Gear Drive Vs Belt . Gear drive requires less space compared to belt drive. Belt and pulley systems, along with gear driven systems represent the common ways that engineers transfer rotational motion and torque from one shaft to another shaft. Lower friction loss compared to belt drive, therefore higher transmission, and more. The main power transmission systems in the market include belt drives, chain drives, and. Gears and belts transmit rotary motion from one shaft to another, often changing speed and torque in the process. In general, for smaller drive systems. In any industry, motors and turbines generate rotational motion to run various tasks. Gear sets are generally used where the two shafts are close. Critical factors to consider are the task to be accomplished, maintenance needs, and cost.

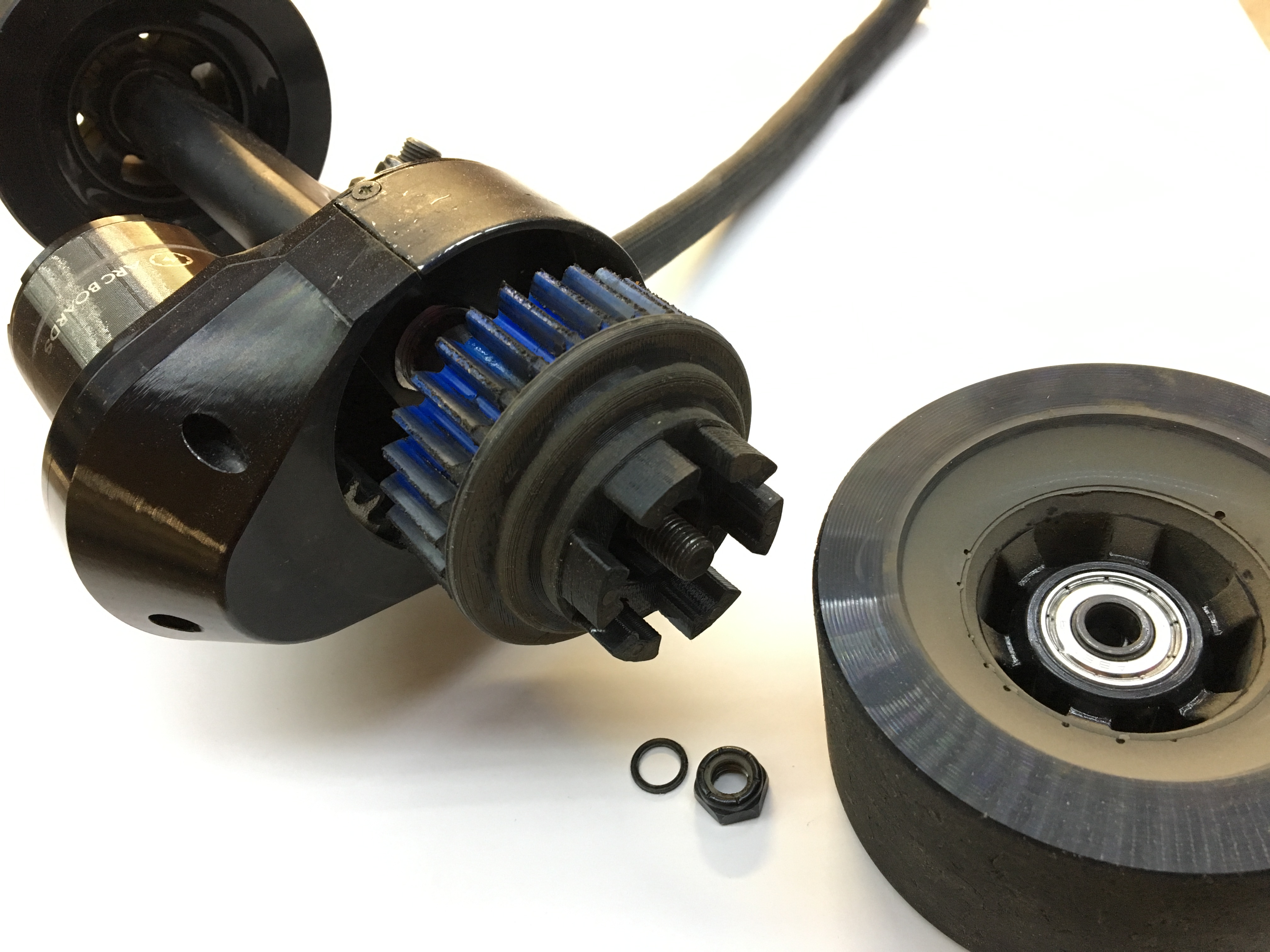

from esk8.news

Gears and belts transmit rotary motion from one shaft to another, often changing speed and torque in the process. Critical factors to consider are the task to be accomplished, maintenance needs, and cost. In any industry, motors and turbines generate rotational motion to run various tasks. Gear sets are generally used where the two shafts are close. Belt and pulley systems, along with gear driven systems represent the common ways that engineers transfer rotational motion and torque from one shaft to another shaft. The main power transmission systems in the market include belt drives, chain drives, and. Lower friction loss compared to belt drive, therefore higher transmission, and more. In general, for smaller drive systems. Gear drive requires less space compared to belt drive.

Know Your Drive Systems Belts vs Hubs vs Direct vs Gears

Gear Drive Vs Belt Lower friction loss compared to belt drive, therefore higher transmission, and more. In any industry, motors and turbines generate rotational motion to run various tasks. In general, for smaller drive systems. Gears and belts transmit rotary motion from one shaft to another, often changing speed and torque in the process. Gear sets are generally used where the two shafts are close. Lower friction loss compared to belt drive, therefore higher transmission, and more. Critical factors to consider are the task to be accomplished, maintenance needs, and cost. The main power transmission systems in the market include belt drives, chain drives, and. Gear drive requires less space compared to belt drive. Belt and pulley systems, along with gear driven systems represent the common ways that engineers transfer rotational motion and torque from one shaft to another shaft.

From schabet47rworkshopfix.z13.web.core.windows.net

