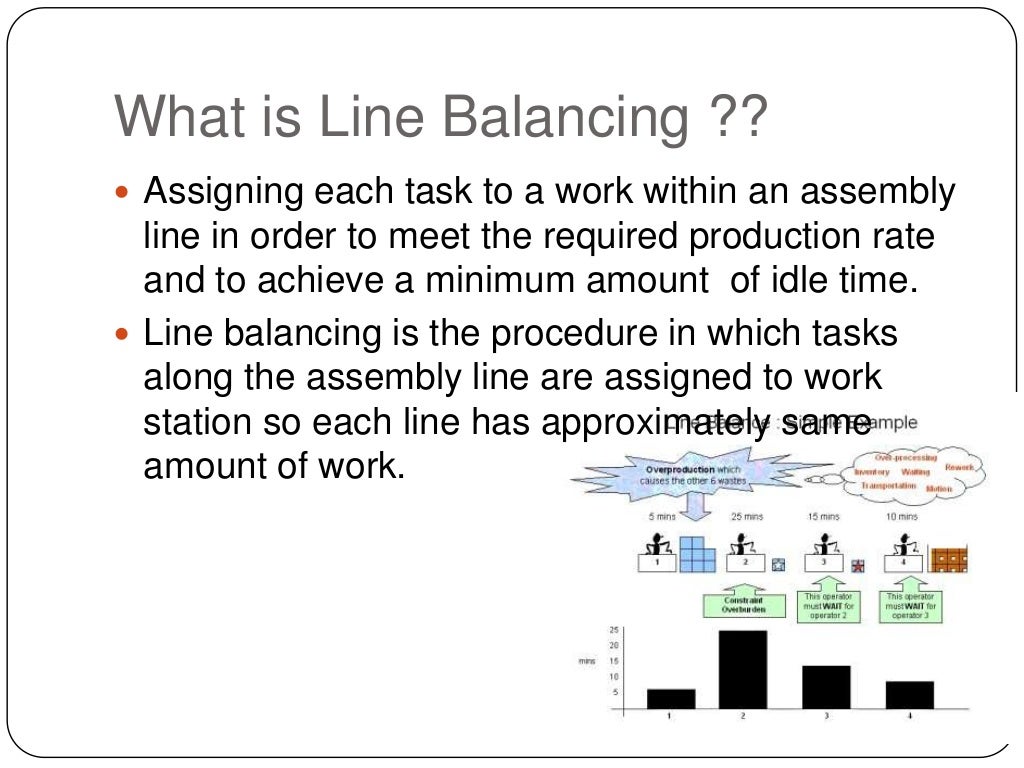

Manufacturing Balancing Process . Line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. By reducing idle time, line balancing. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves. This is done by breaking down the tasks. Discover different methods such as. Determine the required takt time for a product manufacturing line. Learn how to balance your manufacturing line for optimal performance and efficiency. Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a manufacturing line. Line balancing, a fundamental principle in lean manufacturing, involves the even distribution and timing of tasks across. Reduce the wastage from the manufacturing process. We can achieve production line balancing in the following steps.

from pt.slideshare.net

This is done by breaking down the tasks. Line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. We can achieve production line balancing in the following steps. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves. Reduce the wastage from the manufacturing process. Learn how to balance your manufacturing line for optimal performance and efficiency. By reducing idle time, line balancing. Determine the required takt time for a product manufacturing line. Discover different methods such as. Line balancing, a fundamental principle in lean manufacturing, involves the even distribution and timing of tasks across.

assembly line balancing

Manufacturing Balancing Process Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves. Determine the required takt time for a product manufacturing line. Line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a manufacturing line. Line balancing, a fundamental principle in lean manufacturing, involves the even distribution and timing of tasks across. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves. By reducing idle time, line balancing. This is done by breaking down the tasks. We can achieve production line balancing in the following steps. Discover different methods such as. Learn how to balance your manufacturing line for optimal performance and efficiency. Reduce the wastage from the manufacturing process.

From evisualcontrol.com

สมดุลการผลิต Line Balancing Factory Visual Control รับทำ Manufacturing Balancing Process Learn how to balance your manufacturing line for optimal performance and efficiency. Line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. This is done by breaking down the tasks. By reducing idle time, line balancing. Line balancing, a fundamental principle in lean manufacturing, involves the even distribution and timing of. Manufacturing Balancing Process.

From template.mapadapalavra.ba.gov.br

Line Balancing Template Manufacturing Balancing Process Discover different methods such as. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves. By reducing idle time, line balancing. Determine the required takt time for a product manufacturing line. We can achieve production line balancing in the following steps. Line balancing, a. Manufacturing Balancing Process.

From www.slideserve.com

PPT Dynamic Balancing Services PowerPoint Presentation, free download Manufacturing Balancing Process We can achieve production line balancing in the following steps. Learn how to balance your manufacturing line for optimal performance and efficiency. This is done by breaking down the tasks. By reducing idle time, line balancing. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the. Manufacturing Balancing Process.

