Double Cone Blender Schematic Diagram . In this article, we will discuss in detail the principle, working, advantages, disadvantages, and applications of the double cone blender. During the rotation of the double cone, the matter is continuously intermixed. These blenders can blend solids of different bulk densities and percentages in different ratios. Principle of double cone blender. Solid oral dosage forms powder blending. The mixing occur due to tumbling motion. Double cone blender principle dry blending of free solids is the most frequent application for double cone blenders. The conical shape promotes gentle mixing and prevents particle segregation. In the pharmaceutical and nutraceutical industries, the double cone blender is widely used for the dry mixing and blending. İkev meeting may 31, 2001.

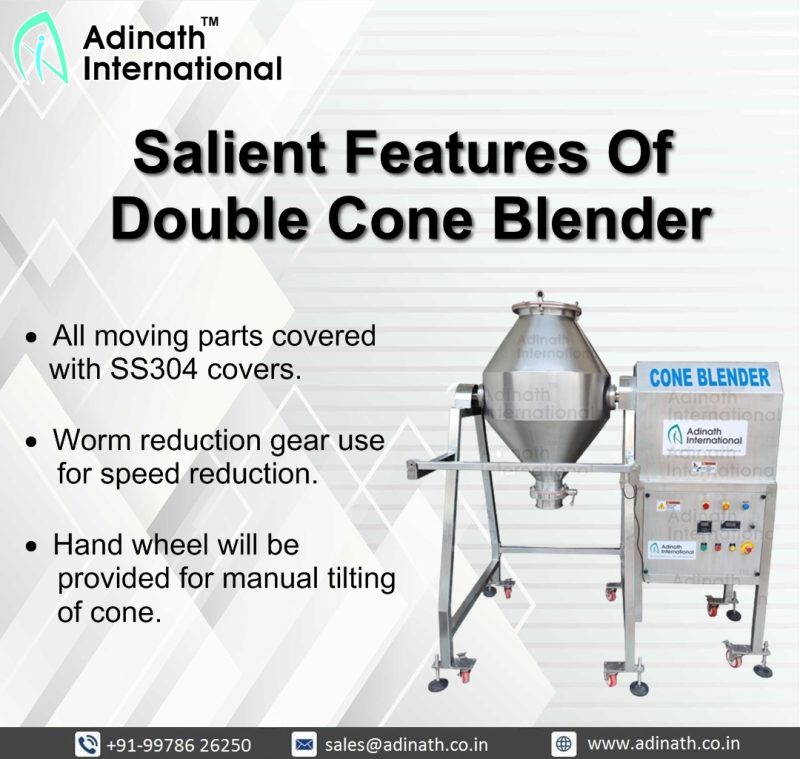

from www.adinath.co.in

Principle of double cone blender. The mixing occur due to tumbling motion. In the pharmaceutical and nutraceutical industries, the double cone blender is widely used for the dry mixing and blending. Double cone blender principle dry blending of free solids is the most frequent application for double cone blenders. These blenders can blend solids of different bulk densities and percentages in different ratios. The conical shape promotes gentle mixing and prevents particle segregation. During the rotation of the double cone, the matter is continuously intermixed. İkev meeting may 31, 2001. In this article, we will discuss in detail the principle, working, advantages, disadvantages, and applications of the double cone blender. Solid oral dosage forms powder blending.

Types of Blenders Ribbon Blender, Octagonal, V Cone Blender and

Double Cone Blender Schematic Diagram The mixing occur due to tumbling motion. The conical shape promotes gentle mixing and prevents particle segregation. Principle of double cone blender. These blenders can blend solids of different bulk densities and percentages in different ratios. Solid oral dosage forms powder blending. During the rotation of the double cone, the matter is continuously intermixed. İkev meeting may 31, 2001. Double cone blender principle dry blending of free solids is the most frequent application for double cone blenders. In the pharmaceutical and nutraceutical industries, the double cone blender is widely used for the dry mixing and blending. The mixing occur due to tumbling motion. In this article, we will discuss in detail the principle, working, advantages, disadvantages, and applications of the double cone blender.

