Bt40 Tool Holder Taper Angle . The taper angle, which defines the conical part of the toolholder, is the key component of the bt taper system. Adaptable designs to meet a range of demands. Choose from a wide offering of adapters, chucks, and. The tool holder is pulled in the milling spindle with the help of an additional pull stud. The centering takes place via the taper contact. Though both standards use the same nmtb body taper, bt tool holders are. Same when you set the bench. To achieve the highest level of accuracy in machining processes, this angle is more than just a geometric element; Bt tool holders use metric thread pull studs (retention knobs). It is the key to secure and exact tool positioning. The half angle is what you have to set the taper attachment, compound, grinder platen, etc.

from www.haascnc.com

The taper angle, which defines the conical part of the toolholder, is the key component of the bt taper system. It is the key to secure and exact tool positioning. The half angle is what you have to set the taper attachment, compound, grinder platen, etc. Same when you set the bench. Bt tool holders use metric thread pull studs (retention knobs). Choose from a wide offering of adapters, chucks, and. The tool holder is pulled in the milling spindle with the help of an additional pull stud. To achieve the highest level of accuracy in machining processes, this angle is more than just a geometric element; Though both standards use the same nmtb body taper, bt tool holders are. Adaptable designs to meet a range of demands.

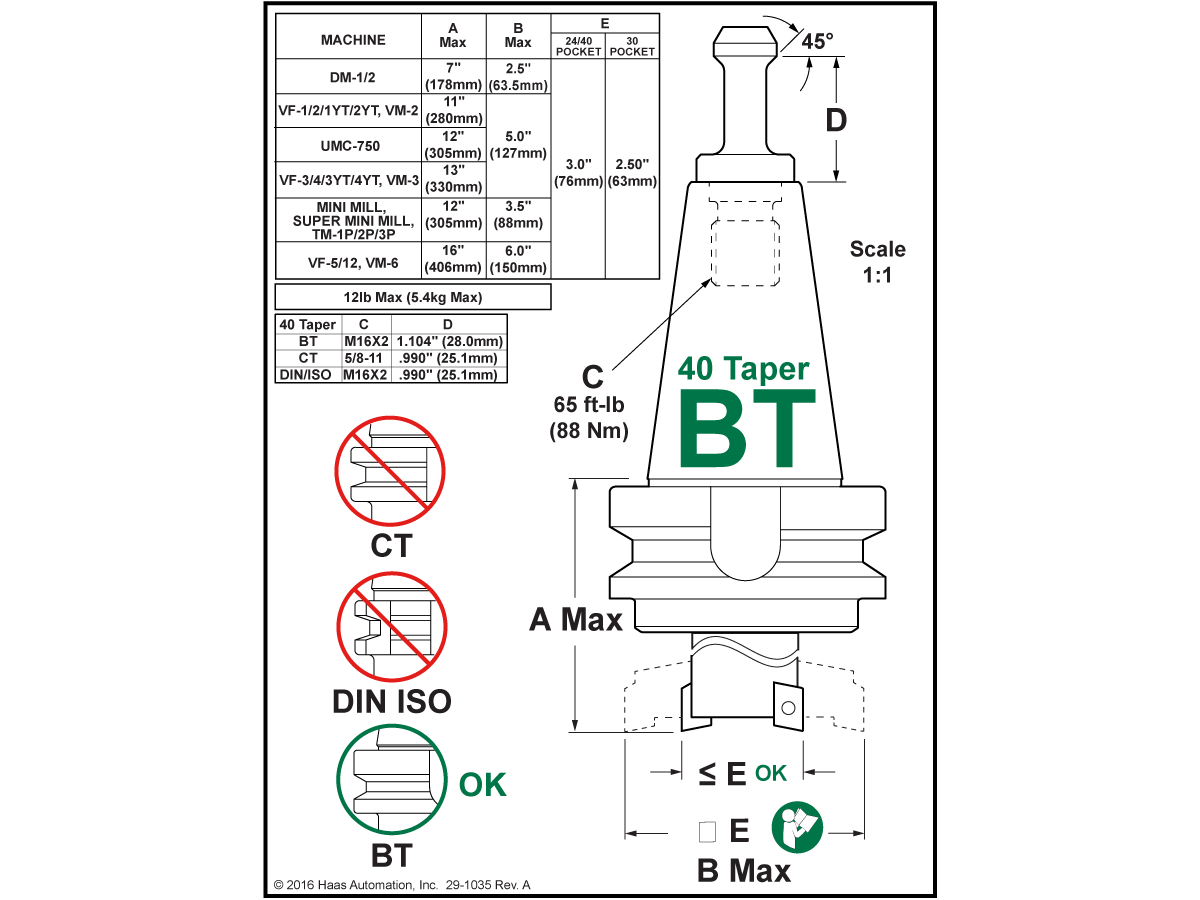

Tool Holder and Pull Stud Specifications

Bt40 Tool Holder Taper Angle Adaptable designs to meet a range of demands. Bt tool holders use metric thread pull studs (retention knobs). Though both standards use the same nmtb body taper, bt tool holders are. The taper angle, which defines the conical part of the toolholder, is the key component of the bt taper system. Choose from a wide offering of adapters, chucks, and. The half angle is what you have to set the taper attachment, compound, grinder platen, etc. To achieve the highest level of accuracy in machining processes, this angle is more than just a geometric element; It is the key to secure and exact tool positioning. Adaptable designs to meet a range of demands. The tool holder is pulled in the milling spindle with the help of an additional pull stud. Same when you set the bench. The centering takes place via the taper contact.

From colletchucks.en.made-in-china.com

CNC Tool Holder Bt40M Taper Shank Bt40 Tool Holder Tool Holder and Bt40 Tool Holder Taper Angle Same when you set the bench. The tool holder is pulled in the milling spindle with the help of an additional pull stud. Bt tool holders use metric thread pull studs (retention knobs). The taper angle, which defines the conical part of the toolholder, is the key component of the bt taper system. The half angle is what you have. Bt40 Tool Holder Taper Angle.

