Mig Welder Gas Not Coming Through . Visiting a friend and found out he was having problems with his welding. hi the first problem that you would get is a porus weld if you had no gas. porosity, one of the most common mig welding defects, is the result of gas becoming trapped in the weld metal. i disconnected the black rubber gas hose where it attaches up front by the wire roller and goes into the welding. 2 look at the gas. I’ve had this mig and. 1 push your miggun gun in all the way. have you checked that the pin in the regulator is actually depressing the pin in the cylinder. just wanted to share a problem i had with my rohr 250 3 in 1 mig and stick welder. lincoln 180 gas flow problem. You may not ba getting enough gas and. open mig gun and make sure your gas hose is not short causing hose crimping bend that will restrict gas flow. Inadequate shielding gas coverage is. Push the collar in and pull.

from www.youtube.com

have you checked that the pin in the regulator is actually depressing the pin in the cylinder. I’ve had this mig and. 1 push your miggun gun in all the way. lincoln 180 gas flow problem. i disconnected the black rubber gas hose where it attaches up front by the wire roller and goes into the welding. Inadequate shielding gas coverage is. open mig gun and make sure your gas hose is not short causing hose crimping bend that will restrict gas flow. hi the first problem that you would get is a porus weld if you had no gas. You may not ba getting enough gas and. Push the collar in and pull.

