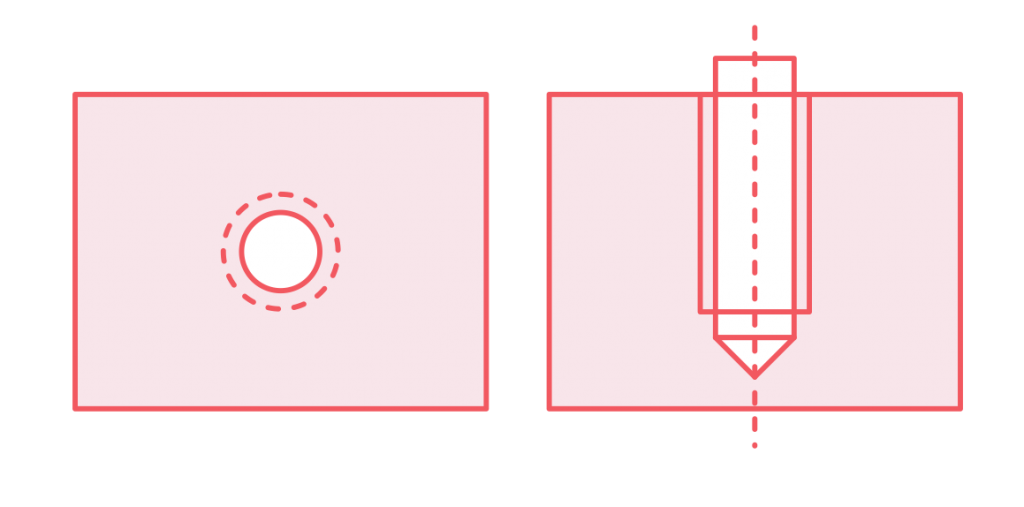

What Is A Blind Hole In Machining . A blind hole is a hole that does not go all the way through a part. This is a complete guide to the types of holes found in machining. A blind hole goes to a specified depth and stops. What the difference is between. What is a blind hole? This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. The different types of holes used in machining. A blind hole, also known as a closed hole or a pocket, refers to a hole that does not go completely through the material. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. In this guide you’ll learn: This deliberate depth is usually less than the total thickness of the material. A blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. How to dimension a blind hole. A blind hole is a carefully designed hole that only partially penetrates the material.

from www.madearia.com

It has a bottom that prevents the hole from. This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. This deliberate depth is usually less than the total thickness of the material. A blind hole goes to a specified depth and stops. A blind hole, also known as a closed hole or a pocket, refers to a hole that does not go completely through the material. A blind hole is a hole that does not go all the way through a part. The different types of holes used in machining. How to dimension a blind hole. This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth.

What Are Blind Holes in Engineering and Machining?

What Is A Blind Hole In Machining This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. What the difference is between. This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. How to dimension a blind hole. This is a complete guide to the types of holes found in machining. A blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. A blind hole, also known as a closed hole or a pocket, refers to a hole that does not go completely through the material. It has a bottom that prevents the hole from. What is a blind hole? A blind hole is a hole that does not go all the way through a part. This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. A blind hole goes to a specified depth and stops. This deliberate depth is usually less than the total thickness of the material. A blind hole is a carefully designed hole that only partially penetrates the material. In this guide you’ll learn:

From rifleshooter.com

Gunsmithing basics Tapping a blind hole What Is A Blind Hole In Machining In this guide you’ll learn: A blind hole goes to a specified depth and stops. This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. This is a complete guide. What Is A Blind Hole In Machining.

From www.machinistguides.com

Guide to Holes on Blueprints [Types, Symbols & Features] Machinist Guides What Is A Blind Hole In Machining A blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side.. What Is A Blind Hole In Machining.

From okdor.com

What is the Difference Between Blind Holes and Through Holes? What Is A Blind Hole In Machining This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. A blind hole is a carefully designed hole that only partially penetrates the material. To specify a. What Is A Blind Hole In Machining.

From www.xometry.com

7 Tips to Help You Design for CNC Machining Xometry What Is A Blind Hole In Machining To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. A blind hole is a hole that does not go all the way through a part. In this guide you’ll. What Is A Blind Hole In Machining.

From at-machining.com

The Engineer's Guide to Blind Holes in Machining ATMachining What Is A Blind Hole In Machining A blind hole, also known as a closed hole or a pocket, refers to a hole that does not go completely through the material. What is a blind hole? A blind hole goes to a specified depth and stops. What the difference is between. This article will explore what a blind hole is, how to make blind holes, and why. What Is A Blind Hole In Machining.

