Countersink Drill Angle . Understand the types and use of. Common countersink angles include 82°, 90°, and 100°. The angle of the countersink bit should match the angle of the screw head. This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). The countersink and pilot hole diameter are also crucial, as they determine the hole size and the depth to which the fastener head can be recessed. These countersinks have a countersink angle of 60°. The standard countersink angle is 82 degrees for (american) fasteners and 90 degrees for metric fasteners. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. In principle, however, deburring can be carried out with any countersink angle.

from www.ablcircuits.co.uk

In principle, however, deburring can be carried out with any countersink angle. The countersink and pilot hole diameter are also crucial, as they determine the hole size and the depth to which the fastener head can be recessed. These countersinks have a countersink angle of 60°. This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). The angle of the countersink bit should match the angle of the screw head. The standard countersink angle is 82 degrees for (american) fasteners and 90 degrees for metric fasteners. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. Understand the types and use of. Common countersink angles include 82°, 90°, and 100°.

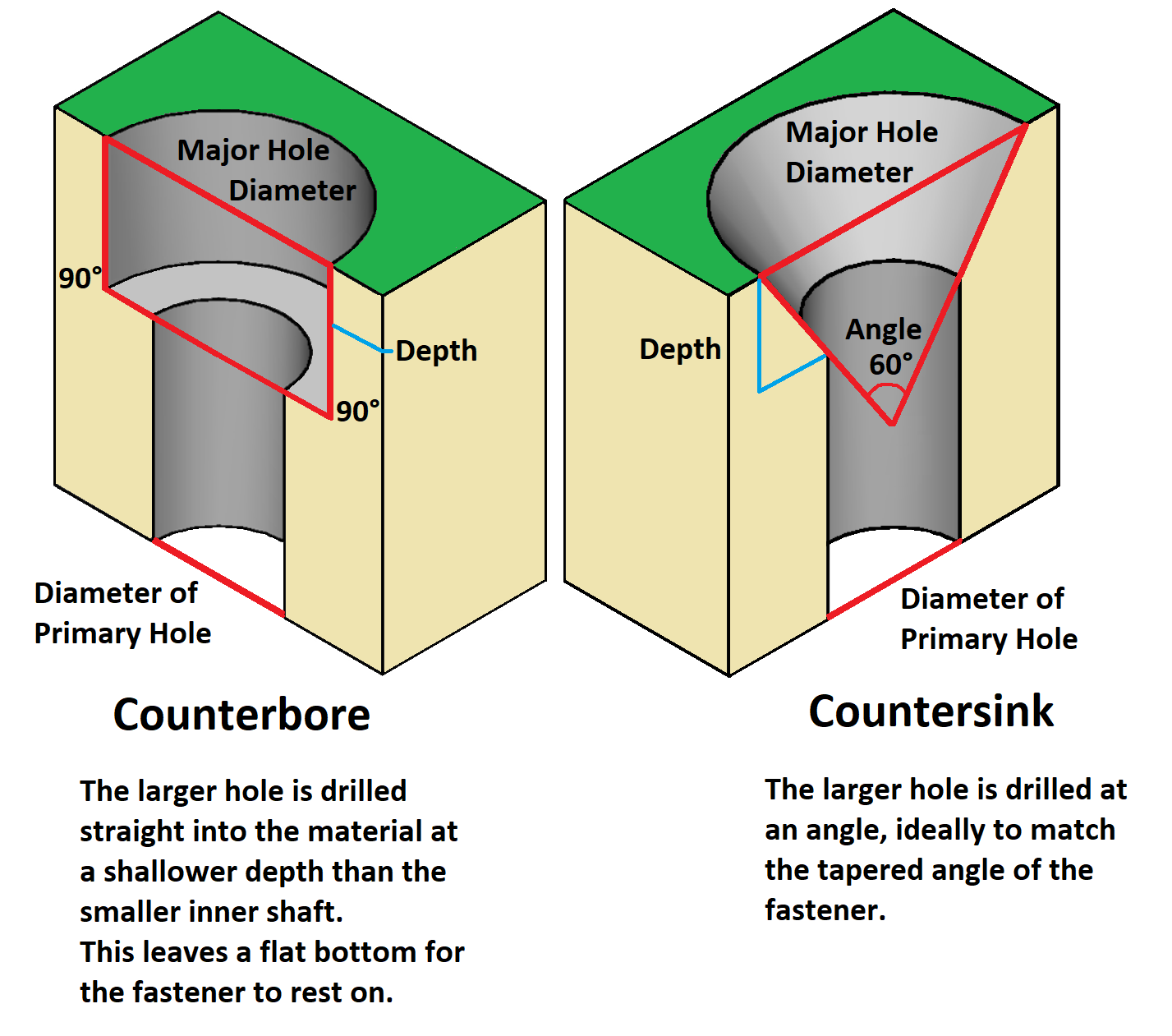

PCB Hole Types Counterbore vs Countersink ABL Circuits

Countersink Drill Angle Common countersink angles include 82°, 90°, and 100°. Common countersink angles include 82°, 90°, and 100°. The countersink and pilot hole diameter are also crucial, as they determine the hole size and the depth to which the fastener head can be recessed. This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). Understand the types and use of. These countersinks have a countersink angle of 60°. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. The standard countersink angle is 82 degrees for (american) fasteners and 90 degrees for metric fasteners. In principle, however, deburring can be carried out with any countersink angle. The angle of the countersink bit should match the angle of the screw head.

From www.aliexpress.com

2Pcs Countersink Drill Bit Set 82 Degree Chamfer Angle HSS 5 Flute Tool Countersink Drill Angle The standard countersink angle is 82 degrees for (american) fasteners and 90 degrees for metric fasteners. These countersinks have a countersink angle of 60°. Common countersink angles include 82°, 90°, and 100°. In principle, however, deburring can be carried out with any countersink angle. The angle of the countersink bit should match the angle of the screw head. Countersunk holes. Countersink Drill Angle.

From www.hvalleytools.com

MLCS Countersink Drill Bits for Wood 5 pc Set Countersink Drill Angle The angle of the countersink bit should match the angle of the screw head. The standard countersink angle is 82 degrees for (american) fasteners and 90 degrees for metric fasteners. This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). In principle, however, deburring can be carried out with any countersink angle.. Countersink Drill Angle.

From www.aliexpress.com

