Piston Oil Ring Direction . • low viscosity monograde oil. perhaps the most critical engine assembly step is file fitting and installing the piston rings with the correct gap—it’s that important to the performance and. a common practice in performance applications is file fitting piston end gaps to a precise end gap using slightly oversized. the oil ring is handling the bulk of the oil control, scraping the oil off the cylinder wall and feeding it back into the crankcase though drainback holes in the piston. in this video, we’re going to cover the installation of 1 and 2 piece oil rings. pistons and rings with a premium grade oil of at least 20w/50 weight before installing in the bores. Remove the coil spring from the oil ring and place the coil spring in the groove, noting the location of the coil. with the taper of the ring upside down, oil will be scraped up with each upward stroke to be left in the combustion chamber and burned on the power.

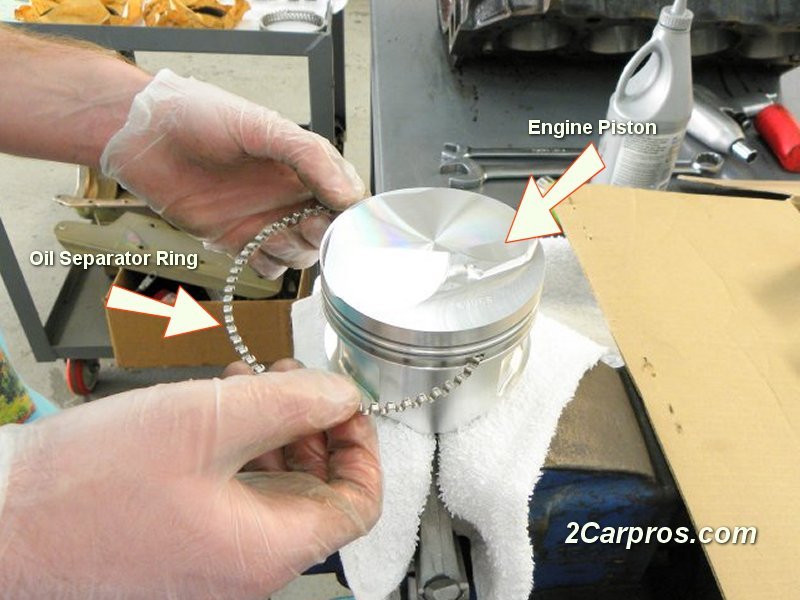

from www.2carpros.com

in this video, we’re going to cover the installation of 1 and 2 piece oil rings. Remove the coil spring from the oil ring and place the coil spring in the groove, noting the location of the coil. • low viscosity monograde oil. a common practice in performance applications is file fitting piston end gaps to a precise end gap using slightly oversized. pistons and rings with a premium grade oil of at least 20w/50 weight before installing in the bores. the oil ring is handling the bulk of the oil control, scraping the oil off the cylinder wall and feeding it back into the crankcase though drainback holes in the piston. with the taper of the ring upside down, oil will be scraped up with each upward stroke to be left in the combustion chamber and burned on the power. perhaps the most critical engine assembly step is file fitting and installing the piston rings with the correct gap—it’s that important to the performance and.

How to Replace Engine Piston Rings

Piston Oil Ring Direction perhaps the most critical engine assembly step is file fitting and installing the piston rings with the correct gap—it’s that important to the performance and. a common practice in performance applications is file fitting piston end gaps to a precise end gap using slightly oversized. pistons and rings with a premium grade oil of at least 20w/50 weight before installing in the bores. with the taper of the ring upside down, oil will be scraped up with each upward stroke to be left in the combustion chamber and burned on the power. • low viscosity monograde oil. the oil ring is handling the bulk of the oil control, scraping the oil off the cylinder wall and feeding it back into the crankcase though drainback holes in the piston. Remove the coil spring from the oil ring and place the coil spring in the groove, noting the location of the coil. in this video, we’re going to cover the installation of 1 and 2 piece oil rings. perhaps the most critical engine assembly step is file fitting and installing the piston rings with the correct gap—it’s that important to the performance and.

From gioijbwad.blob.core.windows.net

How To Put Rings On A Piston at John Drost blog Piston Oil Ring Direction pistons and rings with a premium grade oil of at least 20w/50 weight before installing in the bores. with the taper of the ring upside down, oil will be scraped up with each upward stroke to be left in the combustion chamber and burned on the power. perhaps the most critical engine assembly step is file fitting. Piston Oil Ring Direction.

