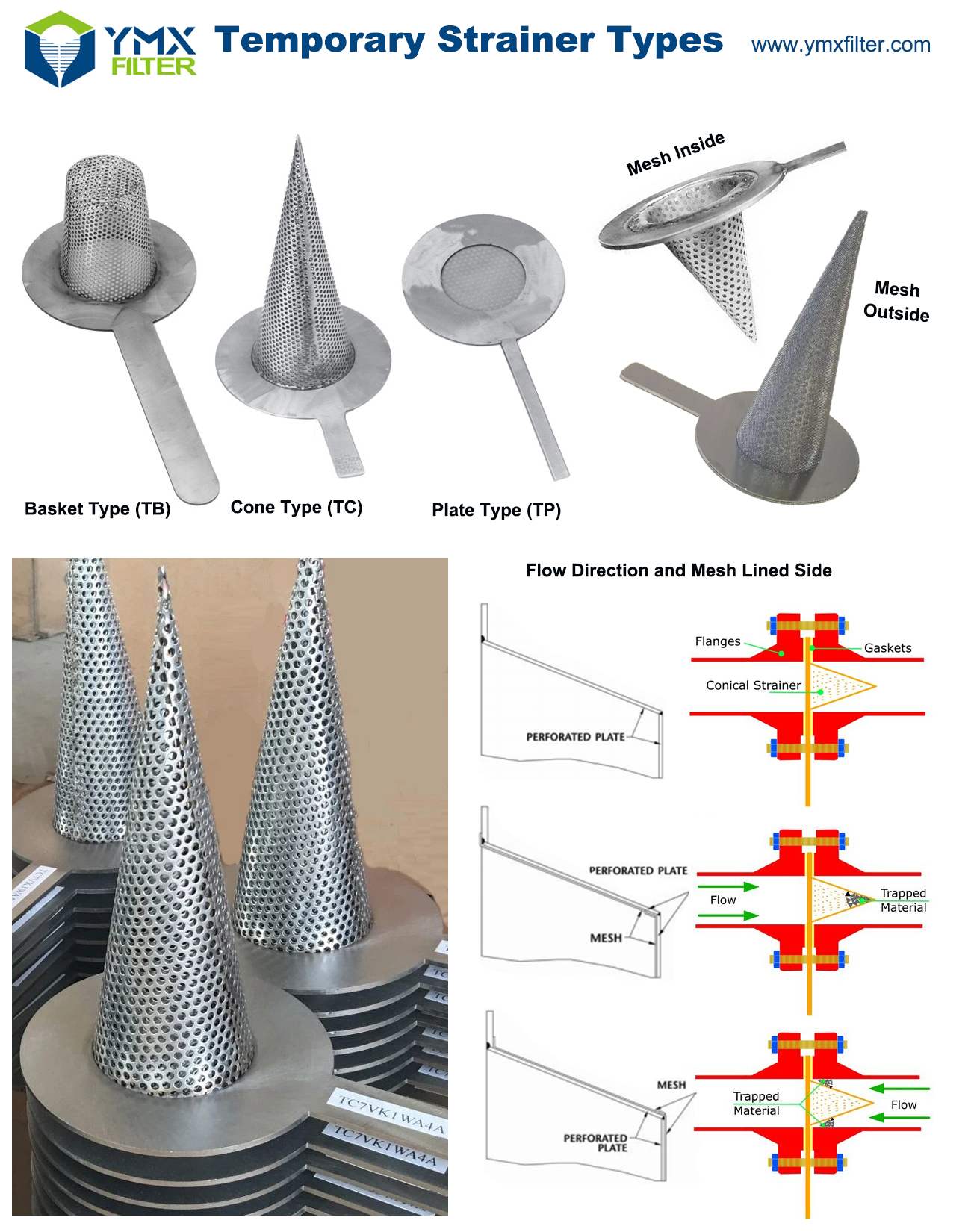

Conical Strainer Direction . For large or heavy temporary strainers, the. The mesh lined side of the temporary strainer is facing in the direction of the pipeline flow. A startup strainer, also called a witch’s hat or conical strainer, in installed in a system to remove unwanted debris from the process stream. In the context of the oil and gas. Basic function of cone strainers. This manual contains information concerning the installation, operation, and maintenance of startup (temporary) strainers. The primary function of a cone strainer is to filter out impurities and solid particles from fluids flowing through pipelines. They are typically pointed upstream. The conical (tp1) and truncated conical (tp2) temporary strainers have been designed to fit between two flanges and are generally used. Cone style temporary strainers can be installed with the pointy end either facing down stream (with the flow) or upstream (against the flow). It can be installed to protect a.