6pcs HSS High Speed Steel Center Drill Bits Set Precision Combined Countersink Drill Angle Common countersink angles include 82°, 90°, and 100°. This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). In principle, however, deburring can be carried out with any countersink angle. The standard countersink angle is 82 degrees for (american) fasteners and 90 degrees for metric fasteners. Countersunk holes are a type of. Countersink Drill Angle.

From www.aliexpress.com

5pc 82 Degree 5 Flutes Angle Counter Sink Bit Tri Flat Shank Countersink Drill Angle Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. The angle of the countersink bit should match the angle of the screw head. This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). The countersink and pilot. Countersink Drill Angle.

From www.ebay.co.uk

127406 90 Degrees Countersink HSS Drill Bit 6.3mm to 60mm eBay Countersink Drill Angle The standard countersink angle is 82 degrees for (american) fasteners and 90 degrees for metric fasteners. The countersink and pilot hole diameter are also crucial, as they determine the hole size and the depth to which the fastener head can be recessed. Understand the types and use of. Countersunk holes are a type of engineering hole most commonly used for. Countersink Drill Angle.

From www.aliexpress.com

5pc Countersink Drill Bit Set 82 & 90 Degree Angle HSS 5 Flute Chamfer Countersink Drill Angle Understand the types and use of. This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. Common countersink angles include 82°, 90°, and 100°. The standard countersink angle. Countersink Drill Angle.

From www.leevalley.com

Countersinks/Counterbores Lee Valley Tools Countersink Drill Angle These countersinks have a countersink angle of 60°. The standard countersink angle is 82 degrees for (american) fasteners and 90 degrees for metric fasteners. The countersink and pilot hole diameter are also crucial, as they determine the hole size and the depth to which the fastener head can be recessed. Countersunk holes are a type of engineering hole most commonly. Countersink Drill Angle.

From diywoodenplans.com

14 Types Of Wood Drill Bits For Every Project (The Ultimate Guide) Countersink Drill Angle The countersink and pilot hole diameter are also crucial, as they determine the hole size and the depth to which the fastener head can be recessed. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. Understand the types and use of. The angle of the. Countersink Drill Angle.

From drillbitguru.com

We Review The 6 Best Countersink Bits (2024) Countersink Drill Angle In principle, however, deburring can be carried out with any countersink angle. This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). These countersinks have a countersink angle of 60°. Common countersink angles include 82°, 90°, and 100°. Understand the types and use of. The countersink and pilot hole diameter are also. Countersink Drill Angle.

From www.aliexpress.com

3pcs 5 Flute Countersink Drill Bit 90 Degree Point Angle Chamfer Countersink Drill Angle Common countersink angles include 82°, 90°, and 100°. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. The angle of the countersink bit should match the angle of the screw head. This chart shows the dimensions of counterbore and countersink holes for different screw sizes,. Countersink Drill Angle.

