What Is A Beveled Joint . Edge preparations usually require a specific bevel. A welding groove is a weld joint type that is created by forming a bevel (taper recess) on the surface of the workpieces to be joined. There are 6 main groove welds:. Bevel in welding is an angled flat surface at the end of the material. Bevel welds are weld joints made between metal pieces that are not parallel or perpendicular to each other. This opening made by gives the welder access to the total thickness of the material wall and allows him to create a uniform. By beveling at least one piece, you can create a larger surface, which allows for a. The purpose of the welding groove is to increase. A groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the groove joint discussed at the start). In welding, a bevel is an edge preparation presented as an angle. Beveled edges are common in butt joints. They can be partially beveled or completely beveled throughout the material thickness.

from welditu.com

The purpose of the welding groove is to increase. Edge preparations usually require a specific bevel. In welding, a bevel is an edge preparation presented as an angle. There are 6 main groove welds:. Bevel in welding is an angled flat surface at the end of the material. This opening made by gives the welder access to the total thickness of the material wall and allows him to create a uniform. A welding groove is a weld joint type that is created by forming a bevel (taper recess) on the surface of the workpieces to be joined. They can be partially beveled or completely beveled throughout the material thickness. By beveling at least one piece, you can create a larger surface, which allows for a. Bevel welds are weld joints made between metal pieces that are not parallel or perpendicular to each other.

Guide to Welding Joint Types and Parts WelditU

What Is A Beveled Joint A welding groove is a weld joint type that is created by forming a bevel (taper recess) on the surface of the workpieces to be joined. The purpose of the welding groove is to increase. Beveled edges are common in butt joints. They can be partially beveled or completely beveled throughout the material thickness. This opening made by gives the welder access to the total thickness of the material wall and allows him to create a uniform. In welding, a bevel is an edge preparation presented as an angle. A groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the groove joint discussed at the start). There are 6 main groove welds:. Bevel welds are weld joints made between metal pieces that are not parallel or perpendicular to each other. Bevel in welding is an angled flat surface at the end of the material. Edge preparations usually require a specific bevel. A welding groove is a weld joint type that is created by forming a bevel (taper recess) on the surface of the workpieces to be joined. By beveling at least one piece, you can create a larger surface, which allows for a.

From www.researchgate.net

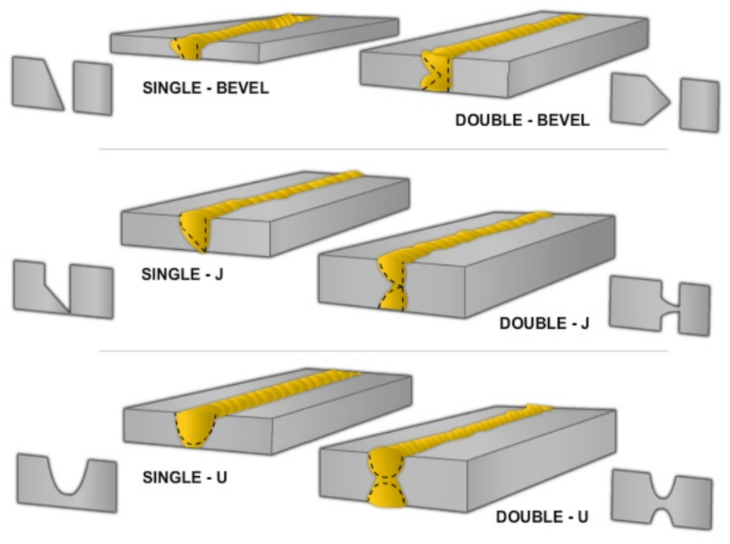

Plates beveling for welding. Download Scientific Diagram What Is A Beveled Joint There are 6 main groove welds:. A groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the groove joint discussed at the start). A welding groove is a weld joint type that is created by forming a bevel (taper recess) on the surface of the workpieces. What Is A Beveled Joint.

From weldinglogic.com

Corner Joint Weld Corner Joint Welding Symbol Strength Types & More What Is A Beveled Joint In welding, a bevel is an edge preparation presented as an angle. Edge preparations usually require a specific bevel. A groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the groove joint discussed at the start). This opening made by gives the welder access to the. What Is A Beveled Joint.

