Electric Motors Winding . Electric motors are relatively simple mechanical devices, but rewinding them isn't—in fact, it's one project that’s usually best left to the professionals. It’s always important to identify the real cause of burned windings and not just to replace the electric motor. Electrical failures disrupt the power supply to the motor. Voltage spike damage occurs more. Unfavorable operating conditions—whether electrical, mechanical, or environmental—can dramatically shorten the life of an electric motor. This fundamental process dictates the motor’s functionality, influencing its efficiency and overall performance. Motor windings have a different appearance in all these failure situations: The design determines the available torque, the electromagnetic force in the system, the electrical resistance, and therefore the application. Given the sheer number of different motors and winding patterns, the rewinding process can vary greatly. An electric motor winding is a coil made up of a conductor wire such as copper or aluminum and used to produce an electromagnetic field inside. It involves intricately winding copper or aluminum wire around a core, typically made of iron. Motor winding is the backbone of any electrical motor, acting as its circulatory system. The electric motor winding definition is, windings in electric motors are wires that are placed within coils, generally enclosed around a coated flexible iron magnetic core to shape magnetic poles while strengthened with the current.

from www.alamy.com

The design determines the available torque, the electromagnetic force in the system, the electrical resistance, and therefore the application. The electric motor winding definition is, windings in electric motors are wires that are placed within coils, generally enclosed around a coated flexible iron magnetic core to shape magnetic poles while strengthened with the current. Electric motors are relatively simple mechanical devices, but rewinding them isn't—in fact, it's one project that’s usually best left to the professionals. It involves intricately winding copper or aluminum wire around a core, typically made of iron. It’s always important to identify the real cause of burned windings and not just to replace the electric motor. An electric motor winding is a coil made up of a conductor wire such as copper or aluminum and used to produce an electromagnetic field inside. Motor windings have a different appearance in all these failure situations: Voltage spike damage occurs more. Electrical failures disrupt the power supply to the motor. Motor winding is the backbone of any electrical motor, acting as its circulatory system.