From www.2carpros.com

How to Replace Engine Piston Rings Piston Oil Ring Direction perhaps the most critical engine assembly step is file fitting and installing the piston rings with the correct gap—it’s that important to the performance and. the oil ring is handling the bulk of the oil control, scraping the oil off the cylinder wall and feeding it back into the crankcase though drainback holes in the piston. a. Piston Oil Ring Direction.

From www.grantpistonrings.com

Piston Ring Basics Piston Oil Ring Direction a common practice in performance applications is file fitting piston end gaps to a precise end gap using slightly oversized. • low viscosity monograde oil. pistons and rings with a premium grade oil of at least 20w/50 weight before installing in the bores. with the taper of the ring upside down, oil will be scraped up with. Piston Oil Ring Direction.

From www.animalia-life.club

Piston Oil Rings Piston Oil Ring Direction the oil ring is handling the bulk of the oil control, scraping the oil off the cylinder wall and feeding it back into the crankcase though drainback holes in the piston. with the taper of the ring upside down, oil will be scraped up with each upward stroke to be left in the combustion chamber and burned on. Piston Oil Ring Direction.

From www.onallcylinders.com

Video How to Install Piston Rings OnAllCylinders Piston Oil Ring Direction perhaps the most critical engine assembly step is file fitting and installing the piston rings with the correct gap—it’s that important to the performance and. • low viscosity monograde oil. a common practice in performance applications is file fitting piston end gaps to a precise end gap using slightly oversized. Remove the coil spring from the oil ring. Piston Oil Ring Direction.

From www.youtube.com

Why Do Engines Need 3 Piston Rings? Explained YouTube Piston Oil Ring Direction with the taper of the ring upside down, oil will be scraped up with each upward stroke to be left in the combustion chamber and burned on the power. perhaps the most critical engine assembly step is file fitting and installing the piston rings with the correct gap—it’s that important to the performance and. the oil ring. Piston Oil Ring Direction.

From blog.diamondracing.net

How to FileFit and Install Piston Rings Piston Oil Ring Direction • low viscosity monograde oil. in this video, we’re going to cover the installation of 1 and 2 piece oil rings. pistons and rings with a premium grade oil of at least 20w/50 weight before installing in the bores. perhaps the most critical engine assembly step is file fitting and installing the piston rings with the correct. Piston Oil Ring Direction.

From www.youtube.com

How to Clock Piston Rings Gap Orientation and Install Tips YouTube Piston Oil Ring Direction Remove the coil spring from the oil ring and place the coil spring in the groove, noting the location of the coil. perhaps the most critical engine assembly step is file fitting and installing the piston rings with the correct gap—it’s that important to the performance and. with the taper of the ring upside down, oil will be. Piston Oil Ring Direction.

From info.jepistons.com

How to Install Motorcycle and ATV Piston Rings Piston Oil Ring Direction with the taper of the ring upside down, oil will be scraped up with each upward stroke to be left in the combustion chamber and burned on the power. in this video, we’re going to cover the installation of 1 and 2 piece oil rings. • low viscosity monograde oil. Remove the coil spring from the oil ring. Piston Oil Ring Direction.

From bikerestart.com

The Three Types Of Piston Rings (All You Need To Know!) Bike Restart Piston Oil Ring Direction in this video, we’re going to cover the installation of 1 and 2 piece oil rings. perhaps the most critical engine assembly step is file fitting and installing the piston rings with the correct gap—it’s that important to the performance and. with the taper of the ring upside down, oil will be scraped up with each upward. Piston Oil Ring Direction.

From enginetech.com

How To Install Rings Blog The Engine Builder's Source Piston Oil Ring Direction pistons and rings with a premium grade oil of at least 20w/50 weight before installing in the bores. • low viscosity monograde oil. in this video, we’re going to cover the installation of 1 and 2 piece oil rings. the oil ring is handling the bulk of the oil control, scraping the oil off the cylinder wall. Piston Oil Ring Direction.

From engineeringlearn.com

Piston Rings Types And Function Guide] Engineering Learn Piston Oil Ring Direction • low viscosity monograde oil. pistons and rings with a premium grade oil of at least 20w/50 weight before installing in the bores. with the taper of the ring upside down, oil will be scraped up with each upward stroke to be left in the combustion chamber and burned on the power. perhaps the most critical engine. Piston Oil Ring Direction.

