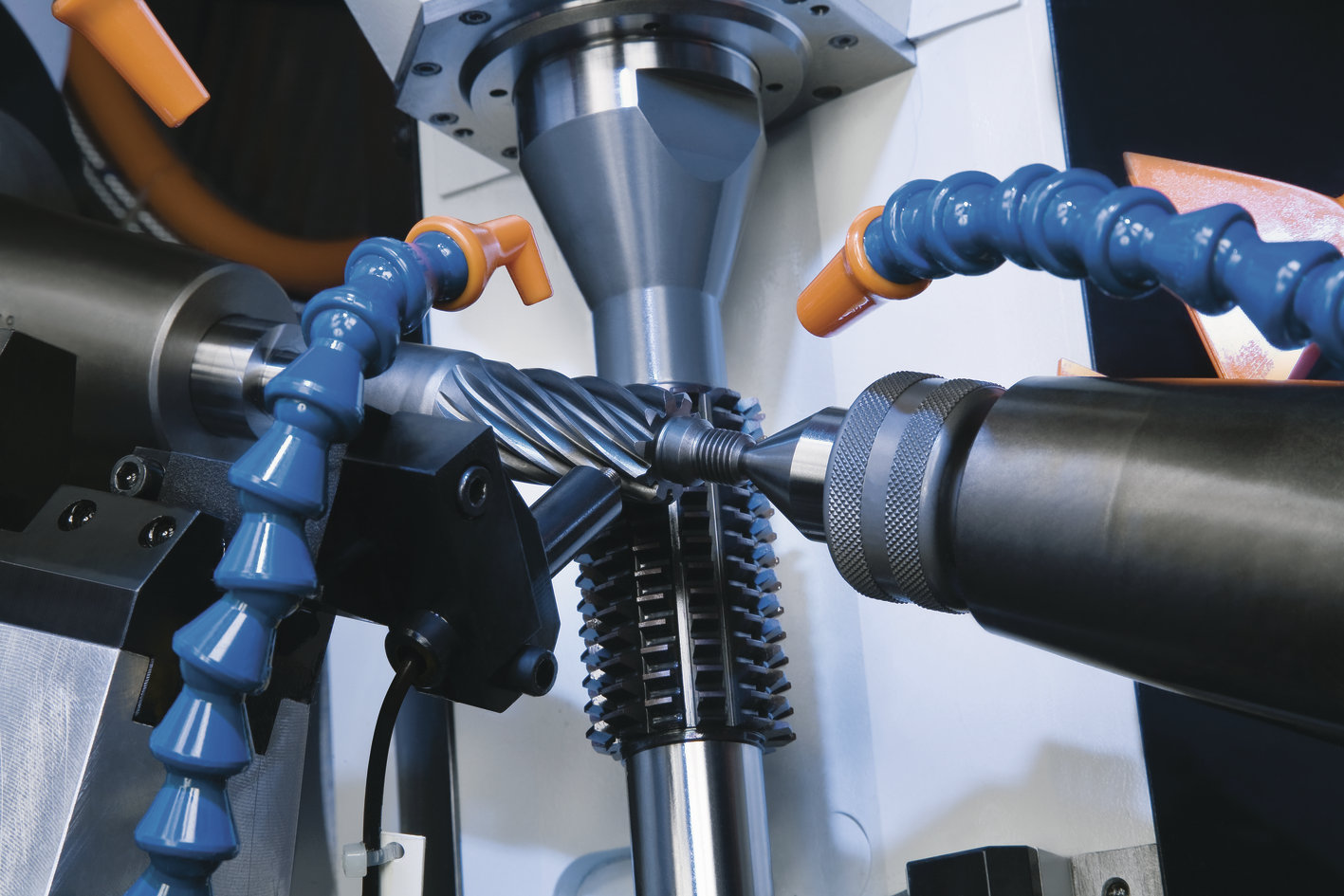

Hobbing Machine Description . They can be used to machine workpieces from 20. It involves using a hobbing machine. The lc 280 α is the perfect way for getting started with gear cutting. It offers maximum flexibility thanks to a diverse range of workpieces, well. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. Hobbing is a machining process used in manufacturing to cut gears, splines, and sprockets. Gear hobbing machine (or hobbing gear machine) is a machining technique for making gears that include concurrently rotating. Whether compact or large, our gear hobbing machines impress with their flexibility. Most gears are produced on a hobbing machine, which, when compared to other methods, has proven efficient and inexpensive.

