Xr6 Turbo Flywheel Bolt Torque . I would even undo and retighten a couple of times as i feel more comfortable that whatever little stretch that is in the bolt is. Chiptorque typically tunes each system to around 300kw at the flywheel. Mal wood quoted to dylan they torque their flywheel to crank bolts up to 65 ft/lbs which is 88nm. If it has, this will also damage and. A slightly striped thread is not good in the back of your crank. You need to torque it right with a good torque wrench. Try and find the torque settings if your not confident mate. The flywheel bolt holes in an au crank are a fair bit shorter than in previous cranks and require special shorter bolts. Just doing the bolt up to the required torque, loctiting it or doing it tighter will not solve this issue.

from www.2carpros.com

You need to torque it right with a good torque wrench. I would even undo and retighten a couple of times as i feel more comfortable that whatever little stretch that is in the bolt is. A slightly striped thread is not good in the back of your crank. Just doing the bolt up to the required torque, loctiting it or doing it tighter will not solve this issue. Mal wood quoted to dylan they torque their flywheel to crank bolts up to 65 ft/lbs which is 88nm. If it has, this will also damage and. Chiptorque typically tunes each system to around 300kw at the flywheel. The flywheel bolt holes in an au crank are a fair bit shorter than in previous cranks and require special shorter bolts. Try and find the torque settings if your not confident mate.

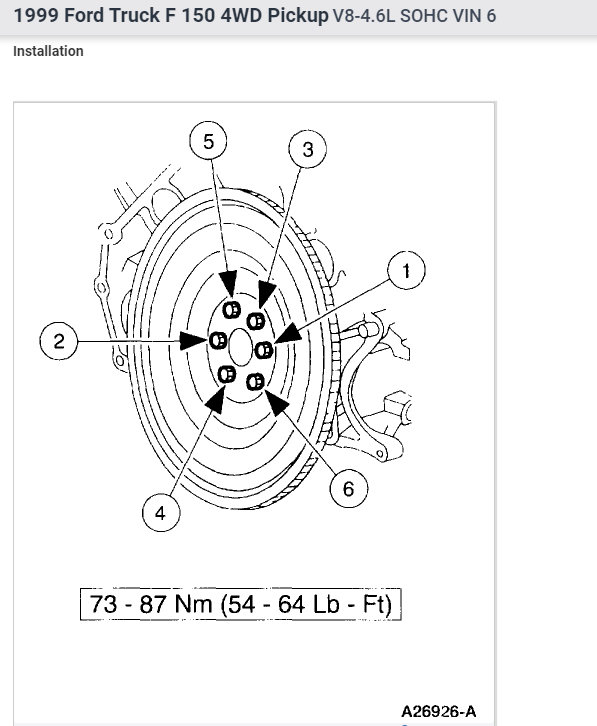

Torque Specs for the Flywheel Needed Torque Specs for Flywheel.

Xr6 Turbo Flywheel Bolt Torque Mal wood quoted to dylan they torque their flywheel to crank bolts up to 65 ft/lbs which is 88nm. The flywheel bolt holes in an au crank are a fair bit shorter than in previous cranks and require special shorter bolts. Mal wood quoted to dylan they torque their flywheel to crank bolts up to 65 ft/lbs which is 88nm. You need to torque it right with a good torque wrench. Try and find the torque settings if your not confident mate. I would even undo and retighten a couple of times as i feel more comfortable that whatever little stretch that is in the bolt is. A slightly striped thread is not good in the back of your crank. Chiptorque typically tunes each system to around 300kw at the flywheel. If it has, this will also damage and. Just doing the bolt up to the required torque, loctiting it or doing it tighter will not solve this issue.

From wiringfixrumanian.z19.web.core.windows.net

Torque Specs Flywheel Bolts Xr6 Turbo Flywheel Bolt Torque Just doing the bolt up to the required torque, loctiting it or doing it tighter will not solve this issue. The flywheel bolt holes in an au crank are a fair bit shorter than in previous cranks and require special shorter bolts. If it has, this will also damage and. Try and find the torque settings if your not confident. Xr6 Turbo Flywheel Bolt Torque.