From welditu.com

Types of Welding Joints and Welds Color Graphics • WelditU What Is A Beveled Joint They can be partially beveled or completely beveled throughout the material thickness. Edge preparations usually require a specific bevel. Bevel in welding is an angled flat surface at the end of the material. By beveling at least one piece, you can create a larger surface, which allows for a. Beveled edges are common in butt joints. In welding, a bevel. What Is A Beveled Joint.

From www.youtube.com

Welding Joints (Types) Weld Types Edge Preparation ISO 9692 YouTube What Is A Beveled Joint Edge preparations usually require a specific bevel. Bevel welds are weld joints made between metal pieces that are not parallel or perpendicular to each other. Bevel in welding is an angled flat surface at the end of the material. A groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or. What Is A Beveled Joint.

From www.midtownlumber.com

Do You Use Bevel Cuts for Your Projects? Midtown Lumber What Is A Beveled Joint There are 6 main groove welds:. By beveling at least one piece, you can create a larger surface, which allows for a. The purpose of the welding groove is to increase. They can be partially beveled or completely beveled throughout the material thickness. A welding groove is a weld joint type that is created by forming a bevel (taper recess). What Is A Beveled Joint.

From www.craftsmanspace.com

Tongue and groove woodworking joints CRAFTSMANSPACE What Is A Beveled Joint A groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the groove joint discussed at the start). By beveling at least one piece, you can create a larger surface, which allows for a. There are 6 main groove welds:. This opening made by gives the welder. What Is A Beveled Joint.

From learnweldingsymbols.com

Understanding Bevel Groove Welding Symbols A Comprehensive Guide What Is A Beveled Joint By beveling at least one piece, you can create a larger surface, which allows for a. Bevel welds are weld joints made between metal pieces that are not parallel or perpendicular to each other. Bevel in welding is an angled flat surface at the end of the material. In welding, a bevel is an edge preparation presented as an angle.. What Is A Beveled Joint.

From engineeringexploration.com

The 5 Types of Welding Joints, pros, cons, and their uses (In Details What Is A Beveled Joint Bevel welds are weld joints made between metal pieces that are not parallel or perpendicular to each other. By beveling at least one piece, you can create a larger surface, which allows for a. Beveled edges are common in butt joints. This opening made by gives the welder access to the total thickness of the material wall and allows him. What Is A Beveled Joint.

From exoquiqcm.blob.core.windows.net

What Is A Bevel Joint at Beatrice Lloyd blog What Is A Beveled Joint Beveled edges are common in butt joints. Bevel in welding is an angled flat surface at the end of the material. There are 6 main groove welds:. In welding, a bevel is an edge preparation presented as an angle. This opening made by gives the welder access to the total thickness of the material wall and allows him to create. What Is A Beveled Joint.

From www.youtube.com

Stepped Bevelled Splice Joint (stepped scarf joint) YouTube What Is A Beveled Joint This opening made by gives the welder access to the total thickness of the material wall and allows him to create a uniform. Bevel welds are weld joints made between metal pieces that are not parallel or perpendicular to each other. The purpose of the welding groove is to increase. Bevel in welding is an angled flat surface at the. What Is A Beveled Joint.

From www.mtm-inc.com

Understanding Weld symbols The groove weld Meyer Tool & Mfg. What Is A Beveled Joint A groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the groove joint discussed at the start). The purpose of the welding groove is to increase. Edge preparations usually require a specific bevel. They can be partially beveled or completely beveled throughout the material thickness. This. What Is A Beveled Joint.

From waterwelders.com

Welding Symbols How to Understand Them (With Charts) WaterWelders What Is A Beveled Joint Beveled edges are common in butt joints. By beveling at least one piece, you can create a larger surface, which allows for a. A groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the groove joint discussed at the start). A welding groove is a weld. What Is A Beveled Joint.

