Forklift Fork Wear . The professional fork wear gauge measures the thickness of forklift forks or tynes as they wear over time with continued use. All fork inspections must follow the requirements of the lifting operations and lifting equipment regulations loler) 1998; No callipers or calculations required! Just open the jaws at the top and close the teeth around the shank to verify the fork diameter which would either be 35, 40, 45, or 50mm. Just open the jaws at the top of the gauge and close the teeth around the shank to verify the fork diameter which would be either 35, 40, 45 or 50mm. The fork wear caliper can also be used as inside calipers for measuring the bore or bushing on shaft/pin type forks. Forklift fork wear (knowing when your forks need replacing) you should check your forks to make sure they haven’t been worn too. How to use the professional fork wear gauge. Please follow the steps outlined in this guide to ensure. Begin by setting the caliper by the thickness of the shank.

from www.lsforklifts.com

Begin by setting the caliper by the thickness of the shank. Just open the jaws at the top and close the teeth around the shank to verify the fork diameter which would either be 35, 40, 45, or 50mm. Just open the jaws at the top of the gauge and close the teeth around the shank to verify the fork diameter which would be either 35, 40, 45 or 50mm. The fork wear caliper can also be used as inside calipers for measuring the bore or bushing on shaft/pin type forks. No callipers or calculations required! The professional fork wear gauge measures the thickness of forklift forks or tynes as they wear over time with continued use. Please follow the steps outlined in this guide to ensure. Forklift fork wear (knowing when your forks need replacing) you should check your forks to make sure they haven’t been worn too. How to use the professional fork wear gauge. All fork inspections must follow the requirements of the lifting operations and lifting equipment regulations loler) 1998;

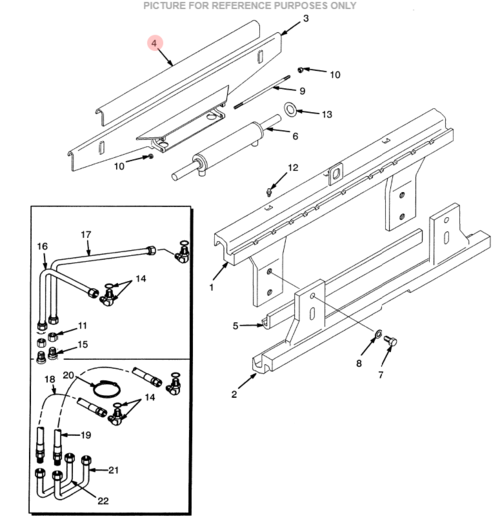

HYSTER WEAR PAD (LS4237) Lsfork Lifts

Forklift Fork Wear No callipers or calculations required! Please follow the steps outlined in this guide to ensure. The fork wear caliper can also be used as inside calipers for measuring the bore or bushing on shaft/pin type forks. Just open the jaws at the top and close the teeth around the shank to verify the fork diameter which would either be 35, 40, 45, or 50mm. Forklift fork wear (knowing when your forks need replacing) you should check your forks to make sure they haven’t been worn too. Just open the jaws at the top of the gauge and close the teeth around the shank to verify the fork diameter which would be either 35, 40, 45 or 50mm. The professional fork wear gauge measures the thickness of forklift forks or tynes as they wear over time with continued use. Begin by setting the caliper by the thickness of the shank. No callipers or calculations required! How to use the professional fork wear gauge. All fork inspections must follow the requirements of the lifting operations and lifting equipment regulations loler) 1998;

From mungfali.com

Forklift Fork Sleeves Forklift Fork Wear The professional fork wear gauge measures the thickness of forklift forks or tynes as they wear over time with continued use. Just open the jaws at the top and close the teeth around the shank to verify the fork diameter which would either be 35, 40, 45, or 50mm. The fork wear caliper can also be used as inside calipers. Forklift Fork Wear.

From www.municayma.gob.pe

Fork Wear GaugeForkliftWear Calliper for Forks Lèvepalettes Forklift Fork Wear The fork wear caliper can also be used as inside calipers for measuring the bore or bushing on shaft/pin type forks. All fork inspections must follow the requirements of the lifting operations and lifting equipment regulations loler) 1998; Please follow the steps outlined in this guide to ensure. No callipers or calculations required! Just open the jaws at the top. Forklift Fork Wear.

From www.forkweargauge.com

Professional Fork Wear Gauge measure wear on forklift forks FB Chain Forklift Fork Wear Begin by setting the caliper by the thickness of the shank. The fork wear caliper can also be used as inside calipers for measuring the bore or bushing on shaft/pin type forks. How to use the professional fork wear gauge. No callipers or calculations required! Just open the jaws at the top of the gauge and close the teeth around. Forklift Fork Wear.

