Float Glass Manufacturing Process Pdf . Once manufactured float glass, which is also known as annealed glass, is sometimes. A schematic diagram of the production process of float glass. The importance of the float process can be placed in perspective by taking a look at the processes used for making flat glass before and at the. Making float glass begins with a mixture of the raw materials based on approximately 50% silica sand, soda ash, limestone, rouge and dolomite. Float forming has undergone continuous development since the process was first introduced for commercial flat glass. There are two basic sources of transmitted distortion, glass inhomogeneities and surface irregularities. This presentation provides an overview of the manufacturing process at nasir glass industries limited (ngil) in bangladesh. The glass inhomogeneities originate in.

from glassed.vitroglazings.com

A schematic diagram of the production process of float glass. Once manufactured float glass, which is also known as annealed glass, is sometimes. This presentation provides an overview of the manufacturing process at nasir glass industries limited (ngil) in bangladesh. There are two basic sources of transmitted distortion, glass inhomogeneities and surface irregularities. Making float glass begins with a mixture of the raw materials based on approximately 50% silica sand, soda ash, limestone, rouge and dolomite. The glass inhomogeneities originate in. The importance of the float process can be placed in perspective by taking a look at the processes used for making flat glass before and at the. Float forming has undergone continuous development since the process was first introduced for commercial flat glass.

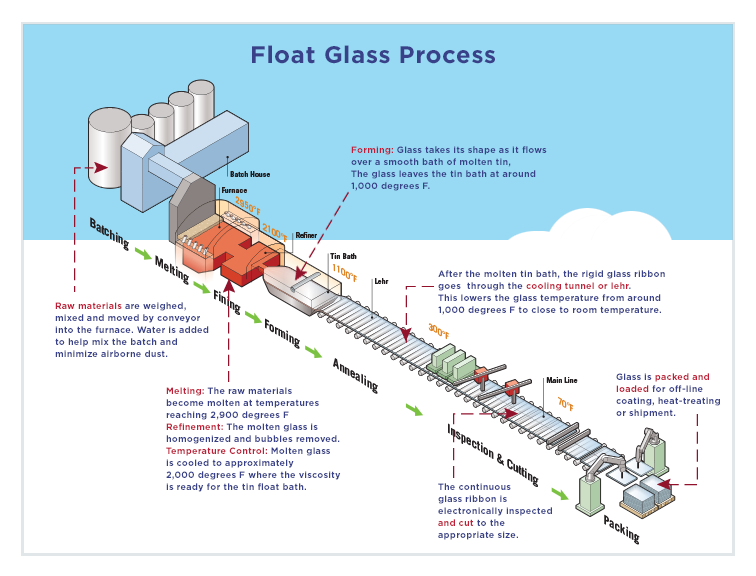

Float Glass Process

Float Glass Manufacturing Process Pdf Making float glass begins with a mixture of the raw materials based on approximately 50% silica sand, soda ash, limestone, rouge and dolomite. The importance of the float process can be placed in perspective by taking a look at the processes used for making flat glass before and at the. Making float glass begins with a mixture of the raw materials based on approximately 50% silica sand, soda ash, limestone, rouge and dolomite. Float forming has undergone continuous development since the process was first introduced for commercial flat glass. This presentation provides an overview of the manufacturing process at nasir glass industries limited (ngil) in bangladesh. Once manufactured float glass, which is also known as annealed glass, is sometimes. There are two basic sources of transmitted distortion, glass inhomogeneities and surface irregularities. A schematic diagram of the production process of float glass. The glass inhomogeneities originate in.

From www.glass-fabricators.com

Glass Companies Glass Suppliers Float Glass Manufacturing Process Pdf The importance of the float process can be placed in perspective by taking a look at the processes used for making flat glass before and at the. Making float glass begins with a mixture of the raw materials based on approximately 50% silica sand, soda ash, limestone, rouge and dolomite. The glass inhomogeneities originate in. A schematic diagram of the. Float Glass Manufacturing Process Pdf.