From www.ablcircuits.co.uk

PCB Hole Types Counterbore vs Countersink ABL Circuits Countersink Drill Angle The standard countersink angle is 82 degrees for (american) fasteners and 90 degrees for metric fasteners. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. The countersink and pilot hole diameter are also crucial, as they determine the hole size and the depth to which. Countersink Drill Angle.

From www.ebay.com

127406 90 Degrees Countersink HSS Drill Bit 6.3mm to 60mm eBay Countersink Drill Angle Common countersink angles include 82°, 90°, and 100°. The standard countersink angle is 82 degrees for (american) fasteners and 90 degrees for metric fasteners. This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). These countersinks have a countersink angle of 60°. The countersink and pilot hole diameter are also crucial, as. Countersink Drill Angle.

From www.aliexpress.com

2pcs HSS 5 Flute Countersink Drill Bit 82Degree Point Angle Chamfer Countersink Drill Angle Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. In principle, however, deburring can be carried out with any countersink angle. The standard countersink angle is 82 degrees for (american) fasteners and 90 degrees for metric fasteners. The countersink and pilot hole diameter are also. Countersink Drill Angle.

From www.amazon.co.uk

HeyuLotus 6 Pcs Countersink Drill Bits Set, High Speed Steel Counter Countersink Drill Angle The standard countersink angle is 82 degrees for (american) fasteners and 90 degrees for metric fasteners. These countersinks have a countersink angle of 60°. In principle, however, deburring can be carried out with any countersink angle. The angle of the countersink bit should match the angle of the screw head. Understand the types and use of. The countersink and pilot. Countersink Drill Angle.

From www.aliexpress.com

2pcs HSS 5 Flute Countersink Drill Bit 82Degree Point Angle Chamfer Countersink Drill Angle In principle, however, deburring can be carried out with any countersink angle. Common countersink angles include 82°, 90°, and 100°. The angle of the countersink bit should match the angle of the screw head. Understand the types and use of. These countersinks have a countersink angle of 60°. The countersink and pilot hole diameter are also crucial, as they determine. Countersink Drill Angle.

From www.carbideanddiamondtooling.com

Countersink 82 Degree Angle Clearance, Drill and Countersink for Flat Countersink Drill Angle Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. The angle of the countersink bit should match the angle of the screw head. Common countersink angles include 82°, 90°, and 100°. These countersinks have a countersink angle of 60°. Understand the types and use of.. Countersink Drill Angle.

From www.aliexpress.com

Buy 2pcs 82 Degree Countersink Drill Bit Set 5 Flutes Countersink Drill Angle This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). These countersinks have a countersink angle of 60°. The countersink and pilot hole diameter are also crucial, as they determine the hole size and the depth to which the fastener head can be recessed. The angle of the countersink bit should match. Countersink Drill Angle.

From www.amazon.co.uk

Countersink Drill Bit Set 1/4'' Shank Counter Sinker Drill Bits for Countersink Drill Angle This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). Understand the types and use of. These countersinks have a countersink angle of 60°. In principle, however, deburring can be carried out with any countersink angle. Common countersink angles include 82°, 90°, and 100°. The standard countersink angle is 82 degrees for. Countersink Drill Angle.

From www.finepowertools.com

Countersink Angles Common Angles and Their Applications Countersink Drill Angle Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. In principle, however, deburring can be carried out with any countersink angle. The angle of the countersink bit should match the angle of the screw head. Understand the types and use of. The standard countersink angle. Countersink Drill Angle.

From www.youtube.com

Countersink drill bit. How to use countersink drill bit. YouTube Countersink Drill Angle In principle, however, deburring can be carried out with any countersink angle. The countersink and pilot hole diameter are also crucial, as they determine the hole size and the depth to which the fastener head can be recessed. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product. Countersink Drill Angle.

From www.aliexpress.com

Woodworking Chamfer Chamfering Countersinking Countersinks Bit Reamer 5 Countersink Drill Angle Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. The angle of the countersink bit should match the angle of the screw head. The standard countersink angle is 82 degrees for (american) fasteners and 90 degrees for metric fasteners. This chart shows the dimensions of. Countersink Drill Angle.

From www.aliexpress.com

5pcs 82 Degree Chamfer Angle HSS 5 Flute Countersink Woodworking Tools Countersink Drill Angle The countersink and pilot hole diameter are also crucial, as they determine the hole size and the depth to which the fastener head can be recessed. In principle, however, deburring can be carried out with any countersink angle. Common countersink angles include 82°, 90°, and 100°. The standard countersink angle is 82 degrees for (american) fasteners and 90 degrees for. Countersink Drill Angle.

