Water Manufacturing Process . Almost every product we use today requires massive amounts of water for production. Freshly blown bottles are sealed in clean bags and stored in the empty bottle warehouse. Artesian water comes from an artesian well, which draws water from a confined aquifer (an underground, porous rock or sand formation that bears water and is under pressure from a layer of rock or clay above it). Water bottles are made using different materials and techniques, depending on the type of bottle being produced. The pdf document on the bottled water production process encompasses detailed information on how bottled water is manufactured, including a. There are three primary processes used to produce purified water: On an elementary level, the process of refining and producing raw materials such as metal, fuel, oil, lumber, chemicals, paper, and plastic demands water. Deionization, distillation and reverse osmosis. Here are the steps involved in.

from www.process-worldwide.com

On an elementary level, the process of refining and producing raw materials such as metal, fuel, oil, lumber, chemicals, paper, and plastic demands water. Almost every product we use today requires massive amounts of water for production. Deionization, distillation and reverse osmosis. Artesian water comes from an artesian well, which draws water from a confined aquifer (an underground, porous rock or sand formation that bears water and is under pressure from a layer of rock or clay above it). The pdf document on the bottled water production process encompasses detailed information on how bottled water is manufactured, including a. Here are the steps involved in. Water bottles are made using different materials and techniques, depending on the type of bottle being produced. There are three primary processes used to produce purified water: Freshly blown bottles are sealed in clean bags and stored in the empty bottle warehouse.

Why the Modernization of Water Production Plants is Necessary

Water Manufacturing Process Here are the steps involved in. Deionization, distillation and reverse osmosis. Artesian water comes from an artesian well, which draws water from a confined aquifer (an underground, porous rock or sand formation that bears water and is under pressure from a layer of rock or clay above it). Freshly blown bottles are sealed in clean bags and stored in the empty bottle warehouse. On an elementary level, the process of refining and producing raw materials such as metal, fuel, oil, lumber, chemicals, paper, and plastic demands water. Water bottles are made using different materials and techniques, depending on the type of bottle being produced. Almost every product we use today requires massive amounts of water for production. There are three primary processes used to produce purified water: Here are the steps involved in. The pdf document on the bottled water production process encompasses detailed information on how bottled water is manufactured, including a.

From www.researchgate.net

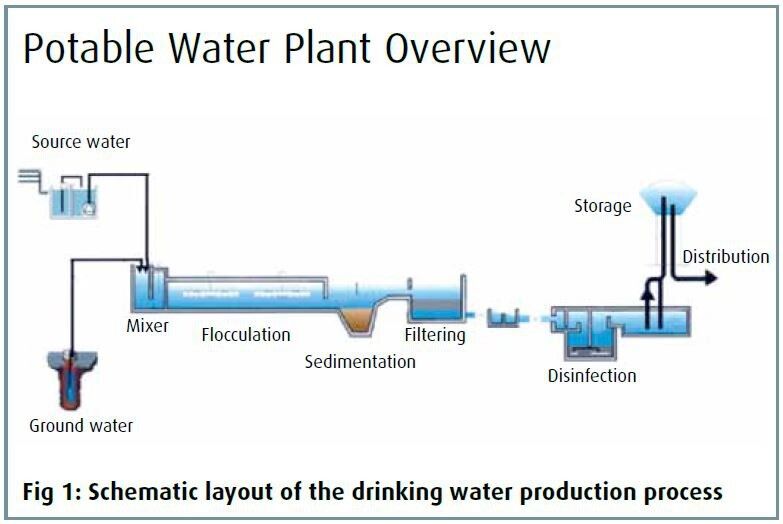

Flowchart of the potable water production plant used in the case study Water Manufacturing Process On an elementary level, the process of refining and producing raw materials such as metal, fuel, oil, lumber, chemicals, paper, and plastic demands water. Artesian water comes from an artesian well, which draws water from a confined aquifer (an underground, porous rock or sand formation that bears water and is under pressure from a layer of rock or clay above. Water Manufacturing Process.

From www.process-worldwide.com

Why the Modernization of Water Production Plants is Necessary Water Manufacturing Process Water bottles are made using different materials and techniques, depending on the type of bottle being produced. There are three primary processes used to produce purified water: Artesian water comes from an artesian well, which draws water from a confined aquifer (an underground, porous rock or sand formation that bears water and is under pressure from a layer of rock. Water Manufacturing Process.

From www.vrogue.co

Bottled Water Manufacturing Process Best Pictures And vrogue.co Water Manufacturing Process On an elementary level, the process of refining and producing raw materials such as metal, fuel, oil, lumber, chemicals, paper, and plastic demands water. Deionization, distillation and reverse osmosis. Artesian water comes from an artesian well, which draws water from a confined aquifer (an underground, porous rock or sand formation that bears water and is under pressure from a layer. Water Manufacturing Process.