from www.emag.com

The lc 280 α is the perfect way for getting started with gear cutting. Gear hobbing machine (or hobbing gear machine) is a machining technique for making gears that include concurrently rotating. Whether compact or large, our gear hobbing machines impress with their flexibility. It involves using a hobbing machine. Hobbing is a machining process used in manufacturing to cut gears, splines, and sprockets. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. They can be used to machine workpieces from 20. It offers maximum flexibility thanks to a diverse range of workpieces, well. Most gears are produced on a hobbing machine, which, when compared to other methods, has proven efficient and inexpensive.

Gear Hobbing Machine K 160 Gear Hobbing at the Highest Level

Hobbing Machine Description It involves using a hobbing machine. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. Whether compact or large, our gear hobbing machines impress with their flexibility. It offers maximum flexibility thanks to a diverse range of workpieces, well. It involves using a hobbing machine. The lc 280 α is the perfect way for getting started with gear cutting. Gear hobbing machine (or hobbing gear machine) is a machining technique for making gears that include concurrently rotating. Hobbing is a machining process used in manufacturing to cut gears, splines, and sprockets. They can be used to machine workpieces from 20. Most gears are produced on a hobbing machine, which, when compared to other methods, has proven efficient and inexpensive.

From enproindustries.en.made-in-china.com

G100 High Speed CNC Gear Hobbing Machine with Controller Siemens Knd Hobbing Machine Description Hobbing is a machining process used in manufacturing to cut gears, splines, and sprockets. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. The lc 280 α is the perfect way for getting started with gear. Hobbing Machine Description.

From www.liebherr.com

LC 180 280 Gear hobbing machines Liebherr Liebherr Hobbing Machine Description It involves using a hobbing machine. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. Most gears are produced on a hobbing machine, which, when compared to other methods, has proven efficient and inexpensive. It offers. Hobbing Machine Description.

From www.cnclathe-machine.com

Y3150e Hobbing Machine Hobbing Machine Tool Grinding Hobbing Machine Hobbing Machine Description Most gears are produced on a hobbing machine, which, when compared to other methods, has proven efficient and inexpensive. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. They can be used to machine workpieces from. Hobbing Machine Description.

From www.equipment-trader.co.uk

Sykes Hv14A Vertical Gear Hobbing Machine Equipment Trader Hobbing Machine Description Whether compact or large, our gear hobbing machines impress with their flexibility. It involves using a hobbing machine. Hobbing is a machining process used in manufacturing to cut gears, splines, and sprockets. They can be used to machine workpieces from 20. Most gears are produced on a hobbing machine, which, when compared to other methods, has proven efficient and inexpensive.. Hobbing Machine Description.

From en.wikipedia.org

FileHobbing machine.jpg Wikipedia Hobbing Machine Description Most gears are produced on a hobbing machine, which, when compared to other methods, has proven efficient and inexpensive. Whether compact or large, our gear hobbing machines impress with their flexibility. The lc 280 α is the perfect way for getting started with gear cutting. Gear hobbing machine (or hobbing gear machine) is a machining technique for making gears that. Hobbing Machine Description.

From www.wotol.com

Gleason PFAUTER GP130 Variable Speed Gear hobbing machine vertical Hobbing Machine Description It involves using a hobbing machine. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. The lc 280 α is the perfect way for getting started with gear cutting. It offers maximum flexibility thanks to a. Hobbing Machine Description.