from www.ymxfilter.com

Basic function of cone strainers. The primary function of a cone strainer is to filter out impurities and solid particles from fluids flowing through pipelines. This manual contains information concerning the installation, operation, and maintenance of startup (temporary) strainers. For large or heavy temporary strainers, the. In the context of the oil and gas. It can be installed to protect a. The mesh lined side of the temporary strainer is facing in the direction of the pipeline flow. Cone style temporary strainers can be installed with the pointy end either facing down stream (with the flow) or upstream (against the flow). They are typically pointed upstream. A startup strainer, also called a witch’s hat or conical strainer, in installed in a system to remove unwanted debris from the process stream.

Temporary Cone Strainer Company

Conical Strainer Direction The primary function of a cone strainer is to filter out impurities and solid particles from fluids flowing through pipelines. The primary function of a cone strainer is to filter out impurities and solid particles from fluids flowing through pipelines. A startup strainer, also called a witch’s hat or conical strainer, in installed in a system to remove unwanted debris from the process stream. The mesh lined side of the temporary strainer is facing in the direction of the pipeline flow. They are typically pointed upstream. This manual contains information concerning the installation, operation, and maintenance of startup (temporary) strainers. It can be installed to protect a. In the context of the oil and gas. The conical (tp1) and truncated conical (tp2) temporary strainers have been designed to fit between two flanges and are generally used. Cone style temporary strainers can be installed with the pointy end either facing down stream (with the flow) or upstream (against the flow). For large or heavy temporary strainers, the. Basic function of cone strainers.

From shop.biggestlittlekitchenstore.com

Conical Strainer Conical Strainer Direction A startup strainer, also called a witch’s hat or conical strainer, in installed in a system to remove unwanted debris from the process stream. The mesh lined side of the temporary strainer is facing in the direction of the pipeline flow. The primary function of a cone strainer is to filter out impurities and solid particles from fluids flowing through. Conical Strainer Direction.

From cadalan.com.sg

Conical Strainer Cadalan Conical Strainer Direction It can be installed to protect a. The primary function of a cone strainer is to filter out impurities and solid particles from fluids flowing through pipelines. They are typically pointed upstream. For large or heavy temporary strainers, the. The conical (tp1) and truncated conical (tp2) temporary strainers have been designed to fit between two flanges and are generally used.. Conical Strainer Direction.

From www.inventvalves.com

Conical Strainer My blog Conical Strainer Direction It can be installed to protect a. The conical (tp1) and truncated conical (tp2) temporary strainers have been designed to fit between two flanges and are generally used. The mesh lined side of the temporary strainer is facing in the direction of the pipeline flow. This manual contains information concerning the installation, operation, and maintenance of startup (temporary) strainers. Basic. Conical Strainer Direction.

From dir.indiamart.com

Conical Strainers Cone Strainer Latest Price, Manufacturers & Suppliers Conical Strainer Direction They are typically pointed upstream. In the context of the oil and gas. For large or heavy temporary strainers, the. Cone style temporary strainers can be installed with the pointy end either facing down stream (with the flow) or upstream (against the flow). The conical (tp1) and truncated conical (tp2) temporary strainers have been designed to fit between two flanges. Conical Strainer Direction.

From www.ymxfilter.com

SS 316 Cone Strainer DN 600 mm Class 300 for Sale Conical Strainer Direction Basic function of cone strainers. This manual contains information concerning the installation, operation, and maintenance of startup (temporary) strainers. The primary function of a cone strainer is to filter out impurities and solid particles from fluids flowing through pipelines. The mesh lined side of the temporary strainer is facing in the direction of the pipeline flow. It can be installed. Conical Strainer Direction.

From www.perforatedmetalsheet.com

Conical Strainer Conical Strainer Direction Cone style temporary strainers can be installed with the pointy end either facing down stream (with the flow) or upstream (against the flow). For large or heavy temporary strainers, the. The mesh lined side of the temporary strainer is facing in the direction of the pipeline flow. Basic function of cone strainers. It can be installed to protect a. In. Conical Strainer Direction.

