Sensor Mount Design . Mounting a sensor on a curved surface with a mounting pad is not possible. Choose from our selection of sensor brackets, including over 140 products in a wide range of styles and sizes. A flush mounted sensors design causes the magnetic field to only generate out of the face of the sensor. Understanding these implications will help you select the correct inductive sensor for you specific application. Four main methods are used for attaching sensors to monitoring. • installation on curved surfaces: There are several mounting options available for. Users must identify and understand any mounting constraints and select a mounting method accordingly. Magnetic mount • maximum frequency response: This allows the sensor to work properly by avoiding triggering from the mount as opposed to the target. In stock and ready to ship.

from www.seaerospace.com

Magnetic mount • maximum frequency response: Users must identify and understand any mounting constraints and select a mounting method accordingly. • installation on curved surfaces: In stock and ready to ship. This allows the sensor to work properly by avoiding triggering from the mount as opposed to the target. Understanding these implications will help you select the correct inductive sensor for you specific application. Four main methods are used for attaching sensors to monitoring. Choose from our selection of sensor brackets, including over 140 products in a wide range of styles and sizes. Mounting a sensor on a curved surface with a mounting pad is not possible. There are several mounting options available for.

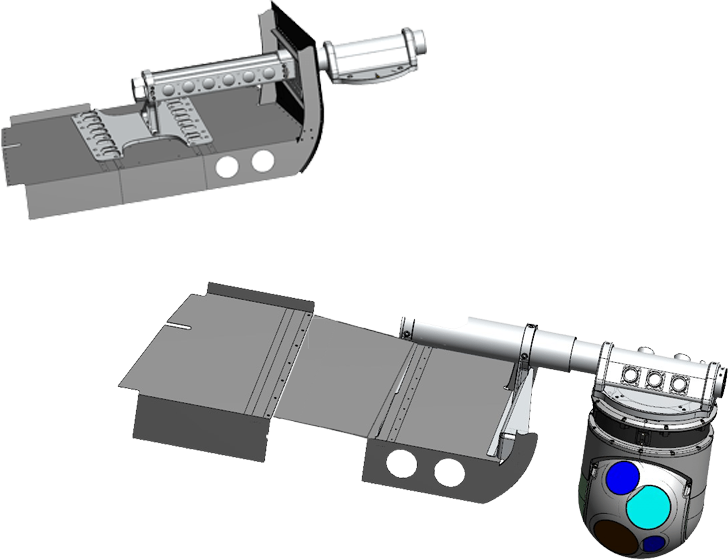

Cessna 206 External Sensor Mount

Sensor Mount Design Magnetic mount • maximum frequency response: There are several mounting options available for. A flush mounted sensors design causes the magnetic field to only generate out of the face of the sensor. Four main methods are used for attaching sensors to monitoring. In stock and ready to ship. Choose from our selection of sensor brackets, including over 140 products in a wide range of styles and sizes. This allows the sensor to work properly by avoiding triggering from the mount as opposed to the target. Understanding these implications will help you select the correct inductive sensor for you specific application. Magnetic mount • maximum frequency response: Mounting a sensor on a curved surface with a mounting pad is not possible. Users must identify and understand any mounting constraints and select a mounting method accordingly. • installation on curved surfaces:

From cults3d.com

Free 3D file filament sensor mount・Design to download and 3D print・Cults Sensor Mount Design This allows the sensor to work properly by avoiding triggering from the mount as opposed to the target. Magnetic mount • maximum frequency response: Four main methods are used for attaching sensors to monitoring. Understanding these implications will help you select the correct inductive sensor for you specific application. Choose from our selection of sensor brackets, including over 140 products. Sensor Mount Design.

From cults3d.com

Free 3D file Sharp GP2Y0A51SK0F Analog Distance Sensor Mount・Design to download and 3D print・Cults Sensor Mount Design Magnetic mount • maximum frequency response: Understanding these implications will help you select the correct inductive sensor for you specific application. This allows the sensor to work properly by avoiding triggering from the mount as opposed to the target. Choose from our selection of sensor brackets, including over 140 products in a wide range of styles and sizes. • installation. Sensor Mount Design.

From thangs.com

BTT Smart Filament Runout Sensor Mount 3D model by NikkiGrubbDesign on Thangs Sensor Mount Design There are several mounting options available for. Mounting a sensor on a curved surface with a mounting pad is not possible. Choose from our selection of sensor brackets, including over 140 products in a wide range of styles and sizes. Understanding these implications will help you select the correct inductive sensor for you specific application. This allows the sensor to. Sensor Mount Design.