From www.abnewswire.com

Float Glass Manufacturing Plant Cost, Manufacturing Process, Business Float Glass Manufacturing Process Pdf This presentation provides an overview of the manufacturing process at nasir glass industries limited (ngil) in bangladesh. Once manufactured float glass, which is also known as annealed glass, is sometimes. Float forming has undergone continuous development since the process was first introduced for commercial flat glass. Making float glass begins with a mixture of the raw materials based on approximately. Float Glass Manufacturing Process Pdf.

From glassforeurope.com

Hot hold operations in the flat glass sector Glass for Europe Float Glass Manufacturing Process Pdf This presentation provides an overview of the manufacturing process at nasir glass industries limited (ngil) in bangladesh. The glass inhomogeneities originate in. A schematic diagram of the production process of float glass. There are two basic sources of transmitted distortion, glass inhomogeneities and surface irregularities. The importance of the float process can be placed in perspective by taking a look. Float Glass Manufacturing Process Pdf.

From agc-glassasia.com

Conventional Float Production Process AGC Glass Asia Pacific Float Glass Manufacturing Process Pdf There are two basic sources of transmitted distortion, glass inhomogeneities and surface irregularities. A schematic diagram of the production process of float glass. The importance of the float process can be placed in perspective by taking a look at the processes used for making flat glass before and at the. Once manufactured float glass, which is also known as annealed. Float Glass Manufacturing Process Pdf.

From www.researchgate.net

Float glass manufacturing process based on the float line of AGC Float Glass Manufacturing Process Pdf This presentation provides an overview of the manufacturing process at nasir glass industries limited (ngil) in bangladesh. Float forming has undergone continuous development since the process was first introduced for commercial flat glass. Once manufactured float glass, which is also known as annealed glass, is sometimes. The importance of the float process can be placed in perspective by taking a. Float Glass Manufacturing Process Pdf.

From www.youtube.com

SaintGobain Glass Float Process YouTube Float Glass Manufacturing Process Pdf A schematic diagram of the production process of float glass. The importance of the float process can be placed in perspective by taking a look at the processes used for making flat glass before and at the. Once manufactured float glass, which is also known as annealed glass, is sometimes. There are two basic sources of transmitted distortion, glass inhomogeneities. Float Glass Manufacturing Process Pdf.

From www.scribd.com

Float Glass Manufacturing Process 002 PDF Float Glass Manufacturing Process Pdf The glass inhomogeneities originate in. Once manufactured float glass, which is also known as annealed glass, is sometimes. This presentation provides an overview of the manufacturing process at nasir glass industries limited (ngil) in bangladesh. There are two basic sources of transmitted distortion, glass inhomogeneities and surface irregularities. Float forming has undergone continuous development since the process was first introduced. Float Glass Manufacturing Process Pdf.

From present5.com

Agenda Company profile Global Glass Float Glass Manufacturing Process Pdf There are two basic sources of transmitted distortion, glass inhomogeneities and surface irregularities. Once manufactured float glass, which is also known as annealed glass, is sometimes. Making float glass begins with a mixture of the raw materials based on approximately 50% silica sand, soda ash, limestone, rouge and dolomite. The importance of the float process can be placed in perspective. Float Glass Manufacturing Process Pdf.

From www.slideshare.net

Float Glass Manufacturing Process PDF Float Glass Manufacturing Process Pdf This presentation provides an overview of the manufacturing process at nasir glass industries limited (ngil) in bangladesh. There are two basic sources of transmitted distortion, glass inhomogeneities and surface irregularities. The importance of the float process can be placed in perspective by taking a look at the processes used for making flat glass before and at the. Making float glass. Float Glass Manufacturing Process Pdf.