From schoolofwoodwork.com

Lap Joints A Primer for Joinery [Educational Infographic] Florida What Is A Beveled Joint Bevel welds are weld joints made between metal pieces that are not parallel or perpendicular to each other. A groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the groove joint discussed at the start). The purpose of the welding groove is to increase. Beveled edges. What Is A Beveled Joint.

From www.youtube.com

HOW TO DESIGN BUTT JOINT/WELD (SINGLE & DOUBLE BEVEL) YouTube What Is A Beveled Joint A groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the groove joint discussed at the start). This opening made by gives the welder access to the total thickness of the material wall and allows him to create a uniform. The purpose of the welding groove. What Is A Beveled Joint.

From informacionpublica2021.svet.gob.gt

Symbolic Representation Of Welding Joints In Drawings, 59 OFF What Is A Beveled Joint By beveling at least one piece, you can create a larger surface, which allows for a. Beveled edges are common in butt joints. A groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the groove joint discussed at the start). Edge preparations usually require a specific. What Is A Beveled Joint.

From exoquiqcm.blob.core.windows.net

What Is A Bevel Joint at Beatrice Lloyd blog What Is A Beveled Joint There are 6 main groove welds:. A welding groove is a weld joint type that is created by forming a bevel (taper recess) on the surface of the workpieces to be joined. A groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the groove joint discussed. What Is A Beveled Joint.

From weldingclarity.com

Tee Joint Welding Definition, Types and Easy Tips What Is A Beveled Joint The purpose of the welding groove is to increase. Bevel in welding is an angled flat surface at the end of the material. Edge preparations usually require a specific bevel. By beveling at least one piece, you can create a larger surface, which allows for a. They can be partially beveled or completely beveled throughout the material thickness. There are. What Is A Beveled Joint.

From primeweld.com

A Guide to Weld Joints PrimeWeld What Is A Beveled Joint The purpose of the welding groove is to increase. There are 6 main groove welds:. This opening made by gives the welder access to the total thickness of the material wall and allows him to create a uniform. A groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap. What Is A Beveled Joint.

From inchbyinch.de

INCH Technical English weld types What Is A Beveled Joint Bevel welds are weld joints made between metal pieces that are not parallel or perpendicular to each other. There are 6 main groove welds:. The purpose of the welding groove is to increase. In welding, a bevel is an edge preparation presented as an angle. Edge preparations usually require a specific bevel. A groove (or butt) weld is a type. What Is A Beveled Joint.

From blog.morganitech.com

Exploring Different Types of Pipe Beveling Joints and Their Applications What Is A Beveled Joint There are 6 main groove welds:. They can be partially beveled or completely beveled throughout the material thickness. A groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the groove joint discussed at the start). The purpose of the welding groove is to increase. In welding,. What Is A Beveled Joint.

From engineersblog.net

What is the design criteria of Bevel Butt Joint? Explain in details What Is A Beveled Joint This opening made by gives the welder access to the total thickness of the material wall and allows him to create a uniform. A groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the groove joint discussed at the start). They can be partially beveled or. What Is A Beveled Joint.

From handcutjoints.blogspot.com

Hand Cut Joints Bevel Dovetails What Is A Beveled Joint This opening made by gives the welder access to the total thickness of the material wall and allows him to create a uniform. A welding groove is a weld joint type that is created by forming a bevel (taper recess) on the surface of the workpieces to be joined. Bevel in welding is an angled flat surface at the end. What Is A Beveled Joint.

From weldguru.com

Butt Welds Explained What Are They? When Are They Used? What Is A Beveled Joint Bevel in welding is an angled flat surface at the end of the material. There are 6 main groove welds:. Bevel welds are weld joints made between metal pieces that are not parallel or perpendicular to each other. A welding groove is a weld joint type that is created by forming a bevel (taper recess) on the surface of the. What Is A Beveled Joint.

From www.weldingis.com

Types Of Welding Joints Design and Welding Symbols What Is A Beveled Joint A welding groove is a weld joint type that is created by forming a bevel (taper recess) on the surface of the workpieces to be joined. There are 6 main groove welds:. Bevel welds are weld joints made between metal pieces that are not parallel or perpendicular to each other. They can be partially beveled or completely beveled throughout the. What Is A Beveled Joint.

