Brewing Under Pressure . This is typically done by fermenting beer inside a closed vessel, which is then pressurized. By fermenting under pressure, you are able to ferment at higher temperatures than normal, which in turn allows for a faster. One of the standout benefits of pressure fermentation is the ability to expedite yeast activity at elevated temperatures without compromising flavor. Pressurized fermentation is a process that ferments beer under pressure higher than 0 psi. Pressure fermentation involves fermenting beer under a controlled amount of pressure, typically using a specially designed fermenter. It’s a popular topic in home brewing communities and is also used by micro and macro breweries. It’s a technique that takes the. The control lager batch finished fermenting in under two weeks and was then. One fermenter was set at 0 psi (atm pressure), one at 15 psi (1 bar), and one at 30 psi (2 bar).

from beerme.com

It’s a popular topic in home brewing communities and is also used by micro and macro breweries. By fermenting under pressure, you are able to ferment at higher temperatures than normal, which in turn allows for a faster. Pressurized fermentation is a process that ferments beer under pressure higher than 0 psi. It’s a technique that takes the. The control lager batch finished fermenting in under two weeks and was then. This is typically done by fermenting beer inside a closed vessel, which is then pressurized. One of the standout benefits of pressure fermentation is the ability to expedite yeast activity at elevated temperatures without compromising flavor. One fermenter was set at 0 psi (atm pressure), one at 15 psi (1 bar), and one at 30 psi (2 bar). Pressure fermentation involves fermenting beer under a controlled amount of pressure, typically using a specially designed fermenter.