From classicoldsmobile.com

Flywheel Bolt Torque Counterforce? Xr6 Turbo Flywheel Bolt Torque Just doing the bolt up to the required torque, loctiting it or doing it tighter will not solve this issue. A slightly striped thread is not good in the back of your crank. The flywheel bolt holes in an au crank are a fair bit shorter than in previous cranks and require special shorter bolts. If it has, this will. Xr6 Turbo Flywheel Bolt Torque.

From exoezqqwk.blob.core.windows.net

Vr6 Flywheel Bolt Torque at Bobbie Herold blog Xr6 Turbo Flywheel Bolt Torque Try and find the torque settings if your not confident mate. The flywheel bolt holes in an au crank are a fair bit shorter than in previous cranks and require special shorter bolts. A slightly striped thread is not good in the back of your crank. I would even undo and retighten a couple of times as i feel more. Xr6 Turbo Flywheel Bolt Torque.

From exoznfhic.blob.core.windows.net

Flywheel Bolt Torque Values at Rosalie Seay blog Xr6 Turbo Flywheel Bolt Torque The flywheel bolt holes in an au crank are a fair bit shorter than in previous cranks and require special shorter bolts. You need to torque it right with a good torque wrench. Chiptorque typically tunes each system to around 300kw at the flywheel. Mal wood quoted to dylan they torque their flywheel to crank bolts up to 65 ft/lbs. Xr6 Turbo Flywheel Bolt Torque.

From arashidynamics.com

NEW PRODUCT RELEASE Fully Bolton XR6 Turbo Arashi Dynamics Xr6 Turbo Flywheel Bolt Torque Mal wood quoted to dylan they torque their flywheel to crank bolts up to 65 ft/lbs which is 88nm. Chiptorque typically tunes each system to around 300kw at the flywheel. Try and find the torque settings if your not confident mate. The flywheel bolt holes in an au crank are a fair bit shorter than in previous cranks and require. Xr6 Turbo Flywheel Bolt Torque.

From www.fordxr6turbo.com

Need Torque Specs For Fg General Tech Ford XR6 Xr6 Turbo Flywheel Bolt Torque Just doing the bolt up to the required torque, loctiting it or doing it tighter will not solve this issue. Chiptorque typically tunes each system to around 300kw at the flywheel. Mal wood quoted to dylan they torque their flywheel to crank bolts up to 65 ft/lbs which is 88nm. You need to torque it right with a good torque. Xr6 Turbo Flywheel Bolt Torque.

From mavink.com

Cylinder Head Bolt Torque Chart Xr6 Turbo Flywheel Bolt Torque I would even undo and retighten a couple of times as i feel more comfortable that whatever little stretch that is in the bolt is. If it has, this will also damage and. You need to torque it right with a good torque wrench. A slightly striped thread is not good in the back of your crank. Chiptorque typically tunes. Xr6 Turbo Flywheel Bolt Torque.

From justjap.com

Xtreme Single Mass Flywheel fits Ford Falcon XR6 Turbo (BABF) Just Jap Xr6 Turbo Flywheel Bolt Torque The flywheel bolt holes in an au crank are a fair bit shorter than in previous cranks and require special shorter bolts. Just doing the bolt up to the required torque, loctiting it or doing it tighter will not solve this issue. A slightly striped thread is not good in the back of your crank. Chiptorque typically tunes each system. Xr6 Turbo Flywheel Bolt Torque.

From schematicdatafurman.z13.web.core.windows.net

Bbc Flywheel Bolt Torque Xr6 Turbo Flywheel Bolt Torque Try and find the torque settings if your not confident mate. I would even undo and retighten a couple of times as i feel more comfortable that whatever little stretch that is in the bolt is. Just doing the bolt up to the required torque, loctiting it or doing it tighter will not solve this issue. You need to torque. Xr6 Turbo Flywheel Bolt Torque.

From www.mydeal.com.au

Buy Aeroflow Flywheel Bolt Toyota 1JZ 2JZ 4AGE Fits BA BF FG XR6 Ford Xr6 Turbo Flywheel Bolt Torque Just doing the bolt up to the required torque, loctiting it or doing it tighter will not solve this issue. Chiptorque typically tunes each system to around 300kw at the flywheel. A slightly striped thread is not good in the back of your crank. Try and find the torque settings if your not confident mate. Mal wood quoted to dylan. Xr6 Turbo Flywheel Bolt Torque.