From cults3d.com

Free 3D file Sharp GP2Y0A51SK0F Analog Distance Sensor Mount・Design to download and 3D print・Cults Sensor Mount Design Magnetic mount • maximum frequency response: Mounting a sensor on a curved surface with a mounting pad is not possible. Choose from our selection of sensor brackets, including over 140 products in a wide range of styles and sizes. In stock and ready to ship. Understanding these implications will help you select the correct inductive sensor for you specific application.. Sensor Mount Design.

From www.elobau.com

Mounting bracket for sensors Suitable for M18 and M30 elobau Sensor Mount Design • installation on curved surfaces: There are several mounting options available for. Users must identify and understand any mounting constraints and select a mounting method accordingly. Choose from our selection of sensor brackets, including over 140 products in a wide range of styles and sizes. This allows the sensor to work properly by avoiding triggering from the mount as opposed. Sensor Mount Design.

From abmsensor.com

ABM Aimer Outside Tank Sensor Mount ABM Sensor Technology Sensor Mount Design Users must identify and understand any mounting constraints and select a mounting method accordingly. Magnetic mount • maximum frequency response: In stock and ready to ship. Choose from our selection of sensor brackets, including over 140 products in a wide range of styles and sizes. Understanding these implications will help you select the correct inductive sensor for you specific application.. Sensor Mount Design.

From www.colabgarage.com

Dual AEM Pressure Sensor Mount — Colab Garage High Performance DCT Vehicle Experts Sensor Mount Design This allows the sensor to work properly by avoiding triggering from the mount as opposed to the target. In stock and ready to ship. Mounting a sensor on a curved surface with a mounting pad is not possible. Magnetic mount • maximum frequency response: Choose from our selection of sensor brackets, including over 140 products in a wide range of. Sensor Mount Design.

From www.colabgarage.com

Single AEM Pressure Sensor Mount — Colab Garage High Performance DCT Vehicle Experts Sensor Mount Design There are several mounting options available for. • installation on curved surfaces: Mounting a sensor on a curved surface with a mounting pad is not possible. Four main methods are used for attaching sensors to monitoring. Understanding these implications will help you select the correct inductive sensor for you specific application. In stock and ready to ship. Users must identify. Sensor Mount Design.

From cults3d.com

Free 3D file CTC i3 Pro B Prusa DYS 10x20 Chain Connector with 18mm Sensor Mount・Design to Sensor Mount Design There are several mounting options available for. Four main methods are used for attaching sensors to monitoring. Users must identify and understand any mounting constraints and select a mounting method accordingly. Choose from our selection of sensor brackets, including over 140 products in a wide range of styles and sizes. In stock and ready to ship. Understanding these implications will. Sensor Mount Design.

From www.colabgarage.com

Dual AEM Pressure Sensor Mount — Colab Garage High Performance DCT Vehicle Experts Sensor Mount Design A flush mounted sensors design causes the magnetic field to only generate out of the face of the sensor. This allows the sensor to work properly by avoiding triggering from the mount as opposed to the target. Four main methods are used for attaching sensors to monitoring. In stock and ready to ship. There are several mounting options available for.. Sensor Mount Design.

From www.seaerospace.com

Cessna 206 External Sensor Mount Sensor Mount Design Mounting a sensor on a curved surface with a mounting pad is not possible. Users must identify and understand any mounting constraints and select a mounting method accordingly. Choose from our selection of sensor brackets, including over 140 products in a wide range of styles and sizes. A flush mounted sensors design causes the magnetic field to only generate out. Sensor Mount Design.

From www.dspe.nl

Ultrastable isostatic bonded optical mount design DSPE Sensor Mount Design Four main methods are used for attaching sensors to monitoring. Mounting a sensor on a curved surface with a mounting pad is not possible. In stock and ready to ship. A flush mounted sensors design causes the magnetic field to only generate out of the face of the sensor. There are several mounting options available for. • installation on curved. Sensor Mount Design.

From www.machinedesign.com

Sensor Mounting Considerations Machine Design Sensor Mount Design In stock and ready to ship. Mounting a sensor on a curved surface with a mounting pad is not possible. Four main methods are used for attaching sensors to monitoring. Users must identify and understand any mounting constraints and select a mounting method accordingly. There are several mounting options available for. A flush mounted sensors design causes the magnetic field. Sensor Mount Design.

From cults3d.com

Free STL file Geeetech ABL Sensor Mount・3D print design to download • Cults Sensor Mount Design Users must identify and understand any mounting constraints and select a mounting method accordingly. This allows the sensor to work properly by avoiding triggering from the mount as opposed to the target. Magnetic mount • maximum frequency response: In stock and ready to ship. • installation on curved surfaces: A flush mounted sensors design causes the magnetic field to only. Sensor Mount Design.