From www.directindustry.com

CNC gearhobbing machine P series Gleason vertical Hobbing Machine Description Most gears are produced on a hobbing machine, which, when compared to other methods, has proven efficient and inexpensive. It involves using a hobbing machine. They can be used to machine workpieces from 20. Gear hobbing machine (or hobbing gear machine) is a machining technique for making gears that include concurrently rotating. Hobbing is a machining process used in manufacturing. Hobbing Machine Description.

From cdvictor.en.made-in-china.com

Horizontal Gear Hobbing Machine (WL3603A) China Horizontal Gear Hobbing Machine Description Hobbing is a machining process used in manufacturing to cut gears, splines, and sprockets. It offers maximum flexibility thanks to a diverse range of workpieces, well. Whether compact or large, our gear hobbing machines impress with their flexibility. Most gears are produced on a hobbing machine, which, when compared to other methods, has proven efficient and inexpensive. The lc 280. Hobbing Machine Description.

From www.wotol.com

Pfauter P 251 Variable Speed Gear Hobbing Machine Vertical Hobbing Machine Description Hobbing is a machining process used in manufacturing to cut gears, splines, and sprockets. Most gears are produced on a hobbing machine, which, when compared to other methods, has proven efficient and inexpensive. It involves using a hobbing machine. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the. Hobbing Machine Description.

From products.pmtmachines.com

CNC GEAR HOBBING MACHINE pmtproducts Hobbing Machine Description Gear hobbing machine (or hobbing gear machine) is a machining technique for making gears that include concurrently rotating. It offers maximum flexibility thanks to a diverse range of workpieces, well. Whether compact or large, our gear hobbing machines impress with their flexibility. Most gears are produced on a hobbing machine, which, when compared to other methods, has proven efficient and. Hobbing Machine Description.

From www.youtube.com

TOS FO6 Gear Hobbing Machine 6 Module x 600 mm Gear Diameter YouTube Hobbing Machine Description Hobbing is a machining process used in manufacturing to cut gears, splines, and sprockets. Whether compact or large, our gear hobbing machines impress with their flexibility. It involves using a hobbing machine. Most gears are produced on a hobbing machine, which, when compared to other methods, has proven efficient and inexpensive. Gear hobbing machine (or hobbing gear machine) is a. Hobbing Machine Description.

From geepro.en.made-in-china.com

G400 6 Axis CNC Gear Hobbing Machine with Automation Ring Loader Hobbing Machine Description Gear hobbing machine (or hobbing gear machine) is a machining technique for making gears that include concurrently rotating. The lc 280 α is the perfect way for getting started with gear cutting. Hobbing is a machining process used in manufacturing to cut gears, splines, and sprockets. Whether compact or large, our gear hobbing machines impress with their flexibility. It involves. Hobbing Machine Description.

From www.liebherr.com

LC 60 130 Gear hobbing machines Liebherr Liebherr Hobbing Machine Description They can be used to machine workpieces from 20. Gear hobbing machine (or hobbing gear machine) is a machining technique for making gears that include concurrently rotating. It offers maximum flexibility thanks to a diverse range of workpieces, well. The lc 280 α is the perfect way for getting started with gear cutting. It involves using a hobbing machine. Most. Hobbing Machine Description.

From www.exportersindia.com

TOS FO 16 Gear Hobbing Machine 16 Module at Best Price in Delhi Jugal Hobbing Machine Description Whether compact or large, our gear hobbing machines impress with their flexibility. Most gears are produced on a hobbing machine, which, when compared to other methods, has proven efficient and inexpensive. It offers maximum flexibility thanks to a diverse range of workpieces, well. The lc 280 α is the perfect way for getting started with gear cutting. Gear hobbing is. Hobbing Machine Description.

From www.star-su.com

Gear Hobbing Machine Tools Vertical Hobbing Machines H 80200 Gear Hobbing Machine Description It involves using a hobbing machine. Most gears are produced on a hobbing machine, which, when compared to other methods, has proven efficient and inexpensive. Whether compact or large, our gear hobbing machines impress with their flexibility. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called. Hobbing Machine Description.