From 4tuneperformance.com.au

Ford Falcon BA BF FG FGX BARRA XR6 Turbo Rebuild Kit with CP Bullet Xr6 Turbo Flywheel Bolt Torque Chiptorque typically tunes each system to around 300kw at the flywheel. I would even undo and retighten a couple of times as i feel more comfortable that whatever little stretch that is in the bolt is. You need to torque it right with a good torque wrench. Just doing the bolt up to the required torque, loctiting it or doing. Xr6 Turbo Flywheel Bolt Torque.

From www.fordxr6turbo.com

Stock Xr6T Flywheel, Solid Or DualMass? Driveline Ford Xr6 Turbo Flywheel Bolt Torque Chiptorque typically tunes each system to around 300kw at the flywheel. The flywheel bolt holes in an au crank are a fair bit shorter than in previous cranks and require special shorter bolts. Just doing the bolt up to the required torque, loctiting it or doing it tighter will not solve this issue. Try and find the torque settings if. Xr6 Turbo Flywheel Bolt Torque.

From www.tuffcarparts.com.au

BA BF FG Ford Falcon XR6 Turbo & V8 Torque Lock LSD & Motive 3.9 Diff Xr6 Turbo Flywheel Bolt Torque Try and find the torque settings if your not confident mate. A slightly striped thread is not good in the back of your crank. Mal wood quoted to dylan they torque their flywheel to crank bolts up to 65 ft/lbs which is 88nm. If it has, this will also damage and. Chiptorque typically tunes each system to around 300kw at. Xr6 Turbo Flywheel Bolt Torque.

From www.fordxr6turbo.com

Photo Essay Ba/bf Ute & Wagon Rear Axle Bearing Replacement Xr6 Turbo Flywheel Bolt Torque I would even undo and retighten a couple of times as i feel more comfortable that whatever little stretch that is in the bolt is. Chiptorque typically tunes each system to around 300kw at the flywheel. If it has, this will also damage and. A slightly striped thread is not good in the back of your crank. The flywheel bolt. Xr6 Turbo Flywheel Bolt Torque.

From diagrampartclarissa.z13.web.core.windows.net

Flywheel Bolt Torque Specs Xr6 Turbo Flywheel Bolt Torque Just doing the bolt up to the required torque, loctiting it or doing it tighter will not solve this issue. If it has, this will also damage and. Chiptorque typically tunes each system to around 300kw at the flywheel. A slightly striped thread is not good in the back of your crank. You need to torque it right with a. Xr6 Turbo Flywheel Bolt Torque.

From www.fordxr6turbo.com

Xr6 Turbo Alloy Flywheel Driveline Ford XR6 Xr6 Turbo Flywheel Bolt Torque Chiptorque typically tunes each system to around 300kw at the flywheel. Try and find the torque settings if your not confident mate. You need to torque it right with a good torque wrench. If it has, this will also damage and. Just doing the bolt up to the required torque, loctiting it or doing it tighter will not solve this. Xr6 Turbo Flywheel Bolt Torque.

From diagramlibrarykachina.z13.web.core.windows.net

Flywheel To Torque Converter Bolts Xr6 Turbo Flywheel Bolt Torque If it has, this will also damage and. Chiptorque typically tunes each system to around 300kw at the flywheel. You need to torque it right with a good torque wrench. Mal wood quoted to dylan they torque their flywheel to crank bolts up to 65 ft/lbs which is 88nm. I would even undo and retighten a couple of times as. Xr6 Turbo Flywheel Bolt Torque.

From www.ebay.com.au

FORD BA BF XR6 MANUAL FLYWHEEL BOLTS (1 SET OF 6) eBay Xr6 Turbo Flywheel Bolt Torque You need to torque it right with a good torque wrench. The flywheel bolt holes in an au crank are a fair bit shorter than in previous cranks and require special shorter bolts. Mal wood quoted to dylan they torque their flywheel to crank bolts up to 65 ft/lbs which is 88nm. If it has, this will also damage and.. Xr6 Turbo Flywheel Bolt Torque.