From www.ipharmachine.com

A Closer Look at the Double Cone Blender Working Principle IPharmachine Double Cone Blender Schematic Diagram Principle of double cone blender. The conical shape promotes gentle mixing and prevents particle segregation. İkev meeting may 31, 2001. Solid oral dosage forms powder blending. The mixing occur due to tumbling motion. In the pharmaceutical and nutraceutical industries, the double cone blender is widely used for the dry mixing and blending. In this article, we will discuss in detail. Double Cone Blender Schematic Diagram.

From www.youtube.com

Double cone blender Twin shell blender v cone blender Part3 Double Cone Blender Schematic Diagram In this article, we will discuss in detail the principle, working, advantages, disadvantages, and applications of the double cone blender. The mixing occur due to tumbling motion. The conical shape promotes gentle mixing and prevents particle segregation. In the pharmaceutical and nutraceutical industries, the double cone blender is widely used for the dry mixing and blending. These blenders can blend. Double Cone Blender Schematic Diagram.

From www.ipharmachine.com

What is Double Cone Blender A Quick Overview IPharmachine Double Cone Blender Schematic Diagram During the rotation of the double cone, the matter is continuously intermixed. İkev meeting may 31, 2001. Principle of double cone blender. In the pharmaceutical and nutraceutical industries, the double cone blender is widely used for the dry mixing and blending. The mixing occur due to tumbling motion. These blenders can blend solids of different bulk densities and percentages in. Double Cone Blender Schematic Diagram.

From www.maxmixers.com

What is the difference between V cone and double cone blender Knowledge Double Cone Blender Schematic Diagram The mixing occur due to tumbling motion. In this article, we will discuss in detail the principle, working, advantages, disadvantages, and applications of the double cone blender. These blenders can blend solids of different bulk densities and percentages in different ratios. Principle of double cone blender. İkev meeting may 31, 2001. Solid oral dosage forms powder blending. The conical shape. Double Cone Blender Schematic Diagram.

From qaziengineering.com

Double Cone Blender Qazi Engineering Double Cone Blender Schematic Diagram In the pharmaceutical and nutraceutical industries, the double cone blender is widely used for the dry mixing and blending. Double cone blender principle dry blending of free solids is the most frequent application for double cone blenders. Principle of double cone blender. The conical shape promotes gentle mixing and prevents particle segregation. The mixing occur due to tumbling motion. Solid. Double Cone Blender Schematic Diagram.

From www.scribd.com

Double Cone Blender PDF Double Cone Blender Schematic Diagram In the pharmaceutical and nutraceutical industries, the double cone blender is widely used for the dry mixing and blending. İkev meeting may 31, 2001. Double cone blender principle dry blending of free solids is the most frequent application for double cone blenders. Solid oral dosage forms powder blending. The mixing occur due to tumbling motion. The conical shape promotes gentle. Double Cone Blender Schematic Diagram.

From www.saintytec.com

Figure 17 Double cone blender SaintyTec Double Cone Blender Schematic Diagram The conical shape promotes gentle mixing and prevents particle segregation. During the rotation of the double cone, the matter is continuously intermixed. Principle of double cone blender. The mixing occur due to tumbling motion. Solid oral dosage forms powder blending. Double cone blender principle dry blending of free solids is the most frequent application for double cone blenders. İkev meeting. Double Cone Blender Schematic Diagram.

From www.solnpharma.com

Double Cone Blender Construction, Working, and More Double Cone Blender Schematic Diagram The conical shape promotes gentle mixing and prevents particle segregation. In this article, we will discuss in detail the principle, working, advantages, disadvantages, and applications of the double cone blender. Principle of double cone blender. During the rotation of the double cone, the matter is continuously intermixed. Solid oral dosage forms powder blending. These blenders can blend solids of different. Double Cone Blender Schematic Diagram.

From www.slideshare.net

Double Cone Blender Double Cone Blender Schematic Diagram During the rotation of the double cone, the matter is continuously intermixed. İkev meeting may 31, 2001. Solid oral dosage forms powder blending. Double cone blender principle dry blending of free solids is the most frequent application for double cone blenders. Principle of double cone blender. In the pharmaceutical and nutraceutical industries, the double cone blender is widely used for. Double Cone Blender Schematic Diagram.

