Die Casting Vs Investment Casting . The overall difference between the two methods based on each process involved is that investment casting utilizes wax patterns. Although these techniques have the same basic principles, investment casting vs die casting have specific differences. Die casting vs investment casting are distinct manufacturing methods for crafting intricate metal components. Die casting involves injecting molten metal, typically aluminum or zinc, into a steel mold under high pressure. While investment casting and die casting employ similar manufacturing principles to produce parts and products, there are clear distinctions between the two processes. While investment casting is utilized in aerospace and medical industries for complex components, die casting is widely used in the. Die casting, investment casting, and sand casting are all casting methods that have unique advantages and disadvantages.

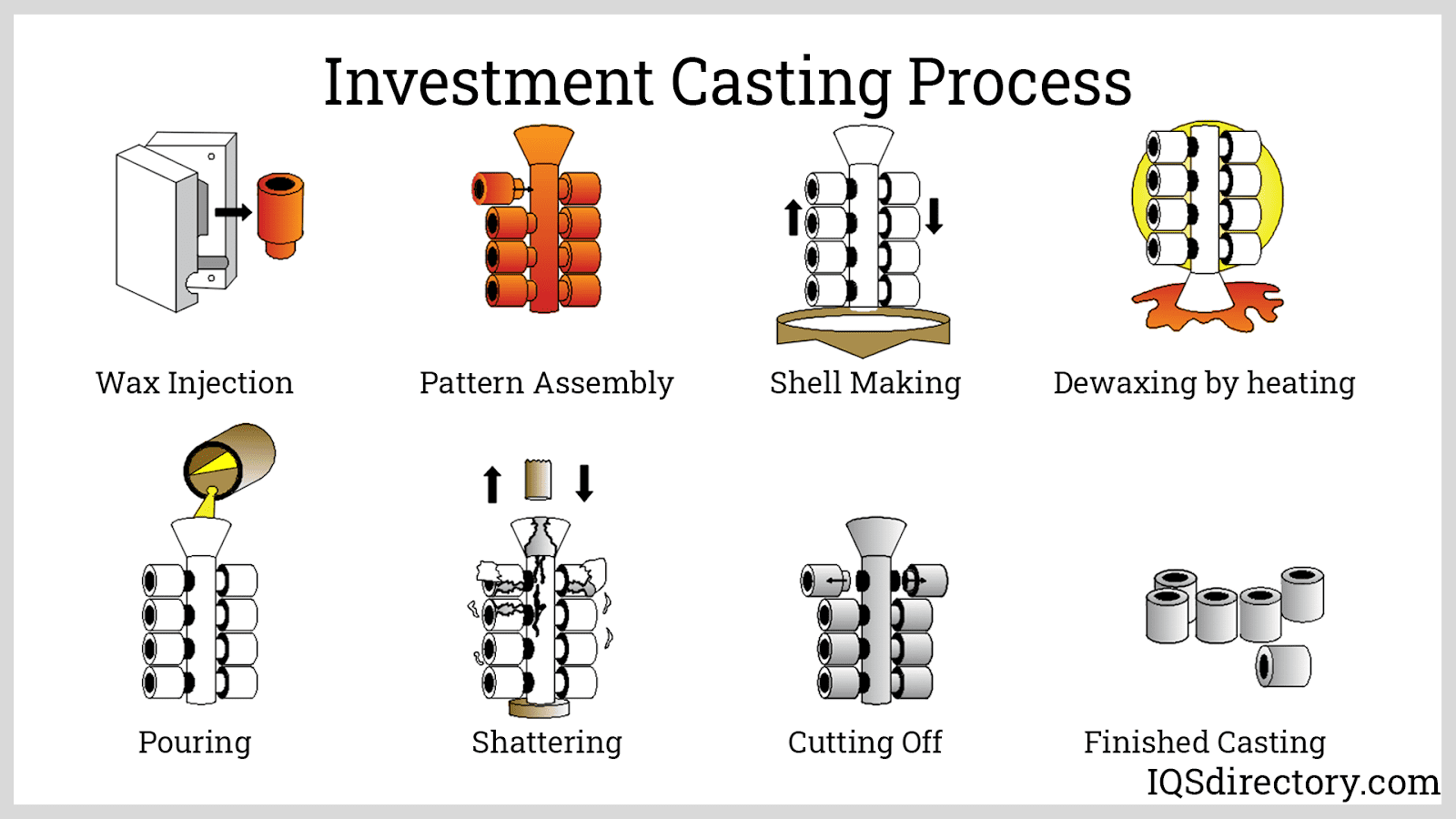

from www.iqsdirectory.com

While investment casting is utilized in aerospace and medical industries for complex components, die casting is widely used in the. Die casting involves injecting molten metal, typically aluminum or zinc, into a steel mold under high pressure. While investment casting and die casting employ similar manufacturing principles to produce parts and products, there are clear distinctions between the two processes. The overall difference between the two methods based on each process involved is that investment casting utilizes wax patterns. Although these techniques have the same basic principles, investment casting vs die casting have specific differences. Die casting vs investment casting are distinct manufacturing methods for crafting intricate metal components. Die casting, investment casting, and sand casting are all casting methods that have unique advantages and disadvantages.

Lost Wax Casting What Is It? How Does It Work? Parts, Metal

Die Casting Vs Investment Casting Die casting, investment casting, and sand casting are all casting methods that have unique advantages and disadvantages. Die casting, investment casting, and sand casting are all casting methods that have unique advantages and disadvantages. Die casting vs investment casting are distinct manufacturing methods for crafting intricate metal components. Die casting involves injecting molten metal, typically aluminum or zinc, into a steel mold under high pressure. While investment casting and die casting employ similar manufacturing principles to produce parts and products, there are clear distinctions between the two processes. The overall difference between the two methods based on each process involved is that investment casting utilizes wax patterns. Although these techniques have the same basic principles, investment casting vs die casting have specific differences. While investment casting is utilized in aerospace and medical industries for complex components, die casting is widely used in the.

From www.iqsdirectory.com