From www.2carpros.com

Torque Specs for the Flywheel Needed Torque Specs for Flywheel. Xr6 Turbo Flywheel Bolt Torque Mal wood quoted to dylan they torque their flywheel to crank bolts up to 65 ft/lbs which is 88nm. Chiptorque typically tunes each system to around 300kw at the flywheel. Just doing the bolt up to the required torque, loctiting it or doing it tighter will not solve this issue. You need to torque it right with a good torque. Xr6 Turbo Flywheel Bolt Torque.

From 4tuneperformance.com.au

Ford Falcon BA BF FG FGX BARRA XR6 Turbo Rebuild Kit with CP Bullet Xr6 Turbo Flywheel Bolt Torque A slightly striped thread is not good in the back of your crank. If it has, this will also damage and. Just doing the bolt up to the required torque, loctiting it or doing it tighter will not solve this issue. You need to torque it right with a good torque wrench. Chiptorque typically tunes each system to around 300kw. Xr6 Turbo Flywheel Bolt Torque.

From www.independentmotorsports.com.au

ARP Ford Falcon Barra XR6 Turbo Flex Plate Bolts Xr6 Turbo Flywheel Bolt Torque A slightly striped thread is not good in the back of your crank. The flywheel bolt holes in an au crank are a fair bit shorter than in previous cranks and require special shorter bolts. Just doing the bolt up to the required torque, loctiting it or doing it tighter will not solve this issue. I would even undo and. Xr6 Turbo Flywheel Bolt Torque.

From mavink.com

Torque Specs Flywheel Bolts Xr6 Turbo Flywheel Bolt Torque The flywheel bolt holes in an au crank are a fair bit shorter than in previous cranks and require special shorter bolts. I would even undo and retighten a couple of times as i feel more comfortable that whatever little stretch that is in the bolt is. Just doing the bolt up to the required torque, loctiting it or doing. Xr6 Turbo Flywheel Bolt Torque.

From fyoiodazb.blob.core.windows.net

Arp Ford Flywheel Bolt Torque at Marie Thorne blog Xr6 Turbo Flywheel Bolt Torque Try and find the torque settings if your not confident mate. You need to torque it right with a good torque wrench. If it has, this will also damage and. I would even undo and retighten a couple of times as i feel more comfortable that whatever little stretch that is in the bolt is. Chiptorque typically tunes each system. Xr6 Turbo Flywheel Bolt Torque.

From www.impalassforum.com

Flywheel bolts torque specs Chevy Impala SS Forum Xr6 Turbo Flywheel Bolt Torque Mal wood quoted to dylan they torque their flywheel to crank bolts up to 65 ft/lbs which is 88nm. The flywheel bolt holes in an au crank are a fair bit shorter than in previous cranks and require special shorter bolts. If it has, this will also damage and. Try and find the torque settings if your not confident mate.. Xr6 Turbo Flywheel Bolt Torque.

From www.boostedfalcon.net

Boosted Falcon • View topic YEAH, JUST ANOTHER BA XR6 TURBO Xr6 Turbo Flywheel Bolt Torque If it has, this will also damage and. Just doing the bolt up to the required torque, loctiting it or doing it tighter will not solve this issue. Try and find the torque settings if your not confident mate. Mal wood quoted to dylan they torque their flywheel to crank bolts up to 65 ft/lbs which is 88nm. A slightly. Xr6 Turbo Flywheel Bolt Torque.

From www.tuffcarparts.com.au

FG Ford Falcon XR6 Turbo Aeroflow Performance Boosted Turbo 1.06 1000HP Xr6 Turbo Flywheel Bolt Torque Mal wood quoted to dylan they torque their flywheel to crank bolts up to 65 ft/lbs which is 88nm. I would even undo and retighten a couple of times as i feel more comfortable that whatever little stretch that is in the bolt is. A slightly striped thread is not good in the back of your crank. Just doing the. Xr6 Turbo Flywheel Bolt Torque.