From www.onestopndt.com

An ultimate Guide to Weld Joints OnestopNDT What Is A Beveled Joint A groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the groove joint discussed at the start). In welding, a bevel is an edge preparation presented as an angle. There are 6 main groove welds:. By beveling at least one piece, you can create a larger. What Is A Beveled Joint.

From www.engineersgallery.com

Welding joints Engineers Gallery What Is A Beveled Joint There are 6 main groove welds:. Beveled edges are common in butt joints. A groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the groove joint discussed at the start). Bevel welds are weld joints made between metal pieces that are not parallel or perpendicular to. What Is A Beveled Joint.

From www.slideserve.com

PPT Welding Joints, Positions, and Symbols PowerPoint Presentation What Is A Beveled Joint A welding groove is a weld joint type that is created by forming a bevel (taper recess) on the surface of the workpieces to be joined. Beveled edges are common in butt joints. Edge preparations usually require a specific bevel. A groove (or butt) weld is a type of weld where parts are joined via a weld between a groove. What Is A Beveled Joint.

From ar.inspiredpencil.com

Cjp Weld Joint What Is A Beveled Joint Edge preparations usually require a specific bevel. The purpose of the welding groove is to increase. They can be partially beveled or completely beveled throughout the material thickness. By beveling at least one piece, you can create a larger surface, which allows for a. In welding, a bevel is an edge preparation presented as an angle. This opening made by. What Is A Beveled Joint.

From welditu.com

Guide to Welding Joint Types and Parts WelditU What Is A Beveled Joint Beveled edges are common in butt joints. Edge preparations usually require a specific bevel. A groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the groove joint discussed at the start). This opening made by gives the welder access to the total thickness of the material. What Is A Beveled Joint.

From welditu.com

Guide to Welding Joint Types and Parts WelditU What Is A Beveled Joint A groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the groove joint discussed at the start). Beveled edges are common in butt joints. Bevel in welding is an angled flat surface at the end of the material. Bevel welds are weld joints made between metal. What Is A Beveled Joint.

From www.finepowertools.com

Bevel vs Chamfer Difference Between the Edges Demystified. What Is A Beveled Joint Edge preparations usually require a specific bevel. A groove (or butt) weld is a type of weld where parts are joined via a weld between a groove or gap (think of the groove joint discussed at the start). Bevel in welding is an angled flat surface at the end of the material. By beveling at least one piece, you can. What Is A Beveled Joint.

From www.dreamstime.com

Type of Wood Joint Set Bevel Lap Splice Style, Perspective 3d with Top What Is A Beveled Joint They can be partially beveled or completely beveled throughout the material thickness. The purpose of the welding groove is to increase. Bevel in welding is an angled flat surface at the end of the material. This opening made by gives the welder access to the total thickness of the material wall and allows him to create a uniform. There are. What Is A Beveled Joint.

From www.thefabricator.com

The next generation of portable beveling What Is A Beveled Joint Bevel in welding is an angled flat surface at the end of the material. Edge preparations usually require a specific bevel. In welding, a bevel is an edge preparation presented as an angle. Beveled edges are common in butt joints. The purpose of the welding groove is to increase. A welding groove is a weld joint type that is created. What Is A Beveled Joint.

From exoquiqcm.blob.core.windows.net

What Is A Bevel Joint at Beatrice Lloyd blog What Is A Beveled Joint Beveled edges are common in butt joints. Bevel welds are weld joints made between metal pieces that are not parallel or perpendicular to each other. In welding, a bevel is an edge preparation presented as an angle. Edge preparations usually require a specific bevel. Bevel in welding is an angled flat surface at the end of the material. They can. What Is A Beveled Joint.

From materialwelding.com

Welding Bevel Types and Symbols you NEED to know! What Is A Beveled Joint This opening made by gives the welder access to the total thickness of the material wall and allows him to create a uniform. Beveled edges are common in butt joints. Bevel in welding is an angled flat surface at the end of the material. The purpose of the welding groove is to increase. By beveling at least one piece, you. What Is A Beveled Joint.