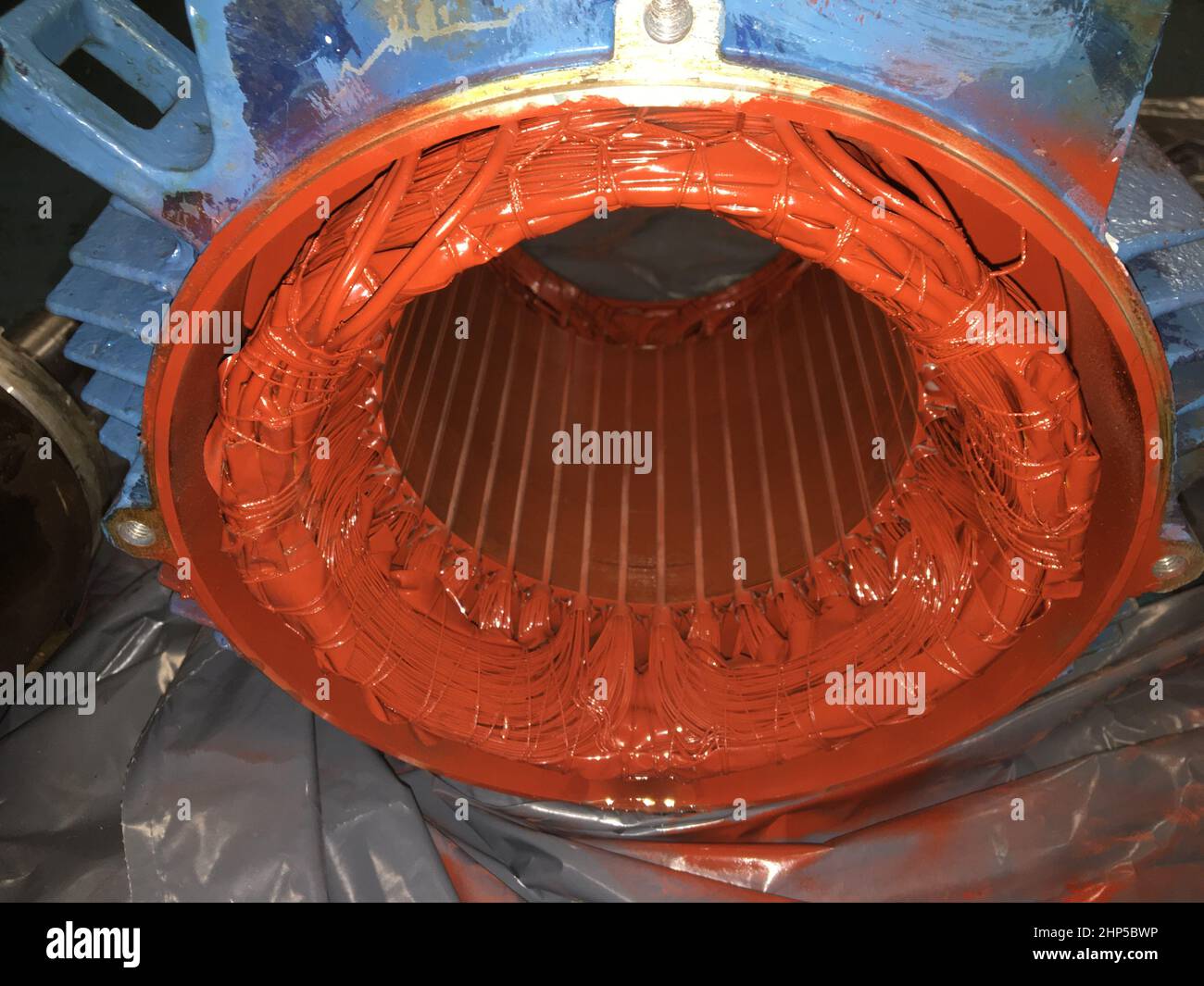

Varnished winding of an electric motor hires stock photography and

Electric Motors Winding The electric motor winding definition is, windings in electric motors are wires that are placed within coils, generally enclosed around a coated flexible iron magnetic core to shape magnetic poles while strengthened with the current. Electrical failures disrupt the power supply to the motor. It’s always important to identify the real cause of burned windings and not just to replace the electric motor. This fundamental process dictates the motor’s functionality, influencing its efficiency and overall performance. Motor winding is the backbone of any electrical motor, acting as its circulatory system. Motor windings have a different appearance in all these failure situations: The electric motor winding definition is, windings in electric motors are wires that are placed within coils, generally enclosed around a coated flexible iron magnetic core to shape magnetic poles while strengthened with the current. Given the sheer number of different motors and winding patterns, the rewinding process can vary greatly. Voltage spike damage occurs more. Electric motors are relatively simple mechanical devices, but rewinding them isn't—in fact, it's one project that’s usually best left to the professionals. Unfavorable operating conditions—whether electrical, mechanical, or environmental—can dramatically shorten the life of an electric motor. It involves intricately winding copper or aluminum wire around a core, typically made of iron. The design determines the available torque, the electromagnetic force in the system, the electrical resistance, and therefore the application. An electric motor winding is a coil made up of a conductor wire such as copper or aluminum and used to produce an electromagnetic field inside.

From

Electric Motors Winding Motor windings have a different appearance in all these failure situations: The electric motor winding definition is, windings in electric motors are wires that are placed within coils, generally enclosed around a coated flexible iron magnetic core to shape magnetic poles while strengthened with the current. Motor winding is the backbone of any electrical motor, acting as its circulatory system.. Electric Motors Winding.

From

Electric Motors Winding Voltage spike damage occurs more. An electric motor winding is a coil made up of a conductor wire such as copper or aluminum and used to produce an electromagnetic field inside. Motor winding is the backbone of any electrical motor, acting as its circulatory system. Unfavorable operating conditions—whether electrical, mechanical, or environmental—can dramatically shorten the life of an electric motor.. Electric Motors Winding.

From

Electric Motors Winding This fundamental process dictates the motor’s functionality, influencing its efficiency and overall performance. Unfavorable operating conditions—whether electrical, mechanical, or environmental—can dramatically shorten the life of an electric motor. It’s always important to identify the real cause of burned windings and not just to replace the electric motor. The electric motor winding definition is, windings in electric motors are wires that. Electric Motors Winding.