From slidetodoc.com

Holes In Auto CAD COMMON HOLES IN MACHINED What Is A Blind Hole In Machining In this guide you’ll learn: How to dimension a blind hole. This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. A blind hole is a hole that does not go all the way through a part. A blind hole, also known as a closed hole or a. What Is A Blind Hole In Machining.

From www.youtube.com

Tapping 105 blind M5 holes in 6061 aluminum with a Procunier TruTap on What Is A Blind Hole In Machining A blind hole is a carefully designed hole that only partially penetrates the material. This is a complete guide to the types of holes found in machining. In this guide you’ll learn: A blind hole is a hole that does not go all the way through a part. To specify a blind hole requires listing the diameter of the hole. What Is A Blind Hole In Machining.

From www.madearia.com

What Are Blind Holes in Engineering and Machining? What Is A Blind Hole In Machining A blind hole is a hole that does not go all the way through a part. It has a bottom that prevents the hole from. How to dimension a blind hole. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. A blind hole goes to a specified depth and stops.. What Is A Blind Hole In Machining.

From www.youtube.com

VersaDrive® Clutched Tapping System for Blind Hole Threading YouTube What Is A Blind Hole In Machining It has a bottom that prevents the hole from. A blind hole, also known as a closed hole or a pocket, refers to a hole that does not go completely through the material. A blind hole is a hole that does not go all the way through a part. This hole can be reamed, milled, or drilled to a specific. What Is A Blind Hole In Machining.

From www.sansmachining.com

Understanding Blind Holes in Machining SANS What Is A Blind Hole In Machining It has a bottom that prevents the hole from. A blind hole is a hole that does not go all the way through a part. This is a complete guide to the types of holes found in machining. The different types of holes used in machining. In this guide you’ll learn: To specify a blind hole requires listing the diameter. What Is A Blind Hole In Machining.

From www.researchgate.net

Schematic diagram of ULTVAG of the blind hole Download Scientific Diagram What Is A Blind Hole In Machining This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. It has a bottom that prevents the hole from. A blind hole, also known as a closed hole or a pocket, refers to a hole that does not go completely through the material. What is a blind hole?. What Is A Blind Hole In Machining.

From okdor.com

What is the Difference Between Blind Holes and Through Holes? What Is A Blind Hole In Machining A blind hole is a carefully designed hole that only partially penetrates the material. It has a bottom that prevents the hole from. This deliberate depth is usually less than the total thickness of the material. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. The different types of holes. What Is A Blind Hole In Machining.

From docs.cadexchanger.com

CAD Exchanger SDK cadex.Machining_Hole Class Reference What Is A Blind Hole In Machining This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. What the difference is between. The different types of holes used in machining. In this guide you’ll learn: To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. What. What Is A Blind Hole In Machining.

From threadingtoolsguide.com

Difference between through hole and blind hole on threadingtools giude What Is A Blind Hole In Machining To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. A blind hole, also known as a closed hole or a pocket, refers to a hole that does not go completely through the material. A blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the. What Is A Blind Hole In Machining.

From www.cnccookbook.com

Blind Hole Tapping Secrets [ Stop Breaking Taps! ] What Is A Blind Hole In Machining To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. The different types of holes used in machining. How to dimension a blind hole. This is a complete guide. What Is A Blind Hole In Machining.

From www.youtube.com

Blind hole broaching with a CNC mill YouTube What Is A Blind Hole In Machining A blind hole is a hole that does not go all the way through a part. The different types of holes used in machining. What is a blind hole? This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. This deliberate depth is usually less than the total. What Is A Blind Hole In Machining.

From westernmachine.com

Precision Machining Blind Flange for Hydro Component Western What Is A Blind Hole In Machining A blind hole is a carefully designed hole that only partially penetrates the material. A blind hole, also known as a closed hole or a pocket, refers to a hole that does not go completely through the material. This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side.. What Is A Blind Hole In Machining.

From okdor.com

What is the Difference Between Blind Holes and Through Holes? What Is A Blind Hole In Machining A blind hole is a hole that does not go all the way through a part. A blind hole, also known as a closed hole or a pocket, refers to a hole that does not go completely through the material. A blind hole goes to a specified depth and stops. This deliberate depth is usually less than the total thickness. What Is A Blind Hole In Machining.

From rifleshooter.com

Gunsmithing basics Tapping a blind hole What Is A Blind Hole In Machining A blind hole, also known as a closed hole or a pocket, refers to a hole that does not go completely through the material. What the difference is between. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. How to dimension a blind hole. This deliberate depth is usually less. What Is A Blind Hole In Machining.

From eureka.patsnap.com

Blind hole electric pulse machining structure and operation method What Is A Blind Hole In Machining A blind hole goes to a specified depth and stops. What the difference is between. What is a blind hole? This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. This is a complete guide to the types of holes found in machining. This deliberate depth is usually. What Is A Blind Hole In Machining.