From indmkt.com

Industrial Marketing Company Double Cone Blender Schematic Diagram Solid oral dosage forms powder blending. During the rotation of the double cone, the matter is continuously intermixed. In this article, we will discuss in detail the principle, working, advantages, disadvantages, and applications of the double cone blender. Double cone blender principle dry blending of free solids is the most frequent application for double cone blenders. Principle of double cone. Double Cone Blender Schematic Diagram.

From www.iqsdirectory.com

Blenders Types, Uses, Features and Benefits Double Cone Blender Schematic Diagram These blenders can blend solids of different bulk densities and percentages in different ratios. Solid oral dosage forms powder blending. In the pharmaceutical and nutraceutical industries, the double cone blender is widely used for the dry mixing and blending. Principle of double cone blender. The conical shape promotes gentle mixing and prevents particle segregation. During the rotation of the double. Double Cone Blender Schematic Diagram.

From www.youtube.com

Double Cone Blender Interchangeable Design, Pharmaceutical Blender Double Cone Blender Schematic Diagram The mixing occur due to tumbling motion. Double cone blender principle dry blending of free solids is the most frequent application for double cone blenders. Principle of double cone blender. The conical shape promotes gentle mixing and prevents particle segregation. İkev meeting may 31, 2001. Solid oral dosage forms powder blending. In the pharmaceutical and nutraceutical industries, the double cone. Double Cone Blender Schematic Diagram.

From www.researchgate.net

1 Sample Locations in Double Cone Blender Download Scientific Diagram Double Cone Blender Schematic Diagram The mixing occur due to tumbling motion. Double cone blender principle dry blending of free solids is the most frequent application for double cone blenders. During the rotation of the double cone, the matter is continuously intermixed. The conical shape promotes gentle mixing and prevents particle segregation. In this article, we will discuss in detail the principle, working, advantages, disadvantages,. Double Cone Blender Schematic Diagram.

From qaziengineering.com

Double Cone Blender Qazi Engineering Double Cone Blender Schematic Diagram These blenders can blend solids of different bulk densities and percentages in different ratios. The mixing occur due to tumbling motion. Principle of double cone blender. During the rotation of the double cone, the matter is continuously intermixed. In the pharmaceutical and nutraceutical industries, the double cone blender is widely used for the dry mixing and blending. İkev meeting may. Double Cone Blender Schematic Diagram.

From www.pharmaceuticalequipmentsmanufacturer.com

Double Cone Blender Manufacturer in Thane, Mumbai Double Cone Blender Schematic Diagram The conical shape promotes gentle mixing and prevents particle segregation. Double cone blender principle dry blending of free solids is the most frequent application for double cone blenders. Principle of double cone blender. In the pharmaceutical and nutraceutical industries, the double cone blender is widely used for the dry mixing and blending. İkev meeting may 31, 2001. Solid oral dosage. Double Cone Blender Schematic Diagram.

From www.adinath.co.in

Comprehensive Guide of Double Cone Blender Double Cone Blender Schematic Diagram In this article, we will discuss in detail the principle, working, advantages, disadvantages, and applications of the double cone blender. The mixing occur due to tumbling motion. İkev meeting may 31, 2001. In the pharmaceutical and nutraceutical industries, the double cone blender is widely used for the dry mixing and blending. Principle of double cone blender. During the rotation of. Double Cone Blender Schematic Diagram.

From www.yindamachinery.com

Double Cone Blenders Yinda Double Cone Blender Schematic Diagram Principle of double cone blender. The mixing occur due to tumbling motion. The conical shape promotes gentle mixing and prevents particle segregation. During the rotation of the double cone, the matter is continuously intermixed. These blenders can blend solids of different bulk densities and percentages in different ratios. Solid oral dosage forms powder blending. In this article, we will discuss. Double Cone Blender Schematic Diagram.

From solutionpharmacy.in

Double Cone Blender Construction and Working Solution Parmacy Double Cone Blender Schematic Diagram In this article, we will discuss in detail the principle, working, advantages, disadvantages, and applications of the double cone blender. The mixing occur due to tumbling motion. İkev meeting may 31, 2001. Double cone blender principle dry blending of free solids is the most frequent application for double cone blenders. The conical shape promotes gentle mixing and prevents particle segregation.. Double Cone Blender Schematic Diagram.

