Pipe Branch Joints . pipe fittings are defined as the piping components that help in pipe routing for directional changes, size. branch connections serve a fundamental purpose within piping systems: A butt weld is a circumferential welded joint connection, and the most common type of joint done in the. a reinforcement pad or rf pad is used to strengthen the fabricated or welded pipe branch connection joints. pipes are linked by screwing with the help of threads provided for each pipe in a threaded junction. saddle joints give users a way to branch out from main pipelines without having to modify parts or weld onto pre. A branch fitting’s strength and corresponding thickness is specified by. npt is the best known and most widely used connection where the pipe thread provides both the mechanical joint and the hydraulic seal. a branch connection is made when the pipe header has either an equal or smaller size branch line connected to it. Some branches or tapings are constructed by drilling a hole in the run pipe and joining a piece of pipe with a smaller diameter to it. Threaded joints are available in sizes ranging from 6mm to 300mm. branch connections are considered to have adequate strength to resist the applied loads from internal. Branch fittings are attached to the run pipe by welding. the branch joint is the intersection of the end of one pipe with the side of another pipe. olets fittings provide a branch connection between the header or run pipe and to the branch or outlet pipe.

from www.hgg-group.com

Some branches or tapings are constructed by drilling a hole in the run pipe and joining a piece of pipe with a smaller diameter to it. olets fittings provide a branch connection between the header or run pipe and to the branch or outlet pipe. branch connections serve a fundamental purpose within piping systems: The resulting joint is sometimes called a. A branch fitting’s strength and corresponding thickness is specified by. A butt weld is a circumferential welded joint connection, and the most common type of joint done in the. This technique is widely used when there is a need to divert or branch off from the main pipeline for various purposes, such as distribution, control, or instrumentation. three types of welded branch connections in the piping standards are used for any piping network, in addition to the standard tee connection for taking branch pipe. Threaded joints are available in sizes ranging from 6mm to 300mm. a pipe joint is a connection point between two sections of pipe or between a pipe and a fitting.