From www.mrkitchen.co.id

Conical Strainer 7.3/4"(20 Cm) N/M. Mr. Kitchen Conical Strainer Direction It can be installed to protect a. The primary function of a cone strainer is to filter out impurities and solid particles from fluids flowing through pipelines. This manual contains information concerning the installation, operation, and maintenance of startup (temporary) strainers. The conical (tp1) and truncated conical (tp2) temporary strainers have been designed to fit between two flanges and are. Conical Strainer Direction.

From www.indiamart.com

SS Polished Conical Strainer Heavy No.7, Capacity 200 ml at Rs 599 in Conical Strainer Direction This manual contains information concerning the installation, operation, and maintenance of startup (temporary) strainers. The mesh lined side of the temporary strainer is facing in the direction of the pipeline flow. Basic function of cone strainers. In the context of the oil and gas. A startup strainer, also called a witch’s hat or conical strainer, in installed in a system. Conical Strainer Direction.

From scindustrialsales.com

Temporary Strainers Engineered Solutions Conical Strainer Direction They are typically pointed upstream. Basic function of cone strainers. A startup strainer, also called a witch’s hat or conical strainer, in installed in a system to remove unwanted debris from the process stream. This manual contains information concerning the installation, operation, and maintenance of startup (temporary) strainers. The primary function of a cone strainer is to filter out impurities. Conical Strainer Direction.

From www.thetamales.com

Stainless Steel Conical Strainer The Tamales Conical Strainer Direction This manual contains information concerning the installation, operation, and maintenance of startup (temporary) strainers. The conical (tp1) and truncated conical (tp2) temporary strainers have been designed to fit between two flanges and are generally used. Basic function of cone strainers. They are typically pointed upstream. The primary function of a cone strainer is to filter out impurities and solid particles. Conical Strainer Direction.

From www.smithrestaurantsupply.com

10" Course S/S Conical Strainer Conical Strainer Direction Basic function of cone strainers. This manual contains information concerning the installation, operation, and maintenance of startup (temporary) strainers. A startup strainer, also called a witch’s hat or conical strainer, in installed in a system to remove unwanted debris from the process stream. For large or heavy temporary strainers, the. In the context of the oil and gas. Cone style. Conical Strainer Direction.

From www.srivenkatengineers.com

Conical Standard Strainer Flat Bottom Conical Strainer Manufacturer Conical Strainer Direction In the context of the oil and gas. A startup strainer, also called a witch’s hat or conical strainer, in installed in a system to remove unwanted debris from the process stream. The conical (tp1) and truncated conical (tp2) temporary strainers have been designed to fit between two flanges and are generally used. Cone style temporary strainers can be installed. Conical Strainer Direction.

From www.industrialstrainers.us

Conical Strainers PE Fabricated LLC Conical Strainer Direction In the context of the oil and gas. It can be installed to protect a. This manual contains information concerning the installation, operation, and maintenance of startup (temporary) strainers. The conical (tp1) and truncated conical (tp2) temporary strainers have been designed to fit between two flanges and are generally used. Basic function of cone strainers. Cone style temporary strainers can. Conical Strainer Direction.

From www.indiamart.com

Conical Strainer at best price in Mumbai by Nisan Scientific Procees Conical Strainer Direction In the context of the oil and gas. A startup strainer, also called a witch’s hat or conical strainer, in installed in a system to remove unwanted debris from the process stream. This manual contains information concerning the installation, operation, and maintenance of startup (temporary) strainers. For large or heavy temporary strainers, the. It can be installed to protect a.. Conical Strainer Direction.

From rafeeqfilters.com

S.S Conical Strainer 3R Filters (RAFEEQ FILTRATION SYSTEMS Conical Strainer Direction They are typically pointed upstream. A startup strainer, also called a witch’s hat or conical strainer, in installed in a system to remove unwanted debris from the process stream. Basic function of cone strainers. This manual contains information concerning the installation, operation, and maintenance of startup (temporary) strainers. The mesh lined side of the temporary strainer is facing in the. Conical Strainer Direction.