From www.researchgate.net

Water treatment process in a typical sachet water factory. Download Water Manufacturing Process Here are the steps involved in. Deionization, distillation and reverse osmosis. Freshly blown bottles are sealed in clean bags and stored in the empty bottle warehouse. On an elementary level, the process of refining and producing raw materials such as metal, fuel, oil, lumber, chemicals, paper, and plastic demands water. Water bottles are made using different materials and techniques, depending. Water Manufacturing Process.

From www.linkedin.com

What is bottled water production process flow chart Water Manufacturing Process Water bottles are made using different materials and techniques, depending on the type of bottle being produced. There are three primary processes used to produce purified water: The pdf document on the bottled water production process encompasses detailed information on how bottled water is manufactured, including a. Artesian water comes from an artesian well, which draws water from a confined. Water Manufacturing Process.

From www.pipeen.com

How To Make A Bottled Water Manufacturing Process Best Pictures and Water Manufacturing Process Deionization, distillation and reverse osmosis. There are three primary processes used to produce purified water: The pdf document on the bottled water production process encompasses detailed information on how bottled water is manufactured, including a. Water bottles are made using different materials and techniques, depending on the type of bottle being produced. Almost every product we use today requires massive. Water Manufacturing Process.

From www.youtube.com

Automatic water bottling plant 24000BPH Water Production line, Water Water Manufacturing Process There are three primary processes used to produce purified water: On an elementary level, the process of refining and producing raw materials such as metal, fuel, oil, lumber, chemicals, paper, and plastic demands water. Artesian water comes from an artesian well, which draws water from a confined aquifer (an underground, porous rock or sand formation that bears water and is. Water Manufacturing Process.

From www.dreamstime.com

The Hitechnology of Drinking Water Manufacturing Process Stock Photo Water Manufacturing Process On an elementary level, the process of refining and producing raw materials such as metal, fuel, oil, lumber, chemicals, paper, and plastic demands water. The pdf document on the bottled water production process encompasses detailed information on how bottled water is manufactured, including a. Artesian water comes from an artesian well, which draws water from a confined aquifer (an underground,. Water Manufacturing Process.

From www.youtube.com

DMZ Natural Mineral Water manufacturing process YouTube Water Manufacturing Process Here are the steps involved in. Deionization, distillation and reverse osmosis. On an elementary level, the process of refining and producing raw materials such as metal, fuel, oil, lumber, chemicals, paper, and plastic demands water. The pdf document on the bottled water production process encompasses detailed information on how bottled water is manufactured, including a. There are three primary processes. Water Manufacturing Process.

From www.alfalaval.id

Industrial water and waste treatment Alfa Laval Water Manufacturing Process Artesian water comes from an artesian well, which draws water from a confined aquifer (an underground, porous rock or sand formation that bears water and is under pressure from a layer of rock or clay above it). The pdf document on the bottled water production process encompasses detailed information on how bottled water is manufactured, including a. Water bottles are. Water Manufacturing Process.

From www.dreamstime.com

The Hitechnology of Drinking Water Manufacturing Process Stock Image Water Manufacturing Process Water bottles are made using different materials and techniques, depending on the type of bottle being produced. Here are the steps involved in. There are three primary processes used to produce purified water: The pdf document on the bottled water production process encompasses detailed information on how bottled water is manufactured, including a. Artesian water comes from an artesian well,. Water Manufacturing Process.

From www.pinterest.co.uk

Mineral water production Carbonated drinks, Water treatment system Water Manufacturing Process Almost every product we use today requires massive amounts of water for production. Deionization, distillation and reverse osmosis. There are three primary processes used to produce purified water: Here are the steps involved in. Water bottles are made using different materials and techniques, depending on the type of bottle being produced. On an elementary level, the process of refining and. Water Manufacturing Process.

From processandwater.com

Process and Waters capabilities include onsite assessments, robust Water Manufacturing Process Water bottles are made using different materials and techniques, depending on the type of bottle being produced. Artesian water comes from an artesian well, which draws water from a confined aquifer (an underground, porous rock or sand formation that bears water and is under pressure from a layer of rock or clay above it). Deionization, distillation and reverse osmosis. There. Water Manufacturing Process.

From www.dreamstime.com

The Hitechnology of Drinking Water Manufacturing Process Stock Photo Water Manufacturing Process The pdf document on the bottled water production process encompasses detailed information on how bottled water is manufactured, including a. Freshly blown bottles are sealed in clean bags and stored in the empty bottle warehouse. Deionization, distillation and reverse osmosis. Water bottles are made using different materials and techniques, depending on the type of bottle being produced. Almost every product. Water Manufacturing Process.