From www.slideshare.net

Float Glass Manufacturing Process PDF Float Glass Manufacturing Process Pdf Float forming has undergone continuous development since the process was first introduced for commercial flat glass. There are two basic sources of transmitted distortion, glass inhomogeneities and surface irregularities. Making float glass begins with a mixture of the raw materials based on approximately 50% silica sand, soda ash, limestone, rouge and dolomite. The importance of the float process can be. Float Glass Manufacturing Process Pdf.

From www.guardianglass.com

Glass manufacturing process production , coating, lamination Float Glass Manufacturing Process Pdf The glass inhomogeneities originate in. This presentation provides an overview of the manufacturing process at nasir glass industries limited (ngil) in bangladesh. A schematic diagram of the production process of float glass. Once manufactured float glass, which is also known as annealed glass, is sometimes. Making float glass begins with a mixture of the raw materials based on approximately 50%. Float Glass Manufacturing Process Pdf.

From www.youtube.com

How Glass is Made? Float Glass Manufacturing Process Glass Factory Float Glass Manufacturing Process Pdf Float forming has undergone continuous development since the process was first introduced for commercial flat glass. A schematic diagram of the production process of float glass. Making float glass begins with a mixture of the raw materials based on approximately 50% silica sand, soda ash, limestone, rouge and dolomite. Once manufactured float glass, which is also known as annealed glass,. Float Glass Manufacturing Process Pdf.

From www.pilkington.com

The Float Process Float Glass Manufacturing Process Pdf The glass inhomogeneities originate in. Float forming has undergone continuous development since the process was first introduced for commercial flat glass. This presentation provides an overview of the manufacturing process at nasir glass industries limited (ngil) in bangladesh. The importance of the float process can be placed in perspective by taking a look at the processes used for making flat. Float Glass Manufacturing Process Pdf.

From www.gw-news.eu

Glass basics How the float glass process has revolutionised the Float Glass Manufacturing Process Pdf The importance of the float process can be placed in perspective by taking a look at the processes used for making flat glass before and at the. This presentation provides an overview of the manufacturing process at nasir glass industries limited (ngil) in bangladesh. There are two basic sources of transmitted distortion, glass inhomogeneities and surface irregularities. The glass inhomogeneities. Float Glass Manufacturing Process Pdf.

From www.metroglasstech.co.nz

9.1 Composition, 9.2 Manufacture Glass Metro GlassTech Float Glass Manufacturing Process Pdf Making float glass begins with a mixture of the raw materials based on approximately 50% silica sand, soda ash, limestone, rouge and dolomite. There are two basic sources of transmitted distortion, glass inhomogeneities and surface irregularities. The importance of the float process can be placed in perspective by taking a look at the processes used for making flat glass before. Float Glass Manufacturing Process Pdf.

From www.liverpoolecho.co.uk

Pilkington in St Helens look inside the glass factory Liverpool Echo Float Glass Manufacturing Process Pdf A schematic diagram of the production process of float glass. Once manufactured float glass, which is also known as annealed glass, is sometimes. The glass inhomogeneities originate in. This presentation provides an overview of the manufacturing process at nasir glass industries limited (ngil) in bangladesh. The importance of the float process can be placed in perspective by taking a look. Float Glass Manufacturing Process Pdf.

From agc-glassasia.com

Conventional Float Production Process AGC Glass Asia Pacific Float Glass Manufacturing Process Pdf There are two basic sources of transmitted distortion, glass inhomogeneities and surface irregularities. This presentation provides an overview of the manufacturing process at nasir glass industries limited (ngil) in bangladesh. Float forming has undergone continuous development since the process was first introduced for commercial flat glass. A schematic diagram of the production process of float glass. The importance of the. Float Glass Manufacturing Process Pdf.

From www.scribd.com

Float Glass Manufacturing Process PDF Float Glass Manufacturing Process Pdf The importance of the float process can be placed in perspective by taking a look at the processes used for making flat glass before and at the. There are two basic sources of transmitted distortion, glass inhomogeneities and surface irregularities. Making float glass begins with a mixture of the raw materials based on approximately 50% silica sand, soda ash, limestone,. Float Glass Manufacturing Process Pdf.