Timing Gear Vs Timing Chain Gear Drive Vs Belt Lower friction loss compared to belt drive, therefore higher transmission, and more. Belt and pulley systems, along with gear driven systems represent the common ways that engineers transfer rotational motion and torque from one shaft to another shaft. In any industry, motors and turbines generate rotational motion to run various tasks. Gear sets are generally used where the two shafts. Gear Drive Vs Belt.

From adventuresder.weebly.com

Difference between drive belt and timing belt adventuresDer Gear Drive Vs Belt Lower friction loss compared to belt drive, therefore higher transmission, and more. In any industry, motors and turbines generate rotational motion to run various tasks. In general, for smaller drive systems. Belt and pulley systems, along with gear driven systems represent the common ways that engineers transfer rotational motion and torque from one shaft to another shaft. The main power. Gear Drive Vs Belt.

From beltposter.blogspot.com

Difference Between Belt Drive Chain Drive And Gear Drive Belt Poster Gear Drive Vs Belt Gear drive requires less space compared to belt drive. The main power transmission systems in the market include belt drives, chain drives, and. Gears and belts transmit rotary motion from one shaft to another, often changing speed and torque in the process. Gear sets are generally used where the two shafts are close. In general, for smaller drive systems. Critical. Gear Drive Vs Belt.

From www.youtube.com

TIMING CHAINS vs. BELTS Differences, Evolution, History and more Gear Drive Vs Belt Lower friction loss compared to belt drive, therefore higher transmission, and more. Belt and pulley systems, along with gear driven systems represent the common ways that engineers transfer rotational motion and torque from one shaft to another shaft. In general, for smaller drive systems. In any industry, motors and turbines generate rotational motion to run various tasks. Gears and belts. Gear Drive Vs Belt.

From www.mechanicaleducation.com

Difference Between Belt Drive and Gear Drive? Mechanical Education Gear Drive Vs Belt Critical factors to consider are the task to be accomplished, maintenance needs, and cost. Gear drive requires less space compared to belt drive. Lower friction loss compared to belt drive, therefore higher transmission, and more. The main power transmission systems in the market include belt drives, chain drives, and. Gears and belts transmit rotary motion from one shaft to another,. Gear Drive Vs Belt.

From simracingsetup.com

Direct Drive vs Belt vs Gear Racing Wheels Which Should You Buy? Gear Drive Vs Belt Gear sets are generally used where the two shafts are close. Gear drive requires less space compared to belt drive. In general, for smaller drive systems. In any industry, motors and turbines generate rotational motion to run various tasks. Gears and belts transmit rotary motion from one shaft to another, often changing speed and torque in the process. The main. Gear Drive Vs Belt.