From www.youtube.com

Complete Bottled Water Production Process from A to Z in plant YouTube Water Manufacturing Process On an elementary level, the process of refining and producing raw materials such as metal, fuel, oil, lumber, chemicals, paper, and plastic demands water. Water bottles are made using different materials and techniques, depending on the type of bottle being produced. Almost every product we use today requires massive amounts of water for production. Deionization, distillation and reverse osmosis. The. Water Manufacturing Process.

From www.youtube.com

Bisleri Drinking WaterFull Automation Process Drinking Water Water Manufacturing Process On an elementary level, the process of refining and producing raw materials such as metal, fuel, oil, lumber, chemicals, paper, and plastic demands water. Deionization, distillation and reverse osmosis. The pdf document on the bottled water production process encompasses detailed information on how bottled water is manufactured, including a. Freshly blown bottles are sealed in clean bags and stored in. Water Manufacturing Process.

From www.proman-machine.com

Bottle water Production Machine Proman Machine Water Manufacturing Process Deionization, distillation and reverse osmosis. Freshly blown bottles are sealed in clean bags and stored in the empty bottle warehouse. Artesian water comes from an artesian well, which draws water from a confined aquifer (an underground, porous rock or sand formation that bears water and is under pressure from a layer of rock or clay above it). The pdf document. Water Manufacturing Process.

From mavink.com

Bottled Water Process Flow Chart Water Manufacturing Process Freshly blown bottles are sealed in clean bags and stored in the empty bottle warehouse. On an elementary level, the process of refining and producing raw materials such as metal, fuel, oil, lumber, chemicals, paper, and plastic demands water. There are three primary processes used to produce purified water: Artesian water comes from an artesian well, which draws water from. Water Manufacturing Process.

From kingmachine.en.made-in-china.com

Automatic Drinking Mineral Water Production Line (CGFXXX) Water Water Manufacturing Process On an elementary level, the process of refining and producing raw materials such as metal, fuel, oil, lumber, chemicals, paper, and plastic demands water. Deionization, distillation and reverse osmosis. Water bottles are made using different materials and techniques, depending on the type of bottle being produced. Freshly blown bottles are sealed in clean bags and stored in the empty bottle. Water Manufacturing Process.

From www.bpms.co.id

Filtration in Bottled Water Processing Water Manufacturing Process Water bottles are made using different materials and techniques, depending on the type of bottle being produced. Freshly blown bottles are sealed in clean bags and stored in the empty bottle warehouse. Almost every product we use today requires massive amounts of water for production. Artesian water comes from an artesian well, which draws water from a confined aquifer (an. Water Manufacturing Process.

From www.youtube.com

bottled water production line, bottled water manufacturing process Water Manufacturing Process On an elementary level, the process of refining and producing raw materials such as metal, fuel, oil, lumber, chemicals, paper, and plastic demands water. Almost every product we use today requires massive amounts of water for production. Water bottles are made using different materials and techniques, depending on the type of bottle being produced. Deionization, distillation and reverse osmosis. Freshly. Water Manufacturing Process.

From mavink.com

Bottled Water Process Flow Chart Water Manufacturing Process Deionization, distillation and reverse osmosis. Here are the steps involved in. On an elementary level, the process of refining and producing raw materials such as metal, fuel, oil, lumber, chemicals, paper, and plastic demands water. Artesian water comes from an artesian well, which draws water from a confined aquifer (an underground, porous rock or sand formation that bears water and. Water Manufacturing Process.

From civilengi.com

Detail of the Wastewater Treatment Process Civilengi Water Manufacturing Process Freshly blown bottles are sealed in clean bags and stored in the empty bottle warehouse. Artesian water comes from an artesian well, which draws water from a confined aquifer (an underground, porous rock or sand formation that bears water and is under pressure from a layer of rock or clay above it). Almost every product we use today requires massive. Water Manufacturing Process.

From www.dreamstime.com

Abstract Scene Hitechnology of Drinking Water Manufacturing Process Water Manufacturing Process Deionization, distillation and reverse osmosis. Freshly blown bottles are sealed in clean bags and stored in the empty bottle warehouse. Water bottles are made using different materials and techniques, depending on the type of bottle being produced. Artesian water comes from an artesian well, which draws water from a confined aquifer (an underground, porous rock or sand formation that bears. Water Manufacturing Process.

