Soldering Galvanized Sheet Metal Flashing . A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for galvanized steel. Do this by pouring the acid into. Start by cleaning the surface of the sheet metal using a suitable cleaning agent and a scrub brush or sponge. Soldering galvanized steel can be challenging due to the zinc coating on the surface of the metal. Remove any dirt, grease, or oxidation hindering the soldering process. Choosing the right flux is important and for galvanized steel, a liquid flux is usually recommended. If the soldering isn’t performed correctly, the life span of the joint might be shorter than desired. The low 350°f melting point of super alloy 1 is ideal for soldering without damaging the protective zinc. Demonstration of soldering some galvanized metal pieces using an express propane soldering. It has acid in the middle, aka acid core, which seems like it could be an added convenience. If none is available, use 'cut' muriatic (hydrochloric) acid. This step is crucial in ensuring a clean and smooth surface for soldering. Hopefully i've got enough to finish. There are some common mistakes that might occur when soldering galvanized steel. For soldering galvanized steel, the right flux will get the best hold on your galvanized steel surface.

from citysheetmetal.com

It has acid in the middle, aka acid core, which seems like it could be an added convenience. This step is crucial in ensuring a clean and smooth surface for soldering. Choosing the right flux is important and for galvanized steel, a liquid flux is usually recommended. Do this by pouring the acid into. If none is available, use 'cut' muriatic (hydrochloric) acid. Hopefully i've got enough to finish. If the soldering isn’t performed correctly, the life span of the joint might be shorter than desired. The low 350°f melting point of super alloy 1 is ideal for soldering without damaging the protective zinc. Soldering galvanized steel can be challenging due to the zinc coating on the surface of the metal. A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for galvanized steel.

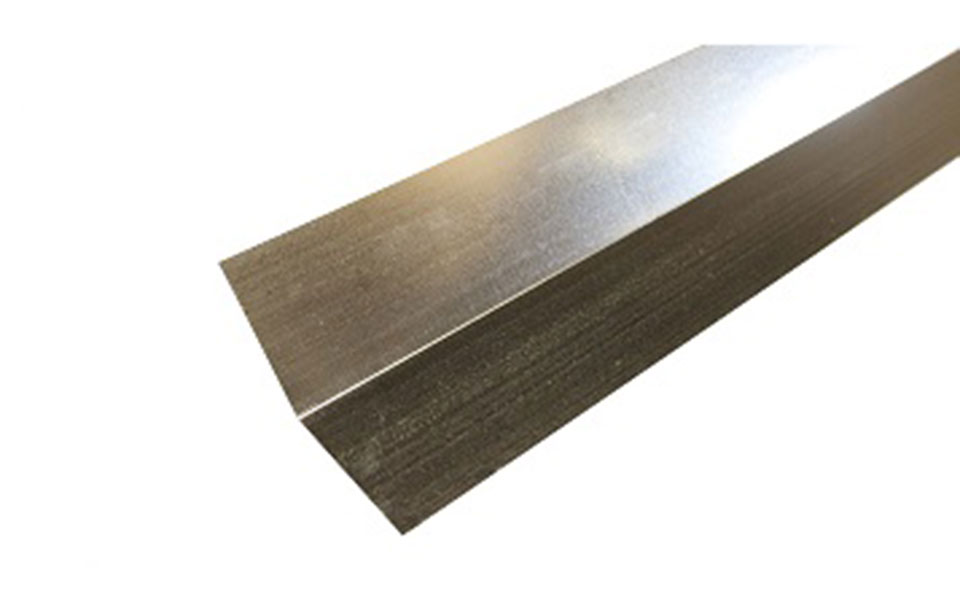

Valley Flashing Flashings, Galvanized City Sheet Metal

Soldering Galvanized Sheet Metal Flashing Hopefully i've got enough to finish. Demonstration of soldering some galvanized metal pieces using an express propane soldering. Do this by pouring the acid into. Choosing the right flux is important and for galvanized steel, a liquid flux is usually recommended. This step is crucial in ensuring a clean and smooth surface for soldering. If the soldering isn’t performed correctly, the life span of the joint might be shorter than desired. The low 350°f melting point of super alloy 1 is ideal for soldering without damaging the protective zinc. It has acid in the middle, aka acid core, which seems like it could be an added convenience. Start by cleaning the surface of the sheet metal using a suitable cleaning agent and a scrub brush or sponge. A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for galvanized steel. Remove any dirt, grease, or oxidation hindering the soldering process. For soldering galvanized steel, the right flux will get the best hold on your galvanized steel surface. There are some common mistakes that might occur when soldering galvanized steel. Hopefully i've got enough to finish. If none is available, use 'cut' muriatic (hydrochloric) acid. Soldering galvanized steel can be challenging due to the zinc coating on the surface of the metal.