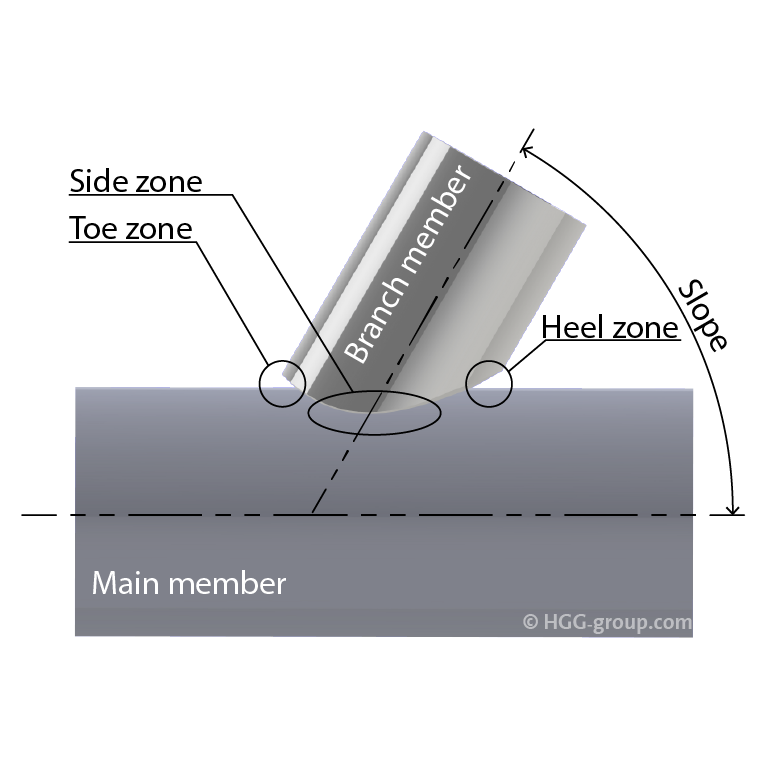

Welding basics; terminology HGG 3D Profiling Specialists

Pipe Branch Joints tee fittings, reinforcing pads or saddles. Threaded joints are available in sizes ranging from 6mm to 300mm. Branch fittings are attached to the run pipe by welding. With this knowledge in your toolbox, you’ll be applying these techniques with confidence and precision, reaping the maximum benefits every single time. Some branches or tapings are constructed by drilling a hole in the run pipe and joining a piece of pipe with a smaller diameter to it. This technique is widely used when there is a need to divert or branch off from the main pipeline for various purposes, such as distribution, control, or instrumentation. typically, when branching a pipe, you can use one of a few options: simply put, a branch fitting is a component designed to join multiple pipes with a common run or branch, while a. in a joint the flow from two gas pipes is united and redirected through a third pipe. A saddle type pipe connection with or. three types of welded branch connections in the piping standards are used for any piping network, in addition to the standard tee connection for taking branch pipe. A branch fitting’s strength and corresponding thickness is specified by. saddle joints give users a way to branch out from main pipelines without having to modify parts or weld onto pre. The tee branch has a restriction bar welded internally to. They enable the connection of a smaller pipe or tubing to a larger main pipeline, allowing for. A butt weld is a circumferential welded joint connection, and the most common type of joint done in the.

From www.youtube.com

Piping Engineering setin or stubin and seton or stubon branching Pipe Branch Joints simply put, a branch fitting is a component designed to join multiple pipes with a common run or branch, while a. The resulting joint is sometimes called a. They enable the connection of a smaller pipe or tubing to a larger main pipeline, allowing for. Its primary function is to ensure a. The tee branch has a restriction bar. Pipe Branch Joints.

From thehvacshop.co.nz

Y Branch 200/150/150 Galvanised (Galvanised Y Branches) Airflow The Pipe Branch Joints a branch connection is made when the pipe header has either an equal or smaller size branch line connected to it. typically, when branching a pipe, you can use one of a few options: In other words, you can say olets fittings are fittings that provide an outlet from a larger pipe to a smaller one (or one. Pipe Branch Joints.

From www.nordfab.com

HV Branch Pipes Parallel Products Nordfab Pipe Branch Joints in a joint the flow from two gas pipes is united and redirected through a third pipe. the branch joint is the intersection of the end of one pipe with the side of another pipe. pipe fittings are defined as the piping components that help in pipe routing for directional changes, size. three types of welded. Pipe Branch Joints.

From blog.thepipingmart.com

What Are The Important Types Of Branch Pipe Connection? Pipe Branch Joints a reinforcement pad or rf pad is used to strengthen the fabricated or welded pipe branch connection joints. saddle joints give users a way to branch out from main pipelines without having to modify parts or weld onto pre. Some branches or tapings are constructed by drilling a hole in the run pipe and joining a piece of. Pipe Branch Joints.

From stock.adobe.com

Welding branch pipes / Preparing the edges of pipes and structural of Pipe Branch Joints Threads are available on cast iron, copper, pvc, and g.i. A branch fitting’s strength and corresponding thickness is specified by. a branch connection is made when the pipe header has either an equal or smaller size branch line connected to it. The resulting joint is sometimes called a. This technique is widely used when there is a need to. Pipe Branch Joints.

From www.alibaba.com

Air Conditioner Branch Joints Disperse Pipe Pipe For Midea Vrf Pipe Branch Joints three types of welded branch connections in the piping standards are used for any piping network, in addition to the standard tee connection for taking branch pipe. They enable the connection of a smaller pipe or tubing to a larger main pipeline, allowing for. tee fittings, reinforcing pads or saddles. A saddle type pipe connection with or. Its. Pipe Branch Joints.

From japaneseclass.jp

Branch JapaneseClass.jp Pipe Branch Joints The resulting joint is sometimes called a. branch connections are considered to have adequate strength to resist the applied loads from internal. Threaded joints are available in sizes ranging from 6mm to 300mm. the branch joint is the intersection of the end of one pipe with the side of another pipe. typically, when branching a pipe, you. Pipe Branch Joints.