From cults3d.com

Free 3D file Sharp GP2Y0A51SK0F Analog Distance Sensor Mount・Design to download and 3D print・Cults Sensor Mount Design Choose from our selection of sensor brackets, including over 140 products in a wide range of styles and sizes. Understanding these implications will help you select the correct inductive sensor for you specific application. Magnetic mount • maximum frequency response: A flush mounted sensors design causes the magnetic field to only generate out of the face of the sensor. •. Sensor Mount Design.

From www.ctconline.com

Vibration Sensor Mounting Techniques CTC Sensor Mount Design Users must identify and understand any mounting constraints and select a mounting method accordingly. This allows the sensor to work properly by avoiding triggering from the mount as opposed to the target. There are several mounting options available for. Mounting a sensor on a curved surface with a mounting pad is not possible. In stock and ready to ship. •. Sensor Mount Design.

From grofusa.com

Sensor Mount, Round KOHLER GROF USA Sensor Mount Design Mounting a sensor on a curved surface with a mounting pad is not possible. Four main methods are used for attaching sensors to monitoring. A flush mounted sensors design causes the magnetic field to only generate out of the face of the sensor. Magnetic mount • maximum frequency response: In stock and ready to ship. Users must identify and understand. Sensor Mount Design.

From www.seaerospace.com

Cessna 206 External Sensor Mount Sensor Mount Design Choose from our selection of sensor brackets, including over 140 products in a wide range of styles and sizes. Four main methods are used for attaching sensors to monitoring. • installation on curved surfaces: This allows the sensor to work properly by avoiding triggering from the mount as opposed to the target. Users must identify and understand any mounting constraints. Sensor Mount Design.

From www.bulksolids-portal.com

Sensor mounting kits for barrel sensors Sensor Mount Design In stock and ready to ship. • installation on curved surfaces: There are several mounting options available for. This allows the sensor to work properly by avoiding triggering from the mount as opposed to the target. Magnetic mount • maximum frequency response: Choose from our selection of sensor brackets, including over 140 products in a wide range of styles and. Sensor Mount Design.

From grabcad.com

Free CAD Designs, Files & 3D Models The GrabCAD Community Library Sensor Mount Design Choose from our selection of sensor brackets, including over 140 products in a wide range of styles and sizes. A flush mounted sensors design causes the magnetic field to only generate out of the face of the sensor. Four main methods are used for attaching sensors to monitoring. Magnetic mount • maximum frequency response: This allows the sensor to work. Sensor Mount Design.

From automation-insights.blog

Inductive Sensor Protection and Positioning Made Easy Use a Prox Mount AUTOMATION INSIGHTS Sensor Mount Design Users must identify and understand any mounting constraints and select a mounting method accordingly. Understanding these implications will help you select the correct inductive sensor for you specific application. Mounting a sensor on a curved surface with a mounting pad is not possible. Magnetic mount • maximum frequency response: Choose from our selection of sensor brackets, including over 140 products. Sensor Mount Design.

From grabcad.com

Free CAD Designs, Files & 3D Models The GrabCAD Community Library Sensor Mount Design Four main methods are used for attaching sensors to monitoring. In stock and ready to ship. There are several mounting options available for. • installation on curved surfaces: Choose from our selection of sensor brackets, including over 140 products in a wide range of styles and sizes. This allows the sensor to work properly by avoiding triggering from the mount. Sensor Mount Design.

From cults3d.com

Free 3D file CTC i3 Pro B Prusa DYS 10x20 Chain Connector with 18mm Sensor Mount・Design to Sensor Mount Design Understanding these implications will help you select the correct inductive sensor for you specific application. • installation on curved surfaces: Four main methods are used for attaching sensors to monitoring. Magnetic mount • maximum frequency response: Users must identify and understand any mounting constraints and select a mounting method accordingly. In stock and ready to ship. Choose from our selection. Sensor Mount Design.

From cults3d.com

Free STL file Sonic Pad Sensor Mount Ender 3 v2 CRTouch 🔧・3D print design to download・Cults Sensor Mount Design Understanding these implications will help you select the correct inductive sensor for you specific application. Choose from our selection of sensor brackets, including over 140 products in a wide range of styles and sizes. Four main methods are used for attaching sensors to monitoring. A flush mounted sensors design causes the magnetic field to only generate out of the face. Sensor Mount Design.

From cults3d.com

Free 3D file Sharp GP2Y0A51SK0F Analog Distance Sensor Mount・Design to download and 3D print・Cults Sensor Mount Design Magnetic mount • maximum frequency response: A flush mounted sensors design causes the magnetic field to only generate out of the face of the sensor. Four main methods are used for attaching sensors to monitoring. Mounting a sensor on a curved surface with a mounting pad is not possible. There are several mounting options available for. Choose from our selection. Sensor Mount Design.