From www.directindustry.com

CNC gearhobbing machine P60 Gleason horizontal Hobbing Machine Description It involves using a hobbing machine. They can be used to machine workpieces from 20. Gear hobbing machine (or hobbing gear machine) is a machining technique for making gears that include concurrently rotating. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the. Hobbing Machine Description.

From www.liebherr.com

LC 180 280 Gear hobbing machines Liebherr Liebherr Hobbing Machine Description It offers maximum flexibility thanks to a diverse range of workpieces, well. They can be used to machine workpieces from 20. Whether compact or large, our gear hobbing machines impress with their flexibility. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the. Hobbing Machine Description.

From www.liebherr.com

LC 600 2000 Gear hobbing machines Liebherr Liebherr Hobbing Machine Description The lc 280 α is the perfect way for getting started with gear cutting. It offers maximum flexibility thanks to a diverse range of workpieces, well. Whether compact or large, our gear hobbing machines impress with their flexibility. It involves using a hobbing machine. Most gears are produced on a hobbing machine, which, when compared to other methods, has proven. Hobbing Machine Description.

From www.liebherr.com

LC 300 500 Gear hobbing machines Liebherr Liebherr Hobbing Machine Description Gear hobbing machine (or hobbing gear machine) is a machining technique for making gears that include concurrently rotating. Hobbing is a machining process used in manufacturing to cut gears, splines, and sprockets. The lc 280 α is the perfect way for getting started with gear cutting. Whether compact or large, our gear hobbing machines impress with their flexibility. Gear hobbing. Hobbing Machine Description.

From www.wotol.com

Strausak 30 5200 rpm Hobbing machine Hobbing Machine Description It offers maximum flexibility thanks to a diverse range of workpieces, well. Hobbing is a machining process used in manufacturing to cut gears, splines, and sprockets. It involves using a hobbing machine. Whether compact or large, our gear hobbing machines impress with their flexibility. The lc 280 α is the perfect way for getting started with gear cutting. Most gears. Hobbing Machine Description.

From nidec-machinetoolamerica.com

Gear Hobbing Machines Nidec Machine Tool America. Hobbing Machine Description Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. Most gears are produced on a hobbing machine, which, when compared to other methods, has proven efficient and inexpensive. It involves using a hobbing machine. It offers. Hobbing Machine Description.

From nidec-machinetoolamerica.com

Gear Hobbing Machines Nidec Machine Tool America. Hobbing Machine Description It offers maximum flexibility thanks to a diverse range of workpieces, well. Hobbing is a machining process used in manufacturing to cut gears, splines, and sprockets. Whether compact or large, our gear hobbing machines impress with their flexibility. The lc 280 α is the perfect way for getting started with gear cutting. It involves using a hobbing machine. Gear hobbing. Hobbing Machine Description.

From www.directindustry.com

CNC gearhobbing machine HGG series HNK Machine Tool Hobbing Machine Description It involves using a hobbing machine. Most gears are produced on a hobbing machine, which, when compared to other methods, has proven efficient and inexpensive. Gear hobbing machine (or hobbing gear machine) is a machining technique for making gears that include concurrently rotating. It offers maximum flexibility thanks to a diverse range of workpieces, well. Whether compact or large, our. Hobbing Machine Description.

From pisellient.com

Gleason Genesis Model 210H CNC Vertical hobbing machine with loading Hobbing Machine Description It involves using a hobbing machine. They can be used to machine workpieces from 20. The lc 280 α is the perfect way for getting started with gear cutting. Most gears are produced on a hobbing machine, which, when compared to other methods, has proven efficient and inexpensive. It offers maximum flexibility thanks to a diverse range of workpieces, well.. Hobbing Machine Description.

From www.star-su.com

H 250400 Vertical Gear Hobbing Machine StarSU Hobbing Machine Description It offers maximum flexibility thanks to a diverse range of workpieces, well. The lc 280 α is the perfect way for getting started with gear cutting. They can be used to machine workpieces from 20. Whether compact or large, our gear hobbing machines impress with their flexibility. It involves using a hobbing machine. Hobbing is a machining process used in. Hobbing Machine Description.