From

Electric Motors Winding Voltage spike damage occurs more. An electric motor winding is a coil made up of a conductor wire such as copper or aluminum and used to produce an electromagnetic field inside. The electric motor winding definition is, windings in electric motors are wires that are placed within coils, generally enclosed around a coated flexible iron magnetic core to shape magnetic. Electric Motors Winding.

From

Electric Motors Winding It involves intricately winding copper or aluminum wire around a core, typically made of iron. Unfavorable operating conditions—whether electrical, mechanical, or environmental—can dramatically shorten the life of an electric motor. It’s always important to identify the real cause of burned windings and not just to replace the electric motor. The electric motor winding definition is, windings in electric motors are. Electric Motors Winding.

From

Electric Motors Winding It’s always important to identify the real cause of burned windings and not just to replace the electric motor. Electrical failures disrupt the power supply to the motor. This fundamental process dictates the motor’s functionality, influencing its efficiency and overall performance. Motor winding is the backbone of any electrical motor, acting as its circulatory system. Voltage spike damage occurs more.. Electric Motors Winding.

From

Electric Motors Winding Voltage spike damage occurs more. Given the sheer number of different motors and winding patterns, the rewinding process can vary greatly. It’s always important to identify the real cause of burned windings and not just to replace the electric motor. Unfavorable operating conditions—whether electrical, mechanical, or environmental—can dramatically shorten the life of an electric motor. Electrical failures disrupt the power. Electric Motors Winding.

From

Electric Motors Winding Unfavorable operating conditions—whether electrical, mechanical, or environmental—can dramatically shorten the life of an electric motor. Motor winding is the backbone of any electrical motor, acting as its circulatory system. An electric motor winding is a coil made up of a conductor wire such as copper or aluminum and used to produce an electromagnetic field inside. Motor windings have a different. Electric Motors Winding.

From

Electric Motors Winding Electrical failures disrupt the power supply to the motor. Motor windings have a different appearance in all these failure situations: Electric motors are relatively simple mechanical devices, but rewinding them isn't—in fact, it's one project that’s usually best left to the professionals. It’s always important to identify the real cause of burned windings and not just to replace the electric. Electric Motors Winding.

From

Electric Motors Winding Unfavorable operating conditions—whether electrical, mechanical, or environmental—can dramatically shorten the life of an electric motor. Motor windings have a different appearance in all these failure situations: Electrical failures disrupt the power supply to the motor. Motor winding is the backbone of any electrical motor, acting as its circulatory system. Voltage spike damage occurs more. The electric motor winding definition is,. Electric Motors Winding.

From

Electric Motors Winding The design determines the available torque, the electromagnetic force in the system, the electrical resistance, and therefore the application. Motor winding is the backbone of any electrical motor, acting as its circulatory system. Motor windings have a different appearance in all these failure situations: It involves intricately winding copper or aluminum wire around a core, typically made of iron. It’s. Electric Motors Winding.

From www.youtube.com

Incredible Electric Motor Winding Methods Amazing Motors & Stator Electric Motors Winding Electrical failures disrupt the power supply to the motor. Electric motors are relatively simple mechanical devices, but rewinding them isn't—in fact, it's one project that’s usually best left to the professionals. Voltage spike damage occurs more. The design determines the available torque, the electromagnetic force in the system, the electrical resistance, and therefore the application. Motor winding is the backbone. Electric Motors Winding.

From

Electric Motors Winding Voltage spike damage occurs more. Electrical failures disrupt the power supply to the motor. It involves intricately winding copper or aluminum wire around a core, typically made of iron. Motor winding is the backbone of any electrical motor, acting as its circulatory system. An electric motor winding is a coil made up of a conductor wire such as copper or. Electric Motors Winding.

From

Electric Motors Winding An electric motor winding is a coil made up of a conductor wire such as copper or aluminum and used to produce an electromagnetic field inside. It’s always important to identify the real cause of burned windings and not just to replace the electric motor. Unfavorable operating conditions—whether electrical, mechanical, or environmental—can dramatically shorten the life of an electric motor.. Electric Motors Winding.