From www.youtube.com

Process Diagrams and Mass Balance YouTube Manufacturing Balancing Process This is done by breaking down the tasks. By reducing idle time, line balancing. Reduce the wastage from the manufacturing process. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves. Learn how to balance your manufacturing line for optimal performance and efficiency. We. Manufacturing Balancing Process.

From www.youtube.com

WHAT IS BALANCING??TYPES??CAUSES??EFFECTS??THEORY OF MACHINES YouTube Manufacturing Balancing Process Line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. Determine the required takt time for a product manufacturing line. Learn how to balance your manufacturing line for optimal performance and efficiency. Reduce the wastage from the manufacturing process. By reducing idle time, line balancing. This is done by breaking down. Manufacturing Balancing Process.

From www.smlease.com

What is production Line Balancing and How to implement it? Manufacturing Balancing Process Line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. By reducing idle time, line balancing. We can achieve production line balancing in the following steps. Reduce the wastage from the manufacturing process. Line balancing, a fundamental principle in lean manufacturing, involves the even distribution and timing of tasks across. Assembly. Manufacturing Balancing Process.

From aai.solutions

Critical Analysis Points in the VCM Balanced Process Manufacturing Balancing Process Reduce the wastage from the manufacturing process. Determine the required takt time for a product manufacturing line. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves. Discover different methods such as. Learn how to balance your manufacturing line for optimal performance and efficiency.. Manufacturing Balancing Process.

From www.youtube.com

Assembly Line Balancing YouTube Manufacturing Balancing Process Reduce the wastage from the manufacturing process. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves. Line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. This is done by breaking down the tasks.. Manufacturing Balancing Process.

From www.youtube.com

Mass Balance For Process Modeling YouTube Manufacturing Balancing Process Line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. By reducing idle time, line balancing. Reduce the wastage from the manufacturing process. Discover different methods such as. Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within. Manufacturing Balancing Process.

From www.slideserve.com

PPT Line Balancing PowerPoint Presentation ID203412 Manufacturing Balancing Process Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a manufacturing line. Line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. We can achieve production line balancing in the following steps. Determine the required takt time. Manufacturing Balancing Process.

From www.linkedin.com

What is Bottleneck Analysis in Lean manufacturing ? Bottleneck Manufacturing Balancing Process By reducing idle time, line balancing. Learn how to balance your manufacturing line for optimal performance and efficiency. This is done by breaking down the tasks. Determine the required takt time for a product manufacturing line. Line balancing, a fundamental principle in lean manufacturing, involves the even distribution and timing of tasks across. Discover different methods such as. Line balancing. Manufacturing Balancing Process.

From www.simul8.com

Implementing Line Balancing Methods with Simulation SIMUL8 Manufacturing Balancing Process Discover different methods such as. Determine the required takt time for a product manufacturing line. We can achieve production line balancing in the following steps. By reducing idle time, line balancing. This is done by breaking down the tasks. Reduce the wastage from the manufacturing process. Line balancing in production management refers to the process of distributing work tasks and. Manufacturing Balancing Process.

From www.tetrahedron.in

Line Balancing in Manufacturing Training Tetrahedron Manufacturing Balancing Process This is done by breaking down the tasks. Line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. We can achieve production line balancing in the following steps. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as. Manufacturing Balancing Process.

From www.officetimeline.com

Balanced Scorecard Basics Manufacturing Balancing Process By reducing idle time, line balancing. Determine the required takt time for a product manufacturing line. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves. Line balancing is a process that involves analyzing the production line and determining the ideal workload for each. Manufacturing Balancing Process.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Manufacturing Balancing Process We can achieve production line balancing in the following steps. This is done by breaking down the tasks. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves. Learn how to balance your manufacturing line for optimal performance and efficiency. Discover different methods such. Manufacturing Balancing Process.

From www.mas-software.com

5 Cara Menerapkan Line Balancing untuk Industri Manufaktur Manufacturing Balancing Process Determine the required takt time for a product manufacturing line. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves. We can achieve production line balancing in the following steps. Reduce the wastage from the manufacturing process. Line balancing, a fundamental principle in lean. Manufacturing Balancing Process.

From www.scribd.com

Line Balancing Ppt Inventory Production And Manufacturing Manufacturing Balancing Process Line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. We can achieve production line balancing in the following steps. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves. Reduce the wastage from the. Manufacturing Balancing Process.

From www.researchgate.net

Process flow sheet with mass balance (kg/d) for a production capacity Manufacturing Balancing Process Reduce the wastage from the manufacturing process. Discover different methods such as. We can achieve production line balancing in the following steps. Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a manufacturing line. Determine the required takt time for a product manufacturing line. This is. Manufacturing Balancing Process.

From pt.slideshare.net

assembly line balancing Manufacturing Balancing Process We can achieve production line balancing in the following steps. Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a manufacturing line. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the. Manufacturing Balancing Process.