From blog.amsoil.com

What Are Piston Rings? And What Do They Do? AMSOIL Blog Piston Oil Ring Direction in this video, we’re going to cover the installation of 1 and 2 piece oil rings. the oil ring is handling the bulk of the oil control, scraping the oil off the cylinder wall and feeding it back into the crankcase though drainback holes in the piston. a common practice in performance applications is file fitting piston. Piston Oil Ring Direction.

From www.researchgate.net

Schematic of the piston rings assembly. Download Scientific Diagram Piston Oil Ring Direction Remove the coil spring from the oil ring and place the coil spring in the groove, noting the location of the coil. a common practice in performance applications is file fitting piston end gaps to a precise end gap using slightly oversized. in this video, we’re going to cover the installation of 1 and 2 piece oil rings.. Piston Oil Ring Direction.

From www.onallcylinders.com

Piston Primer How to Properly Install Pistons OnAllCylinders Piston Oil Ring Direction with the taper of the ring upside down, oil will be scraped up with each upward stroke to be left in the combustion chamber and burned on the power. perhaps the most critical engine assembly step is file fitting and installing the piston rings with the correct gap—it’s that important to the performance and. in this video,. Piston Oil Ring Direction.

From enginetech.com

How To Install Rings Blog The Engine Builder's Source Piston Oil Ring Direction perhaps the most critical engine assembly step is file fitting and installing the piston rings with the correct gap—it’s that important to the performance and. • low viscosity monograde oil. with the taper of the ring upside down, oil will be scraped up with each upward stroke to be left in the combustion chamber and burned on the. Piston Oil Ring Direction.

From www.autozone.com

Repair Guides Engine Mechanical Components Piston & Ring Piston Oil Ring Direction a common practice in performance applications is file fitting piston end gaps to a precise end gap using slightly oversized. • low viscosity monograde oil. pistons and rings with a premium grade oil of at least 20w/50 weight before installing in the bores. Remove the coil spring from the oil ring and place the coil spring in the. Piston Oil Ring Direction.

From www.autozone.com

Repair Guides Engine Mechanical Pistons And Connecting Rods Piston Oil Ring Direction perhaps the most critical engine assembly step is file fitting and installing the piston rings with the correct gap—it’s that important to the performance and. pistons and rings with a premium grade oil of at least 20w/50 weight before installing in the bores. in this video, we’re going to cover the installation of 1 and 2 piece. Piston Oil Ring Direction.

From www.haldimandsyntheticoil.ca

What is the function of piston rings? Piston Oil Ring Direction perhaps the most critical engine assembly step is file fitting and installing the piston rings with the correct gap—it’s that important to the performance and. with the taper of the ring upside down, oil will be scraped up with each upward stroke to be left in the combustion chamber and burned on the power. in this video,. Piston Oil Ring Direction.

From www.2carpros.com

How to Replace Engine Piston Rings Piston Oil Ring Direction perhaps the most critical engine assembly step is file fitting and installing the piston rings with the correct gap—it’s that important to the performance and. with the taper of the ring upside down, oil will be scraped up with each upward stroke to be left in the combustion chamber and burned on the power. the oil ring. Piston Oil Ring Direction.

From carrepairworld.blogspot.com

Car Repair World How To Replace Engine Piston Rings Piston Oil Ring Direction the oil ring is handling the bulk of the oil control, scraping the oil off the cylinder wall and feeding it back into the crankcase though drainback holes in the piston. pistons and rings with a premium grade oil of at least 20w/50 weight before installing in the bores. a common practice in performance applications is file. Piston Oil Ring Direction.

From www.hollywoodchryslerjeep.com

Gearhead Piston Rings Piston Oil Ring Direction pistons and rings with a premium grade oil of at least 20w/50 weight before installing in the bores. • low viscosity monograde oil. with the taper of the ring upside down, oil will be scraped up with each upward stroke to be left in the combustion chamber and burned on the power. Remove the coil spring from the. Piston Oil Ring Direction.

From www.youtube.com

PISTON RING INSTALLATION FULL PROCESS HOW TO INSTALL PISTON RING Piston Oil Ring Direction Remove the coil spring from the oil ring and place the coil spring in the groove, noting the location of the coil. • low viscosity monograde oil. the oil ring is handling the bulk of the oil control, scraping the oil off the cylinder wall and feeding it back into the crankcase though drainback holes in the piston. . Piston Oil Ring Direction.

From forums.pelicanparts.com

piston ring orientation w/ 3 piece oil ring Pelican Parts Forums Piston Oil Ring Direction • low viscosity monograde oil. with the taper of the ring upside down, oil will be scraped up with each upward stroke to be left in the combustion chamber and burned on the power. pistons and rings with a premium grade oil of at least 20w/50 weight before installing in the bores. a common practice in performance. Piston Oil Ring Direction.

