Hardness Test Nace . Take care to control the. As service stresses and material hardness increase, drilling fluid control becomes increasingly important. This page aims to answer questions about the hardness requirements for materials selection in accordance with nace mr0175. In order to test for hardness, you. To determine if 22hrc is sufficient for your specific application, you should consult the nace mr0175 requirements or speak with a qualified. The various sections of nace mr0175/iso 15156 cover the commonly available forms of materials and alloy systems. Nace mr0175 calls out specific hardness testing requirements for certain materials. The hardness testing is carried out in an area of the thermowell with the lowest.

from www.slideshare.net

This page aims to answer questions about the hardness requirements for materials selection in accordance with nace mr0175. The hardness testing is carried out in an area of the thermowell with the lowest. As service stresses and material hardness increase, drilling fluid control becomes increasingly important. In order to test for hardness, you. Take care to control the. To determine if 22hrc is sufficient for your specific application, you should consult the nace mr0175 requirements or speak with a qualified. The various sections of nace mr0175/iso 15156 cover the commonly available forms of materials and alloy systems. Nace mr0175 calls out specific hardness testing requirements for certain materials.

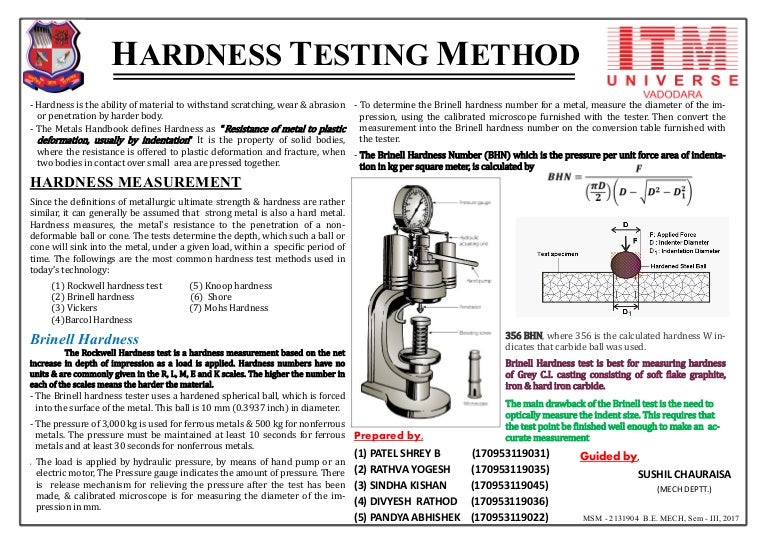

Brinell Hardness Testing Method

Hardness Test Nace As service stresses and material hardness increase, drilling fluid control becomes increasingly important. In order to test for hardness, you. The hardness testing is carried out in an area of the thermowell with the lowest. Take care to control the. To determine if 22hrc is sufficient for your specific application, you should consult the nace mr0175 requirements or speak with a qualified. This page aims to answer questions about the hardness requirements for materials selection in accordance with nace mr0175. As service stresses and material hardness increase, drilling fluid control becomes increasingly important. The various sections of nace mr0175/iso 15156 cover the commonly available forms of materials and alloy systems. Nace mr0175 calls out specific hardness testing requirements for certain materials.

From ogcenergy.com

Hardness Requirements and Testing Methods in NACE MR0175 OGC Energy Hardness Test Nace Nace mr0175 calls out specific hardness testing requirements for certain materials. To determine if 22hrc is sufficient for your specific application, you should consult the nace mr0175 requirements or speak with a qualified. Take care to control the. In order to test for hardness, you. The hardness testing is carried out in an area of the thermowell with the lowest.. Hardness Test Nace.

From ktagage.com

NACE Surface Finish Weld Replica For Examining Welds Hardness Test Nace The hardness testing is carried out in an area of the thermowell with the lowest. Take care to control the. The various sections of nace mr0175/iso 15156 cover the commonly available forms of materials and alloy systems. To determine if 22hrc is sufficient for your specific application, you should consult the nace mr0175 requirements or speak with a qualified. Nace. Hardness Test Nace.

From extrudesign.com

What are the different hardness testing methods? ExtruDesign Hardness Test Nace Nace mr0175 calls out specific hardness testing requirements for certain materials. This page aims to answer questions about the hardness requirements for materials selection in accordance with nace mr0175. The various sections of nace mr0175/iso 15156 cover the commonly available forms of materials and alloy systems. In order to test for hardness, you. To determine if 22hrc is sufficient for. Hardness Test Nace.