From www.saintytec.com

Double Cone Blender SaintyTec Double Cone Blender Schematic Diagram The mixing occur due to tumbling motion. These blenders can blend solids of different bulk densities and percentages in different ratios. In the pharmaceutical and nutraceutical industries, the double cone blender is widely used for the dry mixing and blending. During the rotation of the double cone, the matter is continuously intermixed. Principle of double cone blender. Double cone blender. Double Cone Blender Schematic Diagram.

From www.youtube.com

Construction and working of double cone blender YouTube Double Cone Blender Schematic Diagram The mixing occur due to tumbling motion. The conical shape promotes gentle mixing and prevents particle segregation. Solid oral dosage forms powder blending. In this article, we will discuss in detail the principle, working, advantages, disadvantages, and applications of the double cone blender. In the pharmaceutical and nutraceutical industries, the double cone blender is widely used for the dry mixing. Double Cone Blender Schematic Diagram.

From www.yindamachinery.com

Double Cone Blenders Yinda Double Cone Blender Schematic Diagram Solid oral dosage forms powder blending. These blenders can blend solids of different bulk densities and percentages in different ratios. Principle of double cone blender. During the rotation of the double cone, the matter is continuously intermixed. Double cone blender principle dry blending of free solids is the most frequent application for double cone blenders. In the pharmaceutical and nutraceutical. Double Cone Blender Schematic Diagram.

From www.adinath.co.in

Types of Blenders Ribbon Blender, Octagonal, V Cone Blender and Double Cone Blender Schematic Diagram The conical shape promotes gentle mixing and prevents particle segregation. During the rotation of the double cone, the matter is continuously intermixed. In this article, we will discuss in detail the principle, working, advantages, disadvantages, and applications of the double cone blender. The mixing occur due to tumbling motion. In the pharmaceutical and nutraceutical industries, the double cone blender is. Double Cone Blender Schematic Diagram.

From intence.co.in

Double Cone Blender Intence Engineering Double Cone Blender Schematic Diagram Principle of double cone blender. The mixing occur due to tumbling motion. The conical shape promotes gentle mixing and prevents particle segregation. In this article, we will discuss in detail the principle, working, advantages, disadvantages, and applications of the double cone blender. Solid oral dosage forms powder blending. In the pharmaceutical and nutraceutical industries, the double cone blender is widely. Double Cone Blender Schematic Diagram.

From www.adinath.co.in

Double Cone Blender powder Working Principle Double Cone Blender Schematic Diagram Principle of double cone blender. İkev meeting may 31, 2001. Solid oral dosage forms powder blending. In this article, we will discuss in detail the principle, working, advantages, disadvantages, and applications of the double cone blender. In the pharmaceutical and nutraceutical industries, the double cone blender is widely used for the dry mixing and blending. The conical shape promotes gentle. Double Cone Blender Schematic Diagram.

From pharmatech.co.uk

Double Cone Blenders efficient but gentle blending action Double Cone Blender Schematic Diagram The conical shape promotes gentle mixing and prevents particle segregation. In the pharmaceutical and nutraceutical industries, the double cone blender is widely used for the dry mixing and blending. Double cone blender principle dry blending of free solids is the most frequent application for double cone blenders. Solid oral dosage forms powder blending. İkev meeting may 31, 2001. These blenders. Double Cone Blender Schematic Diagram.

From www.slideshare.net

Double Cone Blender Double Cone Blender Schematic Diagram İkev meeting may 31, 2001. The conical shape promotes gentle mixing and prevents particle segregation. Solid oral dosage forms powder blending. In this article, we will discuss in detail the principle, working, advantages, disadvantages, and applications of the double cone blender. Double cone blender principle dry blending of free solids is the most frequent application for double cone blenders. Principle. Double Cone Blender Schematic Diagram.

