest inventory items are sold or used first, and the most recent stock will be the last to be used or go for sale. The first in, first out (fifo) method is a widely used inventory valuation technique that plays a crucial role in efficient inventory management. The first in, first out (fifo) method of inventory valuation is. What Is Fifo In Manufacturing.

From www.authentichospitalitygroup.com

What is FIFO? Discover the significance of FIFO What Is Fifo In Manufacturing Fifo is an acronym for “first in, first out.” it refers to an inventory system that directs a firm to utilize the oldest items in inventory when a product or part is needed. Fifo lanes are an important part of any lean material flow. The first in, first out (fifo) method is a widely used inventory valuation technique that plays. What Is Fifo In Manufacturing.

From bestforecommerce.com

How do you maintain FIFO in a warehouse? Best Practices Best For What Is Fifo In Manufacturing Fifo lanes are an important part of any lean material flow. Fifo is predicated on the principle that the first items purchased or produced are the first to be sold or used. Discover how fifo optimises inventory and material flow and ensures efficient inventory management. Learn how to apply fifo correctly. Here, the oldest inventory items are sold or used. What Is Fifo In Manufacturing.

From pharmaguddu.com

FIFO, FEFO and LIFO Explanation and Guidelines » Pharmaguddu What Is Fifo In Manufacturing Discover how fifo optimises inventory and material flow and ensures efficient inventory management. The first in, first out (fifo) method of inventory valuation is a cost flow assumption that the first goods purchased are also the first. Fifo is an acronym for “first in, first out.” it refers to an inventory system that directs a firm to utilize the oldest. What Is Fifo In Manufacturing.

From www.lean.org

First In, First Out (FIFO) Lean Enterprise Institute What Is Fifo In Manufacturing First in, first out (fifo) is the principle and practice of maintaining precise production and conveyance sequence by ensuring that the first part to enter a process or storage. The first in, first out (fifo) method is a widely used inventory valuation technique that plays a crucial role in efficient inventory management. The first in, first out (fifo) method of. What Is Fifo In Manufacturing.

From eswap.global

Inventory Valuation Methods FIFO & LIFO (With Examples) eSwap What Is Fifo In Manufacturing Fifo is predicated on the principle that the first items purchased or produced are the first to be sold or used. The first in, first out (fifo) method is a widely used inventory valuation technique that plays a crucial role in efficient inventory management. They are a very simple way to define both the material flow and the. Learn how. What Is Fifo In Manufacturing.

From fulfillment.shiprocket.in

What is FIFO(First In First Out) Method of Inventory Valuation What Is Fifo In Manufacturing Efficient inventory management can significantly improve your business’s bottom line. First in, first out (fifo) is the principle and practice of maintaining precise production and conveyance sequence by ensuring that the first part to enter a process or storage. The first in, first out (fifo) method of inventory valuation is a cost flow assumption that the first goods purchased are. What Is Fifo In Manufacturing.

From www.slideserve.com

PPT FIFO Method PowerPoint Presentation, free download ID4093657 What Is Fifo In Manufacturing Fifo is predicated on the principle that the first items purchased or produced are the first to be sold or used. Discover how fifo optimises inventory and material flow and ensures efficient inventory management. Fifo lanes are an important part of any lean material flow. Fifo is an acronym for “first in, first out.” it refers to an inventory system. What Is Fifo In Manufacturing.

From www.authentichospitalitygroup.com

What is FIFO? Discover the significance of FIFO What Is Fifo In Manufacturing Fifo is predicated on the principle that the first items purchased or produced are the first to be sold or used. Discover how fifo optimises inventory and material flow and ensures efficient inventory management. The first in, first out (fifo) method is a widely used inventory valuation technique that plays a crucial role in efficient inventory management. They are a. What Is Fifo In Manufacturing.

From www.joharidigital.com

Medical Device Manufacturing FIFO (First in, First Out) Inventory What Is Fifo In Manufacturing First in, first out (fifo) is the principle and practice of maintaining precise production and conveyance sequence by ensuring that the first part to enter a process or storage. Fifo is an acronym for “first in, first out.” it refers to an inventory system that directs a firm to utilize the oldest items in inventory when a product or part. What Is Fifo In Manufacturing.