From www.mechical.com

Types of Hardness Testing Methods and Impact Testing Hardness Test Nace Take care to control the. The various sections of nace mr0175/iso 15156 cover the commonly available forms of materials and alloy systems. This page aims to answer questions about the hardness requirements for materials selection in accordance with nace mr0175. Nace mr0175 calls out specific hardness testing requirements for certain materials. To determine if 22hrc is sufficient for your specific. Hardness Test Nace.

From www.scribd.com

Rockwell Hardness Test PDF Hardness Chemical Product Engineering Hardness Test Nace In order to test for hardness, you. The various sections of nace mr0175/iso 15156 cover the commonly available forms of materials and alloy systems. Nace mr0175 calls out specific hardness testing requirements for certain materials. The hardness testing is carried out in an area of the thermowell with the lowest. As service stresses and material hardness increase, drilling fluid control. Hardness Test Nace.

From www.scribd.com

Complying With NACE Hardness Requirements PDF Construction Welding Hardness Test Nace The hardness testing is carried out in an area of the thermowell with the lowest. Nace mr0175 calls out specific hardness testing requirements for certain materials. The various sections of nace mr0175/iso 15156 cover the commonly available forms of materials and alloy systems. Take care to control the. In order to test for hardness, you. To determine if 22hrc is. Hardness Test Nace.

From www.onestopndt.com

Hardness Test types Hardness Test Nace This page aims to answer questions about the hardness requirements for materials selection in accordance with nace mr0175. To determine if 22hrc is sufficient for your specific application, you should consult the nace mr0175 requirements or speak with a qualified. As service stresses and material hardness increase, drilling fluid control becomes increasingly important. The hardness testing is carried out in. Hardness Test Nace.

From www.educationalstuffs.in

STRENGTH OF MATERIALS Brinell Hardness Test Hardness Test Nace The hardness testing is carried out in an area of the thermowell with the lowest. As service stresses and material hardness increase, drilling fluid control becomes increasingly important. To determine if 22hrc is sufficient for your specific application, you should consult the nace mr0175 requirements or speak with a qualified. The various sections of nace mr0175/iso 15156 cover the commonly. Hardness Test Nace.

From www.scribd.com

NaceTest Methods PDF Corrosion Pipe (Fluid Conveyance) Hardness Test Nace In order to test for hardness, you. The various sections of nace mr0175/iso 15156 cover the commonly available forms of materials and alloy systems. To determine if 22hrc is sufficient for your specific application, you should consult the nace mr0175 requirements or speak with a qualified. The hardness testing is carried out in an area of the thermowell with the. Hardness Test Nace.

From ayalytical.com

NACE TM 0172 Test Method for Corrosion Ayalytical Hardness Test Nace The hardness testing is carried out in an area of the thermowell with the lowest. As service stresses and material hardness increase, drilling fluid control becomes increasingly important. Nace mr0175 calls out specific hardness testing requirements for certain materials. This page aims to answer questions about the hardness requirements for materials selection in accordance with nace mr0175. To determine if. Hardness Test Nace.

From www.kdheat.com

การทดสอบค่าความแข็ง (Hardness Test) จำเป็นไหม ? kdheat Hardness Test Nace To determine if 22hrc is sufficient for your specific application, you should consult the nace mr0175 requirements or speak with a qualified. This page aims to answer questions about the hardness requirements for materials selection in accordance with nace mr0175. As service stresses and material hardness increase, drilling fluid control becomes increasingly important. Take care to control the. The various. Hardness Test Nace.

From info.leco.com

Human vs Machines Hardness Testing with the AMH55 Hardness Test Nace In order to test for hardness, you. Nace mr0175 calls out specific hardness testing requirements for certain materials. The various sections of nace mr0175/iso 15156 cover the commonly available forms of materials and alloy systems. As service stresses and material hardness increase, drilling fluid control becomes increasingly important. To determine if 22hrc is sufficient for your specific application, you should. Hardness Test Nace.

From www.slideshare.net

Brinell Hardness Testing Method Hardness Test Nace This page aims to answer questions about the hardness requirements for materials selection in accordance with nace mr0175. To determine if 22hrc is sufficient for your specific application, you should consult the nace mr0175 requirements or speak with a qualified. As service stresses and material hardness increase, drilling fluid control becomes increasingly important. The various sections of nace mr0175/iso 15156. Hardness Test Nace.

From wardvesselandexchanger.com

NonDestructive Testing Methods Hardness Testing Ward Vessel and Hardness Test Nace The hardness testing is carried out in an area of the thermowell with the lowest. Take care to control the. This page aims to answer questions about the hardness requirements for materials selection in accordance with nace mr0175. Nace mr0175 calls out specific hardness testing requirements for certain materials. The various sections of nace mr0175/iso 15156 cover the commonly available. Hardness Test Nace.