From www.forkliftamerica.com

Understanding Forklift Forks Forklift America Forklift Fork Wear Just open the jaws at the top and close the teeth around the shank to verify the fork diameter which would either be 35, 40, 45, or 50mm. Just open the jaws at the top of the gauge and close the teeth around the shank to verify the fork diameter which would be either 35, 40, 45 or 50mm. Forklift. Forklift Fork Wear.

From www.forkliftamerica.com

Forklift Fork Wear Gauge Calipers Forklift America Forklift Fork Wear All fork inspections must follow the requirements of the lifting operations and lifting equipment regulations loler) 1998; The fork wear caliper can also be used as inside calipers for measuring the bore or bushing on shaft/pin type forks. Forklift fork wear (knowing when your forks need replacing) you should check your forks to make sure they haven’t been worn too.. Forklift Fork Wear.

From mhdsupplychain.com.au

Forkwear protection wearing correct clothing for forklift operation Forklift Fork Wear No callipers or calculations required! All fork inspections must follow the requirements of the lifting operations and lifting equipment regulations loler) 1998; The fork wear caliper can also be used as inside calipers for measuring the bore or bushing on shaft/pin type forks. Please follow the steps outlined in this guide to ensure. The professional fork wear gauge measures the. Forklift Fork Wear.

From www.forkweargauge.com

Professional Fork Wear Gauge measure wear on forklift forks FB Chain Forklift Fork Wear No callipers or calculations required! Begin by setting the caliper by the thickness of the shank. Forklift fork wear (knowing when your forks need replacing) you should check your forks to make sure they haven’t been worn too. The professional fork wear gauge measures the thickness of forklift forks or tynes as they wear over time with continued use. All. Forklift Fork Wear.

From www.forkweargauge.com

Professional Fork Wear Gauge measure wear on forklift forks FB Chain Forklift Fork Wear All fork inspections must follow the requirements of the lifting operations and lifting equipment regulations loler) 1998; Forklift fork wear (knowing when your forks need replacing) you should check your forks to make sure they haven’t been worn too. How to use the professional fork wear gauge. No callipers or calculations required! Just open the jaws at the top of. Forklift Fork Wear.

From www.plantmachineryvehicles.com

New measuring tool gives visual indication of fork heel wear PMV Forklift Fork Wear How to use the professional fork wear gauge. Forklift fork wear (knowing when your forks need replacing) you should check your forks to make sure they haven’t been worn too. Please follow the steps outlined in this guide to ensure. Just open the jaws at the top of the gauge and close the teeth around the shank to verify the. Forklift Fork Wear.

From tontio.com

Forklift Forks and Tines Guide Learn Before You Buy Tontio Forklift Fork Wear Just open the jaws at the top and close the teeth around the shank to verify the fork diameter which would either be 35, 40, 45, or 50mm. All fork inspections must follow the requirements of the lifting operations and lifting equipment regulations loler) 1998; How to use the professional fork wear gauge. Begin by setting the caliper by the. Forklift Fork Wear.

From yabe.chudov.com

53200004.jpg of NEW Cascade Hyster Forklift Fork Gauge Tool Part No Forklift Fork Wear Forklift fork wear (knowing when your forks need replacing) you should check your forks to make sure they haven’t been worn too. The fork wear caliper can also be used as inside calipers for measuring the bore or bushing on shaft/pin type forks. Please follow the steps outlined in this guide to ensure. How to use the professional fork wear. Forklift Fork Wear.

From www.municayma.gob.pe

Fork Wear GaugeForkliftWear Calliper for Forks Lèvepalettes Forklift Fork Wear Please follow the steps outlined in this guide to ensure. Just open the jaws at the top and close the teeth around the shank to verify the fork diameter which would either be 35, 40, 45, or 50mm. Just open the jaws at the top of the gauge and close the teeth around the shank to verify the fork diameter. Forklift Fork Wear.

From www.slideshare.net

Forklift Fork Maintenance Caliper Guide from Cascade Corporation Forklift Fork Wear Begin by setting the caliper by the thickness of the shank. How to use the professional fork wear gauge. The fork wear caliper can also be used as inside calipers for measuring the bore or bushing on shaft/pin type forks. All fork inspections must follow the requirements of the lifting operations and lifting equipment regulations loler) 1998; Please follow the. Forklift Fork Wear.