From www.vrogue.co

Mechanics Map Belt And Gear Driven Systems vrogue.co Gear Drive Vs Belt The main power transmission systems in the market include belt drives, chain drives, and. Critical factors to consider are the task to be accomplished, maintenance needs, and cost. Gear drive requires less space compared to belt drive. Lower friction loss compared to belt drive, therefore higher transmission, and more. In any industry, motors and turbines generate rotational motion to run. Gear Drive Vs Belt.

From www.stratviewresearch.com

Gears, Chains, and Belts How Power Transmission Works Gear Drive Vs Belt Gear drive requires less space compared to belt drive. Critical factors to consider are the task to be accomplished, maintenance needs, and cost. Belt and pulley systems, along with gear driven systems represent the common ways that engineers transfer rotational motion and torque from one shaft to another shaft. In general, for smaller drive systems. Lower friction loss compared to. Gear Drive Vs Belt.

From alanyailanlar.com

Types of belts for belt drives tecscience (2022) Gear Drive Vs Belt Gear sets are generally used where the two shafts are close. In general, for smaller drive systems. The main power transmission systems in the market include belt drives, chain drives, and. Belt and pulley systems, along with gear driven systems represent the common ways that engineers transfer rotational motion and torque from one shaft to another shaft. Gears and belts. Gear Drive Vs Belt.

From www.cbac.com

Car Basics All the Drive Belts Explained Christian Brothers Gear Drive Vs Belt Gears and belts transmit rotary motion from one shaft to another, often changing speed and torque in the process. Gear sets are generally used where the two shafts are close. In general, for smaller drive systems. In any industry, motors and turbines generate rotational motion to run various tasks. The main power transmission systems in the market include belt drives,. Gear Drive Vs Belt.

From www.youtube.com

Spur Gear Drive vs Pro Belt drive Which did I choose? Billy Wiz Gear Drive Vs Belt In general, for smaller drive systems. The main power transmission systems in the market include belt drives, chain drives, and. Lower friction loss compared to belt drive, therefore higher transmission, and more. Gear sets are generally used where the two shafts are close. Gear drive requires less space compared to belt drive. In any industry, motors and turbines generate rotational. Gear Drive Vs Belt.

From engineeringlearner.com

Types of Belt Drive Material, Applications, Advantages & Disadvantages Gear Drive Vs Belt Belt and pulley systems, along with gear driven systems represent the common ways that engineers transfer rotational motion and torque from one shaft to another shaft. Gear drive requires less space compared to belt drive. Gear sets are generally used where the two shafts are close. In any industry, motors and turbines generate rotational motion to run various tasks. The. Gear Drive Vs Belt.

From www.pbclinear.eu

Belt Drive Or Lead Screw? Plain Linear Bearing, Shaft, Actuator, Rail Gear Drive Vs Belt Lower friction loss compared to belt drive, therefore higher transmission, and more. Gears and belts transmit rotary motion from one shaft to another, often changing speed and torque in the process. Gear drive requires less space compared to belt drive. In any industry, motors and turbines generate rotational motion to run various tasks. Belt and pulley systems, along with gear. Gear Drive Vs Belt.

From info.designatronics.com

Gear Drive vs. Belt Drive Gear Drive Vs Belt Gears and belts transmit rotary motion from one shaft to another, often changing speed and torque in the process. Critical factors to consider are the task to be accomplished, maintenance needs, and cost. Belt and pulley systems, along with gear driven systems represent the common ways that engineers transfer rotational motion and torque from one shaft to another shaft. Lower. Gear Drive Vs Belt.

From www.len.com.ng

Belt and Pulley Drives Types of belt in belt drives Gear Drive Vs Belt Belt and pulley systems, along with gear driven systems represent the common ways that engineers transfer rotational motion and torque from one shaft to another shaft. Critical factors to consider are the task to be accomplished, maintenance needs, and cost. The main power transmission systems in the market include belt drives, chain drives, and. Lower friction loss compared to belt. Gear Drive Vs Belt.

From garagerepaircremonas.z5.web.core.windows.net

Gear Drive Vs Timing Chain Gear Drive Vs Belt In any industry, motors and turbines generate rotational motion to run various tasks. In general, for smaller drive systems. Lower friction loss compared to belt drive, therefore higher transmission, and more. Gear drive requires less space compared to belt drive. The main power transmission systems in the market include belt drives, chain drives, and. Belt and pulley systems, along with. Gear Drive Vs Belt.