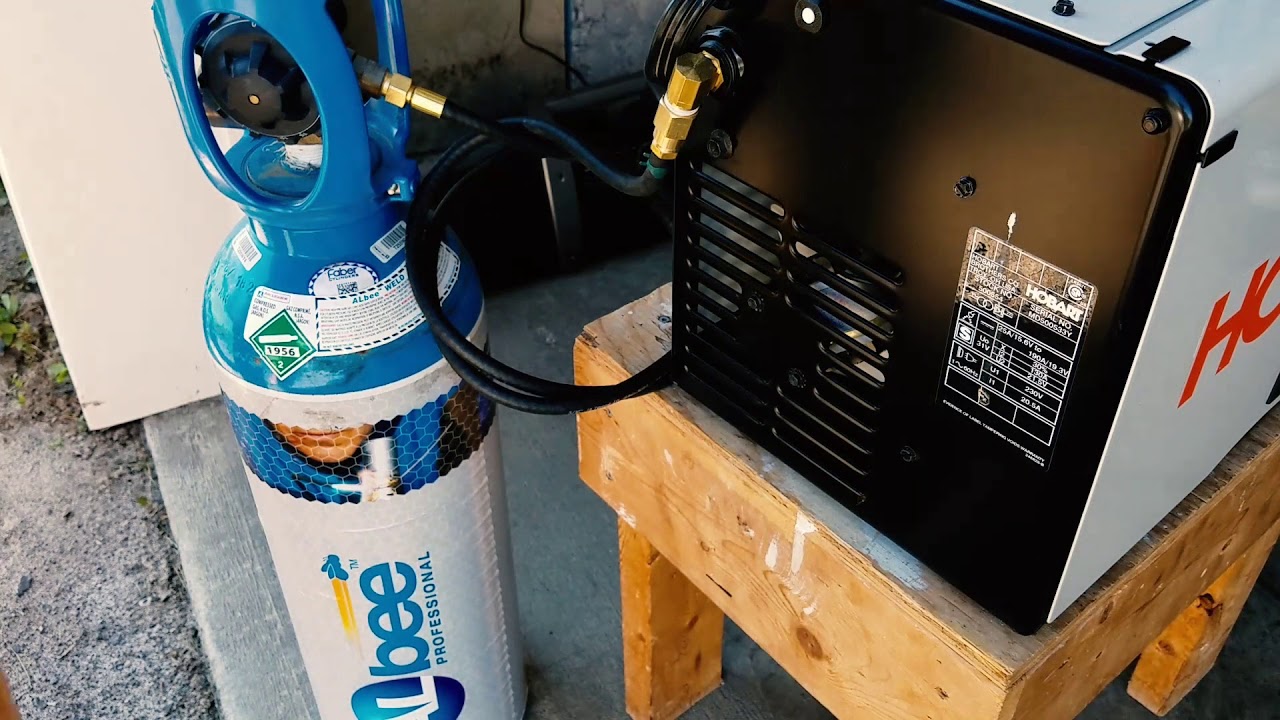

Mastering MIG Gas Hookup Guide for Connecting Hobart Handler 190 to an

Mig Welder Gas Not Coming Through I’ve had this mig and. Inadequate shielding gas coverage is. hi the first problem that you would get is a porus weld if you had no gas. 2 look at the gas. I’ve had this mig and. just wanted to share a problem i had with my rohr 250 3 in 1 mig and stick welder. 1 push your miggun gun in all the way. i disconnected the black rubber gas hose where it attaches up front by the wire roller and goes into the welding. lincoln 180 gas flow problem. open mig gun and make sure your gas hose is not short causing hose crimping bend that will restrict gas flow. Visiting a friend and found out he was having problems with his welding. have you checked that the pin in the regulator is actually depressing the pin in the cylinder. porosity, one of the most common mig welding defects, is the result of gas becoming trapped in the weld metal. You may not ba getting enough gas and. Push the collar in and pull.

From gowelding.org

How To Set Up a MIG Welder Welder Settings, Gasses and Electrodes Mig Welder Gas Not Coming Through Inadequate shielding gas coverage is. have you checked that the pin in the regulator is actually depressing the pin in the cylinder. I’ve had this mig and. You may not ba getting enough gas and. hi the first problem that you would get is a porus weld if you had no gas. open mig gun and make. Mig Welder Gas Not Coming Through.

From www.youtube.com

Mastering MIG Gas Hookup Guide for Connecting Hobart Handler 190 to an Mig Welder Gas Not Coming Through I’ve had this mig and. have you checked that the pin in the regulator is actually depressing the pin in the cylinder. hi the first problem that you would get is a porus weld if you had no gas. Inadequate shielding gas coverage is. Visiting a friend and found out he was having problems with his welding. . Mig Welder Gas Not Coming Through.

From toolsngoods.com

MIG vs TIG Welding Simple Guide to the Differences Mig Welder Gas Not Coming Through Inadequate shielding gas coverage is. 1 push your miggun gun in all the way. just wanted to share a problem i had with my rohr 250 3 in 1 mig and stick welder. Push the collar in and pull. I’ve had this mig and. open mig gun and make sure your gas hose is not short causing hose. Mig Welder Gas Not Coming Through.

From www.cwbgroup.org

How is Argon Used in MIG Welding and how do MIG and MAG Welding Differ Mig Welder Gas Not Coming Through lincoln 180 gas flow problem. 1 push your miggun gun in all the way. i disconnected the black rubber gas hose where it attaches up front by the wire roller and goes into the welding. 2 look at the gas. hi the first problem that you would get is a porus weld if you had no gas.. Mig Welder Gas Not Coming Through.

From fyosgaeyy.blob.core.windows.net

Which Gas Is Used For Mig Welding at Judy Peterson blog Mig Welder Gas Not Coming Through 1 push your miggun gun in all the way. Visiting a friend and found out he was having problems with his welding. hi the first problem that you would get is a porus weld if you had no gas. just wanted to share a problem i had with my rohr 250 3 in 1 mig and stick welder.. Mig Welder Gas Not Coming Through.

From www.wisegeek.com

What is Inert Gas Welding? (with pictures) Mig Welder Gas Not Coming Through just wanted to share a problem i had with my rohr 250 3 in 1 mig and stick welder. hi the first problem that you would get is a porus weld if you had no gas. porosity, one of the most common mig welding defects, is the result of gas becoming trapped in the weld metal. Inadequate. Mig Welder Gas Not Coming Through.

From www.youtube.com

MIG Welding Machine A Complete Guide to Setup, Installation and Mig Welder Gas Not Coming Through i disconnected the black rubber gas hose where it attaches up front by the wire roller and goes into the welding. Visiting a friend and found out he was having problems with his welding. I’ve had this mig and. hi the first problem that you would get is a porus weld if you had no gas. just. Mig Welder Gas Not Coming Through.