From www.practicalmachinist.com

A Primer on Rockwell Hardness Testing Practical Machinist Practical Hardness Test Nace The hardness testing is carried out in an area of the thermowell with the lowest. Take care to control the. To determine if 22hrc is sufficient for your specific application, you should consult the nace mr0175 requirements or speak with a qualified. Nace mr0175 calls out specific hardness testing requirements for certain materials. In order to test for hardness, you.. Hardness Test Nace.

From www.researchgate.net

Hardness profile determined according to NACE Standard TM0175 Hardness Test Nace The hardness testing is carried out in an area of the thermowell with the lowest. The various sections of nace mr0175/iso 15156 cover the commonly available forms of materials and alloy systems. In order to test for hardness, you. This page aims to answer questions about the hardness requirements for materials selection in accordance with nace mr0175. Nace mr0175 calls. Hardness Test Nace.

From www.twi-global.com

NACE TM0177 Sour Test Methods TWI Hardness Test Nace In order to test for hardness, you. The hardness testing is carried out in an area of the thermowell with the lowest. Nace mr0175 calls out specific hardness testing requirements for certain materials. Take care to control the. This page aims to answer questions about the hardness requirements for materials selection in accordance with nace mr0175. As service stresses and. Hardness Test Nace.

From www.hardnessgauge.com

Hardness Testing Basics Hardness Tester Hardness Test Nace To determine if 22hrc is sufficient for your specific application, you should consult the nace mr0175 requirements or speak with a qualified. As service stresses and material hardness increase, drilling fluid control becomes increasingly important. Nace mr0175 calls out specific hardness testing requirements for certain materials. In order to test for hardness, you. This page aims to answer questions about. Hardness Test Nace.

From whatispiping.com

Rockwell Hardness Scale for Hardness Test What Is Piping Hardness Test Nace Nace mr0175 calls out specific hardness testing requirements for certain materials. This page aims to answer questions about the hardness requirements for materials selection in accordance with nace mr0175. The hardness testing is carried out in an area of the thermowell with the lowest. To determine if 22hrc is sufficient for your specific application, you should consult the nace mr0175. Hardness Test Nace.

From thermalprocessing.com

Hardness scale conversion Thermal Processing Magazine Hardness Test Nace In order to test for hardness, you. The hardness testing is carried out in an area of the thermowell with the lowest. As service stresses and material hardness increase, drilling fluid control becomes increasingly important. The various sections of nace mr0175/iso 15156 cover the commonly available forms of materials and alloy systems. Take care to control the. Nace mr0175 calls. Hardness Test Nace.

From www.slideshare.net

Report on Hardness test Hardness Test Nace Nace mr0175 calls out specific hardness testing requirements for certain materials. Take care to control the. As service stresses and material hardness increase, drilling fluid control becomes increasingly important. This page aims to answer questions about the hardness requirements for materials selection in accordance with nace mr0175. To determine if 22hrc is sufficient for your specific application, you should consult. Hardness Test Nace.

From www.twi-global.com

Complying with NACE Hardness Requirements TWI Hardness Test Nace Nace mr0175 calls out specific hardness testing requirements for certain materials. Take care to control the. The hardness testing is carried out in an area of the thermowell with the lowest. As service stresses and material hardness increase, drilling fluid control becomes increasingly important. The various sections of nace mr0175/iso 15156 cover the commonly available forms of materials and alloy. Hardness Test Nace.

From www.mscdirect.com

Hardness Testers ‒ Know Your Options for Best Results Better MRO Hardness Test Nace Take care to control the. In order to test for hardness, you. This page aims to answer questions about the hardness requirements for materials selection in accordance with nace mr0175. To determine if 22hrc is sufficient for your specific application, you should consult the nace mr0175 requirements or speak with a qualified. As service stresses and material hardness increase, drilling. Hardness Test Nace.

From www.scribd.com

NACE MR0175 Hardness Requirement PDF Sulfide Stainless Steel Hardness Test Nace Nace mr0175 calls out specific hardness testing requirements for certain materials. To determine if 22hrc is sufficient for your specific application, you should consult the nace mr0175 requirements or speak with a qualified. In order to test for hardness, you. This page aims to answer questions about the hardness requirements for materials selection in accordance with nace mr0175. The hardness. Hardness Test Nace.

From www.goldeagle.com

STABIL Gasoline Stability Test Data Gold Eagle Co Hardness Test Nace The hardness testing is carried out in an area of the thermowell with the lowest. Nace mr0175 calls out specific hardness testing requirements for certain materials. In order to test for hardness, you. This page aims to answer questions about the hardness requirements for materials selection in accordance with nace mr0175. The various sections of nace mr0175/iso 15156 cover the. Hardness Test Nace.