From pearlengineering.com

Line Balancing Calculating an Optimal Process Pearl Engineering Manufacturing Balancing Process Determine the required takt time for a product manufacturing line. By reducing idle time, line balancing. Line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. Reduce the wastage from the manufacturing process. This is done by breaking down the tasks. Line balancing, a fundamental principle in lean manufacturing, involves the. Manufacturing Balancing Process.

From www.smlease.com

What is production Line Balancing and How to implement it? Manufacturing Balancing Process We can achieve production line balancing in the following steps. Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a manufacturing line. Reduce the wastage from the manufacturing process. This is done by breaking down the tasks. Assembly line balancing (alb) is a process used in. Manufacturing Balancing Process.

From www.proplanner.com

Assembly Process Planning Proplanner Manufacturing Balancing Process Line balancing, a fundamental principle in lean manufacturing, involves the even distribution and timing of tasks across. Discover different methods such as. This is done by breaking down the tasks. Line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. By reducing idle time, line balancing. Assembly line balancing (alb) is. Manufacturing Balancing Process.

From fcc.chalmers.se

Automatic Path Planning and Line BalancingFraunhoferChalmers Centre Manufacturing Balancing Process Learn how to balance your manufacturing line for optimal performance and efficiency. We can achieve production line balancing in the following steps. Line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. This is done by breaking down the tasks. By reducing idle time, line balancing. Line balancing in production management. Manufacturing Balancing Process.

From www.researchgate.net

Main stages of the tire manufacturing process. Download Scientific Manufacturing Balancing Process Line balancing, a fundamental principle in lean manufacturing, involves the even distribution and timing of tasks across. Reduce the wastage from the manufacturing process. Discover different methods such as. This is done by breaking down the tasks. Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within. Manufacturing Balancing Process.

From www.youtube.com

Performing a Material Balance on a Single Unit YouTube Manufacturing Balancing Process By reducing idle time, line balancing. Discover different methods such as. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves. Line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. This is done by. Manufacturing Balancing Process.

From www.researchgate.net

Process flow improvement and line balancing methodology Download Manufacturing Balancing Process Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves. We can achieve production line balancing in the following steps. Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a. Manufacturing Balancing Process.

From www.iscc-system.org

Mass Balance ISCC System Manufacturing Balancing Process Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves. We can achieve production line balancing in the following steps. Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a. Manufacturing Balancing Process.

From www.youtube.com

𝐋𝐢𝐧𝐞 𝐁𝐚𝐥𝐚𝐧𝐜𝐢𝐧𝐠 Production Line Balancing ? Assembly Line Balancing Manufacturing Balancing Process By reducing idle time, line balancing. Learn how to balance your manufacturing line for optimal performance and efficiency. Line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. Reduce the wastage from the manufacturing process. Discover different methods such as. We can achieve production line balancing in the following steps. Determine. Manufacturing Balancing Process.

From collectionperformance.com

Maximizing Efficiency A Guide to Line Balancing in Production Manufacturing Balancing Process This is done by breaking down the tasks. Discover different methods such as. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves. By reducing idle time, line balancing. We can achieve production line balancing in the following steps. Line balancing is a process. Manufacturing Balancing Process.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Manufacturing Balancing Process Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves. By reducing idle time, line balancing. We can achieve production line balancing in the following steps. Line balancing is a process that involves analyzing the production line and determining the ideal workload for each. Manufacturing Balancing Process.

From www.researchgate.net

Mass and energy balance in an integrated steel mill (baseline blast Manufacturing Balancing Process This is done by breaking down the tasks. Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a manufacturing line. Determine the required takt time for a product manufacturing line. Line balancing, a fundamental principle in lean manufacturing, involves the even distribution and timing of tasks. Manufacturing Balancing Process.

From www.youtube.com

Assembly line balancing part3 Line balancing Target IES YouTube Manufacturing Balancing Process We can achieve production line balancing in the following steps. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves. This is done by breaking down the tasks. Determine the required takt time for a product manufacturing line. Discover different methods such as. By. Manufacturing Balancing Process.

From public.amwaly.com

Assembly Line Balancing أموالي Manufacturing Balancing Process Learn how to balance your manufacturing line for optimal performance and efficiency. We can achieve production line balancing in the following steps. Reduce the wastage from the manufacturing process. Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a manufacturing line. Assembly line balancing (alb) is. Manufacturing Balancing Process.

From studiousguy.com

Operations Management StudiousGuy Manufacturing Balancing Process By reducing idle time, line balancing. Discover different methods such as. Learn how to balance your manufacturing line for optimal performance and efficiency. Line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. Line balancing, a fundamental principle in lean manufacturing, involves the even distribution and timing of tasks across. This. Manufacturing Balancing Process.

From www.youtube.com

What is Line Balancing YouTube Manufacturing Balancing Process Line balancing in production management refers to the process of distributing work tasks and activities evenly across different workstations or production stages within a manufacturing line. Learn how to balance your manufacturing line for optimal performance and efficiency. We can achieve production line balancing in the following steps. Discover different methods such as. Assembly line balancing (alb) is a process. Manufacturing Balancing Process.