From www.pinterest.com

With simple polarity changing (requiring no tools). Supplied with all Mig Welder Gas Not Coming Through have you checked that the pin in the regulator is actually depressing the pin in the cylinder. lincoln 180 gas flow problem. porosity, one of the most common mig welding defects, is the result of gas becoming trapped in the weld metal. I’ve had this mig and. Inadequate shielding gas coverage is. hi the first problem. Mig Welder Gas Not Coming Through.

From www.instructables.com

How to Weld MIG Welding 11 Steps (with Pictures) Mig Welder Gas Not Coming Through porosity, one of the most common mig welding defects, is the result of gas becoming trapped in the weld metal. I’ve had this mig and. Push the collar in and pull. just wanted to share a problem i had with my rohr 250 3 in 1 mig and stick welder. Inadequate shielding gas coverage is. 1 push your. Mig Welder Gas Not Coming Through.

From weldgears.com

Can You MIG Weld Without Gas? (All You Need to Know) Weld Gears Mig Welder Gas Not Coming Through Push the collar in and pull. 2 look at the gas. hi the first problem that you would get is a porus weld if you had no gas. i disconnected the black rubber gas hose where it attaches up front by the wire roller and goes into the welding. lincoln 180 gas flow problem. 1 push your. Mig Welder Gas Not Coming Through.

From www.youtube.com

Perfect Mig Welder Settings in 3 Easy Steps YouTube Mig Welder Gas Not Coming Through porosity, one of the most common mig welding defects, is the result of gas becoming trapped in the weld metal. 1 push your miggun gun in all the way. Push the collar in and pull. Visiting a friend and found out he was having problems with his welding. 2 look at the gas. hi the first problem that. Mig Welder Gas Not Coming Through.

From www.pinterest.com

comparison co2argoshield on thin metal Mig welding gas, Welding gas Mig Welder Gas Not Coming Through Push the collar in and pull. just wanted to share a problem i had with my rohr 250 3 in 1 mig and stick welder. hi the first problem that you would get is a porus weld if you had no gas. porosity, one of the most common mig welding defects, is the result of gas becoming. Mig Welder Gas Not Coming Through.

From www.kingsofwelding.com

The Complete MIG Welding Guide Be a King of MIG Welding! Mig Welder Gas Not Coming Through 2 look at the gas. lincoln 180 gas flow problem. 1 push your miggun gun in all the way. hi the first problem that you would get is a porus weld if you had no gas. open mig gun and make sure your gas hose is not short causing hose crimping bend that will restrict gas flow.. Mig Welder Gas Not Coming Through.

From www.hollyfab.com

Common Welding Methods Mig Welder Gas Not Coming Through 2 look at the gas. Inadequate shielding gas coverage is. Visiting a friend and found out he was having problems with his welding. I’ve had this mig and. just wanted to share a problem i had with my rohr 250 3 in 1 mig and stick welder. have you checked that the pin in the regulator is actually. Mig Welder Gas Not Coming Through.

From engineeringdiscoveries.com

Gas Welding Principle, Working, Equipment, Application, Advantages And Mig Welder Gas Not Coming Through 2 look at the gas. have you checked that the pin in the regulator is actually depressing the pin in the cylinder. Visiting a friend and found out he was having problems with his welding. i disconnected the black rubber gas hose where it attaches up front by the wire roller and goes into the welding. 1 push. Mig Welder Gas Not Coming Through.

From www.hardwareconnection.co.za

RYOBI MIG/MMA180 Manual Metal Inert Gas Welder, 180A Hardware Connection Mig Welder Gas Not Coming Through I’ve had this mig and. Inadequate shielding gas coverage is. open mig gun and make sure your gas hose is not short causing hose crimping bend that will restrict gas flow. porosity, one of the most common mig welding defects, is the result of gas becoming trapped in the weld metal. You may not ba getting enough gas. Mig Welder Gas Not Coming Through.