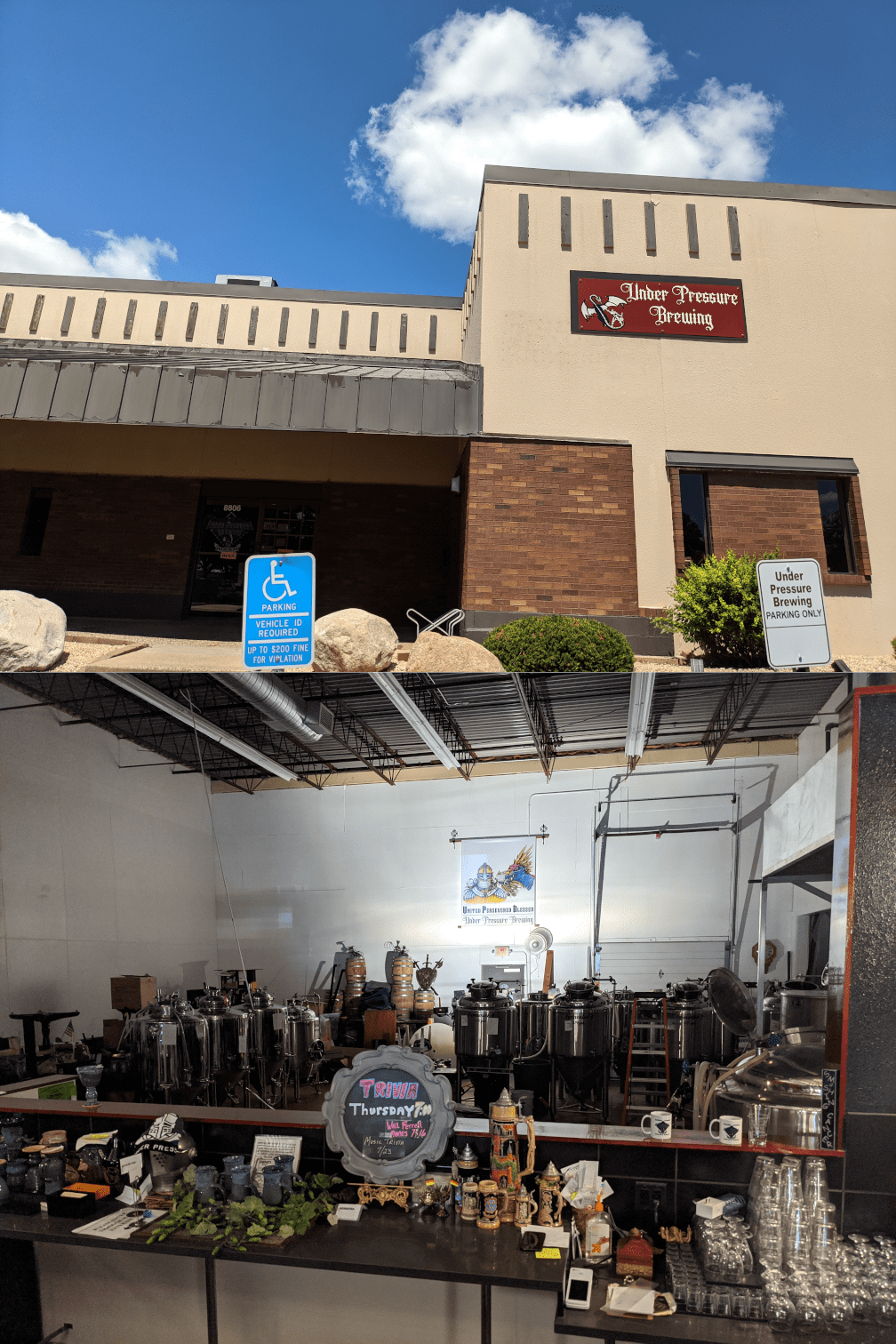

Beer Me! — Under Pressure Brewing Company LLC — Golden Valley

Brewing Under Pressure This is typically done by fermenting beer inside a closed vessel, which is then pressurized. One fermenter was set at 0 psi (atm pressure), one at 15 psi (1 bar), and one at 30 psi (2 bar). The control lager batch finished fermenting in under two weeks and was then. It’s a popular topic in home brewing communities and is also used by micro and macro breweries. This is typically done by fermenting beer inside a closed vessel, which is then pressurized. One of the standout benefits of pressure fermentation is the ability to expedite yeast activity at elevated temperatures without compromising flavor. Pressurized fermentation is a process that ferments beer under pressure higher than 0 psi. Pressure fermentation involves fermenting beer under a controlled amount of pressure, typically using a specially designed fermenter. It’s a technique that takes the. By fermenting under pressure, you are able to ferment at higher temperatures than normal, which in turn allows for a faster.

From www.alamy.com

Espresso is a coffeebrewing method of Italian origin, in which a small Brewing Under Pressure This is typically done by fermenting beer inside a closed vessel, which is then pressurized. The control lager batch finished fermenting in under two weeks and was then. It’s a technique that takes the. Pressurized fermentation is a process that ferments beer under pressure higher than 0 psi. Pressure fermentation involves fermenting beer under a controlled amount of pressure, typically. Brewing Under Pressure.

From www.youtube.com

Under Pressure Brewing Celebrates 4Year Anniversary in Golden Valley Brewing Under Pressure It’s a popular topic in home brewing communities and is also used by micro and macro breweries. One fermenter was set at 0 psi (atm pressure), one at 15 psi (1 bar), and one at 30 psi (2 bar). Pressure fermentation involves fermenting beer under a controlled amount of pressure, typically using a specially designed fermenter. Pressurized fermentation is a. Brewing Under Pressure.

From www.pinterest.com

Brewing Under Pressure Pocket Fuel Daily Devotional Brewing, Daily Brewing Under Pressure Pressurized fermentation is a process that ferments beer under pressure higher than 0 psi. The control lager batch finished fermenting in under two weeks and was then. One fermenter was set at 0 psi (atm pressure), one at 15 psi (1 bar), and one at 30 psi (2 bar). It’s a popular topic in home brewing communities and is also. Brewing Under Pressure.

From drhansbrewery.com

Experimenting with Hot Fermented Lagers Pressure vs No Pressure Brewing Under Pressure The control lager batch finished fermenting in under two weeks and was then. This is typically done by fermenting beer inside a closed vessel, which is then pressurized. By fermenting under pressure, you are able to ferment at higher temperatures than normal, which in turn allows for a faster. One fermenter was set at 0 psi (atm pressure), one at. Brewing Under Pressure.

From www.pinterest.co.uk

Buy a 7.1 Gallon FermZilla Conical Fermenter Get a Free 20 Gift Card Brewing Under Pressure Pressurized fermentation is a process that ferments beer under pressure higher than 0 psi. By fermenting under pressure, you are able to ferment at higher temperatures than normal, which in turn allows for a faster. One of the standout benefits of pressure fermentation is the ability to expedite yeast activity at elevated temperatures without compromising flavor. This is typically done. Brewing Under Pressure.

From beerme.com

Beer Me! — Under Pressure Brewing Company LLC — Golden Valley Brewing Under Pressure By fermenting under pressure, you are able to ferment at higher temperatures than normal, which in turn allows for a faster. One of the standout benefits of pressure fermentation is the ability to expedite yeast activity at elevated temperatures without compromising flavor. It’s a technique that takes the. One fermenter was set at 0 psi (atm pressure), one at 15. Brewing Under Pressure.