Investment Casting What Is It? How Does It Work? Uses Die Casting Vs Investment Casting Although these techniques have the same basic principles, investment casting vs die casting have specific differences. Die casting vs investment casting are distinct manufacturing methods for crafting intricate metal components. Die casting involves injecting molten metal, typically aluminum or zinc, into a steel mold under high pressure. While investment casting and die casting employ similar manufacturing principles to produce parts. Die Casting Vs Investment Casting.

From www.empcasting.com

High Pressure Die Casting VS Gravity Die Casting EMP Tech Co.,Ltd Die Casting Vs Investment Casting The overall difference between the two methods based on each process involved is that investment casting utilizes wax patterns. Although these techniques have the same basic principles, investment casting vs die casting have specific differences. While investment casting and die casting employ similar manufacturing principles to produce parts and products, there are clear distinctions between the two processes. While investment. Die Casting Vs Investment Casting.

From www.customcastingparts.com

Investment Casting vs Die Casting China Investment Casting Factory Die Casting Vs Investment Casting Although these techniques have the same basic principles, investment casting vs die casting have specific differences. Die casting involves injecting molten metal, typically aluminum or zinc, into a steel mold under high pressure. Die casting, investment casting, and sand casting are all casting methods that have unique advantages and disadvantages. The overall difference between the two methods based on each. Die Casting Vs Investment Casting.

From capablemachining.com

Investment Casting vs Die Casting Capable Machining Die Casting Vs Investment Casting While investment casting and die casting employ similar manufacturing principles to produce parts and products, there are clear distinctions between the two processes. Although these techniques have the same basic principles, investment casting vs die casting have specific differences. The overall difference between the two methods based on each process involved is that investment casting utilizes wax patterns. Die casting. Die Casting Vs Investment Casting.

From businessshed.ca

Investment Casting vs. Die Casting: 7 Things to Consider Businesss Hed Die Casting Vs Investment Casting Although these techniques have the same basic principles, investment casting vs die casting have specific differences. The overall difference between the two methods based on each process involved is that investment casting utilizes wax patterns. While investment casting and die casting employ similar manufacturing principles to produce parts and products, there are clear distinctions between the two processes. Die casting. Die Casting Vs Investment Casting.

From redstonemanufacturing.com

Investment Casting vs. Die Casting Redstone Manufacturing® Die Casting Vs Investment Casting The overall difference between the two methods based on each process involved is that investment casting utilizes wax patterns. Die casting, investment casting, and sand casting are all casting methods that have unique advantages and disadvantages. Die casting vs investment casting are distinct manufacturing methods for crafting intricate metal components. While investment casting and die casting employ similar manufacturing principles. Die Casting Vs Investment Casting.