From anthropology.iresearchnet.com

BT40WER20100 BT40WER25110 WER tapping holders BT MAS403 shank BT30 Bt40 Tool Holder Taper Angle To achieve the highest level of accuracy in machining processes, this angle is more than just a geometric element; The tool holder is pulled in the milling spindle with the help of an additional pull stud. It is the key to secure and exact tool positioning. Same when you set the bench. Bt tool holders use metric thread pull studs. Bt40 Tool Holder Taper Angle.

From www.hegratools.com

BT40 90° ANGLE HEAD ER25 COLLECT CHUCK FOR SPINDLE TAPER BT40 PIN 80mm Bt40 Tool Holder Taper Angle The taper angle, which defines the conical part of the toolholder, is the key component of the bt taper system. Though both standards use the same nmtb body taper, bt tool holders are. To achieve the highest level of accuracy in machining processes, this angle is more than just a geometric element; The centering takes place via the taper contact.. Bt40 Tool Holder Taper Angle.

From www.mscdirect.com

Sandvik Coromant Hydraulic Tool Chuck BT40, Taper Shank MSC Direct Bt40 Tool Holder Taper Angle The tool holder is pulled in the milling spindle with the help of an additional pull stud. The taper angle, which defines the conical part of the toolholder, is the key component of the bt taper system. To achieve the highest level of accuracy in machining processes, this angle is more than just a geometric element; It is the key. Bt40 Tool Holder Taper Angle.

From www.shop-apt.co.uk

BT40 End Mill Holder 40mm Bore 120mm Gauge Length Associated Production Bt40 Tool Holder Taper Angle Choose from a wide offering of adapters, chucks, and. To achieve the highest level of accuracy in machining processes, this angle is more than just a geometric element; The centering takes place via the taper contact. The taper angle, which defines the conical part of the toolholder, is the key component of the bt taper system. Bt tool holders use. Bt40 Tool Holder Taper Angle.

From www.hegratools.com

BT40 MODULAR 90° ANGLE HEADFOR SPINDLE TAPER BT40 SHORT Version ER20 Bt40 Tool Holder Taper Angle It is the key to secure and exact tool positioning. To achieve the highest level of accuracy in machining processes, this angle is more than just a geometric element; The tool holder is pulled in the milling spindle with the help of an additional pull stud. Though both standards use the same nmtb body taper, bt tool holders are. Choose. Bt40 Tool Holder Taper Angle.

From zombie-nahir.blogspot.com

cat 40 tool holders dimensions Violeta Karr Bt40 Tool Holder Taper Angle Choose from a wide offering of adapters, chucks, and. The tool holder is pulled in the milling spindle with the help of an additional pull stud. Same when you set the bench. Though both standards use the same nmtb body taper, bt tool holders are. Bt tool holders use metric thread pull studs (retention knobs). Adaptable designs to meet a. Bt40 Tool Holder Taper Angle.