From beltposter.blogspot.com

Belt Drive Vs Chain Drive Vs Gear Drive Belt Poster Gear Drive Vs Belt The main power transmission systems in the market include belt drives, chain drives, and. Gears and belts transmit rotary motion from one shaft to another, often changing speed and torque in the process. Gear sets are generally used where the two shafts are close. Belt and pulley systems, along with gear driven systems represent the common ways that engineers transfer. Gear Drive Vs Belt.

From simracingsetup.com

Direct Drive vs Belt vs Gear Racing Wheels Which Should You Buy? Gear Drive Vs Belt In any industry, motors and turbines generate rotational motion to run various tasks. Critical factors to consider are the task to be accomplished, maintenance needs, and cost. In general, for smaller drive systems. Gear sets are generally used where the two shafts are close. Belt and pulley systems, along with gear driven systems represent the common ways that engineers transfer. Gear Drive Vs Belt.

From ibtinc.com

VBelt vs Synchronous Belt ━ 5 Reasons To Upgrade Your Belt Drive Gear Drive Vs Belt In any industry, motors and turbines generate rotational motion to run various tasks. Gears and belts transmit rotary motion from one shaft to another, often changing speed and torque in the process. In general, for smaller drive systems. Critical factors to consider are the task to be accomplished, maintenance needs, and cost. Lower friction loss compared to belt drive, therefore. Gear Drive Vs Belt.

From www.youtube.com

Special Direct Drive vs Belt Driven vs Gear Driven YouTube Gear Drive Vs Belt Belt and pulley systems, along with gear driven systems represent the common ways that engineers transfer rotational motion and torque from one shaft to another shaft. Critical factors to consider are the task to be accomplished, maintenance needs, and cost. Gear sets are generally used where the two shafts are close. Gear drive requires less space compared to belt drive.. Gear Drive Vs Belt.

From simracingsetup.com

Direct Drive vs Belt vs Gear Racing Wheels Which Should You Buy? Gear Drive Vs Belt Belt and pulley systems, along with gear driven systems represent the common ways that engineers transfer rotational motion and torque from one shaft to another shaft. In any industry, motors and turbines generate rotational motion to run various tasks. The main power transmission systems in the market include belt drives, chain drives, and. Critical factors to consider are the task. Gear Drive Vs Belt.

From www.youtube.com

Differences between Flat Belt Drive and V Belt Drive Gear Drive Vs Belt Gear sets are generally used where the two shafts are close. Critical factors to consider are the task to be accomplished, maintenance needs, and cost. In any industry, motors and turbines generate rotational motion to run various tasks. The main power transmission systems in the market include belt drives, chain drives, and. Gears and belts transmit rotary motion from one. Gear Drive Vs Belt.

From www.youtube.com

Differences between Belt Drive and Chain Drive MechanicalEngineering4u Gear Drive Vs Belt Lower friction loss compared to belt drive, therefore higher transmission, and more. In any industry, motors and turbines generate rotational motion to run various tasks. Belt and pulley systems, along with gear driven systems represent the common ways that engineers transfer rotational motion and torque from one shaft to another shaft. Critical factors to consider are the task to be. Gear Drive Vs Belt.

From esk8.news

Know Your Drive Systems Belts vs Hubs vs Direct vs Gears Gear Drive Vs Belt Belt and pulley systems, along with gear driven systems represent the common ways that engineers transfer rotational motion and torque from one shaft to another shaft. Gears and belts transmit rotary motion from one shaft to another, often changing speed and torque in the process. The main power transmission systems in the market include belt drives, chain drives, and. In. Gear Drive Vs Belt.

From giofoshbg.blob.core.windows.net

Gear Drive Vs Belt Drive at Jeffrey Wilson blog Gear Drive Vs Belt Gear sets are generally used where the two shafts are close. In any industry, motors and turbines generate rotational motion to run various tasks. Lower friction loss compared to belt drive, therefore higher transmission, and more. Critical factors to consider are the task to be accomplished, maintenance needs, and cost. The main power transmission systems in the market include belt. Gear Drive Vs Belt.

From www.pinterest.com

Timing belt vs timing chain — difference explained in 2024 Timing Gear Drive Vs Belt Belt and pulley systems, along with gear driven systems represent the common ways that engineers transfer rotational motion and torque from one shaft to another shaft. Gears and belts transmit rotary motion from one shaft to another, often changing speed and torque in the process. Gear sets are generally used where the two shafts are close. Critical factors to consider. Gear Drive Vs Belt.