From 4tuneperformance.com.au

Ford Falcon BA BF FG FGX XR6 Barra Turbo Spool H Beam Conrods 4TUNE Xr6 Turbo Flywheel Bolt Torque A slightly striped thread is not good in the back of your crank. Chiptorque typically tunes each system to around 300kw at the flywheel. You need to torque it right with a good torque wrench. Just doing the bolt up to the required torque, loctiting it or doing it tighter will not solve this issue. If it has, this will. Xr6 Turbo Flywheel Bolt Torque.

From www.fordxr6turbo.com

How Do I Convert Torque? General Tech Ford XR6 Xr6 Turbo Flywheel Bolt Torque Mal wood quoted to dylan they torque their flywheel to crank bolts up to 65 ft/lbs which is 88nm. The flywheel bolt holes in an au crank are a fair bit shorter than in previous cranks and require special shorter bolts. Chiptorque typically tunes each system to around 300kw at the flywheel. Just doing the bolt up to the required. Xr6 Turbo Flywheel Bolt Torque.

From www.manminchurch.se

Bolt Torque Chart Showing Suggested Torque Values And Corresponding Xr6 Turbo Flywheel Bolt Torque Mal wood quoted to dylan they torque their flywheel to crank bolts up to 65 ft/lbs which is 88nm. A slightly striped thread is not good in the back of your crank. Try and find the torque settings if your not confident mate. I would even undo and retighten a couple of times as i feel more comfortable that whatever. Xr6 Turbo Flywheel Bolt Torque.

From www.fordxr6turbo.com

New Precision BoltOn Turbo Page 2 Turbo Ford XR6 Xr6 Turbo Flywheel Bolt Torque A slightly striped thread is not good in the back of your crank. Chiptorque typically tunes each system to around 300kw at the flywheel. The flywheel bolt holes in an au crank are a fair bit shorter than in previous cranks and require special shorter bolts. If it has, this will also damage and. Just doing the bolt up to. Xr6 Turbo Flywheel Bolt Torque.

From www.fordxr6turbo.com

F6 Torque Curve FPV PERFORMANCE INC. Ford XR6 Xr6 Turbo Flywheel Bolt Torque Just doing the bolt up to the required torque, loctiting it or doing it tighter will not solve this issue. You need to torque it right with a good torque wrench. I would even undo and retighten a couple of times as i feel more comfortable that whatever little stretch that is in the bolt is. Chiptorque typically tunes each. Xr6 Turbo Flywheel Bolt Torque.

From www.2carpros.com

Torque Specs for the Flywheel Needed Torque Specs for Flywheel. Xr6 Turbo Flywheel Bolt Torque A slightly striped thread is not good in the back of your crank. I would even undo and retighten a couple of times as i feel more comfortable that whatever little stretch that is in the bolt is. Try and find the torque settings if your not confident mate. Just doing the bolt up to the required torque, loctiting it. Xr6 Turbo Flywheel Bolt Torque.

From mavink.com

Torque Specs Flywheel Bolts Xr6 Turbo Flywheel Bolt Torque A slightly striped thread is not good in the back of your crank. You need to torque it right with a good torque wrench. If it has, this will also damage and. Mal wood quoted to dylan they torque their flywheel to crank bolts up to 65 ft/lbs which is 88nm. Chiptorque typically tunes each system to around 300kw at. Xr6 Turbo Flywheel Bolt Torque.

From exotdewyh.blob.core.windows.net

Hdj79 Flywheel Bolt Torque at Lisa Doyle blog Xr6 Turbo Flywheel Bolt Torque A slightly striped thread is not good in the back of your crank. Mal wood quoted to dylan they torque their flywheel to crank bolts up to 65 ft/lbs which is 88nm. I would even undo and retighten a couple of times as i feel more comfortable that whatever little stretch that is in the bolt is. If it has,. Xr6 Turbo Flywheel Bolt Torque.

From 4tuneperformance.com.au

Ford Falcon BA BF FG FGX XR6 Turbo Spool Drag Pro I Beam Conrods and CP Xr6 Turbo Flywheel Bolt Torque The flywheel bolt holes in an au crank are a fair bit shorter than in previous cranks and require special shorter bolts. If it has, this will also damage and. A slightly striped thread is not good in the back of your crank. You need to torque it right with a good torque wrench. Try and find the torque settings. Xr6 Turbo Flywheel Bolt Torque.