From redstagfulfillment.com

What Is FIFO? First In, First Out Explained Red Stag Fulfillment What Is Fifo In Manufacturing Fifo lanes are an important part of any lean material flow. Learn how to apply fifo correctly. Discover how fifo optimises inventory and material flow and ensures efficient inventory management. The first in, first out (fifo) method of inventory valuation is a cost flow assumption that the first goods purchased are also the first. The first in, first out (fifo). What Is Fifo In Manufacturing.

From sellercloud.com

FIFO vs. LIFO Choosing the Best Inventory Valuation for Your Business What Is Fifo In Manufacturing First in, first out (fifo) is the principle and practice of maintaining precise production and conveyance sequence by ensuring that the first part to enter a process or storage. Efficient inventory management can significantly improve your business’s bottom line. Here, the oldest inventory items are sold or used first, and the most recent stock will be the last to be. What Is Fifo In Manufacturing.

From www.strike.money

First In, First Out (FIFO) Definition, and How it Works What Is Fifo In Manufacturing Fifo is an acronym for “first in, first out.” it refers to an inventory system that directs a firm to utilize the oldest items in inventory when a product or part is needed. Learn how to apply fifo correctly. The first in, first out (fifo) method of inventory valuation is a cost flow assumption that the first goods purchased are. What Is Fifo In Manufacturing.

From advancestorageproducts.com

FIFO vs LIFO Inventory Flow Advance Storage Products What Is Fifo In Manufacturing The first in, first out (fifo) method is a widely used inventory valuation technique that plays a crucial role in efficient inventory management. They are a very simple way to define both the material flow and the. Here, the oldest inventory items are sold or used first, and the most recent stock will be the last to be used or. What Is Fifo In Manufacturing.

From blog.megaventory.com

FIFO vs. LIFO Which One Is Best For Your Business The Megaventory Blog What Is Fifo In Manufacturing Efficient inventory management can significantly improve your business’s bottom line. Fifo lanes are an important part of any lean material flow. Fifo is an acronym for “first in, first out.” it refers to an inventory system that directs a firm to utilize the oldest items in inventory when a product or part is needed. The first in, first out (fifo). What Is Fifo In Manufacturing.

From www.forbes.com

What Is The FIFO Method? FIFO Inventory Guide Forbes Advisor What Is Fifo In Manufacturing The first in, first out (fifo) method is a widely used inventory valuation technique that plays a crucial role in efficient inventory management. Fifo is predicated on the principle that the first items purchased or produced are the first to be sold or used. Here, the oldest inventory items are sold or used first, and the most recent stock will. What Is Fifo In Manufacturing.

From fifa-memo.com

How To Prepare Fifo Method What Is Fifo In Manufacturing Fifo is an acronym for “first in, first out.” it refers to an inventory system that directs a firm to utilize the oldest items in inventory when a product or part is needed. Fifo lanes are an important part of any lean material flow. They are a very simple way to define both the material flow and the. Learn how. What Is Fifo In Manufacturing.

From www.joharidigital.com

Medical Device Manufacturing FIFO (First in, First Out) Inventory What Is Fifo In Manufacturing Discover how fifo optimises inventory and material flow and ensures efficient inventory management. First in, first out (fifo) is the principle and practice of maintaining precise production and conveyance sequence by ensuring that the first part to enter a process or storage. Here, the oldest inventory items are sold or used first, and the most recent stock will be the. What Is Fifo In Manufacturing.

From www.amalo-recrutement.fr

Qu'estce que la méthode FIFO / LIFO What Is Fifo In Manufacturing Fifo is an acronym for “first in, first out.” it refers to an inventory system that directs a firm to utilize the oldest items in inventory when a product or part is needed. The first in, first out (fifo) method is a widely used inventory valuation technique that plays a crucial role in efficient inventory management. They are a very. What Is Fifo In Manufacturing.

From www.investopedia.com

FIFO What the First In, First Out Method Is and How to Use It What Is Fifo In Manufacturing Discover how fifo optimises inventory and material flow and ensures efficient inventory management. Fifo is predicated on the principle that the first items purchased or produced are the first to be sold or used. Learn how to apply fifo correctly. Fifo lanes are an important part of any lean material flow. Fifo is an acronym for “first in, first out.”. What Is Fifo In Manufacturing.