From www.forklifttines.com.au

Forklift Tines Rubber Forklift Tyne Grip Covers 125 x 1830mm Forklift Fork Wear Just open the jaws at the top and close the teeth around the shank to verify the fork diameter which would either be 35, 40, 45, or 50mm. The fork wear caliper can also be used as inside calipers for measuring the bore or bushing on shaft/pin type forks. The professional fork wear gauge measures the thickness of forklift forks. Forklift Fork Wear.

From www.drivingtests.co.nz

How to measure wear on a forklift's forks Forklift Fork Wear No callipers or calculations required! Forklift fork wear (knowing when your forks need replacing) you should check your forks to make sure they haven’t been worn too. Please follow the steps outlined in this guide to ensure. The fork wear caliper can also be used as inside calipers for measuring the bore or bushing on shaft/pin type forks. All fork. Forklift Fork Wear.

From www.forklift-attachments.co.uk

Fork Heel Wear Protectors Forklift Forks & Pallet Tines Forklift Fork Wear Just open the jaws at the top of the gauge and close the teeth around the shank to verify the fork diameter which would be either 35, 40, 45 or 50mm. The professional fork wear gauge measures the thickness of forklift forks or tynes as they wear over time with continued use. The fork wear caliper can also be used. Forklift Fork Wear.

From www.youtube.com

Forklift Operator Safety Proper Fork Height for Driving YouTube Forklift Fork Wear The fork wear caliper can also be used as inside calipers for measuring the bore or bushing on shaft/pin type forks. Begin by setting the caliper by the thickness of the shank. All fork inspections must follow the requirements of the lifting operations and lifting equipment regulations loler) 1998; Forklift fork wear (knowing when your forks need replacing) you should. Forklift Fork Wear.

From liftway.ca

FORK INSPECTION Tips & Guidelines Forklift Fork Wear How to use the professional fork wear gauge. Please follow the steps outlined in this guide to ensure. Forklift fork wear (knowing when your forks need replacing) you should check your forks to make sure they haven’t been worn too. The fork wear caliper can also be used as inside calipers for measuring the bore or bushing on shaft/pin type. Forklift Fork Wear.

From sinoliftforklift.com

Do you need to wear a harness when using a forklift cage? SINOLIFT Forklift Fork Wear All fork inspections must follow the requirements of the lifting operations and lifting equipment regulations loler) 1998; Forklift fork wear (knowing when your forks need replacing) you should check your forks to make sure they haven’t been worn too. Please follow the steps outlined in this guide to ensure. The fork wear caliper can also be used as inside calipers. Forklift Fork Wear.

From www.forkliftamerica.com

Forklift Fork Wear Gauge Calipers Forklift America Forklift Fork Wear Please follow the steps outlined in this guide to ensure. How to use the professional fork wear gauge. All fork inspections must follow the requirements of the lifting operations and lifting equipment regulations loler) 1998; Begin by setting the caliper by the thickness of the shank. Just open the jaws at the top and close the teeth around the shank. Forklift Fork Wear.

From www.forklift-attachments.co.uk

Fork Heel Wear Protectors Forklift Forks & Pallet Tines Forklift Fork Wear The fork wear caliper can also be used as inside calipers for measuring the bore or bushing on shaft/pin type forks. Forklift fork wear (knowing when your forks need replacing) you should check your forks to make sure they haven’t been worn too. No callipers or calculations required! How to use the professional fork wear gauge. Begin by setting the. Forklift Fork Wear.

From www.drivingtests.co.nz

How to measure wear on a forklift's forks Forklift Fork Wear Just open the jaws at the top and close the teeth around the shank to verify the fork diameter which would either be 35, 40, 45, or 50mm. How to use the professional fork wear gauge. The professional fork wear gauge measures the thickness of forklift forks or tynes as they wear over time with continued use. Begin by setting. Forklift Fork Wear.

From www.municayma.gob.pe

Fork Wear GaugeForkliftWear Calliper for Forks Lèvepalettes Forklift Fork Wear All fork inspections must follow the requirements of the lifting operations and lifting equipment regulations loler) 1998; The fork wear caliper can also be used as inside calipers for measuring the bore or bushing on shaft/pin type forks. Just open the jaws at the top and close the teeth around the shank to verify the fork diameter which would either. Forklift Fork Wear.

From www.forklift-attachments.co.uk

Fork Protectors Forklift Forks & Pallet Tines Forklift Attachments Forklift Fork Wear No callipers or calculations required! Forklift fork wear (knowing when your forks need replacing) you should check your forks to make sure they haven’t been worn too. How to use the professional fork wear gauge. Begin by setting the caliper by the thickness of the shank. The professional fork wear gauge measures the thickness of forklift forks or tynes as. Forklift Fork Wear.