From www.youtube.com

Soldering copper tube to galvanized steel pans 1 YouTube Soldering Galvanized Sheet Metal Flashing This step is crucial in ensuring a clean and smooth surface for soldering. Hopefully i've got enough to finish. A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for galvanized steel. For soldering galvanized steel, the right flux will get the best hold on your galvanized steel surface. It has. Soldering Galvanized Sheet Metal Flashing.

From sdtgmaterial.en.made-in-china.com

Galvanized Sheet Metal Flashing Rolls 28 Gauge Thickness Multi Pack Soldering Galvanized Sheet Metal Flashing Remove any dirt, grease, or oxidation hindering the soldering process. Start by cleaning the surface of the sheet metal using a suitable cleaning agent and a scrub brush or sponge. It has acid in the middle, aka acid core, which seems like it could be an added convenience. If none is available, use 'cut' muriatic (hydrochloric) acid. A great liquid. Soldering Galvanized Sheet Metal Flashing.

From www.youtube.com

How To Solder Stainless Steel YouTube Soldering Galvanized Sheet Metal Flashing If none is available, use 'cut' muriatic (hydrochloric) acid. Hopefully i've got enough to finish. There are some common mistakes that might occur when soldering galvanized steel. For soldering galvanized steel, the right flux will get the best hold on your galvanized steel surface. If the soldering isn’t performed correctly, the life span of the joint might be shorter than. Soldering Galvanized Sheet Metal Flashing.

From stellartechnical.com

What Is The Best Way To Solder Galvanized Steel? Soldering Galvanized Sheet Metal Flashing Remove any dirt, grease, or oxidation hindering the soldering process. If none is available, use 'cut' muriatic (hydrochloric) acid. Hopefully i've got enough to finish. The low 350°f melting point of super alloy 1 is ideal for soldering without damaging the protective zinc. For soldering galvanized steel, the right flux will get the best hold on your galvanized steel surface.. Soldering Galvanized Sheet Metal Flashing.

From www.homedepot.com

Gibraltar Building Products 4 in. x 5 in. x 10 ft. 26Gauge Galvanized Soldering Galvanized Sheet Metal Flashing If none is available, use 'cut' muriatic (hydrochloric) acid. A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for galvanized steel. Soldering galvanized steel can be challenging due to the zinc coating on the surface of the metal. There are some common mistakes that might occur when soldering galvanized steel.. Soldering Galvanized Sheet Metal Flashing.

From exyoldepl.blob.core.windows.net

Solder Copper To Galvanized Steel at Carol Mcbride blog Soldering Galvanized Sheet Metal Flashing Hopefully i've got enough to finish. Choosing the right flux is important and for galvanized steel, a liquid flux is usually recommended. Soldering galvanized steel can be challenging due to the zinc coating on the surface of the metal. It has acid in the middle, aka acid core, which seems like it could be an added convenience. There are some. Soldering Galvanized Sheet Metal Flashing.

From exotoxrjp.blob.core.windows.net

Sheet Metal Soldering Kit at Elizabeth James blog Soldering Galvanized Sheet Metal Flashing The low 350°f melting point of super alloy 1 is ideal for soldering without damaging the protective zinc. Start by cleaning the surface of the sheet metal using a suitable cleaning agent and a scrub brush or sponge. A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for galvanized steel.. Soldering Galvanized Sheet Metal Flashing.

From ducan.com

DEKMASTER® Galvanized Metal Flashing 6 FT Ducan Soldering Galvanized Sheet Metal Flashing Demonstration of soldering some galvanized metal pieces using an express propane soldering. The low 350°f melting point of super alloy 1 is ideal for soldering without damaging the protective zinc. If none is available, use 'cut' muriatic (hydrochloric) acid. There are some common mistakes that might occur when soldering galvanized steel. Start by cleaning the surface of the sheet metal. Soldering Galvanized Sheet Metal Flashing.

