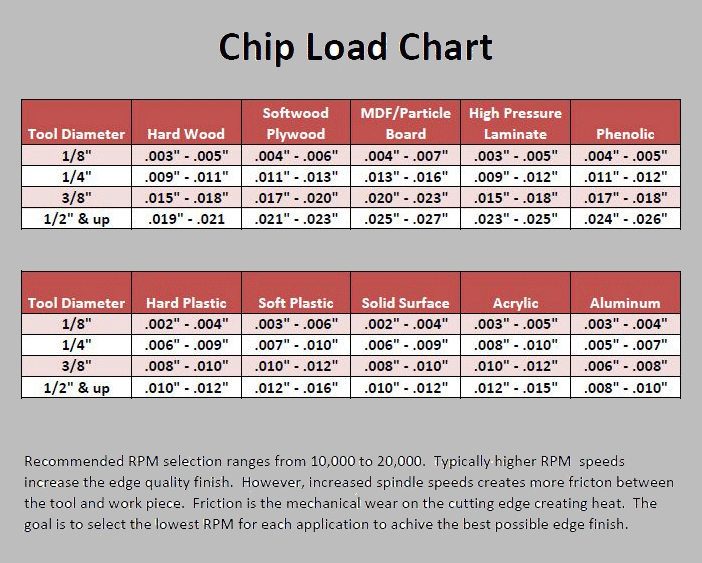

End Mill Chip Load . the chart below provides the suggested chip load starting range typical for material type and tool diameter in use. Chip load = feed rate (inches per minute) / (rpm x. the chip load (maximum chip thickness), is the largest chip that a cutting edge can handle without breaking and still maintain. This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of the tool. calculate tangential force, torque, and machining power for end milling applications. chip load (maximum chip thickness) is one of the most important parameters for achieving a productive and reliable milling. — this handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. — chip load is the size of the piece of material you make when your end mill cuts into it. — chip load is defined as the thickness of the chips removed during a machining operation. The size of the chips you make is important to.

from hallmanufacturingsolutions.com

This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of the tool. — chip load is defined as the thickness of the chips removed during a machining operation. the chart below provides the suggested chip load starting range typical for material type and tool diameter in use. the chip load (maximum chip thickness), is the largest chip that a cutting edge can handle without breaking and still maintain. The size of the chips you make is important to. chip load (maximum chip thickness) is one of the most important parameters for achieving a productive and reliable milling. Chip load = feed rate (inches per minute) / (rpm x. — chip load is the size of the piece of material you make when your end mill cuts into it. calculate tangential force, torque, and machining power for end milling applications. — this handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut.

Hall Manufacturing Solutions

End Mill Chip Load calculate tangential force, torque, and machining power for end milling applications. the chart below provides the suggested chip load starting range typical for material type and tool diameter in use. This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of the tool. — chip load is the size of the piece of material you make when your end mill cuts into it. the chip load (maximum chip thickness), is the largest chip that a cutting edge can handle without breaking and still maintain. The size of the chips you make is important to. Chip load = feed rate (inches per minute) / (rpm x. — this handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. — chip load is defined as the thickness of the chips removed during a machining operation. chip load (maximum chip thickness) is one of the most important parameters for achieving a productive and reliable milling. calculate tangential force, torque, and machining power for end milling applications.

From www.makerstore.com.au

Straight Cut End Mill With Chip Breakers Maker Store PTY LTD End Mill Chip Load — this handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. — chip load is the size of the piece of material you make when your end mill cuts into it. calculate tangential force, torque, and machining power for end milling applications. The size. End Mill Chip Load.

From www.kyocera-unimerco.com

SC end mill End Mill Chip Load the chart below provides the suggested chip load starting range typical for material type and tool diameter in use. This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of the tool. Chip load = feed rate (inches per minute) / (rpm x. calculate tangential force,. End Mill Chip Load.

From www.ebay.com

LOT ( 2 PCS ) NEW 1/4" GWS 310100 SOLID CARBIDE END MILLS MILLING End Mill Chip Load This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of the tool. The size of the chips you make is important to. the chip load (maximum chip thickness), is the largest chip that a cutting edge can handle without breaking and still maintain. — this. End Mill Chip Load.

From www.mekanika.io

Feeds & Speeds Explained MEKANIKA End Mill Chip Load Chip load = feed rate (inches per minute) / (rpm x. — this handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. — chip load is defined as the thickness of the chips removed during a machining operation. chip load (maximum chip thickness) is. End Mill Chip Load.

From bitsbits.com

1/8 Single Flute End Mill 1/4 x 61/2" End Mill Chip Load calculate tangential force, torque, and machining power for end milling applications. The size of the chips you make is important to. Chip load = feed rate (inches per minute) / (rpm x. This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of the tool. —. End Mill Chip Load.

From dxovbpskp.blob.core.windows.net

Milling Bits For Router at Margaret Williams blog End Mill Chip Load — this handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. calculate tangential force, torque, and machining power for end milling applications. This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of. End Mill Chip Load.