From www.desertcart.com.kw

Buy Lab Vacuum Filtration Distillation Apparatus 250mL 1000ML Brewing Under Pressure It’s a popular topic in home brewing communities and is also used by micro and macro breweries. Pressure fermentation involves fermenting beer under a controlled amount of pressure, typically using a specially designed fermenter. This is typically done by fermenting beer inside a closed vessel, which is then pressurized. Pressurized fermentation is a process that ferments beer under pressure higher. Brewing Under Pressure.

From twincitiesgeek.com

Under Pressure Brewing Concocts a Medieval Experience in Golden Valley Brewing Under Pressure Pressure fermentation involves fermenting beer under a controlled amount of pressure, typically using a specially designed fermenter. By fermenting under pressure, you are able to ferment at higher temperatures than normal, which in turn allows for a faster. The control lager batch finished fermenting in under two weeks and was then. One of the standout benefits of pressure fermentation is. Brewing Under Pressure.

From www.youtube.com

Mistakes!! brewing under pressure YouTube Brewing Under Pressure The control lager batch finished fermenting in under two weeks and was then. This is typically done by fermenting beer inside a closed vessel, which is then pressurized. One of the standout benefits of pressure fermentation is the ability to expedite yeast activity at elevated temperatures without compromising flavor. It’s a technique that takes the. By fermenting under pressure, you. Brewing Under Pressure.

From www.bustersliquors.com

Meddlesome Brewing Under Pressure Vanilla Porter 6 pack 12 oz. Can Brewing Under Pressure One fermenter was set at 0 psi (atm pressure), one at 15 psi (1 bar), and one at 30 psi (2 bar). This is typically done by fermenting beer inside a closed vessel, which is then pressurized. It’s a popular topic in home brewing communities and is also used by micro and macro breweries. It’s a technique that takes the.. Brewing Under Pressure.

From www.pinterest.com

Fermenting & Dry Hopping Under Pressure Scott Janish Fermenting Brewing Under Pressure This is typically done by fermenting beer inside a closed vessel, which is then pressurized. By fermenting under pressure, you are able to ferment at higher temperatures than normal, which in turn allows for a faster. One of the standout benefits of pressure fermentation is the ability to expedite yeast activity at elevated temperatures without compromising flavor. The control lager. Brewing Under Pressure.

From www.onlyinyourstate.com

Under Pressure Brewing Company In Minnesota Serves Great Butterbeer Brewing Under Pressure Pressurized fermentation is a process that ferments beer under pressure higher than 0 psi. One of the standout benefits of pressure fermentation is the ability to expedite yeast activity at elevated temperatures without compromising flavor. This is typically done by fermenting beer inside a closed vessel, which is then pressurized. By fermenting under pressure, you are able to ferment at. Brewing Under Pressure.

From www.gopuff.com

Paperback Brewing Under Pressure Pale Ale 4pk 16oz Cans Alcohol fast Brewing Under Pressure One of the standout benefits of pressure fermentation is the ability to expedite yeast activity at elevated temperatures without compromising flavor. Pressure fermentation involves fermenting beer under a controlled amount of pressure, typically using a specially designed fermenter. It’s a technique that takes the. Pressurized fermentation is a process that ferments beer under pressure higher than 0 psi. By fermenting. Brewing Under Pressure.

From my-beers.com

Pressure Drop Brewing / プレッシャードロップブリューイング(米国) クラフトビール探すならMyBeer Brewing Under Pressure One fermenter was set at 0 psi (atm pressure), one at 15 psi (1 bar), and one at 30 psi (2 bar). Pressure fermentation involves fermenting beer under a controlled amount of pressure, typically using a specially designed fermenter. It’s a popular topic in home brewing communities and is also used by micro and macro breweries. Pressurized fermentation is a. Brewing Under Pressure.

From happyhopshomebrewing.com

BrewBuilt™ Kit for Fermenting Under Pressure Happy Hops Home Brewing Brewing Under Pressure It’s a popular topic in home brewing communities and is also used by micro and macro breweries. Pressurized fermentation is a process that ferments beer under pressure higher than 0 psi. By fermenting under pressure, you are able to ferment at higher temperatures than normal, which in turn allows for a faster. One fermenter was set at 0 psi (atm. Brewing Under Pressure.