From nidec-machinetoolamerica.com

Gear Hobbing Machines Nidec Machine Tool America. Hobbing Machine Description They can be used to machine workpieces from 20. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. Hobbing is a machining process used in manufacturing to cut gears, splines, and sprockets. It involves using a. Hobbing Machine Description.

From www.wotol.com

Emag WF180 1500 rpm Gear hobbing machine vertical Hobbing Machine Description The lc 280 α is the perfect way for getting started with gear cutting. It involves using a hobbing machine. They can be used to machine workpieces from 20. It offers maximum flexibility thanks to a diverse range of workpieces, well. Most gears are produced on a hobbing machine, which, when compared to other methods, has proven efficient and inexpensive.. Hobbing Machine Description.

From www.indiamart.com

TOS FO 6 Gear Hobbing Machine at Rs 8500/piece Gear Hobbing Machine Hobbing Machine Description Most gears are produced on a hobbing machine, which, when compared to other methods, has proven efficient and inexpensive. It involves using a hobbing machine. Hobbing is a machining process used in manufacturing to cut gears, splines, and sprockets. Gear hobbing machine (or hobbing gear machine) is a machining technique for making gears that include concurrently rotating. Whether compact or. Hobbing Machine Description.

From www.emag.com

Gear Hobbing Machine K 160 Gear Hobbing at the Highest Level Hobbing Machine Description Whether compact or large, our gear hobbing machines impress with their flexibility. The lc 280 α is the perfect way for getting started with gear cutting. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. They. Hobbing Machine Description.

From engineeringlearn.com

Gear Hobbing Machine Definition, Types, Uses, Working & Construction Hobbing Machine Description Most gears are produced on a hobbing machine, which, when compared to other methods, has proven efficient and inexpensive. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. The lc 280 α is the perfect way. Hobbing Machine Description.

From www.kishanind.com

Gear Hobbing Machines 6 Module Kishan Industries Hobbing Machine Description Whether compact or large, our gear hobbing machines impress with their flexibility. Hobbing is a machining process used in manufacturing to cut gears, splines, and sprockets. The lc 280 α is the perfect way for getting started with gear cutting. It offers maximum flexibility thanks to a diverse range of workpieces, well. They can be used to machine workpieces from. Hobbing Machine Description.

From nidec-machinetoolamerica.com

Gear Hobbing Machines Nidec Machine Tool America. Hobbing Machine Description The lc 280 α is the perfect way for getting started with gear cutting. Most gears are produced on a hobbing machine, which, when compared to other methods, has proven efficient and inexpensive. It offers maximum flexibility thanks to a diverse range of workpieces, well. Whether compact or large, our gear hobbing machines impress with their flexibility. It involves using. Hobbing Machine Description.

From www.emag.com

Gear Hobbing Machines for Precise Gear Hobbing Hobbing Machine Description Gear hobbing machine (or hobbing gear machine) is a machining technique for making gears that include concurrently rotating. It involves using a hobbing machine. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. They can be. Hobbing Machine Description.

From www.liebherr.com

LC 300 500 Gear hobbing machines Liebherr Liebherr Hobbing Machine Description Hobbing is a machining process used in manufacturing to cut gears, splines, and sprockets. Gear hobbing machine (or hobbing gear machine) is a machining technique for making gears that include concurrently rotating. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same. Hobbing Machine Description.

From www.liebherr.com

LC 300 500 Gear hobbing machines Liebherr Liebherr Hobbing Machine Description Most gears are produced on a hobbing machine, which, when compared to other methods, has proven efficient and inexpensive. It involves using a hobbing machine. Gear hobbing is a process in which gear is cut by a generating process by rotating the gear blank and the cutter called a hob at the same time with a fixed gearing. They can. Hobbing Machine Description.