From bestimagescure.blogspot.com

Galvanized Aluminum Flashing / It's soft and workable, holding its Soldering Galvanized Sheet Metal Flashing This step is crucial in ensuring a clean and smooth surface for soldering. Choosing the right flux is important and for galvanized steel, a liquid flux is usually recommended. If none is available, use 'cut' muriatic (hydrochloric) acid. Start by cleaning the surface of the sheet metal using a suitable cleaning agent and a scrub brush or sponge. For soldering. Soldering Galvanized Sheet Metal Flashing.

From www.lowes.com

CMI 1in x 10ft Galvanized Steel Sheet Flashing at Soldering Galvanized Sheet Metal Flashing Remove any dirt, grease, or oxidation hindering the soldering process. Choosing the right flux is important and for galvanized steel, a liquid flux is usually recommended. Demonstration of soldering some galvanized metal pieces using an express propane soldering. Do this by pouring the acid into. For soldering galvanized steel, the right flux will get the best hold on your galvanized. Soldering Galvanized Sheet Metal Flashing.

From www.amazon.co.uk

MYJIO Silver Solder Flux Copper Soldering Flux Liquid For Galvanized Soldering Galvanized Sheet Metal Flashing If none is available, use 'cut' muriatic (hydrochloric) acid. Choosing the right flux is important and for galvanized steel, a liquid flux is usually recommended. This step is crucial in ensuring a clean and smooth surface for soldering. The low 350°f melting point of super alloy 1 is ideal for soldering without damaging the protective zinc. If the soldering isn’t. Soldering Galvanized Sheet Metal Flashing.

From www.riversidesheetmetal.net

J Channel Flashing Metal Copper, Aluminum, Steel Soldering Galvanized Sheet Metal Flashing Soldering galvanized steel can be challenging due to the zinc coating on the surface of the metal. If the soldering isn’t performed correctly, the life span of the joint might be shorter than desired. Hopefully i've got enough to finish. Do this by pouring the acid into. Start by cleaning the surface of the sheet metal using a suitable cleaning. Soldering Galvanized Sheet Metal Flashing.

From www.nepal.ubuy.com

EAGLE Galvanized Sheet Metal Flashing 28 Gauge 10 Ft Long Soldering Galvanized Sheet Metal Flashing Start by cleaning the surface of the sheet metal using a suitable cleaning agent and a scrub brush or sponge. Remove any dirt, grease, or oxidation hindering the soldering process. Do this by pouring the acid into. Hopefully i've got enough to finish. A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a. Soldering Galvanized Sheet Metal Flashing.

From www.youtube.com

Soldering Galvanized Sheet Metal Tacking YouTube Soldering Galvanized Sheet Metal Flashing Choosing the right flux is important and for galvanized steel, a liquid flux is usually recommended. If the soldering isn’t performed correctly, the life span of the joint might be shorter than desired. Start by cleaning the surface of the sheet metal using a suitable cleaning agent and a scrub brush or sponge. The low 350°f melting point of super. Soldering Galvanized Sheet Metal Flashing.

From stellartechnical.com

What is the Best Flux for Soldering Galvanized Steel? Soldering Galvanized Sheet Metal Flashing For soldering galvanized steel, the right flux will get the best hold on your galvanized steel surface. This step is crucial in ensuring a clean and smooth surface for soldering. If the soldering isn’t performed correctly, the life span of the joint might be shorter than desired. Choosing the right flux is important and for galvanized steel, a liquid flux. Soldering Galvanized Sheet Metal Flashing.

From constructionhow.com

How To Solder Galvanized Steel Gutters? Construction How Soldering Galvanized Sheet Metal Flashing The low 350°f melting point of super alloy 1 is ideal for soldering without damaging the protective zinc. Start by cleaning the surface of the sheet metal using a suitable cleaning agent and a scrub brush or sponge. If the soldering isn’t performed correctly, the life span of the joint might be shorter than desired. Hopefully i've got enough to. Soldering Galvanized Sheet Metal Flashing.

From citysheetmetal.com

Valley Flashing Flashings, Galvanized City Sheet Metal Soldering Galvanized Sheet Metal Flashing If the soldering isn’t performed correctly, the life span of the joint might be shorter than desired. This step is crucial in ensuring a clean and smooth surface for soldering. It has acid in the middle, aka acid core, which seems like it could be an added convenience. Do this by pouring the acid into. A great liquid flux that. Soldering Galvanized Sheet Metal Flashing.