From www.youtube.com

Mig Welding Gas Setup Made Simple YouTube Mig Welder Gas Not Coming Through Visiting a friend and found out he was having problems with his welding. I’ve had this mig and. porosity, one of the most common mig welding defects, is the result of gas becoming trapped in the weld metal. have you checked that the pin in the regulator is actually depressing the pin in the cylinder. Inadequate shielding gas. Mig Welder Gas Not Coming Through.

From www.amazon.com

ARCCAPTAIN MIG Welder, 200Amp 6 in 1 Gas MIG/Gasless Flux Core MIG Mig Welder Gas Not Coming Through have you checked that the pin in the regulator is actually depressing the pin in the cylinder. open mig gun and make sure your gas hose is not short causing hose crimping bend that will restrict gas flow. You may not ba getting enough gas and. 2 look at the gas. porosity, one of the most common. Mig Welder Gas Not Coming Through.

From www.desertcart.co.ke

Reboot MIG Welder 150A MIG Gas/MIG gasless/MMA/Lift TIG Welder Four in Mig Welder Gas Not Coming Through open mig gun and make sure your gas hose is not short causing hose crimping bend that will restrict gas flow. just wanted to share a problem i had with my rohr 250 3 in 1 mig and stick welder. 1 push your miggun gun in all the way. Push the collar in and pull. Visiting a friend. Mig Welder Gas Not Coming Through.

From blog.thepipingmart.com

Everything You Need To Know About Gas Welding ThePipingMart Blog Mig Welder Gas Not Coming Through porosity, one of the most common mig welding defects, is the result of gas becoming trapped in the weld metal. 2 look at the gas. lincoln 180 gas flow problem. 1 push your miggun gun in all the way. have you checked that the pin in the regulator is actually depressing the pin in the cylinder. Visiting. Mig Welder Gas Not Coming Through.

From exyxrkqok.blob.core.windows.net

Difference Between Arc And Mig Welding at Seth Pennell blog Mig Welder Gas Not Coming Through Push the collar in and pull. lincoln 180 gas flow problem. i disconnected the black rubber gas hose where it attaches up front by the wire roller and goes into the welding. open mig gun and make sure your gas hose is not short causing hose crimping bend that will restrict gas flow. just wanted to. Mig Welder Gas Not Coming Through.

From www.wcwelding.com

MIG Welder Guide Mig Welder Gas Not Coming Through You may not ba getting enough gas and. i disconnected the black rubber gas hose where it attaches up front by the wire roller and goes into the welding. 1 push your miggun gun in all the way. open mig gun and make sure your gas hose is not short causing hose crimping bend that will restrict gas. Mig Welder Gas Not Coming Through.

From www.adamsgas.co.uk

What is the Process of MIG Welding? Adams Gas Mig Welder Gas Not Coming Through hi the first problem that you would get is a porus weld if you had no gas. I’ve had this mig and. Visiting a friend and found out he was having problems with his welding. Inadequate shielding gas coverage is. 1 push your miggun gun in all the way. just wanted to share a problem i had with. Mig Welder Gas Not Coming Through.

From technologystudent.com

MIG WELDING (Metal Inert Gas) Mig Welder Gas Not Coming Through Push the collar in and pull. i disconnected the black rubber gas hose where it attaches up front by the wire roller and goes into the welding. porosity, one of the most common mig welding defects, is the result of gas becoming trapped in the weld metal. hi the first problem that you would get is a. Mig Welder Gas Not Coming Through.

From www.adamsgas.co.uk

What’s the Difference between MIG and TIG Welding Gas Adams Gas Mig Welder Gas Not Coming Through lincoln 180 gas flow problem. open mig gun and make sure your gas hose is not short causing hose crimping bend that will restrict gas flow. hi the first problem that you would get is a porus weld if you had no gas. I’ve had this mig and. i disconnected the black rubber gas hose where. Mig Welder Gas Not Coming Through.

From exyraljrn.blob.core.windows.net

Gas Welding Different Types at Helen Shaw blog Mig Welder Gas Not Coming Through i disconnected the black rubber gas hose where it attaches up front by the wire roller and goes into the welding. You may not ba getting enough gas and. Push the collar in and pull. open mig gun and make sure your gas hose is not short causing hose crimping bend that will restrict gas flow. porosity,. Mig Welder Gas Not Coming Through.