From www.slideshare.net

Forklift Tire and Chain Wear Charts Forklift Fork Wear How to use the professional fork wear gauge. Just open the jaws at the top and close the teeth around the shank to verify the fork diameter which would either be 35, 40, 45, or 50mm. No callipers or calculations required! All fork inspections must follow the requirements of the lifting operations and lifting equipment regulations loler) 1998; The professional. Forklift Fork Wear.

From www.conger.com

Forklift Forks Everything You Need to Know Conger Industries Inc Forklift Fork Wear The fork wear caliper can also be used as inside calipers for measuring the bore or bushing on shaft/pin type forks. Please follow the steps outlined in this guide to ensure. Just open the jaws at the top and close the teeth around the shank to verify the fork diameter which would either be 35, 40, 45, or 50mm. Just. Forklift Fork Wear.

From www.liftinggeardirect.co.uk

FFB Forklift Fork Bumpers Fork Load Buffers Lifting Gear Direct Forklift Fork Wear No callipers or calculations required! The professional fork wear gauge measures the thickness of forklift forks or tynes as they wear over time with continued use. Begin by setting the caliper by the thickness of the shank. Just open the jaws at the top and close the teeth around the shank to verify the fork diameter which would either be. Forklift Fork Wear.

From www.lsforklifts.com

HYSTER WEAR PAD (LS4237) Lsfork Lifts Forklift Fork Wear The professional fork wear gauge measures the thickness of forklift forks or tynes as they wear over time with continued use. No callipers or calculations required! All fork inspections must follow the requirements of the lifting operations and lifting equipment regulations loler) 1998; Just open the jaws at the top of the gauge and close the teeth around the shank. Forklift Fork Wear.

From www.forkliftamerica.com

Forklift Fork Wear Gauge Calipers Forklift America Forklift Fork Wear Just open the jaws at the top and close the teeth around the shank to verify the fork diameter which would either be 35, 40, 45, or 50mm. Forklift fork wear (knowing when your forks need replacing) you should check your forks to make sure they haven’t been worn too. Begin by setting the caliper by the thickness of the. Forklift Fork Wear.

From www.safetysigns4less.co.uk

Fork Lift Truck Safety Poster Safety Posters First Aid Posters Forklift Fork Wear Begin by setting the caliper by the thickness of the shank. Just open the jaws at the top of the gauge and close the teeth around the shank to verify the fork diameter which would be either 35, 40, 45 or 50mm. All fork inspections must follow the requirements of the lifting operations and lifting equipment regulations loler) 1998; The. Forklift Fork Wear.

From www.dreamstime.com

Male Worker in Safety Vest and Helmet Sitting in Forklift Machine Stock Forklift Fork Wear No callipers or calculations required! All fork inspections must follow the requirements of the lifting operations and lifting equipment regulations loler) 1998; The professional fork wear gauge measures the thickness of forklift forks or tynes as they wear over time with continued use. Forklift fork wear (knowing when your forks need replacing) you should check your forks to make sure. Forklift Fork Wear.

From www.youtube.com

How to check wear and tear on your forklift forks. When to replace your Forklift Fork Wear Just open the jaws at the top and close the teeth around the shank to verify the fork diameter which would either be 35, 40, 45, or 50mm. The professional fork wear gauge measures the thickness of forklift forks or tynes as they wear over time with continued use. All fork inspections must follow the requirements of the lifting operations. Forklift Fork Wear.

From www.forkweargauge.com

Professional Fork Wear Gauge measure wear on forklift forks FB Chain Forklift Fork Wear No callipers or calculations required! Begin by setting the caliper by the thickness of the shank. Please follow the steps outlined in this guide to ensure. Just open the jaws at the top and close the teeth around the shank to verify the fork diameter which would either be 35, 40, 45, or 50mm. Forklift fork wear (knowing when your. Forklift Fork Wear.

From www.forkliftamerica.com

Forklift Fork Wear Gauge Calipers Forklift America Forklift Fork Wear Just open the jaws at the top of the gauge and close the teeth around the shank to verify the fork diameter which would be either 35, 40, 45 or 50mm. The professional fork wear gauge measures the thickness of forklift forks or tynes as they wear over time with continued use. All fork inspections must follow the requirements of. Forklift Fork Wear.

From www.keysigns.co.uk

Fork Lift Trucks Operating Wear High Visibility Clothing Signs from Forklift Fork Wear Forklift fork wear (knowing when your forks need replacing) you should check your forks to make sure they haven’t been worn too. The fork wear caliper can also be used as inside calipers for measuring the bore or bushing on shaft/pin type forks. No callipers or calculations required! How to use the professional fork wear gauge. Just open the jaws. Forklift Fork Wear.