From www.indiamart.com

Sparkling Water Manufacturing Process at Rs 8000/onwards in Bengaluru Water Manufacturing Process Here are the steps involved in. Water bottles are made using different materials and techniques, depending on the type of bottle being produced. Freshly blown bottles are sealed in clean bags and stored in the empty bottle warehouse. Deionization, distillation and reverse osmosis. On an elementary level, the process of refining and producing raw materials such as metal, fuel, oil,. Water Manufacturing Process.

From www.dreamstime.com

Abstract Scene Hitechnology of Drinking Water Manufacturing Process Water Manufacturing Process Deionization, distillation and reverse osmosis. The pdf document on the bottled water production process encompasses detailed information on how bottled water is manufactured, including a. Water bottles are made using different materials and techniques, depending on the type of bottle being produced. Almost every product we use today requires massive amounts of water for production. Artesian water comes from an. Water Manufacturing Process.

From international.lubron.eu

Process water for the industry Lubron Water Technologies Water Manufacturing Process Freshly blown bottles are sealed in clean bags and stored in the empty bottle warehouse. Here are the steps involved in. The pdf document on the bottled water production process encompasses detailed information on how bottled water is manufactured, including a. Deionization, distillation and reverse osmosis. Artesian water comes from an artesian well, which draws water from a confined aquifer. Water Manufacturing Process.

From www.vrogue.co

Bottled Water Manufacturing Process Best Pictures And vrogue.co Water Manufacturing Process Freshly blown bottles are sealed in clean bags and stored in the empty bottle warehouse. Deionization, distillation and reverse osmosis. The pdf document on the bottled water production process encompasses detailed information on how bottled water is manufactured, including a. Water bottles are made using different materials and techniques, depending on the type of bottle being produced. There are three. Water Manufacturing Process.

From www.vrogue.co

Bottled Water Manufacturing Process Best Pictures And vrogue.co Water Manufacturing Process Water bottles are made using different materials and techniques, depending on the type of bottle being produced. Almost every product we use today requires massive amounts of water for production. Here are the steps involved in. Artesian water comes from an artesian well, which draws water from a confined aquifer (an underground, porous rock or sand formation that bears water. Water Manufacturing Process.

From processflowsheets.blogspot.com

Process flow sheets Purified water production process with flow chart Water Manufacturing Process Artesian water comes from an artesian well, which draws water from a confined aquifer (an underground, porous rock or sand formation that bears water and is under pressure from a layer of rock or clay above it). Deionization, distillation and reverse osmosis. Freshly blown bottles are sealed in clean bags and stored in the empty bottle warehouse. The pdf document. Water Manufacturing Process.

From www.dreamstime.com

The Hitechnology of Drinking Water Manufacturing Process Stock Photo Water Manufacturing Process Freshly blown bottles are sealed in clean bags and stored in the empty bottle warehouse. There are three primary processes used to produce purified water: Deionization, distillation and reverse osmosis. Water bottles are made using different materials and techniques, depending on the type of bottle being produced. The pdf document on the bottled water production process encompasses detailed information on. Water Manufacturing Process.

From www.scribd.com

Packaged Drinking Water Plant Process Flow Chart PDF Water Manufacturing Process Here are the steps involved in. On an elementary level, the process of refining and producing raw materials such as metal, fuel, oil, lumber, chemicals, paper, and plastic demands water. The pdf document on the bottled water production process encompasses detailed information on how bottled water is manufactured, including a. Almost every product we use today requires massive amounts of. Water Manufacturing Process.

From www.3mindia.in

Bottled Water 3M India Water Manufacturing Process Deionization, distillation and reverse osmosis. On an elementary level, the process of refining and producing raw materials such as metal, fuel, oil, lumber, chemicals, paper, and plastic demands water. Freshly blown bottles are sealed in clean bags and stored in the empty bottle warehouse. Here are the steps involved in. Almost every product we use today requires massive amounts of. Water Manufacturing Process.

From www.dreamstime.com

The Hitechnology of Drinking Water Manufacturing Process Stock Image Water Manufacturing Process Freshly blown bottles are sealed in clean bags and stored in the empty bottle warehouse. There are three primary processes used to produce purified water: Almost every product we use today requires massive amounts of water for production. On an elementary level, the process of refining and producing raw materials such as metal, fuel, oil, lumber, chemicals, paper, and plastic. Water Manufacturing Process.

From www.jmtings.com

The process of the bottle mineral water production line TINGS Water Manufacturing Process Artesian water comes from an artesian well, which draws water from a confined aquifer (an underground, porous rock or sand formation that bears water and is under pressure from a layer of rock or clay above it). Deionization, distillation and reverse osmosis. Water bottles are made using different materials and techniques, depending on the type of bottle being produced. Here. Water Manufacturing Process.