From electricalworkbook.com

What is Gear Drive? Diagram, Working & Applications ElectricalWorkbook Gear Drive Vs Belt Gear sets are generally used where the two shafts are close. Lower friction loss compared to belt drive, therefore higher transmission, and more. The main power transmission systems in the market include belt drives, chain drives, and. In general, for smaller drive systems. In any industry, motors and turbines generate rotational motion to run various tasks. Gears and belts transmit. Gear Drive Vs Belt.

From wheretheroadforks.com

Belt Drive Vs Chain Drive Bike Pros and Cons Where The Road Forks Gear Drive Vs Belt Lower friction loss compared to belt drive, therefore higher transmission, and more. Gear drive requires less space compared to belt drive. The main power transmission systems in the market include belt drives, chain drives, and. In general, for smaller drive systems. Belt and pulley systems, along with gear driven systems represent the common ways that engineers transfer rotational motion and. Gear Drive Vs Belt.

From mudwyr4s2workshopfix.z13.web.core.windows.net

Timing Gear Vs Timing Chain Gear Drive Vs Belt Gear drive requires less space compared to belt drive. Lower friction loss compared to belt drive, therefore higher transmission, and more. The main power transmission systems in the market include belt drives, chain drives, and. Critical factors to consider are the task to be accomplished, maintenance needs, and cost. Gears and belts transmit rotary motion from one shaft to another,. Gear Drive Vs Belt.

From engineeringlearn.com

5 Types of Chain Drive Mechanism, Uses, Design, Applications Gear Drive Vs Belt Lower friction loss compared to belt drive, therefore higher transmission, and more. In general, for smaller drive systems. The main power transmission systems in the market include belt drives, chain drives, and. Gears and belts transmit rotary motion from one shaft to another, often changing speed and torque in the process. Critical factors to consider are the task to be. Gear Drive Vs Belt.

From www.polyurethaneconveyorbelt.com

Heavy Duty Flat Rubber Drive V Belts For Auto Parts / Textile Machinery Gear Drive Vs Belt In any industry, motors and turbines generate rotational motion to run various tasks. Lower friction loss compared to belt drive, therefore higher transmission, and more. Critical factors to consider are the task to be accomplished, maintenance needs, and cost. In general, for smaller drive systems. Belt and pulley systems, along with gear driven systems represent the common ways that engineers. Gear Drive Vs Belt.

From www.tec-science.com

Advantages and Disadvantages of belt drives tecscience Gear Drive Vs Belt Lower friction loss compared to belt drive, therefore higher transmission, and more. Gear sets are generally used where the two shafts are close. In any industry, motors and turbines generate rotational motion to run various tasks. Gear drive requires less space compared to belt drive. Belt and pulley systems, along with gear driven systems represent the common ways that engineers. Gear Drive Vs Belt.

From garagerepaircremonas.z5.web.core.windows.net

Gear Drive Vs Timing Chain Gear Drive Vs Belt In general, for smaller drive systems. The main power transmission systems in the market include belt drives, chain drives, and. Critical factors to consider are the task to be accomplished, maintenance needs, and cost. In any industry, motors and turbines generate rotational motion to run various tasks. Gear drive requires less space compared to belt drive. Lower friction loss compared. Gear Drive Vs Belt.

From simracingsetup.com

Direct Drive vs Belt vs Gear Racing Wheels Which Should You Buy? Gear Drive Vs Belt The main power transmission systems in the market include belt drives, chain drives, and. Lower friction loss compared to belt drive, therefore higher transmission, and more. Gear sets are generally used where the two shafts are close. Belt and pulley systems, along with gear driven systems represent the common ways that engineers transfer rotational motion and torque from one shaft. Gear Drive Vs Belt.

From www.youtube.com

Differences between Gear Drive and Belt Drive MechanicalEngineering4u Gear Drive Vs Belt Critical factors to consider are the task to be accomplished, maintenance needs, and cost. In general, for smaller drive systems. Gears and belts transmit rotary motion from one shaft to another, often changing speed and torque in the process. Belt and pulley systems, along with gear driven systems represent the common ways that engineers transfer rotational motion and torque from. Gear Drive Vs Belt.