From www.colabgarage.com

Triple AEM Pressure Sensor Mount — Colab Garage High Performance DCT Vehicle Experts Sensor Mount Design In stock and ready to ship. Magnetic mount • maximum frequency response: Mounting a sensor on a curved surface with a mounting pad is not possible. Choose from our selection of sensor brackets, including over 140 products in a wide range of styles and sizes. • installation on curved surfaces: Four main methods are used for attaching sensors to monitoring.. Sensor Mount Design.

From www.printables.com

Creality Ender 3 / V2 "Creality" Filament Sensor Mount by Sean Saunders Download free STL Sensor Mount Design A flush mounted sensors design causes the magnetic field to only generate out of the face of the sensor. Mounting a sensor on a curved surface with a mounting pad is not possible. • installation on curved surfaces: Magnetic mount • maximum frequency response: Four main methods are used for attaching sensors to monitoring. This allows the sensor to work. Sensor Mount Design.

From www.colabgarage.com

Triple AEM Pressure Sensor Mount — Colab Garage High Performance DCT Vehicle Experts Sensor Mount Design Choose from our selection of sensor brackets, including over 140 products in a wide range of styles and sizes. Magnetic mount • maximum frequency response: In stock and ready to ship. Four main methods are used for attaching sensors to monitoring. This allows the sensor to work properly by avoiding triggering from the mount as opposed to the target. Mounting. Sensor Mount Design.

From us.misumi-ec.com

Sensor Mounting Introduction to Sensors MISUMI Mech Lab Blog Sensor Mount Design There are several mounting options available for. Mounting a sensor on a curved surface with a mounting pad is not possible. This allows the sensor to work properly by avoiding triggering from the mount as opposed to the target. In stock and ready to ship. A flush mounted sensors design causes the magnetic field to only generate out of the. Sensor Mount Design.

From cults3d.com

Download free STL file Ultrasonic Sensor Mount • Design to 3D print ・ Cults Sensor Mount Design Mounting a sensor on a curved surface with a mounting pad is not possible. Four main methods are used for attaching sensors to monitoring. There are several mounting options available for. Magnetic mount • maximum frequency response: Understanding these implications will help you select the correct inductive sensor for you specific application. A flush mounted sensors design causes the magnetic. Sensor Mount Design.

From www.controlsdrivesautomation.com

CDA Sensor mounting system Sensor Mount Design Mounting a sensor on a curved surface with a mounting pad is not possible. Four main methods are used for attaching sensors to monitoring. This allows the sensor to work properly by avoiding triggering from the mount as opposed to the target. Magnetic mount • maximum frequency response: A flush mounted sensors design causes the magnetic field to only generate. Sensor Mount Design.

From www.campbellsci.com

CM255LS AdjustableAngle Solar Sensor Mounting Stand with Leveling... Sensor Mount Design • installation on curved surfaces: A flush mounted sensors design causes the magnetic field to only generate out of the face of the sensor. Magnetic mount • maximum frequency response: This allows the sensor to work properly by avoiding triggering from the mount as opposed to the target. There are several mounting options available for. Four main methods are used. Sensor Mount Design.

From cults3d.com

Free 3D file Creality Sonic Pad X Axis Sensor Mount Ender 3 S1 🧞♂️・3D printer design to Sensor Mount Design Mounting a sensor on a curved surface with a mounting pad is not possible. There are several mounting options available for. Choose from our selection of sensor brackets, including over 140 products in a wide range of styles and sizes. Four main methods are used for attaching sensors to monitoring. This allows the sensor to work properly by avoiding triggering. Sensor Mount Design.

From cults3d.com

STL file GSensor Mount Ender 5 S1 Sonic Pad 🧞♂️・3D printer design to download・Cults Sensor Mount Design There are several mounting options available for. In stock and ready to ship. A flush mounted sensors design causes the magnetic field to only generate out of the face of the sensor. • installation on curved surfaces: Mounting a sensor on a curved surface with a mounting pad is not possible. Choose from our selection of sensor brackets, including over. Sensor Mount Design.

From www.printables.com

Adjustable BLTouch sensor mount for Ender 3 and CR10 (with STEP file) by MyStoopidStuff Sensor Mount Design Understanding these implications will help you select the correct inductive sensor for you specific application. A flush mounted sensors design causes the magnetic field to only generate out of the face of the sensor. In stock and ready to ship. Magnetic mount • maximum frequency response: This allows the sensor to work properly by avoiding triggering from the mount as. Sensor Mount Design.