From pharmacymcqshayeque.blogspot.com

Equipment for mixing and Double cone blender, V cone blender Double Cone Blender Schematic Diagram These blenders can blend solids of different bulk densities and percentages in different ratios. During the rotation of the double cone, the matter is continuously intermixed. In this article, we will discuss in detail the principle, working, advantages, disadvantages, and applications of the double cone blender. Double cone blender principle dry blending of free solids is the most frequent application. Double Cone Blender Schematic Diagram.

From www.ipharmachine.com

A Comprehensive Look at the Construction of Double Cone Blender Double Cone Blender Schematic Diagram Solid oral dosage forms powder blending. During the rotation of the double cone, the matter is continuously intermixed. These blenders can blend solids of different bulk densities and percentages in different ratios. In the pharmaceutical and nutraceutical industries, the double cone blender is widely used for the dry mixing and blending. Double cone blender principle dry blending of free solids. Double Cone Blender Schematic Diagram.

From www.ipharmachine.com

Parts of a V Blender A Comprehensive Guide IPharmachine Double Cone Blender Schematic Diagram Solid oral dosage forms powder blending. These blenders can blend solids of different bulk densities and percentages in different ratios. The conical shape promotes gentle mixing and prevents particle segregation. In this article, we will discuss in detail the principle, working, advantages, disadvantages, and applications of the double cone blender. During the rotation of the double cone, the matter is. Double Cone Blender Schematic Diagram.

From www.okgemco.com

Double Cone Mixers & Blenders GEMCO Double Cone Blender Schematic Diagram In this article, we will discuss in detail the principle, working, advantages, disadvantages, and applications of the double cone blender. Principle of double cone blender. The conical shape promotes gentle mixing and prevents particle segregation. Solid oral dosage forms powder blending. Double cone blender principle dry blending of free solids is the most frequent application for double cone blenders. The. Double Cone Blender Schematic Diagram.

From www.drymixer.com

JHSP stainless steel pharmacy mixer Double Cone Chemical Mixer dry Double Cone Blender Schematic Diagram Double cone blender principle dry blending of free solids is the most frequent application for double cone blenders. During the rotation of the double cone, the matter is continuously intermixed. İkev meeting may 31, 2001. Solid oral dosage forms powder blending. The conical shape promotes gentle mixing and prevents particle segregation. The mixing occur due to tumbling motion. These blenders. Double Cone Blender Schematic Diagram.

From www.researchgate.net

Mechanism of Double cone blender Download Scientific Diagram Double Cone Blender Schematic Diagram İkev meeting may 31, 2001. During the rotation of the double cone, the matter is continuously intermixed. The mixing occur due to tumbling motion. In this article, we will discuss in detail the principle, working, advantages, disadvantages, and applications of the double cone blender. Principle of double cone blender. In the pharmaceutical and nutraceutical industries, the double cone blender is. Double Cone Blender Schematic Diagram.

From www.pinterest.com

Double Cone Blender Parts, Principle and Diagram Cone, Doubles Double Cone Blender Schematic Diagram İkev meeting may 31, 2001. Double cone blender principle dry blending of free solids is the most frequent application for double cone blenders. In the pharmaceutical and nutraceutical industries, the double cone blender is widely used for the dry mixing and blending. Principle of double cone blender. These blenders can blend solids of different bulk densities and percentages in different. Double Cone Blender Schematic Diagram.

From www.slideshare.net

Double Cone Blender Double Cone Blender Schematic Diagram During the rotation of the double cone, the matter is continuously intermixed. The mixing occur due to tumbling motion. Principle of double cone blender. These blenders can blend solids of different bulk densities and percentages in different ratios. In the pharmaceutical and nutraceutical industries, the double cone blender is widely used for the dry mixing and blending. Double cone blender. Double Cone Blender Schematic Diagram.

From shreeengineeringservice.com

Double Cone Blender Shree Engineering Service Double Cone Blender Schematic Diagram Solid oral dosage forms powder blending. These blenders can blend solids of different bulk densities and percentages in different ratios. Principle of double cone blender. The conical shape promotes gentle mixing and prevents particle segregation. In this article, we will discuss in detail the principle, working, advantages, disadvantages, and applications of the double cone blender. Double cone blender principle dry. Double Cone Blender Schematic Diagram.