From www.homedepot.com

Gibraltar Building Products 5 in. x 10 ft. Galvanized Steel Angle Soldering Galvanized Sheet Metal Flashing If none is available, use 'cut' muriatic (hydrochloric) acid. Do this by pouring the acid into. Soldering galvanized steel can be challenging due to the zinc coating on the surface of the metal. Choosing the right flux is important and for galvanized steel, a liquid flux is usually recommended. The low 350°f melting point of super alloy 1 is ideal. Soldering Galvanized Sheet Metal Flashing.

From www.youtube.com

Soldering (galvanized steel) cowboymetalandwood4965 YouTube Soldering Galvanized Sheet Metal Flashing This step is crucial in ensuring a clean and smooth surface for soldering. For soldering galvanized steel, the right flux will get the best hold on your galvanized steel surface. If none is available, use 'cut' muriatic (hydrochloric) acid. A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for galvanized. Soldering Galvanized Sheet Metal Flashing.

From bahamas.desertcart.com

Buy EAGLE 1 Galvanized Sheet Metal Flashing Rolls 10 Ft Long 28 Soldering Galvanized Sheet Metal Flashing Remove any dirt, grease, or oxidation hindering the soldering process. There are some common mistakes that might occur when soldering galvanized steel. A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for galvanized steel. It has acid in the middle, aka acid core, which seems like it could be an. Soldering Galvanized Sheet Metal Flashing.

From www.lowes.com

Construction Metals Inc. 2.37in x 120in x 0.75in Galvanized Steel Z Soldering Galvanized Sheet Metal Flashing Soldering galvanized steel can be challenging due to the zinc coating on the surface of the metal. Start by cleaning the surface of the sheet metal using a suitable cleaning agent and a scrub brush or sponge. Choosing the right flux is important and for galvanized steel, a liquid flux is usually recommended. If the soldering isn’t performed correctly, the. Soldering Galvanized Sheet Metal Flashing.

From www.lowes.com

Shop Union Corrugating 6in x 6in Galvanized Steel Step Flashing at Soldering Galvanized Sheet Metal Flashing The low 350°f melting point of super alloy 1 is ideal for soldering without damaging the protective zinc. This step is crucial in ensuring a clean and smooth surface for soldering. Remove any dirt, grease, or oxidation hindering the soldering process. Demonstration of soldering some galvanized metal pieces using an express propane soldering. Soldering galvanized steel can be challenging due. Soldering Galvanized Sheet Metal Flashing.

From www.riversidesheetmetal.net

Flashing Metal Bending Roofing Copper, Aluminum, Steel Soldering Galvanized Sheet Metal Flashing If the soldering isn’t performed correctly, the life span of the joint might be shorter than desired. Choosing the right flux is important and for galvanized steel, a liquid flux is usually recommended. Remove any dirt, grease, or oxidation hindering the soldering process. This step is crucial in ensuring a clean and smooth surface for soldering. The low 350°f melting. Soldering Galvanized Sheet Metal Flashing.

From www.homedepot.com

8 in. x 10 ft. Galvanized Angle Flashing Prebent 3 in. x 5 in.02043R Soldering Galvanized Sheet Metal Flashing A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for galvanized steel. If none is available, use 'cut' muriatic (hydrochloric) acid. Demonstration of soldering some galvanized metal pieces using an express propane soldering. If the soldering isn’t performed correctly, the life span of the joint might be shorter than desired.. Soldering Galvanized Sheet Metal Flashing.

From exomkiyfw.blob.core.windows.net

Best Flux For Galvanized Steel Soldering at Frances Carmouche blog Soldering Galvanized Sheet Metal Flashing Remove any dirt, grease, or oxidation hindering the soldering process. If the soldering isn’t performed correctly, the life span of the joint might be shorter than desired. Choosing the right flux is important and for galvanized steel, a liquid flux is usually recommended. A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a. Soldering Galvanized Sheet Metal Flashing.

From flashingkings.com

Flashing Kings 26 Gauge Galvanized Sheet Metal Flashing Roll Ten Foot Soldering Galvanized Sheet Metal Flashing Demonstration of soldering some galvanized metal pieces using an express propane soldering. There are some common mistakes that might occur when soldering galvanized steel. Hopefully i've got enough to finish. This step is crucial in ensuring a clean and smooth surface for soldering. It has acid in the middle, aka acid core, which seems like it could be an added. Soldering Galvanized Sheet Metal Flashing.