From www.laceupsolutions.com

FIFO and LIFO 2 methods for warehouse movement of products What Is Fifo In Manufacturing First in, first out (fifo) is the principle and practice of maintaining precise production and conveyance sequence by ensuring that the first part to enter a process or storage. Fifo lanes are an important part of any lean material flow. Discover how fifo optimises inventory and material flow and ensures efficient inventory management. Fifo is predicated on the principle that. What Is Fifo In Manufacturing.

From www.lean.org

First In, First Out (FIFO) Lean Enterprise Institute What Is Fifo In Manufacturing Fifo is an acronym for “first in, first out.” it refers to an inventory system that directs a firm to utilize the oldest items in inventory when a product or part is needed. The first in, first out (fifo) method is a widely used inventory valuation technique that plays a crucial role in efficient inventory management. First in, first out. What Is Fifo In Manufacturing.

From www.okestorage.com

FIFO Racking System, Pallet Flow Rack, Pallet Racking System OKE What Is Fifo In Manufacturing Fifo is an acronym for “first in, first out.” it refers to an inventory system that directs a firm to utilize the oldest items in inventory when a product or part is needed. Here, the oldest inventory items are sold or used first, and the most recent stock will be the last to be used or go for sale. First. What Is Fifo In Manufacturing.

From www.sagesoftware.co.in

What is FIFO method in Inventory? Definition and how to use it? What Is Fifo In Manufacturing Fifo is an acronym for “first in, first out.” it refers to an inventory system that directs a firm to utilize the oldest items in inventory when a product or part is needed. Fifo lanes are an important part of any lean material flow. They are a very simple way to define both the material flow and the. Discover how. What Is Fifo In Manufacturing.

From www.shiksha.com

Difference Between FIFO and LIFO Shiksha Online What Is Fifo In Manufacturing Here, the oldest inventory items are sold or used first, and the most recent stock will be the last to be used or go for sale. The first in, first out (fifo) method of inventory valuation is a cost flow assumption that the first goods purchased are also the first. Efficient inventory management can significantly improve your business’s bottom line.. What Is Fifo In Manufacturing.

From redstagfulfillment.com

What Is FIFO? First In, First Out Explained Red Stag Fulfillment What Is Fifo In Manufacturing Efficient inventory management can significantly improve your business’s bottom line. Learn how to apply fifo correctly. Discover how fifo optimises inventory and material flow and ensures efficient inventory management. Here, the oldest inventory items are sold or used first, and the most recent stock will be the last to be used or go for sale. First in, first out (fifo). What Is Fifo In Manufacturing.

From www.youtube.com

Differences between LIFO and FIFO. YouTube What Is Fifo In Manufacturing Fifo lanes are an important part of any lean material flow. The first in, first out (fifo) method is a widely used inventory valuation technique that plays a crucial role in efficient inventory management. Fifo is an acronym for “first in, first out.” it refers to an inventory system that directs a firm to utilize the oldest items in inventory. What Is Fifo In Manufacturing.

From mediavueltadigital.com

Método Fifo ¿Qué es?, ¿En qué consiste? y más Media Vuelta Digital What Is Fifo In Manufacturing The first in, first out (fifo) method of inventory valuation is a cost flow assumption that the first goods purchased are also the first. First in, first out (fifo) is the principle and practice of maintaining precise production and conveyance sequence by ensuring that the first part to enter a process or storage. Learn how to apply fifo correctly. Here,. What Is Fifo In Manufacturing.

From www.slideshare.net

First in First out method (FIFO) What Is Fifo In Manufacturing Discover how fifo optimises inventory and material flow and ensures efficient inventory management. Fifo is an acronym for “first in, first out.” it refers to an inventory system that directs a firm to utilize the oldest items in inventory when a product or part is needed. Fifo is predicated on the principle that the first items purchased or produced are. What Is Fifo In Manufacturing.

From www.akounto.com

What is FIFO Method in Accounting & How to Use it? Akounto What Is Fifo In Manufacturing They are a very simple way to define both the material flow and the. Fifo is an acronym for “first in, first out.” it refers to an inventory system that directs a firm to utilize the oldest items in inventory when a product or part is needed. First in, first out (fifo) is the principle and practice of maintaining precise. What Is Fifo In Manufacturing.