From www.practicalmachinist.com

Corner rounding endmills in a vmc. End Mill Chip Load — chip load is the size of the piece of material you make when your end mill cuts into it. calculate tangential force, torque, and machining power for end milling applications. — chip load is defined as the thickness of the chips removed during a machining operation. This calculator provides a starting reference range only for shank. End Mill Chip Load.

From dxotlsxdv.blob.core.windows.net

End Mill Feed Per Tooth at Adrienne Papenfuss blog End Mill Chip Load — chip load is the size of the piece of material you make when your end mill cuts into it. — chip load is defined as the thickness of the chips removed during a machining operation. — this handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load. End Mill Chip Load.

From precisionboard.com

Updated Speeds and Feeds for Precision Board HDU Precision Board End Mill Chip Load the chip load (maximum chip thickness), is the largest chip that a cutting edge can handle without breaking and still maintain. The size of the chips you make is important to. chip load (maximum chip thickness) is one of the most important parameters for achieving a productive and reliable milling. — this handy cnc chip load calculator. End Mill Chip Load.

From www.uniontool.com

Carbide End Mills Union Tool Europe S.A. End Mill Chip Load — chip load is the size of the piece of material you make when your end mill cuts into it. calculate tangential force, torque, and machining power for end milling applications. chip load (maximum chip thickness) is one of the most important parameters for achieving a productive and reliable milling. This calculator provides a starting reference range. End Mill Chip Load.

From www.widia.com

VariMill Chip Splitters WIDIA End Mill Chip Load — chip load is the size of the piece of material you make when your end mill cuts into it. the chip load (maximum chip thickness), is the largest chip that a cutting edge can handle without breaking and still maintain. calculate tangential force, torque, and machining power for end milling applications. This calculator provides a starting. End Mill Chip Load.

From probots.co.in

Probots 50pcs End Mill Engraving Bits Kit Set 3.175mm Shank CNC Router End Mill Chip Load — chip load is the size of the piece of material you make when your end mill cuts into it. Chip load = feed rate (inches per minute) / (rpm x. chip load (maximum chip thickness) is one of the most important parameters for achieving a productive and reliable milling. The size of the chips you make is. End Mill Chip Load.

From www.etmm-online.com

End mill for high chip removal rates also suits five cutting operations End Mill Chip Load This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of the tool. the chip load (maximum chip thickness), is the largest chip that a cutting edge can handle without breaking and still maintain. calculate tangential force, torque, and machining power for end milling applications. . End Mill Chip Load.

From www.qualitytechtool.com

General Purpose End Mills Inch Quality Tech Tool End Mill Chip Load calculate tangential force, torque, and machining power for end milling applications. chip load (maximum chip thickness) is one of the most important parameters for achieving a productive and reliable milling. — this handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. This calculator provides. End Mill Chip Load.

From www.tool-factory.de

HSS end mills Tool Factory End Mill Chip Load chip load (maximum chip thickness) is one of the most important parameters for achieving a productive and reliable milling. This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of the tool. — chip load is defined as the thickness of the chips removed during a. End Mill Chip Load.

From exoiopcib.blob.core.windows.net

Standard End Mill Sizes Chart at Joann Pellegrin blog End Mill Chip Load Chip load = feed rate (inches per minute) / (rpm x. — this handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of the. End Mill Chip Load.

From osgblog.com

AT2 Carbide Thread Mill with EndCutting Edge OSG Blog End Mill Chip Load chip load (maximum chip thickness) is one of the most important parameters for achieving a productive and reliable milling. — chip load is defined as the thickness of the chips removed during a machining operation. This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of. End Mill Chip Load.

From www.researchgate.net

Chip load in end milling. Download Scientific Diagram End Mill Chip Load the chip load (maximum chip thickness), is the largest chip that a cutting edge can handle without breaking and still maintain. Chip load = feed rate (inches per minute) / (rpm x. — this handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. —. End Mill Chip Load.

From hallmanufacturingsolutions.com

Hall Manufacturing Solutions End Mill Chip Load — chip load is defined as the thickness of the chips removed during a machining operation. calculate tangential force, torque, and machining power for end milling applications. Chip load = feed rate (inches per minute) / (rpm x. — chip load is the size of the piece of material you make when your end mill cuts into. End Mill Chip Load.

From www.productivity.com

High Efficiency Milling How to Apply and Boost Shop Productivity End Mill Chip Load chip load (maximum chip thickness) is one of the most important parameters for achieving a productive and reliable milling. — chip load is defined as the thickness of the chips removed during a machining operation. calculate tangential force, torque, and machining power for end milling applications. the chip load (maximum chip thickness), is the largest chip. End Mill Chip Load.

From www.ebay.com

LOT ( 2 PCS ) NEW 1/4" GWS 310100 SOLID CARBIDE END MILLS MILLING End Mill Chip Load the chip load (maximum chip thickness), is the largest chip that a cutting edge can handle without breaking and still maintain. This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of the tool. Chip load = feed rate (inches per minute) / (rpm x. —. End Mill Chip Load.