From www.reddit.com

Why isn't "Under Pressure" brewing talked about more? r/minnesotabeer Brewing Under Pressure It’s a popular topic in home brewing communities and is also used by micro and macro breweries. The control lager batch finished fermenting in under two weeks and was then. By fermenting under pressure, you are able to ferment at higher temperatures than normal, which in turn allows for a faster. It’s a technique that takes the. One of the. Brewing Under Pressure.

From www.supramatic.com

Pressure Brew Aroma System PBAS Brew Facts Brewing Under Pressure One fermenter was set at 0 psi (atm pressure), one at 15 psi (1 bar), and one at 30 psi (2 bar). It’s a popular topic in home brewing communities and is also used by micro and macro breweries. One of the standout benefits of pressure fermentation is the ability to expedite yeast activity at elevated temperatures without compromising flavor.. Brewing Under Pressure.

From untappd.com

Under Pressure Brewing Golden Valley, MN Untappd Brewing Under Pressure It’s a popular topic in home brewing communities and is also used by micro and macro breweries. Pressurized fermentation is a process that ferments beer under pressure higher than 0 psi. It’s a technique that takes the. This is typically done by fermenting beer inside a closed vessel, which is then pressurized. One fermenter was set at 0 psi (atm. Brewing Under Pressure.

From byo.com

Under Pressure Capturing CO2 During Fermentation Brew Your Own Brewing Under Pressure Pressurized fermentation is a process that ferments beer under pressure higher than 0 psi. It’s a technique that takes the. The control lager batch finished fermenting in under two weeks and was then. One fermenter was set at 0 psi (atm pressure), one at 15 psi (1 bar), and one at 30 psi (2 bar). This is typically done by. Brewing Under Pressure.

From www.alamy.com

Manual brewing hires stock photography and images Alamy Brewing Under Pressure Pressurized fermentation is a process that ferments beer under pressure higher than 0 psi. This is typically done by fermenting beer inside a closed vessel, which is then pressurized. Pressure fermentation involves fermenting beer under a controlled amount of pressure, typically using a specially designed fermenter. By fermenting under pressure, you are able to ferment at higher temperatures than normal,. Brewing Under Pressure.

From buffalonews.com

Pressure Drop Brewing up for sale Brewing Under Pressure One of the standout benefits of pressure fermentation is the ability to expedite yeast activity at elevated temperatures without compromising flavor. Pressure fermentation involves fermenting beer under a controlled amount of pressure, typically using a specially designed fermenter. Pressurized fermentation is a process that ferments beer under pressure higher than 0 psi. One fermenter was set at 0 psi (atm. Brewing Under Pressure.

From www.yelp.com

UNDER PRESSURE BREWING 40 Photos & 36 Reviews 8806 7th Ave N Brewing Under Pressure It’s a popular topic in home brewing communities and is also used by micro and macro breweries. By fermenting under pressure, you are able to ferment at higher temperatures than normal, which in turn allows for a faster. Pressurized fermentation is a process that ferments beer under pressure higher than 0 psi. One of the standout benefits of pressure fermentation. Brewing Under Pressure.

From www.bizjournals.com

Hot Spots Golden Valley's first brewery is now open Minneapolis / St Brewing Under Pressure Pressure fermentation involves fermenting beer under a controlled amount of pressure, typically using a specially designed fermenter. It’s a popular topic in home brewing communities and is also used by micro and macro breweries. One fermenter was set at 0 psi (atm pressure), one at 15 psi (1 bar), and one at 30 psi (2 bar). One of the standout. Brewing Under Pressure.

From brother-beer.nl

Little Rain Brewing Under Pressure Brother Beer Brewing Under Pressure The control lager batch finished fermenting in under two weeks and was then. It’s a popular topic in home brewing communities and is also used by micro and macro breweries. This is typically done by fermenting beer inside a closed vessel, which is then pressurized. One of the standout benefits of pressure fermentation is the ability to expedite yeast activity. Brewing Under Pressure.

From www.helenacoffee.vn

Coffee Brewing Methods Unraveled From French Press to Espresso Brewing Under Pressure The control lager batch finished fermenting in under two weeks and was then. By fermenting under pressure, you are able to ferment at higher temperatures than normal, which in turn allows for a faster. It’s a technique that takes the. This is typically done by fermenting beer inside a closed vessel, which is then pressurized. One of the standout benefits. Brewing Under Pressure.