From news.ewmfg.com

Investment Casting vs. Die Casting 7 Considerations When Choosing a Die Casting Vs Investment Casting The overall difference between the two methods based on each process involved is that investment casting utilizes wax patterns. Die casting, investment casting, and sand casting are all casting methods that have unique advantages and disadvantages. Die casting vs investment casting are distinct manufacturing methods for crafting intricate metal components. While investment casting is utilized in aerospace and medical industries. Die Casting Vs Investment Casting.

From blog.thepipingmart.com

Shell Molding vs Investment Casting What's the Difference Die Casting Vs Investment Casting While investment casting and die casting employ similar manufacturing principles to produce parts and products, there are clear distinctions between the two processes. Die casting, investment casting, and sand casting are all casting methods that have unique advantages and disadvantages. The overall difference between the two methods based on each process involved is that investment casting utilizes wax patterns. Die. Die Casting Vs Investment Casting.

From www.linkedin.com

Teamsworld Innovation Inc. on LinkedIn Comparison Die Casting vs Die Casting Vs Investment Casting Die casting, investment casting, and sand casting are all casting methods that have unique advantages and disadvantages. While investment casting and die casting employ similar manufacturing principles to produce parts and products, there are clear distinctions between the two processes. While investment casting is utilized in aerospace and medical industries for complex components, die casting is widely used in the.. Die Casting Vs Investment Casting.

From technosurvivor.com

Benefits of Die Casting Die Casting Vs Investment Casting Die casting, investment casting, and sand casting are all casting methods that have unique advantages and disadvantages. Although these techniques have the same basic principles, investment casting vs die casting have specific differences. The overall difference between the two methods based on each process involved is that investment casting utilizes wax patterns. While investment casting and die casting employ similar. Die Casting Vs Investment Casting.

From news.ewmfg.com

Investment Casting vs. Die Casting 7 Considerations When Choosing a Die Casting Vs Investment Casting While investment casting is utilized in aerospace and medical industries for complex components, die casting is widely used in the. While investment casting and die casting employ similar manufacturing principles to produce parts and products, there are clear distinctions between the two processes. The overall difference between the two methods based on each process involved is that investment casting utilizes. Die Casting Vs Investment Casting.

From diecastingmfg.net

Die Casting vs Sand Casting A Comparative Analysis Die Casting Vs Investment Casting Die casting, investment casting, and sand casting are all casting methods that have unique advantages and disadvantages. Although these techniques have the same basic principles, investment casting vs die casting have specific differences. Die casting vs investment casting are distinct manufacturing methods for crafting intricate metal components. The overall difference between the two methods based on each process involved is. Die Casting Vs Investment Casting.

From capablemachining.com

Investment Casting vs Die Casting Capable Machining Die Casting Vs Investment Casting While investment casting and die casting employ similar manufacturing principles to produce parts and products, there are clear distinctions between the two processes. Die casting involves injecting molten metal, typically aluminum or zinc, into a steel mold under high pressure. Although these techniques have the same basic principles, investment casting vs die casting have specific differences. Die casting vs investment. Die Casting Vs Investment Casting.

From batesvilleproducts.com

Die Casting vs. Permanent Mold Batesville products, inc. Die Casting Vs Investment Casting While investment casting is utilized in aerospace and medical industries for complex components, die casting is widely used in the. While investment casting and die casting employ similar manufacturing principles to produce parts and products, there are clear distinctions between the two processes. Although these techniques have the same basic principles, investment casting vs die casting have specific differences. Die. Die Casting Vs Investment Casting.

From diecastingmfg.net

Die Casting vs. Investment Casting A Comparative Analysis Die Casting Vs Investment Casting Die casting vs investment casting are distinct manufacturing methods for crafting intricate metal components. While investment casting is utilized in aerospace and medical industries for complex components, die casting is widely used in the. Die casting, investment casting, and sand casting are all casting methods that have unique advantages and disadvantages. While investment casting and die casting employ similar manufacturing. Die Casting Vs Investment Casting.

From www.iqsdirectory.com

Die Casting What is it? Overview, Process, Design, Material Die Casting Vs Investment Casting Although these techniques have the same basic principles, investment casting vs die casting have specific differences. Die casting, investment casting, and sand casting are all casting methods that have unique advantages and disadvantages. While investment casting is utilized in aerospace and medical industries for complex components, die casting is widely used in the. The overall difference between the two methods. Die Casting Vs Investment Casting.