From makepipingeasy.com

Olets Fittings A Complete Guide Make Piping Easy Pipe Branch Joints a pipe joint is a connection point between two sections of pipe or between a pipe and a fitting. simply put, a branch fitting is a component designed to join multiple pipes with a common run or branch, while a. three types of welded branch connections in the piping standards are used for any piping network, in. Pipe Branch Joints.

From scottfrio.en.alibaba.com

Y Joint Branch joint Pipe for VRV/VRF System Pipe Branch Joints a branch connection is made when the pipe header has either an equal or smaller size branch line connected to it. a reinforcement pad or rf pad is used to strengthen the fabricated or welded pipe branch connection joints. npt is the best known and most widely used connection where the pipe thread provides both the mechanical. Pipe Branch Joints.

From www.kaweller.com

Copper Pipe JointsKWT10 website Pipe Branch Joints They enable the connection of a smaller pipe or tubing to a larger main pipeline, allowing for. The resulting joint is sometimes called a. pipes are linked by screwing with the help of threads provided for each pipe in a threaded junction. simply put, a branch fitting is a component designed to join multiple pipes with a common. Pipe Branch Joints.

From www.indiamart.com

Copper VRF Y Joints, For Gas Pipe, Size 1/2 inch at Rs 4000/piece in Pipe Branch Joints Its primary function is to ensure a. the branch joint is the intersection of the end of one pipe with the side of another pipe. typically, when branching a pipe, you can use one of a few options: With this knowledge in your toolbox, you’ll be applying these techniques with confidence and precision, reaping the maximum benefits every. Pipe Branch Joints.

From winlandmetal.en.made-in-china.com

Fqzhn Copper Y Branch Pipe for Vrf/Vrv System Air Conditioner Branch Pipe Branch Joints Threads are available on cast iron, copper, pvc, and g.i. tee fittings, reinforcing pads or saddles. A branch fitting’s strength and corresponding thickness is specified by. The resulting joint is sometimes called a. olets fittings provide a branch connection between the header or run pipe and to the branch or outlet pipe. saddle joints give users a. Pipe Branch Joints.

From www.alibaba.com

Y Branch Pipe Joint Vrv/vrf System Y Connect Mxjya2512m Buy Pipe Branch Joints typically, when branching a pipe, you can use one of a few options: A branch fitting’s strength and corresponding thickness is specified by. Branch fittings are attached to the run pipe by welding. The tee branch has a restriction bar welded internally to. Threads are available on cast iron, copper, pvc, and g.i. a pipe joint is a. Pipe Branch Joints.

From www.youtube.com

PIPING BRANCH FIT UP EASY METHOD TUTORIAL. Pipe fit up tutorials Pipe Branch Joints branch connections are considered to have adequate strength to resist the applied loads from internal. So in principal three network elements of. npt is the best known and most widely used connection where the pipe thread provides both the mechanical joint and the hydraulic seal. Its primary function is to ensure a. Both types are permitted by many. Pipe Branch Joints.

From www.youtube.com

ms pipe welding ms pipe welding methods ms pipe welding joints ms Pipe Branch Joints Some branches or tapings are constructed by drilling a hole in the run pipe and joining a piece of pipe with a smaller diameter to it. Its primary function is to ensure a. A saddle type pipe connection with or. npt is the best known and most widely used connection where the pipe thread provides both the mechanical joint. Pipe Branch Joints.

From www.coowor.com

TOSHIBA YShape Joints VRF Branch Copper Pipes Pipe Branch Joints branch connections are considered to have adequate strength to resist the applied loads from internal. tee fittings, reinforcing pads or saddles. A branch fitting’s strength and corresponding thickness is specified by. Threads are available on cast iron, copper, pvc, and g.i. This technique is widely used when there is a need to divert or branch off from the. Pipe Branch Joints.