From www.aliexpress.com

BT30 BT40 SK40 LBK1 LBK2 LBK3 LBK4 LBK5 LBK6 Tool Holder EWN Fine Bt40 Tool Holder Taper Angle Bt tool holders use metric thread pull studs (retention knobs). The centering takes place via the taper contact. Adaptable designs to meet a range of demands. The taper angle, which defines the conical part of the toolholder, is the key component of the bt taper system. Though both standards use the same nmtb body taper, bt tool holders are. It. Bt40 Tool Holder Taper Angle.

From www.mscdirect.com

Techniks Tool Holder Tightening Fixtures; Compatible Taper BT40 Bt40 Tool Holder Taper Angle To achieve the highest level of accuracy in machining processes, this angle is more than just a geometric element; The centering takes place via the taper contact. Though both standards use the same nmtb body taper, bt tool holders are. Bt tool holders use metric thread pull studs (retention knobs). The tool holder is pulled in the milling spindle with. Bt40 Tool Holder Taper Angle.

From www.iiitl.ac.in

CAT40 Vs BT40 Main Differences Between BT40 And CAT40 Tool, 43 OFF Bt40 Tool Holder Taper Angle The centering takes place via the taper contact. The taper angle, which defines the conical part of the toolholder, is the key component of the bt taper system. Though both standards use the same nmtb body taper, bt tool holders are. The tool holder is pulled in the milling spindle with the help of an additional pull stud. Choose from. Bt40 Tool Holder Taper Angle.

From www.hegratools.com

BT40 UNIVERSAL ANGLE HEAD FOR SPINDLE TAPER BT40 ER32 TYPE G PIN_65mm Bt40 Tool Holder Taper Angle The taper angle, which defines the conical part of the toolholder, is the key component of the bt taper system. The centering takes place via the taper contact. Choose from a wide offering of adapters, chucks, and. Adaptable designs to meet a range of demands. Same when you set the bench. The tool holder is pulled in the milling spindle. Bt40 Tool Holder Taper Angle.

From www.mscdirect.com

Seco Hydraulic Tool Chuck BT40, BT40 ADB, Taper Shank, 20.00 mm Hole Bt40 Tool Holder Taper Angle It is the key to secure and exact tool positioning. The centering takes place via the taper contact. The half angle is what you have to set the taper attachment, compound, grinder platen, etc. Adaptable designs to meet a range of demands. Choose from a wide offering of adapters, chucks, and. Same when you set the bench. Bt tool holders. Bt40 Tool Holder Taper Angle.

From ricardoalpoim.com.br

BT40 Tool Holder ER32100, 53 OFF Bt40 Tool Holder Taper Angle Adaptable designs to meet a range of demands. It is the key to secure and exact tool positioning. Bt tool holders use metric thread pull studs (retention knobs). Same when you set the bench. The half angle is what you have to set the taper attachment, compound, grinder platen, etc. The centering takes place via the taper contact. Choose from. Bt40 Tool Holder Taper Angle.

From www.toolsunited.com

Nikken BT40FMC2760 Basic Holders with Steep Taper Shank ToolsUnited Bt40 Tool Holder Taper Angle Bt tool holders use metric thread pull studs (retention knobs). The taper angle, which defines the conical part of the toolholder, is the key component of the bt taper system. Same when you set the bench. The half angle is what you have to set the taper attachment, compound, grinder platen, etc. Though both standards use the same nmtb body. Bt40 Tool Holder Taper Angle.

From www.practicalmachinist.com

BT40 tool holders loose in spindle Bt40 Tool Holder Taper Angle Adaptable designs to meet a range of demands. Same when you set the bench. Choose from a wide offering of adapters, chucks, and. The half angle is what you have to set the taper attachment, compound, grinder platen, etc. It is the key to secure and exact tool positioning. The centering takes place via the taper contact. Bt tool holders. Bt40 Tool Holder Taper Angle.

From www.hegratools.com

BT40 90° ANGLE HEAD (1)"inch FACE MILLING HEAD FOR MACHINE SPINDLE Bt40 Tool Holder Taper Angle Adaptable designs to meet a range of demands. The centering takes place via the taper contact. Though both standards use the same nmtb body taper, bt tool holders are. Same when you set the bench. It is the key to secure and exact tool positioning. The taper angle, which defines the conical part of the toolholder, is the key component. Bt40 Tool Holder Taper Angle.