From jameskidd.co.uk

Conical Strainer 23cm Kitchen Strainers & Skimmers James Kidd Conical Strainer Direction The conical (tp1) and truncated conical (tp2) temporary strainers have been designed to fit between two flanges and are generally used. The primary function of a cone strainer is to filter out impurities and solid particles from fluids flowing through pipelines. They are typically pointed upstream. This manual contains information concerning the installation, operation, and maintenance of startup (temporary) strainers.. Conical Strainer Direction.

From www.swecofab.com

Conical, Basket, Line, TeeType Strainers & Perforated Plates Products Conical Strainer Direction For large or heavy temporary strainers, the. They are typically pointed upstream. It can be installed to protect a. Basic function of cone strainers. A startup strainer, also called a witch’s hat or conical strainer, in installed in a system to remove unwanted debris from the process stream. The mesh lined side of the temporary strainer is facing in the. Conical Strainer Direction.

From fluidfiltrationmfg.com

Temporary Cone, Basket, and Flat type Strainers Conical Strainer Direction The conical (tp1) and truncated conical (tp2) temporary strainers have been designed to fit between two flanges and are generally used. A startup strainer, also called a witch’s hat or conical strainer, in installed in a system to remove unwanted debris from the process stream. They are typically pointed upstream. Cone style temporary strainers can be installed with the pointy. Conical Strainer Direction.

From www.scribd.com

Conical Strainer PDF Pipe (Fluid Conveyance) Mechanical Engineering Conical Strainer Direction They are typically pointed upstream. Basic function of cone strainers. It can be installed to protect a. A startup strainer, also called a witch’s hat or conical strainer, in installed in a system to remove unwanted debris from the process stream. The conical (tp1) and truncated conical (tp2) temporary strainers have been designed to fit between two flanges and are. Conical Strainer Direction.

From www.ubooem.com

Stainless Steel Conical Strainer,filter element,UBO international Co Conical Strainer Direction For large or heavy temporary strainers, the. Basic function of cone strainers. The mesh lined side of the temporary strainer is facing in the direction of the pipeline flow. Cone style temporary strainers can be installed with the pointy end either facing down stream (with the flow) or upstream (against the flow). In the context of the oil and gas.. Conical Strainer Direction.

From www.pipingengineer.org

Piping Materials Temporary Conical Strainers The Piping Engineering Conical Strainer Direction For large or heavy temporary strainers, the. The mesh lined side of the temporary strainer is facing in the direction of the pipeline flow. The primary function of a cone strainer is to filter out impurities and solid particles from fluids flowing through pipelines. Basic function of cone strainers. A startup strainer, also called a witch’s hat or conical strainer,. Conical Strainer Direction.

From www.ymxfilter.com

Temporary Cone Strainer Company Conical Strainer Direction A startup strainer, also called a witch’s hat or conical strainer, in installed in a system to remove unwanted debris from the process stream. The conical (tp1) and truncated conical (tp2) temporary strainers have been designed to fit between two flanges and are generally used. It can be installed to protect a. For large or heavy temporary strainers, the. They. Conical Strainer Direction.

From www.flowlinkepl.com.au

CONICAL STRAINERS “FC” Flowlink Enterprises Conical Strainer Direction In the context of the oil and gas. It can be installed to protect a. Basic function of cone strainers. The conical (tp1) and truncated conical (tp2) temporary strainers have been designed to fit between two flanges and are generally used. For large or heavy temporary strainers, the. They are typically pointed upstream. A startup strainer, also called a witch’s. Conical Strainer Direction.

From perforatedmetalsheet.com

Conical Strainer Conical Strainer Direction It can be installed to protect a. The primary function of a cone strainer is to filter out impurities and solid particles from fluids flowing through pipelines. A startup strainer, also called a witch’s hat or conical strainer, in installed in a system to remove unwanted debris from the process stream. They are typically pointed upstream. For large or heavy. Conical Strainer Direction.

From www.inventvalves.com

Conical Strainer My blog Conical Strainer Direction The conical (tp1) and truncated conical (tp2) temporary strainers have been designed to fit between two flanges and are generally used. It can be installed to protect a. In the context of the oil and gas. For large or heavy temporary strainers, the. This manual contains information concerning the installation, operation, and maintenance of startup (temporary) strainers. Cone style temporary. Conical Strainer Direction.