From www.grainger.com

EAZYPOWER Drill Bit Countersink, 60 ° Countersink Angle, 9/64 in Drill Countersink Drill Angle The angle of the countersink bit should match the angle of the screw head. These countersinks have a countersink angle of 60°. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. The countersink and pilot hole diameter are also crucial, as they determine the hole. Countersink Drill Angle.

From www.youtube.com

The best countersink drill bit in the world ? YouTube Countersink Drill Angle Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. The countersink and pilot hole diameter are also crucial, as they determine the hole size and the depth to which the fastener head can be recessed. Common countersink angles include 82°, 90°, and 100°. The standard. Countersink Drill Angle.

From www.aliexpress.com

2pcs 5 Flute Countersink Drill Bit HSS 82 Degree Point Angle Chamfer Countersink Drill Angle The angle of the countersink bit should match the angle of the screw head. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. In principle, however, deburring can be carried out with any countersink angle. The standard countersink angle is 82 degrees for (american) fasteners. Countersink Drill Angle.

From engineersbible.com

Countersunk Hole Size for Machine Screw (ANSI Metric) Countersink Drill Angle Understand the types and use of. This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). In principle, however, deburring can be carried out with any countersink angle. Common countersink angles include 82°, 90°, and 100°. The standard countersink angle is 82 degrees for (american) fasteners and 90 degrees for metric fasteners.. Countersink Drill Angle.

From www.aliexpress.com

2pcs HSS 5 Flute Countersink Drill Bit 82Degree Point Angle Chamfer Countersink Drill Angle Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. The angle of the countersink bit should match the angle of the screw head. Understand the types and use of. This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric. Countersink Drill Angle.

From www.reidtimber.co.uk

Countersink Drill Bits Countersink Drill Angle The countersink and pilot hole diameter are also crucial, as they determine the hole size and the depth to which the fastener head can be recessed. Common countersink angles include 82°, 90°, and 100°. The angle of the countersink bit should match the angle of the screw head. This chart shows the dimensions of counterbore and countersink holes for different. Countersink Drill Angle.

From www.ebay.co.uk

90 Degrees Countersink HSS Drill Bit Wood Steel Aluminum 8mm to 50mm Countersink Drill Angle The countersink and pilot hole diameter are also crucial, as they determine the hole size and the depth to which the fastener head can be recessed. Understand the types and use of. The standard countersink angle is 82 degrees for (american) fasteners and 90 degrees for metric fasteners. The angle of the countersink bit should match the angle of the. Countersink Drill Angle.

From www.tongyutools.com

DIN335C 90 Degree 3 Flutes HSS Chamfer Countersink Drill Bit_China Countersink Drill Angle In principle, however, deburring can be carried out with any countersink angle. This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). These countersinks have a countersink angle of 60°. Common countersink angles include 82°, 90°, and 100°. The countersink and pilot hole diameter are also crucial, as they determine the hole. Countersink Drill Angle.

From www.aliexpress.com

Buy 2PC 1/4 Shank 82 Degree Point Angle Countersink Countersink Drill Angle Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. The angle of the countersink bit should match the angle of the screw head. The countersink and pilot hole diameter are also crucial, as they determine the hole size and the depth to which the fastener. Countersink Drill Angle.

From www.aliexpress.com

ZtDpLsd 1/4" Hex Shank 82 Degrees 5 Flute Countersink Drill Bit Five Countersink Drill Angle These countersinks have a countersink angle of 60°. The countersink and pilot hole diameter are also crucial, as they determine the hole size and the depth to which the fastener head can be recessed. In principle, however, deburring can be carried out with any countersink angle. Common countersink angles include 82°, 90°, and 100°. The standard countersink angle is 82. Countersink Drill Angle.

From www.taiwantrade.com

45Degree Angle Drill Guide & Countersink Drill Taiwantrade Countersink Drill Angle This chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. These countersinks have a countersink angle of 60°. The standard countersink angle is 82 degrees for (american) fasteners. Countersink Drill Angle.

From shopee.ph

90 Degrees Countersink HSS Drill Bit Wood Steel Aluminum Shopee Countersink Drill Angle These countersinks have a countersink angle of 60°. Common countersink angles include 82°, 90°, and 100°. The countersink and pilot hole diameter are also crucial, as they determine the hole size and the depth to which the fastener head can be recessed. Understand the types and use of. Countersunk holes are a type of engineering hole most commonly used for. Countersink Drill Angle.