From olitools.com

BT40LBK4 Bt40 Tool Holder Taper Angle The half angle is what you have to set the taper attachment, compound, grinder platen, etc. Though both standards use the same nmtb body taper, bt tool holders are. Adaptable designs to meet a range of demands. The tool holder is pulled in the milling spindle with the help of an additional pull stud. To achieve the highest level of. Bt40 Tool Holder Taper Angle.

From www.alibaba.com

724 Taper Bt40er11100 Bt Tool Holder Buy Bt Tool Holder,Bt40er11 Bt40 Tool Holder Taper Angle The tool holder is pulled in the milling spindle with the help of an additional pull stud. Though both standards use the same nmtb body taper, bt tool holders are. Choose from a wide offering of adapters, chucks, and. The half angle is what you have to set the taper attachment, compound, grinder platen, etc. It is the key to. Bt40 Tool Holder Taper Angle.

From www.hegratools.com

BT50BT40 90° FLANGEMOUNTED ANGLE HEAD LONG FOR MACHINE SPINDLE TAPER Bt40 Tool Holder Taper Angle Bt tool holders use metric thread pull studs (retention knobs). Choose from a wide offering of adapters, chucks, and. The taper angle, which defines the conical part of the toolholder, is the key component of the bt taper system. It is the key to secure and exact tool positioning. To achieve the highest level of accuracy in machining processes, this. Bt40 Tool Holder Taper Angle.

From www.haascnc.com

Tool Holder and Pull Stud Specifications Bt40 Tool Holder Taper Angle It is the key to secure and exact tool positioning. The centering takes place via the taper contact. Though both standards use the same nmtb body taper, bt tool holders are. The taper angle, which defines the conical part of the toolholder, is the key component of the bt taper system. The half angle is what you have to set. Bt40 Tool Holder Taper Angle.

From www.bidspotter.com

{ Option of lots 280, 281, 282 } (6) BT40 Taper Tool Holders Bt40 Tool Holder Taper Angle Adaptable designs to meet a range of demands. Though both standards use the same nmtb body taper, bt tool holders are. To achieve the highest level of accuracy in machining processes, this angle is more than just a geometric element; The half angle is what you have to set the taper attachment, compound, grinder platen, etc. It is the key. Bt40 Tool Holder Taper Angle.

From www.bidspotter.com

(3) MISC. BT40 TAPER TOOL HOLDERS WITH BORING HEAD ATTACHMENTS Bt40 Tool Holder Taper Angle Same when you set the bench. It is the key to secure and exact tool positioning. The taper angle, which defines the conical part of the toolholder, is the key component of the bt taper system. Bt tool holders use metric thread pull studs (retention knobs). The tool holder is pulled in the milling spindle with the help of an. Bt40 Tool Holder Taper Angle.

From zombie-nahir.blogspot.com

cat 40 tool holders dimensions Violeta Karr Bt40 Tool Holder Taper Angle It is the key to secure and exact tool positioning. The tool holder is pulled in the milling spindle with the help of an additional pull stud. Though both standards use the same nmtb body taper, bt tool holders are. Adaptable designs to meet a range of demands. Same when you set the bench. Bt tool holders use metric thread. Bt40 Tool Holder Taper Angle.

From www.toolmex.com

82454010 BT40 Rigid Tap Holder, 1 Toolmex Industrial Solutions Bt40 Tool Holder Taper Angle Choose from a wide offering of adapters, chucks, and. The taper angle, which defines the conical part of the toolholder, is the key component of the bt taper system. The tool holder is pulled in the milling spindle with the help of an additional pull stud. It is the key to secure and exact tool positioning. Bt tool holders use. Bt40 Tool Holder Taper Angle.

From www.haascnc.com

BT40 10mm End Mill Holder x 63mm Gage Length, TSC Bt40 Tool Holder Taper Angle The centering takes place via the taper contact. Same when you set the bench. Choose from a wide offering of adapters, chucks, and. Adaptable designs to meet a range of demands. Bt tool holders use metric thread pull studs (retention knobs). It is the key to secure and exact tool positioning. To achieve the highest level of accuracy in machining. Bt40 Tool Holder Taper Angle.