From www.mscdirect.com

Kyocera Indexable HighFeed End Mill 1" Cut Dia, 1" Standard Shank End Mill Chip Load calculate tangential force, torque, and machining power for end milling applications. Chip load = feed rate (inches per minute) / (rpm x. The size of the chips you make is important to. chip load (maximum chip thickness) is one of the most important parameters for achieving a productive and reliable milling. — chip load is the size. End Mill Chip Load.

From dxoerufgl.blob.core.windows.net

End Mill In Hand Drill at Anthony Fowler blog End Mill Chip Load — this handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. the chart below provides the suggested chip load starting range typical for material type and tool diameter in use. — chip load is defined as the thickness of the chips removed during a. End Mill Chip Load.

From www.youtube.com

Control Your Chips! Chip Splitters and Roughing End Mills Haas End Mill Chip Load the chart below provides the suggested chip load starting range typical for material type and tool diameter in use. — chip load is the size of the piece of material you make when your end mill cuts into it. chip load (maximum chip thickness) is one of the most important parameters for achieving a productive and reliable. End Mill Chip Load.

From www.harveyperformance.com

Chipbreaker vs. Knuckle Rougher End Mills In The Loupe End Mill Chip Load the chip load (maximum chip thickness), is the largest chip that a cutting edge can handle without breaking and still maintain. calculate tangential force, torque, and machining power for end milling applications. — chip load is defined as the thickness of the chips removed during a machining operation. — chip load is the size of the. End Mill Chip Load.

From www.sainsmart.com

Calculate CNC Speeds and Feeds with Suggested Chip Load for Common Too End Mill Chip Load — chip load is the size of the piece of material you make when your end mill cuts into it. Chip load = feed rate (inches per minute) / (rpm x. This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of the tool. — this. End Mill Chip Load.

From www.cmc-consultants.com

Metal Machining How To Improve Finish through Speeds & Feeds End Mill Chip Load — chip load is defined as the thickness of the chips removed during a machining operation. chip load (maximum chip thickness) is one of the most important parameters for achieving a productive and reliable milling. This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of. End Mill Chip Load.

From toolnotes.com

Cutting Parameters for Milling ToolNotes End Mill Chip Load the chip load (maximum chip thickness), is the largest chip that a cutting edge can handle without breaking and still maintain. chip load (maximum chip thickness) is one of the most important parameters for achieving a productive and reliable milling. — this handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives. End Mill Chip Load.

From toolnotes.com

End Mills ToolNotes End Mill Chip Load The size of the chips you make is important to. — chip load is the size of the piece of material you make when your end mill cuts into it. — this handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. the chart below. End Mill Chip Load.

From www.maritool.com

5/8 Variable 5 Flute End Mill x 2.25 LOC with Chip Breaker MariTool End Mill Chip Load This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of the tool. the chip load (maximum chip thickness), is the largest chip that a cutting edge can handle without breaking and still maintain. — this handy cnc chip load calculator takes spindle speed, feedrate, and. End Mill Chip Load.

From community.carbide3d.com

Tutorial on feeds and speeds Tutorials Carbide 3D Community Site End Mill Chip Load calculate tangential force, torque, and machining power for end milling applications. Chip load = feed rate (inches per minute) / (rpm x. The size of the chips you make is important to. — chip load is the size of the piece of material you make when your end mill cuts into it. — this handy cnc chip. End Mill Chip Load.

From www.chegg.com

Solved A Face Milling Operation on machine steel plate is End Mill Chip Load — chip load is the size of the piece of material you make when your end mill cuts into it. the chart below provides the suggested chip load starting range typical for material type and tool diameter in use. Chip load = feed rate (inches per minute) / (rpm x. — this handy cnc chip load calculator. End Mill Chip Load.

From www.ebay.com

LOT ( 2 PCS ) NEW 1/4" GWS 310100 SOLID CARBIDE END MILLS MILLING End Mill Chip Load Chip load = feed rate (inches per minute) / (rpm x. — chip load is the size of the piece of material you make when your end mill cuts into it. calculate tangential force, torque, and machining power for end milling applications. — chip load is defined as the thickness of the chips removed during a machining. End Mill Chip Load.

From www.mmc-carbide.com

End Mill Terminology Technical Info / Cutting Formula MITSUBISHI End Mill Chip Load — chip load is defined as the thickness of the chips removed during a machining operation. — this handy cnc chip load calculator takes spindle speed, feedrate, and number of flutes and gives back the chip load of the cut. — chip load is the size of the piece of material you make when your end mill. End Mill Chip Load.

From www.youtube.com

How to Remove Aluminum Chip Weld from End Mills and Drills YouTube End Mill Chip Load — chip load is defined as the thickness of the chips removed during a machining operation. The size of the chips you make is important to. chip load (maximum chip thickness) is one of the most important parameters for achieving a productive and reliable milling. the chip load (maximum chip thickness), is the largest chip that a. End Mill Chip Load.