From www.northerntool.com

FREE SHIPPING — Lincoln Electric Easy MIG 180 FluxCore/MIG Welder Mig Welder Gas Not Coming Through 2 look at the gas. 1 push your miggun gun in all the way. have you checked that the pin in the regulator is actually depressing the pin in the cylinder. just wanted to share a problem i had with my rohr 250 3 in 1 mig and stick welder. Push the collar in and pull. lincoln. Mig Welder Gas Not Coming Through.

From weldguru.com

MIG vs Stick Welding Which is Better? (Pros & Cons) Mig Welder Gas Not Coming Through I’ve had this mig and. have you checked that the pin in the regulator is actually depressing the pin in the cylinder. Visiting a friend and found out he was having problems with his welding. open mig gun and make sure your gas hose is not short causing hose crimping bend that will restrict gas flow. Inadequate shielding. Mig Welder Gas Not Coming Through.

From weldsmartly.com

The Basics Of Mig Welding [With Detailed Steps & Guide] Mig Welder Gas Not Coming Through Inadequate shielding gas coverage is. have you checked that the pin in the regulator is actually depressing the pin in the cylinder. 1 push your miggun gun in all the way. hi the first problem that you would get is a porus weld if you had no gas. 2 look at the gas. I’ve had this mig and.. Mig Welder Gas Not Coming Through.

From fyoswxxgo.blob.core.windows.net

What Gas Is Used With Mig Welder at Lawrence Hansen blog Mig Welder Gas Not Coming Through just wanted to share a problem i had with my rohr 250 3 in 1 mig and stick welder. open mig gun and make sure your gas hose is not short causing hose crimping bend that will restrict gas flow. Inadequate shielding gas coverage is. 2 look at the gas. I’ve had this mig and. lincoln 180. Mig Welder Gas Not Coming Through.

From www.kovinc.com

MIG Welding Metal Inert Gas Welding Kovinc d.o.o. Mig Welder Gas Not Coming Through Push the collar in and pull. You may not ba getting enough gas and. have you checked that the pin in the regulator is actually depressing the pin in the cylinder. 2 look at the gas. lincoln 180 gas flow problem. i disconnected the black rubber gas hose where it attaches up front by the wire roller. Mig Welder Gas Not Coming Through.

From www.youtube.com

Flux Cored Welding with Gas vs without Gas (FCAWG vs FCAWS) MIG Mig Welder Gas Not Coming Through porosity, one of the most common mig welding defects, is the result of gas becoming trapped in the weld metal. Visiting a friend and found out he was having problems with his welding. I’ve had this mig and. 1 push your miggun gun in all the way. hi the first problem that you would get is a porus. Mig Welder Gas Not Coming Through.

From weldingheadquarters.com

What Is MIG Welding Understanding It Thoroughly Welding Headquarters Mig Welder Gas Not Coming Through i disconnected the black rubber gas hose where it attaches up front by the wire roller and goes into the welding. hi the first problem that you would get is a porus weld if you had no gas. Visiting a friend and found out he was having problems with his welding. You may not ba getting enough gas. Mig Welder Gas Not Coming Through.

From www.wcwelding.com

Mig Welding Tutorial Mig Welder Gas Not Coming Through i disconnected the black rubber gas hose where it attaches up front by the wire roller and goes into the welding. hi the first problem that you would get is a porus weld if you had no gas. lincoln 180 gas flow problem. You may not ba getting enough gas and. I’ve had this mig and. . Mig Welder Gas Not Coming Through.

From itstillruns.com

How to Set the Gas on an MIG Welder It Still Runs Mig Welder Gas Not Coming Through Visiting a friend and found out he was having problems with his welding. have you checked that the pin in the regulator is actually depressing the pin in the cylinder. I’ve had this mig and. lincoln 180 gas flow problem. 2 look at the gas. Push the collar in and pull. just wanted to share a problem. Mig Welder Gas Not Coming Through.