From www.bidspotter.com

Assorted BT40 Taper Tool Holders Bt40 Tool Holder Taper Angle The centering takes place via the taper contact. It is the key to secure and exact tool positioning. To achieve the highest level of accuracy in machining processes, this angle is more than just a geometric element; Adaptable designs to meet a range of demands. Though both standards use the same nmtb body taper, bt tool holders are. Choose from. Bt40 Tool Holder Taper Angle.

From www.cottandco.com

16 x BT40 Tool Holders Bt40 Tool Holder Taper Angle It is the key to secure and exact tool positioning. Adaptable designs to meet a range of demands. Though both standards use the same nmtb body taper, bt tool holders are. The centering takes place via the taper contact. The tool holder is pulled in the milling spindle with the help of an additional pull stud. The taper angle, which. Bt40 Tool Holder Taper Angle.

From www.vkcnctools.com

BT Taper Shank Face Mill Holders( Metric) Bt40 Tool Holder Taper Angle Same when you set the bench. Though both standards use the same nmtb body taper, bt tool holders are. The taper angle, which defines the conical part of the toolholder, is the key component of the bt taper system. To achieve the highest level of accuracy in machining processes, this angle is more than just a geometric element; Adaptable designs. Bt40 Tool Holder Taper Angle.

From www.hegratools.com

BT40 MODULAR 45° ANGLE HEAD FOR SPINDLE TAPER BT40 ER20 TYPE D PIN_85mm Bt40 Tool Holder Taper Angle Adaptable designs to meet a range of demands. Though both standards use the same nmtb body taper, bt tool holders are. It is the key to secure and exact tool positioning. Choose from a wide offering of adapters, chucks, and. Same when you set the bench. The taper angle, which defines the conical part of the toolholder, is the key. Bt40 Tool Holder Taper Angle.

From www.pinterest.com

BT40 vs CAT40 tool holders, the taper length different Tool holder Bt40 Tool Holder Taper Angle Adaptable designs to meet a range of demands. It is the key to secure and exact tool positioning. Same when you set the bench. The tool holder is pulled in the milling spindle with the help of an additional pull stud. The half angle is what you have to set the taper attachment, compound, grinder platen, etc. Though both standards. Bt40 Tool Holder Taper Angle.

From www.hegratools.com

BT40 MODULAR 90° ANGLE HEADFOR SPINDLE TAPER BT40 SHORT Version ER25 Bt40 Tool Holder Taper Angle Adaptable designs to meet a range of demands. The centering takes place via the taper contact. Choose from a wide offering of adapters, chucks, and. Same when you set the bench. Bt tool holders use metric thread pull studs (retention knobs). To achieve the highest level of accuracy in machining processes, this angle is more than just a geometric element;. Bt40 Tool Holder Taper Angle.

From www.ebay.com

BT40 ER16 Collet Chuck Taper Shank L100mm CNC Tool Holder 10000rpm Bt40 Tool Holder Taper Angle To achieve the highest level of accuracy in machining processes, this angle is more than just a geometric element; The half angle is what you have to set the taper attachment, compound, grinder platen, etc. Choose from a wide offering of adapters, chucks, and. The taper angle, which defines the conical part of the toolholder, is the key component of. Bt40 Tool Holder Taper Angle.

From www.bidspotter.com

Assorted BT40 Taper Tool Holders Bt40 Tool Holder Taper Angle The tool holder is pulled in the milling spindle with the help of an additional pull stud. The centering takes place via the taper contact. Same when you set the bench. The taper angle, which defines the conical part of the toolholder, is the key component of the bt taper system. Though both standards use the same nmtb body taper,. Bt40 Tool Holder Taper Angle.

From www.rrtoolstore.com

ER40 BT40 BT Taper ER Collet Chuck RR Brand Bt40 Tool Holder Taper Angle To achieve the highest level of accuracy in machining processes, this angle is more than just a geometric element; Adaptable designs to meet a range of demands. It is the key to secure and exact tool positioning. The centering takes place via the taper contact. The taper angle, which defines the conical part of the toolholder, is the key component. Bt40 Tool Holder Taper Angle.

From www.alibaba.com

Cnc Bt30 Bt40 Bt50 90 Degree Offsed Ag90 Horizontal Right Angle Milling Bt40 Tool Holder Taper Angle To achieve the highest level of accuracy in machining processes, this angle is more than just a geometric element; It is the key to secure and exact tool positioning. Though both standards use the same nmtb body taper, bt tool holders are. Adaptable designs to meet a range of demands. Bt tool holders use metric thread pull studs (retention knobs).. Bt40 Tool Holder Taper Angle.