From www.hgg-group.com

Welding basics; terminology HGG 3D Profiling Specialists Pipe Branch Joints Threaded joints are available in sizes ranging from 6mm to 300mm. Threads are available on cast iron, copper, pvc, and g.i. The resulting joint is sometimes called a. npt is the best known and most widely used connection where the pipe thread provides both the mechanical joint and the hydraulic seal. In other words, you can say olets fittings. Pipe Branch Joints.

From www.slrfoundry.com

Manufacture Saddle with Screwed Branch for pvc pipe Pipe Branch Joints In other words, you can say olets fittings are fittings that provide an outlet from a larger pipe to a smaller one (or one of the same size). They enable the connection of a smaller pipe or tubing to a larger main pipeline, allowing for. typically, when branching a pipe, you can use one of a few options: So. Pipe Branch Joints.

From www.alibaba.com

Y Branch Joint Copper Pipe For Vrf Gree Air Conditioning Buy Y Branch Pipe Branch Joints So in principal three network elements of. the branch joint is the intersection of the end of one pipe with the side of another pipe. olets fittings provide a branch connection between the header or run pipe and to the branch or outlet pipe. Threads are available on cast iron, copper, pvc, and g.i. branch connections serve. Pipe Branch Joints.

From www.tingertech.com

Multi Standard Refrigeration Pipe Fittings Copper Y Joint Disperse Pipe Branch Joints Threaded joints are available in sizes ranging from 6mm to 300mm. Branch fittings are attached to the run pipe by welding. In other words, you can say olets fittings are fittings that provide an outlet from a larger pipe to a smaller one (or one of the same size). pipe fittings are defined as the piping components that help. Pipe Branch Joints.

From www.alibaba.com

Samsung Copper Branch Pipe For Vrv Air Conditioning Buy Pipe Branch Joints So in principal three network elements of. saddle joints give users a way to branch out from main pipelines without having to modify parts or weld onto pre. In other words, you can say olets fittings are fittings that provide an outlet from a larger pipe to a smaller one (or one of the same size). in a. Pipe Branch Joints.

From whatispiping.com

Types of Pipe Joints / Piping Joints What Is Piping Pipe Branch Joints pipe fittings are defined as the piping components that help in pipe routing for directional changes, size. olets fittings provide a branch connection between the header or run pipe and to the branch or outlet pipe. A saddle type pipe connection with or. a barred tee, also known as a scrapper tee, is used in pigged pipelines.. Pipe Branch Joints.

From www.tingertech.com

Copper VRV VRF Air Conditioner Y Branch, Y Joint, Branch Piping, Pipe Branch Joints Some branches or tapings are constructed by drilling a hole in the run pipe and joining a piece of pipe with a smaller diameter to it. Branch fittings are attached to the run pipe by welding. pipe fittings are defined as the piping components that help in pipe routing for directional changes, size. This technique is widely used when. Pipe Branch Joints.

From makepipingeasy.com

Reinforcement Pad Calculation for Branch Connection Make Piping Easy Pipe Branch Joints So in principal three network elements of. The tee branch has a restriction bar welded internally to. tee fittings, reinforcing pads or saddles. olets fittings provide a branch connection between the header or run pipe and to the branch or outlet pipe. This technique is widely used when there is a need to divert or branch off from. Pipe Branch Joints.

From ahssinsights.org

Induction Seam Welding of Pipe and Tubing Archives AHSS Guidelines Pipe Branch Joints They enable the connection of a smaller pipe or tubing to a larger main pipeline, allowing for. So in principal three network elements of. Its primary function is to ensure a. A branch fitting’s strength and corresponding thickness is specified by. Branch fittings are attached to the run pipe by welding. in a joint the flow from two gas. Pipe Branch Joints.

From www.alibaba.com

Y Branch Joint Copper Pipe For Vrf Gree Air Conditioning Buy Y Branch Pipe Branch Joints three types of welded branch connections in the piping standards are used for any piping network, in addition to the standard tee connection for taking branch pipe. They enable the connection of a smaller pipe or tubing to a larger main pipeline, allowing for. branch connections are considered to have adequate strength to resist the applied loads from. Pipe Branch Joints.