From diecastingmfg.net

Die Casting vs. Investment Casting A Comparative Analysis Die Casting Vs Investment Casting While investment casting and die casting employ similar manufacturing principles to produce parts and products, there are clear distinctions between the two processes. Die casting vs investment casting are distinct manufacturing methods for crafting intricate metal components. Die casting, investment casting, and sand casting are all casting methods that have unique advantages and disadvantages. Although these techniques have the same. Die Casting Vs Investment Casting.

From www.omicroncasting.com

Die Casting vs. Foundry Casting & Investment Casting Die Casting Vs Investment Casting The overall difference between the two methods based on each process involved is that investment casting utilizes wax patterns. Die casting, investment casting, and sand casting are all casting methods that have unique advantages and disadvantages. While investment casting and die casting employ similar manufacturing principles to produce parts and products, there are clear distinctions between the two processes. Die. Die Casting Vs Investment Casting.

From capablemachining.com

Investment Casting vs Die Casting Capable Machining Die Casting Vs Investment Casting Die casting involves injecting molten metal, typically aluminum or zinc, into a steel mold under high pressure. Die casting vs investment casting are distinct manufacturing methods for crafting intricate metal components. While investment casting and die casting employ similar manufacturing principles to produce parts and products, there are clear distinctions between the two processes. Die casting, investment casting, and sand. Die Casting Vs Investment Casting.

From businessshed.ca

Investment Casting vs. Die Casting: 7 Things to Consider Businesss Hed Die Casting Vs Investment Casting Although these techniques have the same basic principles, investment casting vs die casting have specific differences. Die casting vs investment casting are distinct manufacturing methods for crafting intricate metal components. Die casting, investment casting, and sand casting are all casting methods that have unique advantages and disadvantages. While investment casting and die casting employ similar manufacturing principles to produce parts. Die Casting Vs Investment Casting.

From www.hanryk.com

Die Casting vs. Investment Casting Which is Right for Your Project Die Casting Vs Investment Casting While investment casting is utilized in aerospace and medical industries for complex components, die casting is widely used in the. Die casting involves injecting molten metal, typically aluminum or zinc, into a steel mold under high pressure. The overall difference between the two methods based on each process involved is that investment casting utilizes wax patterns. Die casting, investment casting,. Die Casting Vs Investment Casting.

From blog.thepipingmart.com

Die Casting vs Permanent Mold Casting What's the Difference Die Casting Vs Investment Casting Die casting vs investment casting are distinct manufacturing methods for crafting intricate metal components. Die casting, investment casting, and sand casting are all casting methods that have unique advantages and disadvantages. While investment casting is utilized in aerospace and medical industries for complex components, die casting is widely used in the. While investment casting and die casting employ similar manufacturing. Die Casting Vs Investment Casting.

From xjlpowertech.com

Investment casting VS Die casting Precision Casting Solutions Die Casting Vs Investment Casting Die casting vs investment casting are distinct manufacturing methods for crafting intricate metal components. The overall difference between the two methods based on each process involved is that investment casting utilizes wax patterns. While investment casting and die casting employ similar manufacturing principles to produce parts and products, there are clear distinctions between the two processes. Die casting, investment casting,. Die Casting Vs Investment Casting.

From news.ewmfg.com

Investment Casting vs. Die Casting 7 Considerations When Choosing a Die Casting Vs Investment Casting While investment casting and die casting employ similar manufacturing principles to produce parts and products, there are clear distinctions between the two processes. Die casting, investment casting, and sand casting are all casting methods that have unique advantages and disadvantages. Die casting involves injecting molten metal, typically aluminum or zinc, into a steel mold under high pressure. The overall difference. Die Casting Vs Investment Casting.

From 2022.help.altair.com

Gravity Process Die Casting Vs Investment Casting While investment casting is utilized in aerospace and medical industries for complex components, die casting is widely used in the. Die casting vs investment casting are distinct manufacturing methods for crafting intricate metal components. While investment casting and die casting employ similar manufacturing principles to produce parts and products, there are clear distinctions between the two processes. The overall difference. Die Casting Vs Investment Casting.