From www.ch-machiningparts.com

Blind Hole In Machining What It Is And How To Drill? Knowledge What Is A Blind Hole In Machining What the difference is between. This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. What is a blind hole? How to dimension a blind hole. In. What Is A Blind Hole In Machining.

From www.researchgate.net

Drilling process (a) blind holes (b) through holes [10]. Download What Is A Blind Hole In Machining What the difference is between. This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. It has a bottom that prevents the hole from. The different types of holes used in machining. This hole can be reamed, milled, or drilled to a specific depth without completely going through the. What Is A Blind Hole In Machining.

From okdor.com

10 Expert Tips for Achieving the Perfect CNC Milling Finish What Is A Blind Hole In Machining A blind hole goes to a specified depth and stops. This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. What is a blind hole? What the difference is between. The different types of holes used in machining. A blind hole is a hole that does not go all. What Is A Blind Hole In Machining.

From www.youtube.com

To cut a through hole, blind hole and half hole by Nine9 hole making What Is A Blind Hole In Machining The different types of holes used in machining. In this guide you’ll learn: A blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. This hole can be reamed, milled, or drilled to. What Is A Blind Hole In Machining.

From rifleshooter.com

Gunsmithing basics Tapping a blind hole What Is A Blind Hole In Machining It has a bottom that prevents the hole from. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. What is a blind hole? A blind hole is a. What Is A Blind Hole In Machining.

From www.madearia.com

What Are Blind Holes in Engineering and Machining? What Is A Blind Hole In Machining This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. A blind hole goes to a specified depth and stops. What is a blind hole? This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. In this. What Is A Blind Hole In Machining.

From www.youtube.com

CNC Broaching Blind Internal Keyway YouTube What Is A Blind Hole In Machining In this guide you’ll learn: A blind hole goes to a specified depth and stops. It has a bottom that prevents the hole from. A blind hole is a carefully designed hole that only partially penetrates the material. A blind hole is a hole that does not go all the way through a part. To specify a blind hole requires. What Is A Blind Hole In Machining.

From www.xometry.com

What Are Blind Holes in Engineering and Machining? Xometry What Is A Blind Hole In Machining What the difference is between. A blind hole is a hole that does not go all the way through a part. In this guide you’ll learn: A blind hole is a carefully designed hole that only partially penetrates the material. It has a bottom that prevents the hole from. This is a complete guide to the types of holes found. What Is A Blind Hole In Machining.

From www.researchgate.net

Drilling process (a) blind holes (b) through holes [10]. Download What Is A Blind Hole In Machining How to dimension a blind hole. In this guide you’ll learn: This deliberate depth is usually less than the total thickness of the material. What is a blind hole? This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. A blind hole goes to a specified depth and. What Is A Blind Hole In Machining.

From www.machinistguides.com

Blind Holes All About Machinist Guides What Is A Blind Hole In Machining This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. It has a bottom that prevents the hole from. This hole can be reamed, milled, or drilled to a specific. What Is A Blind Hole In Machining.

From klatsdbza.blob.core.windows.net

What Is A Blind Hole In Drilling at Donny Reily blog What Is A Blind Hole In Machining To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. This is a complete guide to the types of holes found in machining. A blind or pocket hole is. What Is A Blind Hole In Machining.

From www.youtube.com

Sir Meccanica S.p.A. In line boring and overlay welding on a blind What Is A Blind Hole In Machining This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. A blind hole is a carefully designed hole that only partially penetrates the material. In this guide you’ll learn: What the difference is between. What is a blind hole? This deliberate depth is usually less than the total. What Is A Blind Hole In Machining.

From klatsdbza.blob.core.windows.net

What Is A Blind Hole In Drilling at Donny Reily blog What Is A Blind Hole In Machining This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. What is a blind hole? The different types of holes used in machining. A blind hole is a carefully designed hole that only partially penetrates the material. In this guide you’ll learn: This article will explore what a. What Is A Blind Hole In Machining.

From rifleshooter.com

Gunsmithing basics Tapping a blind hole What Is A Blind Hole In Machining This is a complete guide to the types of holes found in machining. It has a bottom that prevents the hole from. This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. This deliberate depth is usually less than the total thickness of the material. The different types of. What Is A Blind Hole In Machining.

From www.researchgate.net

Fast hole EDM drilling models of blindhole stage and breakthroughhole What Is A Blind Hole In Machining This hole can be reamed, milled, or drilled to a specific depth without completely going through the material to the opposite side. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. A blind hole goes to a specified depth and stops. A blind hole is a carefully designed hole that. What Is A Blind Hole In Machining.