From jagomart.net

Manufacturing Process Pdf 222746 Brochure Expert Series En Doc5 Mfg Float Glass Manufacturing Process Pdf The glass inhomogeneities originate in. There are two basic sources of transmitted distortion, glass inhomogeneities and surface irregularities. This presentation provides an overview of the manufacturing process at nasir glass industries limited (ngil) in bangladesh. Float forming has undergone continuous development since the process was first introduced for commercial flat glass. Making float glass begins with a mixture of the. Float Glass Manufacturing Process Pdf.

From dokumen.tips

(PDF) 02_Float Glass Manufacturing Process.pdf DOKUMEN.TIPS Float Glass Manufacturing Process Pdf Float forming has undergone continuous development since the process was first introduced for commercial flat glass. There are two basic sources of transmitted distortion, glass inhomogeneities and surface irregularities. The importance of the float process can be placed in perspective by taking a look at the processes used for making flat glass before and at the. Making float glass begins. Float Glass Manufacturing Process Pdf.

From www.glass-fabricators.com

Glass Companies Glass Suppliers Float Glass Manufacturing Process Pdf A schematic diagram of the production process of float glass. Making float glass begins with a mixture of the raw materials based on approximately 50% silica sand, soda ash, limestone, rouge and dolomite. The importance of the float process can be placed in perspective by taking a look at the processes used for making flat glass before and at the.. Float Glass Manufacturing Process Pdf.

From glassed.vitroglazings.com

Float Glass Process Float Glass Manufacturing Process Pdf This presentation provides an overview of the manufacturing process at nasir glass industries limited (ngil) in bangladesh. Once manufactured float glass, which is also known as annealed glass, is sometimes. A schematic diagram of the production process of float glass. The importance of the float process can be placed in perspective by taking a look at the processes used for. Float Glass Manufacturing Process Pdf.

From www.studocu.com

Float glass manufacturing process Float glass process flow chart Float Glass Manufacturing Process Pdf Once manufactured float glass, which is also known as annealed glass, is sometimes. The importance of the float process can be placed in perspective by taking a look at the processes used for making flat glass before and at the. Making float glass begins with a mixture of the raw materials based on approximately 50% silica sand, soda ash, limestone,. Float Glass Manufacturing Process Pdf.

From www.slideshare.net

Float glass manufacturing process Float Glass Manufacturing Process Pdf This presentation provides an overview of the manufacturing process at nasir glass industries limited (ngil) in bangladesh. The glass inhomogeneities originate in. Making float glass begins with a mixture of the raw materials based on approximately 50% silica sand, soda ash, limestone, rouge and dolomite. Once manufactured float glass, which is also known as annealed glass, is sometimes. The importance. Float Glass Manufacturing Process Pdf.

From visiontir.com

Temperature control in float glass manufacturing VisionTIR Float Glass Manufacturing Process Pdf Making float glass begins with a mixture of the raw materials based on approximately 50% silica sand, soda ash, limestone, rouge and dolomite. This presentation provides an overview of the manufacturing process at nasir glass industries limited (ngil) in bangladesh. The importance of the float process can be placed in perspective by taking a look at the processes used for. Float Glass Manufacturing Process Pdf.

From glassed.vitroglazings.com

Float Glass Process Float Glass Manufacturing Process Pdf The glass inhomogeneities originate in. There are two basic sources of transmitted distortion, glass inhomogeneities and surface irregularities. The importance of the float process can be placed in perspective by taking a look at the processes used for making flat glass before and at the. Float forming has undergone continuous development since the process was first introduced for commercial flat. Float Glass Manufacturing Process Pdf.