From

Electric Motors Winding Electric motors are relatively simple mechanical devices, but rewinding them isn't—in fact, it's one project that’s usually best left to the professionals. Unfavorable operating conditions—whether electrical, mechanical, or environmental—can dramatically shorten the life of an electric motor. The electric motor winding definition is, windings in electric motors are wires that are placed within coils, generally enclosed around a coated flexible. Electric Motors Winding.

From webmotor.org

3 Phase Ac Motor Winding Diagram Electric Motors Winding Voltage spike damage occurs more. The design determines the available torque, the electromagnetic force in the system, the electrical resistance, and therefore the application. An electric motor winding is a coil made up of a conductor wire such as copper or aluminum and used to produce an electromagnetic field inside. Given the sheer number of different motors and winding patterns,. Electric Motors Winding.

From www.dukeelectric.com

3phase stator winding failure [With examples] Duke Electric Electric Motors Winding Electric motors are relatively simple mechanical devices, but rewinding them isn't—in fact, it's one project that’s usually best left to the professionals. It’s always important to identify the real cause of burned windings and not just to replace the electric motor. Electrical failures disrupt the power supply to the motor. Given the sheer number of different motors and winding patterns,. Electric Motors Winding.

From

Electric Motors Winding Unfavorable operating conditions—whether electrical, mechanical, or environmental—can dramatically shorten the life of an electric motor. An electric motor winding is a coil made up of a conductor wire such as copper or aluminum and used to produce an electromagnetic field inside. Electrical failures disrupt the power supply to the motor. Electric motors are relatively simple mechanical devices, but rewinding them. Electric Motors Winding.

From

Electric Motors Winding The design determines the available torque, the electromagnetic force in the system, the electrical resistance, and therefore the application. Given the sheer number of different motors and winding patterns, the rewinding process can vary greatly. Motor windings have a different appearance in all these failure situations: This fundamental process dictates the motor’s functionality, influencing its efficiency and overall performance. Voltage. Electric Motors Winding.

From

Electric Motors Winding The electric motor winding definition is, windings in electric motors are wires that are placed within coils, generally enclosed around a coated flexible iron magnetic core to shape magnetic poles while strengthened with the current. Motor winding is the backbone of any electrical motor, acting as its circulatory system. It’s always important to identify the real cause of burned windings. Electric Motors Winding.

From slaymakergroup.com

Electric Motor Rewinding Gallery Slaymaker Group Electric Motors Winding Motor winding is the backbone of any electrical motor, acting as its circulatory system. It involves intricately winding copper or aluminum wire around a core, typically made of iron. Electric motors are relatively simple mechanical devices, but rewinding them isn't—in fact, it's one project that’s usually best left to the professionals. This fundamental process dictates the motor’s functionality, influencing its. Electric Motors Winding.

From

Electric Motors Winding Electrical failures disrupt the power supply to the motor. Electric motors are relatively simple mechanical devices, but rewinding them isn't—in fact, it's one project that’s usually best left to the professionals. Unfavorable operating conditions—whether electrical, mechanical, or environmental—can dramatically shorten the life of an electric motor. The electric motor winding definition is, windings in electric motors are wires that are. Electric Motors Winding.

From

Electric Motors Winding The design determines the available torque, the electromagnetic force in the system, the electrical resistance, and therefore the application. Electrical failures disrupt the power supply to the motor. Motor winding is the backbone of any electrical motor, acting as its circulatory system. This fundamental process dictates the motor’s functionality, influencing its efficiency and overall performance. An electric motor winding is. Electric Motors Winding.

From www.youtube.com

Single phase motor winding connection with diagram full detailed video Electric Motors Winding It’s always important to identify the real cause of burned windings and not just to replace the electric motor. It involves intricately winding copper or aluminum wire around a core, typically made of iron. Electrical failures disrupt the power supply to the motor. The electric motor winding definition is, windings in electric motors are wires that are placed within coils,. Electric Motors Winding.

From

Electric Motors Winding The electric motor winding definition is, windings in electric motors are wires that are placed within coils, generally enclosed around a coated flexible iron magnetic core to shape magnetic poles while strengthened with the current. The design determines the available torque, the electromagnetic force in the system, the electrical resistance, and therefore the application. Motor winding is the backbone of. Electric Motors Winding.