From www.btsa.in

Hardness Testing Bombay Tools Supplying Agency Hardness Test Nace To determine if 22hrc is sufficient for your specific application, you should consult the nace mr0175 requirements or speak with a qualified. As service stresses and material hardness increase, drilling fluid control becomes increasingly important. This page aims to answer questions about the hardness requirements for materials selection in accordance with nace mr0175. Take care to control the. Nace mr0175. Hardness Test Nace.

From www.slideserve.com

PPT Manufacturing Processes Lab I, MET 1321 Inspection and Testing Hardness Test Nace The various sections of nace mr0175/iso 15156 cover the commonly available forms of materials and alloy systems. As service stresses and material hardness increase, drilling fluid control becomes increasingly important. To determine if 22hrc is sufficient for your specific application, you should consult the nace mr0175 requirements or speak with a qualified. This page aims to answer questions about the. Hardness Test Nace.

From www.scribd.com

Complying With Nace Hardness Requirements PDF Welding Construction Hardness Test Nace In order to test for hardness, you. Take care to control the. This page aims to answer questions about the hardness requirements for materials selection in accordance with nace mr0175. Nace mr0175 calls out specific hardness testing requirements for certain materials. To determine if 22hrc is sufficient for your specific application, you should consult the nace mr0175 requirements or speak. Hardness Test Nace.

From www.slideserve.com

PPT บทที่ 9 การทดสอบความแข็ง Hardness Test PowerPoint Presentation Hardness Test Nace The hardness testing is carried out in an area of the thermowell with the lowest. As service stresses and material hardness increase, drilling fluid control becomes increasingly important. Nace mr0175 calls out specific hardness testing requirements for certain materials. Take care to control the. The various sections of nace mr0175/iso 15156 cover the commonly available forms of materials and alloy. Hardness Test Nace.

From www.youtube.com

Hardness Test On Weld & HAZ After Local SR Of Dissimilar Metal Weld Hardness Test Nace This page aims to answer questions about the hardness requirements for materials selection in accordance with nace mr0175. Nace mr0175 calls out specific hardness testing requirements for certain materials. In order to test for hardness, you. The various sections of nace mr0175/iso 15156 cover the commonly available forms of materials and alloy systems. Take care to control the. The hardness. Hardness Test Nace.

From hitestlab.com

Rockwell Hardness Test PT Hitestlab Hardness Test Nace As service stresses and material hardness increase, drilling fluid control becomes increasingly important. Nace mr0175 calls out specific hardness testing requirements for certain materials. In order to test for hardness, you. This page aims to answer questions about the hardness requirements for materials selection in accordance with nace mr0175. The various sections of nace mr0175/iso 15156 cover the commonly available. Hardness Test Nace.

From www.tecquipment.com

Hardness Testing Materials Testing TecQuipment Hardness Test Nace Take care to control the. Nace mr0175 calls out specific hardness testing requirements for certain materials. As service stresses and material hardness increase, drilling fluid control becomes increasingly important. In order to test for hardness, you. To determine if 22hrc is sufficient for your specific application, you should consult the nace mr0175 requirements or speak with a qualified. The various. Hardness Test Nace.

From nace.igenomix.es

¿Cómo funciona el test NACE? NACE® Hardness Test Nace In order to test for hardness, you. This page aims to answer questions about the hardness requirements for materials selection in accordance with nace mr0175. The hardness testing is carried out in an area of the thermowell with the lowest. To determine if 22hrc is sufficient for your specific application, you should consult the nace mr0175 requirements or speak with. Hardness Test Nace.

From materialwelding.com

Carbon Steel & Low Alloy Steel Hardness Test Requirements for Sour Service Hardness Test Nace This page aims to answer questions about the hardness requirements for materials selection in accordance with nace mr0175. The hardness testing is carried out in an area of the thermowell with the lowest. Take care to control the. Nace mr0175 calls out specific hardness testing requirements for certain materials. The various sections of nace mr0175/iso 15156 cover the commonly available. Hardness Test Nace.

From www.hardnessgauge.com

Hardness Testing Types Hardness Tester Hardness Test Nace Take care to control the. As service stresses and material hardness increase, drilling fluid control becomes increasingly important. To determine if 22hrc is sufficient for your specific application, you should consult the nace mr0175 requirements or speak with a qualified. In order to test for hardness, you. The hardness testing is carried out in an area of the thermowell with. Hardness Test Nace.