From glassed.vitroglazings.com

Float Glass Process Float Glass Manufacturing Process Pdf Making float glass begins with a mixture of the raw materials based on approximately 50% silica sand, soda ash, limestone, rouge and dolomite. Once manufactured float glass, which is also known as annealed glass, is sometimes. This presentation provides an overview of the manufacturing process at nasir glass industries limited (ngil) in bangladesh. There are two basic sources of transmitted. Float Glass Manufacturing Process Pdf.

From issuu.com

Float Glass Manufacturing Plant Project Report 20212026 PDF Float Glass Manufacturing Process Pdf There are two basic sources of transmitted distortion, glass inhomogeneities and surface irregularities. A schematic diagram of the production process of float glass. The importance of the float process can be placed in perspective by taking a look at the processes used for making flat glass before and at the. Float forming has undergone continuous development since the process was. Float Glass Manufacturing Process Pdf.

From www.fivesgroup.com

Float glass lines with key process equipment Float Glass Manufacturing Process Pdf Once manufactured float glass, which is also known as annealed glass, is sometimes. This presentation provides an overview of the manufacturing process at nasir glass industries limited (ngil) in bangladesh. Making float glass begins with a mixture of the raw materials based on approximately 50% silica sand, soda ash, limestone, rouge and dolomite. There are two basic sources of transmitted. Float Glass Manufacturing Process Pdf.

From mavink.com

Glass Process Flow Chart Float Glass Manufacturing Process Pdf A schematic diagram of the production process of float glass. This presentation provides an overview of the manufacturing process at nasir glass industries limited (ngil) in bangladesh. Float forming has undergone continuous development since the process was first introduced for commercial flat glass. The importance of the float process can be placed in perspective by taking a look at the. Float Glass Manufacturing Process Pdf.

From khatabook.com

Float Glass History, manufacturing process and its applications Float Glass Manufacturing Process Pdf There are two basic sources of transmitted distortion, glass inhomogeneities and surface irregularities. Once manufactured float glass, which is also known as annealed glass, is sometimes. Making float glass begins with a mixture of the raw materials based on approximately 50% silica sand, soda ash, limestone, rouge and dolomite. Float forming has undergone continuous development since the process was first. Float Glass Manufacturing Process Pdf.

From info.glass.com

What Is the Float Glass Process? How Float Glass is Made Float Glass Manufacturing Process Pdf Once manufactured float glass, which is also known as annealed glass, is sometimes. Float forming has undergone continuous development since the process was first introduced for commercial flat glass. A schematic diagram of the production process of float glass. There are two basic sources of transmitted distortion, glass inhomogeneities and surface irregularities. Making float glass begins with a mixture of. Float Glass Manufacturing Process Pdf.

From www.researchgate.net

Float glass manufacturing process based on the float line of AGC Float Glass Manufacturing Process Pdf Once manufactured float glass, which is also known as annealed glass, is sometimes. Float forming has undergone continuous development since the process was first introduced for commercial flat glass. The importance of the float process can be placed in perspective by taking a look at the processes used for making flat glass before and at the. The glass inhomogeneities originate. Float Glass Manufacturing Process Pdf.

From gharpedia.com

Raw Materials Used in Glass Manufacturing Process Float Glass Manufacturing Process Pdf There are two basic sources of transmitted distortion, glass inhomogeneities and surface irregularities. This presentation provides an overview of the manufacturing process at nasir glass industries limited (ngil) in bangladesh. The importance of the float process can be placed in perspective by taking a look at the processes used for making flat glass before and at the. Making float glass. Float Glass Manufacturing Process Pdf.

From www.scribd.com

Float Glass Production Process 001 PDF Glasses Process Management Float Glass Manufacturing Process Pdf Once manufactured float glass, which is also known as annealed glass, is sometimes. The importance of the float process can be placed in perspective by taking a look at the processes used for making flat glass before and at the. There are two basic sources of transmitted distortion, glass inhomogeneities and surface irregularities. This presentation provides an overview of the. Float Glass Manufacturing Process Pdf.