From www.gteek.com

Conical strainer Conical Strainer Direction It can be installed to protect a. The primary function of a cone strainer is to filter out impurities and solid particles from fluids flowing through pipelines. Cone style temporary strainers can be installed with the pointy end either facing down stream (with the flow) or upstream (against the flow). This manual contains information concerning the installation, operation, and maintenance. Conical Strainer Direction.

From www.swecofab.com

Conical, Basket, Line, TeeType Strainers & Perforated Plates Products Conical Strainer Direction This manual contains information concerning the installation, operation, and maintenance of startup (temporary) strainers. In the context of the oil and gas. The conical (tp1) and truncated conical (tp2) temporary strainers have been designed to fit between two flanges and are generally used. The primary function of a cone strainer is to filter out impurities and solid particles from fluids. Conical Strainer Direction.

From www.roesle.com

Buy Conical Strainer Ø 18 cm7.1 in. online at RÖSLE GmbH & Co. KG Conical Strainer Direction Basic function of cone strainers. This manual contains information concerning the installation, operation, and maintenance of startup (temporary) strainers. The primary function of a cone strainer is to filter out impurities and solid particles from fluids flowing through pipelines. They are typically pointed upstream. A startup strainer, also called a witch’s hat or conical strainer, in installed in a system. Conical Strainer Direction.

From studylib.net

TITAN FCI MODEL TEMPORARY CONE AND BASKET STRAINERS Conical Strainer Direction A startup strainer, also called a witch’s hat or conical strainer, in installed in a system to remove unwanted debris from the process stream. It can be installed to protect a. Cone style temporary strainers can be installed with the pointy end either facing down stream (with the flow) or upstream (against the flow). For large or heavy temporary strainers,. Conical Strainer Direction.

From www.tradeindia.com

Stainless Steel Conical Strainer at 2000.00 INR in Gurugram Engineers Conical Strainer Direction The primary function of a cone strainer is to filter out impurities and solid particles from fluids flowing through pipelines. This manual contains information concerning the installation, operation, and maintenance of startup (temporary) strainers. Basic function of cone strainers. The conical (tp1) and truncated conical (tp2) temporary strainers have been designed to fit between two flanges and are generally used.. Conical Strainer Direction.

From www.tradeindia.com

Design Of Conical Strainer at 4000.00 INR in Navi Mumbai Ashi Conical Strainer Direction The conical (tp1) and truncated conical (tp2) temporary strainers have been designed to fit between two flanges and are generally used. Cone style temporary strainers can be installed with the pointy end either facing down stream (with the flow) or upstream (against the flow). A startup strainer, also called a witch’s hat or conical strainer, in installed in a system. Conical Strainer Direction.

From www.ymxfilter.com

Conical Line Strainer Supply Conical Strainer Direction The mesh lined side of the temporary strainer is facing in the direction of the pipeline flow. They are typically pointed upstream. A startup strainer, also called a witch’s hat or conical strainer, in installed in a system to remove unwanted debris from the process stream. In the context of the oil and gas. The conical (tp1) and truncated conical. Conical Strainer Direction.

From perforatedmetalsheet.com

Conical Strainer Conical Strainer Direction They are typically pointed upstream. A startup strainer, also called a witch’s hat or conical strainer, in installed in a system to remove unwanted debris from the process stream. This manual contains information concerning the installation, operation, and maintenance of startup (temporary) strainers. For large or heavy temporary strainers, the. The conical (tp1) and truncated conical (tp2) temporary strainers have. Conical Strainer Direction.

From www.barrandwray.com

Conical Strainers Conical Strainer Direction A startup strainer, also called a witch’s hat or conical strainer, in installed in a system to remove unwanted debris from the process stream. The mesh lined side of the temporary strainer is facing in the direction of the pipeline flow. Basic function of cone strainers. They are typically pointed upstream. Cone style temporary strainers can be installed with the. Conical Strainer Direction.

From www.enproengineers.com

CONICAL STRAINER Enproengineers Conical Strainer Direction For large or heavy temporary strainers, the. They are typically pointed upstream. The mesh lined side of the temporary strainer is facing in the direction of the pipeline flow. In the context of the oil and gas. The primary function of a cone strainer is to filter out impurities and solid particles from fluids flowing through pipelines. Basic function of. Conical Strainer Direction.