From www.triadbellows.com

The 5 Most Common Types of Pipe Expansion Joints Triad Bellows Pipe Branch Joints three types of welded branch connections in the piping standards are used for any piping network, in addition to the standard tee connection for taking branch pipe. a barred tee, also known as a scrapper tee, is used in pigged pipelines. So in principal three network elements of. Some branches or tapings are constructed by drilling a hole. Pipe Branch Joints.

From fittertraining.com

Lateral pipe tee branch 20"×78" 22"×78" 24"×78" 26"×78" PDF chart Pipe Branch Joints With this knowledge in your toolbox, you’ll be applying these techniques with confidence and precision, reaping the maximum benefits every single time. Some branches or tapings are constructed by drilling a hole in the run pipe and joining a piece of pipe with a smaller diameter to it. This technique is widely used when there is a need to divert. Pipe Branch Joints.

From www.engineersgallery.com

Welding joints Engineers Gallery Pipe Branch Joints olets fittings provide a branch connection between the header or run pipe and to the branch or outlet pipe. branch connections are considered to have adequate strength to resist the applied loads from internal. One pipe has internal threads, while the other has threads on the outside. branch connections serve a fundamental purpose within piping systems: . Pipe Branch Joints.

From www.mcwaneductile.com

Mechanical Joint Lock Joint Pipe McWane Ductile Iron Strong Pipe Branch Joints three types of welded branch connections in the piping standards are used for any piping network, in addition to the standard tee connection for taking branch pipe. The tee branch has a restriction bar welded internally to. pipes are linked by screwing with the help of threads provided for each pipe in a threaded junction. simply put,. Pipe Branch Joints.

From www.dreamstime.com

Welded Joints of the Pipeline and Branch Du50, Welded by Manual Arc Pipe Branch Joints a reinforcement pad or rf pad is used to strengthen the fabricated or welded pipe branch connection joints. A butt weld is a circumferential welded joint connection, and the most common type of joint done in the. the branch joint is the intersection of the end of one pipe with the side of another pipe. So in principal. Pipe Branch Joints.

From chinagangli.en.made-in-china.com

YShape Branch Joints Joint Pipe Distribution Tube Copper Pipe Pipe Branch Joints Some branches or tapings are constructed by drilling a hole in the run pipe and joining a piece of pipe with a smaller diameter to it. A butt weld is a circumferential welded joint connection, and the most common type of joint done in the. A branch fitting’s strength and corresponding thickness is specified by. in a joint the. Pipe Branch Joints.

From zhujist.en.made-in-china.com

Toshiba Y Branch Joint Copper Pipe China Branch Pipe and Branch Joint Pipe Branch Joints Both types are permitted by many international codes and standards, including asme b31. A saddle type pipe connection with or. typically, when branching a pipe, you can use one of a few options: Some branches or tapings are constructed by drilling a hole in the run pipe and joining a piece of pipe with a smaller diameter to it.. Pipe Branch Joints.

From www.ecplaza.net

Y Joint Branch Pipe/Branch Joint For DAIKIN Fuzhou Pipe Branch Joints Branch fittings are attached to the run pipe by welding. This technique is widely used when there is a need to divert or branch off from the main pipeline for various purposes, such as distribution, control, or instrumentation. In other words, you can say olets fittings are fittings that provide an outlet from a larger pipe to a smaller one. Pipe Branch Joints.

From sea.itwwelding.com

ITW Welding Singapore Proper Weld Joint Preparation for Successful Pipe Branch Joints Both types are permitted by many international codes and standards, including asme b31. Threaded joints are available in sizes ranging from 6mm to 300mm. saddle joints give users a way to branch out from main pipelines without having to modify parts or weld onto pre. in a joint the flow from two gas pipes is united and redirected. Pipe Branch Joints.