From www.autozone.com

Repair Guides Piston Oil Ring Direction pistons and rings with a premium grade oil of at least 20w/50 weight before installing in the bores. perhaps the most critical engine assembly step is file fitting and installing the piston rings with the correct gap—it’s that important to the performance and. with the taper of the ring upside down, oil will be scraped up with. Piston Oil Ring Direction.

From www.webmagazinetoday.com

How to install piston rings 4 stroke on motorbike and car Piston Oil Ring Direction perhaps the most critical engine assembly step is file fitting and installing the piston rings with the correct gap—it’s that important to the performance and. in this video, we’re going to cover the installation of 1 and 2 piece oil rings. with the taper of the ring upside down, oil will be scraped up with each upward. Piston Oil Ring Direction.

From www.enginelabs.com

Hidden Horsepower Revealing The Secrets Of The Oil Control Rings Piston Oil Ring Direction perhaps the most critical engine assembly step is file fitting and installing the piston rings with the correct gap—it’s that important to the performance and. pistons and rings with a premium grade oil of at least 20w/50 weight before installing in the bores. Remove the coil spring from the oil ring and place the coil spring in the. Piston Oil Ring Direction.

From garage.grumpysperformance.com

ring gapping and basic piston ring info YOULL NEED Grumpys Piston Oil Ring Direction a common practice in performance applications is file fitting piston end gaps to a precise end gap using slightly oversized. pistons and rings with a premium grade oil of at least 20w/50 weight before installing in the bores. Remove the coil spring from the oil ring and place the coil spring in the groove, noting the location of. Piston Oil Ring Direction.

From www.enginebasics.com

Engine Piston Ring Basics How Piston Rings Work Car Automotive Piston Oil Ring Direction with the taper of the ring upside down, oil will be scraped up with each upward stroke to be left in the combustion chamber and burned on the power. perhaps the most critical engine assembly step is file fitting and installing the piston rings with the correct gap—it’s that important to the performance and. in this video,. Piston Oil Ring Direction.

From blog.amsoil.com

What Are Piston Rings? And What Do They Do? AMSOIL Blog Piston Oil Ring Direction • low viscosity monograde oil. Remove the coil spring from the oil ring and place the coil spring in the groove, noting the location of the coil. the oil ring is handling the bulk of the oil control, scraping the oil off the cylinder wall and feeding it back into the crankcase though drainback holes in the piston. . Piston Oil Ring Direction.

From ar.inspiredpencil.com

Piston Oil Rings Piston Oil Ring Direction • low viscosity monograde oil. pistons and rings with a premium grade oil of at least 20w/50 weight before installing in the bores. Remove the coil spring from the oil ring and place the coil spring in the groove, noting the location of the coil. a common practice in performance applications is file fitting piston end gaps to. Piston Oil Ring Direction.

From enginetech.com

How To Install Rings Blog The Engine Builder's Source Piston Oil Ring Direction Remove the coil spring from the oil ring and place the coil spring in the groove, noting the location of the coil. • low viscosity monograde oil. with the taper of the ring upside down, oil will be scraped up with each upward stroke to be left in the combustion chamber and burned on the power. perhaps the. Piston Oil Ring Direction.

From www.youtube.com

SBC Piston Ring and Rod Orientation (For the First time Builders) YouTube Piston Oil Ring Direction • low viscosity monograde oil. the oil ring is handling the bulk of the oil control, scraping the oil off the cylinder wall and feeding it back into the crankcase though drainback holes in the piston. perhaps the most critical engine assembly step is file fitting and installing the piston rings with the correct gap—it’s that important to. Piston Oil Ring Direction.

From www.autozone.com

Repair Guides Piston Oil Ring Direction Remove the coil spring from the oil ring and place the coil spring in the groove, noting the location of the coil. with the taper of the ring upside down, oil will be scraped up with each upward stroke to be left in the combustion chamber and burned on the power. perhaps the most critical engine assembly step. Piston Oil Ring Direction.

From www.2carpros.com

How to Replace Engine Piston Rings Piston Oil Ring Direction a common practice in performance applications is file fitting piston end gaps to a precise end gap using slightly oversized. pistons and rings with a premium grade oil of at least 20w/50 weight before installing in the bores. with the taper of the ring upside down, oil will be scraped up with each upward stroke to be. Piston Oil Ring Direction.