From www.iqsdirectory.com

Lost Wax Casting What Is It? How Does It Work? Parts, Metal Die Casting Vs Investment Casting Although these techniques have the same basic principles, investment casting vs die casting have specific differences. Die casting, investment casting, and sand casting are all casting methods that have unique advantages and disadvantages. Die casting involves injecting molten metal, typically aluminum or zinc, into a steel mold under high pressure. The overall difference between the two methods based on each. Die Casting Vs Investment Casting.

From www.deangroup-int.co.uk

Investment Casting vs Die Casting Die Casting Vs Investment Casting Die casting, investment casting, and sand casting are all casting methods that have unique advantages and disadvantages. Die casting involves injecting molten metal, typically aluminum or zinc, into a steel mold under high pressure. While investment casting is utilized in aerospace and medical industries for complex components, die casting is widely used in the. The overall difference between the two. Die Casting Vs Investment Casting.

From simalex.com

AN INSIDER LOOK AT GRAVITY DIE CASTING VS PRESSURE DIE CASTING Simalex Die Casting Vs Investment Casting Although these techniques have the same basic principles, investment casting vs die casting have specific differences. Die casting involves injecting molten metal, typically aluminum or zinc, into a steel mold under high pressure. Die casting vs investment casting are distinct manufacturing methods for crafting intricate metal components. Die casting, investment casting, and sand casting are all casting methods that have. Die Casting Vs Investment Casting.

From www.newayprecision.com

Metal Injection Molding (MIM) Vs. Investment Casting Die Casting Vs Investment Casting Die casting involves injecting molten metal, typically aluminum or zinc, into a steel mold under high pressure. The overall difference between the two methods based on each process involved is that investment casting utilizes wax patterns. Die casting vs investment casting are distinct manufacturing methods for crafting intricate metal components. While investment casting and die casting employ similar manufacturing principles. Die Casting Vs Investment Casting.

From blog.thepipingmart.com

Die Casting vs What's the Difference Die Casting Vs Investment Casting Die casting, investment casting, and sand casting are all casting methods that have unique advantages and disadvantages. While investment casting is utilized in aerospace and medical industries for complex components, die casting is widely used in the. Die casting involves injecting molten metal, typically aluminum or zinc, into a steel mold under high pressure. The overall difference between the two. Die Casting Vs Investment Casting.

From unitymanufacture.com

What Is The Difference Between Sand Casting And Die Casting? Unity Die Casting Vs Investment Casting While investment casting and die casting employ similar manufacturing principles to produce parts and products, there are clear distinctions between the two processes. Die casting involves injecting molten metal, typically aluminum or zinc, into a steel mold under high pressure. Die casting, investment casting, and sand casting are all casting methods that have unique advantages and disadvantages. The overall difference. Die Casting Vs Investment Casting.

From precisecast.com

Sand Casting vs Die Casting The Pros and Cons Blog Precise Cast Die Casting Vs Investment Casting Die casting vs investment casting are distinct manufacturing methods for crafting intricate metal components. Although these techniques have the same basic principles, investment casting vs die casting have specific differences. While investment casting is utilized in aerospace and medical industries for complex components, die casting is widely used in the. The overall difference between the two methods based on each. Die Casting Vs Investment Casting.

From www.metaltek.com

Die Casting vs. Investment Casting vs. Sand Casting MetalTek Die Casting Vs Investment Casting The overall difference between the two methods based on each process involved is that investment casting utilizes wax patterns. Die casting involves injecting molten metal, typically aluminum or zinc, into a steel mold under high pressure. Although these techniques have the same basic principles, investment casting vs die casting have specific differences. While investment casting is utilized in aerospace and. Die Casting Vs Investment Casting.

From capablemachining.com

Investment Casting vs Die Casting Capable Machining Die Casting Vs Investment Casting While investment casting and die casting employ similar manufacturing principles to produce parts and products, there are clear distinctions between the two processes. Die casting vs investment casting are distinct manufacturing methods for crafting intricate metal components. The overall difference between the two methods based on each process involved is that investment casting utilizes wax patterns. Die casting, investment casting,. Die Casting Vs Investment Casting.

From www.mapyourinfo.com

Investment Casting vs. Die Casting Map Your Info Die Casting Vs Investment Casting Although these techniques have the same basic principles, investment casting vs die casting have specific differences. While investment casting is utilized in aerospace and medical industries for complex components, die casting is widely used in the. The overall difference between the two methods based on each process involved is that investment casting utilizes wax patterns. While investment casting and die. Die Casting Vs Investment Casting.