From exomkiyfw.blob.core.windows.net

Best Flux For Galvanized Steel Soldering at Frances Carmouche blog Soldering Galvanized Sheet Metal Flashing Choosing the right flux is important and for galvanized steel, a liquid flux is usually recommended. Hopefully i've got enough to finish. Remove any dirt, grease, or oxidation hindering the soldering process. Demonstration of soldering some galvanized metal pieces using an express propane soldering. For soldering galvanized steel, the right flux will get the best hold on your galvanized steel. Soldering Galvanized Sheet Metal Flashing.

From exomkiyfw.blob.core.windows.net

Best Flux For Galvanized Steel Soldering at Frances Carmouche blog Soldering Galvanized Sheet Metal Flashing It has acid in the middle, aka acid core, which seems like it could be an added convenience. The low 350°f melting point of super alloy 1 is ideal for soldering without damaging the protective zinc. Do this by pouring the acid into. If the soldering isn’t performed correctly, the life span of the joint might be shorter than desired.. Soldering Galvanized Sheet Metal Flashing.

From exomkiyfw.blob.core.windows.net

Best Flux For Galvanized Steel Soldering at Frances Carmouche blog Soldering Galvanized Sheet Metal Flashing Do this by pouring the acid into. If none is available, use 'cut' muriatic (hydrochloric) acid. Start by cleaning the surface of the sheet metal using a suitable cleaning agent and a scrub brush or sponge. Choosing the right flux is important and for galvanized steel, a liquid flux is usually recommended. Soldering galvanized steel can be challenging due to. Soldering Galvanized Sheet Metal Flashing.

From www.lowes.com

CMI 3in x 10ft Galvanized Steel Sheet Flashing in the Step Flashing Soldering Galvanized Sheet Metal Flashing For soldering galvanized steel, the right flux will get the best hold on your galvanized steel surface. Demonstration of soldering some galvanized metal pieces using an express propane soldering. There are some common mistakes that might occur when soldering galvanized steel. Do this by pouring the acid into. A great liquid flux that has an active chloride formation like johnson’s. Soldering Galvanized Sheet Metal Flashing.

From bestimagescure.blogspot.com

Galvanized Aluminum Flashing / It's soft and workable, holding its Soldering Galvanized Sheet Metal Flashing If none is available, use 'cut' muriatic (hydrochloric) acid. A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for galvanized steel. Do this by pouring the acid into. Choosing the right flux is important and for galvanized steel, a liquid flux is usually recommended. If the soldering isn’t performed correctly,. Soldering Galvanized Sheet Metal Flashing.

From www.youtube.com

Soldering Aluminum to Galvanized Steel YouTube Soldering Galvanized Sheet Metal Flashing If the soldering isn’t performed correctly, the life span of the joint might be shorter than desired. Hopefully i've got enough to finish. This step is crucial in ensuring a clean and smooth surface for soldering. A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for galvanized steel. Do this. Soldering Galvanized Sheet Metal Flashing.

From solderingrepair.com

How to Solder Galvanized Sheet Metal Soldering Galvanized Sheet Metal Flashing If none is available, use 'cut' muriatic (hydrochloric) acid. Demonstration of soldering some galvanized metal pieces using an express propane soldering. Hopefully i've got enough to finish. This step is crucial in ensuring a clean and smooth surface for soldering. It has acid in the middle, aka acid core, which seems like it could be an added convenience. Do this. Soldering Galvanized Sheet Metal Flashing.

From www.lowes.com

CMI 0.43in x 10ft Galvanized Steel Sheet Flashing at Soldering Galvanized Sheet Metal Flashing There are some common mistakes that might occur when soldering galvanized steel. Soldering galvanized steel can be challenging due to the zinc coating on the surface of the metal. The low 350°f melting point of super alloy 1 is ideal for soldering without damaging the protective zinc. Demonstration of soldering some galvanized metal pieces using an express propane soldering. Start. Soldering Galvanized Sheet Metal Flashing.

From www.lowes.com

CMI 6in x 10ft Galvanized Steel Sheet Flashing at Soldering Galvanized Sheet Metal Flashing A great liquid flux that has an active chloride formation like johnson’s galvanized steel flux is a great choice for galvanized steel. Soldering galvanized steel can be challenging due to the zinc coating on the surface of the metal. Remove any dirt, grease, or oxidation hindering the soldering process. For soldering galvanized steel, the right flux will get the best. Soldering Galvanized Sheet Metal Flashing.