From www.homebrewfinds.com

Fermenting Under Pressure! Homebrew Finds Brewing Under Pressure One fermenter was set at 0 psi (atm pressure), one at 15 psi (1 bar), and one at 30 psi (2 bar). The control lager batch finished fermenting in under two weeks and was then. It’s a popular topic in home brewing communities and is also used by micro and macro breweries. By fermenting under pressure, you are able to. Brewing Under Pressure.

From www.gopuff.com

Paperback Brewing Under Pressure Pale Ale 4pk 16oz Cans Alcohol fast Brewing Under Pressure Pressure fermentation involves fermenting beer under a controlled amount of pressure, typically using a specially designed fermenter. One of the standout benefits of pressure fermentation is the ability to expedite yeast activity at elevated temperatures without compromising flavor. Pressurized fermentation is a process that ferments beer under pressure higher than 0 psi. It’s a popular topic in home brewing communities. Brewing Under Pressure.

From www.bitterandesters.com

Under Pressure Bitter & Esters Brewing Under Pressure By fermenting under pressure, you are able to ferment at higher temperatures than normal, which in turn allows for a faster. Pressurized fermentation is a process that ferments beer under pressure higher than 0 psi. It’s a popular topic in home brewing communities and is also used by micro and macro breweries. One fermenter was set at 0 psi (atm. Brewing Under Pressure.

From www.bustersliquors.com

Meddlesome Brewing Under Pressure Vanilla Porter 6 pack 12 oz. Can Brewing Under Pressure It’s a popular topic in home brewing communities and is also used by micro and macro breweries. One of the standout benefits of pressure fermentation is the ability to expedite yeast activity at elevated temperatures without compromising flavor. The control lager batch finished fermenting in under two weeks and was then. By fermenting under pressure, you are able to ferment. Brewing Under Pressure.

From meddlesomebrewing.com

» Under Pressure Meddlesome Brewing Company Brewing Under Pressure It’s a popular topic in home brewing communities and is also used by micro and macro breweries. By fermenting under pressure, you are able to ferment at higher temperatures than normal, which in turn allows for a faster. One fermenter was set at 0 psi (atm pressure), one at 15 psi (1 bar), and one at 30 psi (2 bar).. Brewing Under Pressure.

From drhansbrewery.com

Experimenting with Hot Fermented Lagers Pressure vs No Pressure Brewing Under Pressure One of the standout benefits of pressure fermentation is the ability to expedite yeast activity at elevated temperatures without compromising flavor. Pressurized fermentation is a process that ferments beer under pressure higher than 0 psi. It’s a popular topic in home brewing communities and is also used by micro and macro breweries. It’s a technique that takes the. The control. Brewing Under Pressure.

From untappd.com

Under Pressure Choice Bros Brewing Photos Untappd Brewing Under Pressure One fermenter was set at 0 psi (atm pressure), one at 15 psi (1 bar), and one at 30 psi (2 bar). By fermenting under pressure, you are able to ferment at higher temperatures than normal, which in turn allows for a faster. One of the standout benefits of pressure fermentation is the ability to expedite yeast activity at elevated. Brewing Under Pressure.

From www.youtube.com

Home Brewing Fermenting under pressure The Malt Miller YouTube Brewing Under Pressure One fermenter was set at 0 psi (atm pressure), one at 15 psi (1 bar), and one at 30 psi (2 bar). Pressurized fermentation is a process that ferments beer under pressure higher than 0 psi. One of the standout benefits of pressure fermentation is the ability to expedite yeast activity at elevated temperatures without compromising flavor. Pressure fermentation involves. Brewing Under Pressure.

From www.pinterest.com

Fermenting under pressure DIY Brewing Blether Coopers Community Brewing Under Pressure By fermenting under pressure, you are able to ferment at higher temperatures than normal, which in turn allows for a faster. Pressurized fermentation is a process that ferments beer under pressure higher than 0 psi. The control lager batch finished fermenting in under two weeks and was then. One of the standout benefits of pressure fermentation is the ability to. Brewing Under Pressure.

From www.pinterest.com

Beer Temperature Guide How to Store and Serve Every Brew [Infographic Brewing Under Pressure The control lager batch finished fermenting in under two weeks and was then. Pressure fermentation involves fermenting beer under a controlled amount of pressure, typically using a specially designed fermenter. It’s a technique that takes the. This is typically done by fermenting beer inside a closed vessel, which is then pressurized. One fermenter was set at 0 psi (atm pressure),. Brewing Under Pressure.