From

Electric Motors Winding An electric motor winding is a coil made up of a conductor wire such as copper or aluminum and used to produce an electromagnetic field inside. The design determines the available torque, the electromagnetic force in the system, the electrical resistance, and therefore the application. The electric motor winding definition is, windings in electric motors are wires that are placed. Electric Motors Winding.

From www.electrician-1.com

on video Understanding electric motor Windings! electrical and Electric Motors Winding Unfavorable operating conditions—whether electrical, mechanical, or environmental—can dramatically shorten the life of an electric motor. Given the sheer number of different motors and winding patterns, the rewinding process can vary greatly. Motor winding is the backbone of any electrical motor, acting as its circulatory system. It’s always important to identify the real cause of burned windings and not just to. Electric Motors Winding.

From

Electric Motors Winding An electric motor winding is a coil made up of a conductor wire such as copper or aluminum and used to produce an electromagnetic field inside. Voltage spike damage occurs more. The electric motor winding definition is, windings in electric motors are wires that are placed within coils, generally enclosed around a coated flexible iron magnetic core to shape magnetic. Electric Motors Winding.

From

Electric Motors Winding Unfavorable operating conditions—whether electrical, mechanical, or environmental—can dramatically shorten the life of an electric motor. The electric motor winding definition is, windings in electric motors are wires that are placed within coils, generally enclosed around a coated flexible iron magnetic core to shape magnetic poles while strengthened with the current. Electric motors are relatively simple mechanical devices, but rewinding them. Electric Motors Winding.

From

Electric Motors Winding The design determines the available torque, the electromagnetic force in the system, the electrical resistance, and therefore the application. Electric motors are relatively simple mechanical devices, but rewinding them isn't—in fact, it's one project that’s usually best left to the professionals. It’s always important to identify the real cause of burned windings and not just to replace the electric motor.. Electric Motors Winding.

From electricalgang.com

What Is Motor Winding? Types of Motor Winding Electric Motors Winding Electric motors are relatively simple mechanical devices, but rewinding them isn't—in fact, it's one project that’s usually best left to the professionals. Motor windings have a different appearance in all these failure situations: Unfavorable operating conditions—whether electrical, mechanical, or environmental—can dramatically shorten the life of an electric motor. Electrical failures disrupt the power supply to the motor. It involves intricately. Electric Motors Winding.

From

Electric Motors Winding Voltage spike damage occurs more. Electric motors are relatively simple mechanical devices, but rewinding them isn't—in fact, it's one project that’s usually best left to the professionals. Given the sheer number of different motors and winding patterns, the rewinding process can vary greatly. The design determines the available torque, the electromagnetic force in the system, the electrical resistance, and therefore. Electric Motors Winding.

From circuitengineeclair.z21.web.core.windows.net

Electric Motor Winding Diagram Electric Motors Winding Unfavorable operating conditions—whether electrical, mechanical, or environmental—can dramatically shorten the life of an electric motor. Motor winding is the backbone of any electrical motor, acting as its circulatory system. Given the sheer number of different motors and winding patterns, the rewinding process can vary greatly. Electrical failures disrupt the power supply to the motor. Motor windings have a different appearance. Electric Motors Winding.

From

Electric Motors Winding Unfavorable operating conditions—whether electrical, mechanical, or environmental—can dramatically shorten the life of an electric motor. It involves intricately winding copper or aluminum wire around a core, typically made of iron. Voltage spike damage occurs more. This fundamental process dictates the motor’s functionality, influencing its efficiency and overall performance. Motor windings have a different appearance in all these failure situations: An. Electric Motors Winding.

From

Electric Motors Winding Unfavorable operating conditions—whether electrical, mechanical, or environmental—can dramatically shorten the life of an electric motor. Given the sheer number of different motors and winding patterns, the rewinding process can vary greatly. Electrical failures disrupt the power supply to the motor. This fundamental process dictates the motor’s functionality, influencing its efficiency and overall performance. It involves intricately winding copper or aluminum. Electric Motors Winding.