Press Fit For Plastic Parts . Press fits are great for adapting to many situations, aligning parts, and forming lasting bonds between components. Simple interference fits can be used to hold parts together. Plastic press fitting provides a simple, fast and economical means for parts assembly. Parts made of lustran abs, san and centrex polymers can be solvent bonded using similar procedures and different solvents. So, what are the key aspects of press fits, and are they right for your application? Press fit assembly is an exact manufacturing process that involves joining two or more metal components by creating an interference fit. The parts to be entered will. This is one of the most preferred fastening methods for applications that require a lasting bond and perfect alignment. Press fits can be used with similar or dissimilar materials and can eliminate screws, metal. In mechanical engineering, tolerance press fit is the permissible deviation from the assigned dimensions or nominal size.

from coloringchaos.github.io

Press fits are great for adapting to many situations, aligning parts, and forming lasting bonds between components. This is one of the most preferred fastening methods for applications that require a lasting bond and perfect alignment. So, what are the key aspects of press fits, and are they right for your application? Simple interference fits can be used to hold parts together. Press fit assembly is an exact manufacturing process that involves joining two or more metal components by creating an interference fit. Plastic press fitting provides a simple, fast and economical means for parts assembly. Press fits can be used with similar or dissimilar materials and can eliminate screws, metal. Parts made of lustran abs, san and centrex polymers can be solvent bonded using similar procedures and different solvents. The parts to be entered will. In mechanical engineering, tolerance press fit is the permissible deviation from the assigned dimensions or nominal size.

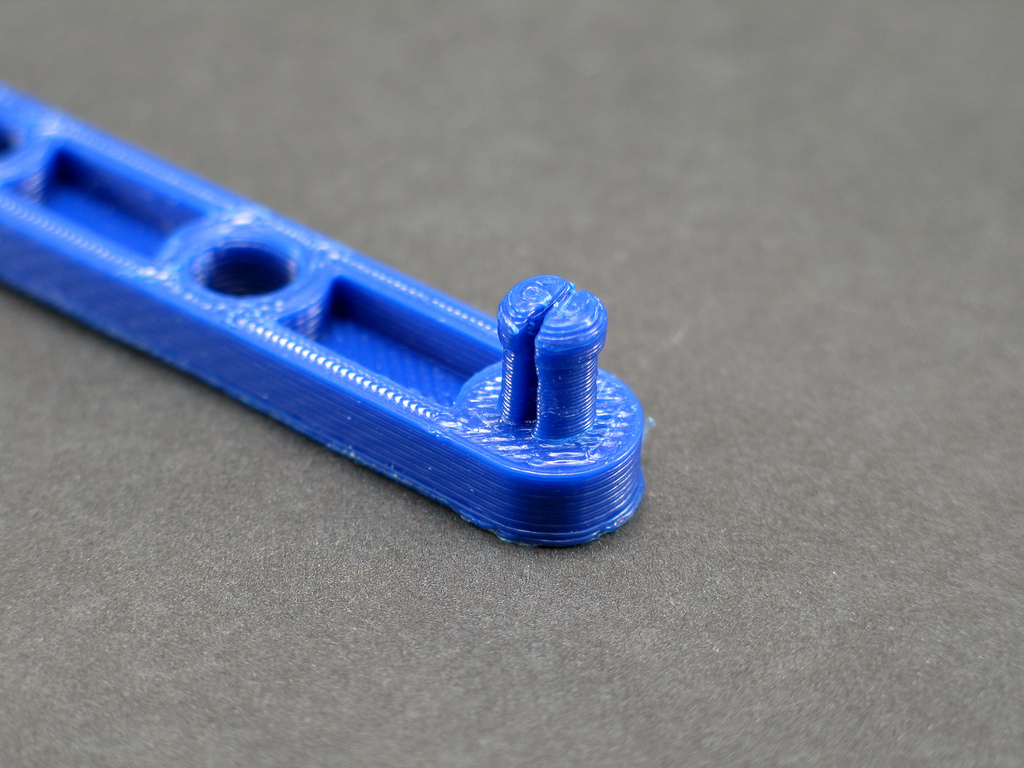

3D Printing Joints

Press Fit For Plastic Parts Press fit assembly is an exact manufacturing process that involves joining two or more metal components by creating an interference fit. Plastic press fitting provides a simple, fast and economical means for parts assembly. The parts to be entered will. Parts made of lustran abs, san and centrex polymers can be solvent bonded using similar procedures and different solvents. In mechanical engineering, tolerance press fit is the permissible deviation from the assigned dimensions or nominal size. Press fits can be used with similar or dissimilar materials and can eliminate screws, metal. So, what are the key aspects of press fits, and are they right for your application? This is one of the most preferred fastening methods for applications that require a lasting bond and perfect alignment. Press fits are great for adapting to many situations, aligning parts, and forming lasting bonds between components. Simple interference fits can be used to hold parts together. Press fit assembly is an exact manufacturing process that involves joining two or more metal components by creating an interference fit.

From coloringchaos.github.io

3D Printing Joints Press Fit For Plastic Parts Press fits are great for adapting to many situations, aligning parts, and forming lasting bonds between components. Parts made of lustran abs, san and centrex polymers can be solvent bonded using similar procedures and different solvents. Plastic press fitting provides a simple, fast and economical means for parts assembly. Simple interference fits can be used to hold parts together. So,. Press Fit For Plastic Parts.

From www.fictiv.com

Too Tight or Perfect Fit? When to Use Press Fits in Your Assemblies Press Fit For Plastic Parts Parts made of lustran abs, san and centrex polymers can be solvent bonded using similar procedures and different solvents. This is one of the most preferred fastening methods for applications that require a lasting bond and perfect alignment. In mechanical engineering, tolerance press fit is the permissible deviation from the assigned dimensions or nominal size. Press fits are great for. Press Fit For Plastic Parts.

From www.ennomotive.com

Revolutionizing the Injection Molding Process Press Fit For Plastic Parts Press fit assembly is an exact manufacturing process that involves joining two or more metal components by creating an interference fit. Simple interference fits can be used to hold parts together. So, what are the key aspects of press fits, and are they right for your application? The parts to be entered will. In mechanical engineering, tolerance press fit is. Press Fit For Plastic Parts.

From makezine.com

Tips for 3D Printing PressFit Parts — Make Press Fit For Plastic Parts Press fits are great for adapting to many situations, aligning parts, and forming lasting bonds between components. The parts to be entered will. Plastic press fitting provides a simple, fast and economical means for parts assembly. In mechanical engineering, tolerance press fit is the permissible deviation from the assigned dimensions or nominal size. So, what are the key aspects of. Press Fit For Plastic Parts.

From energize-group.co.jp

M5 THREADED SOLID Brass Inserts Push fit Press in for Plastics,10X 100X Press Fit For Plastic Parts Simple interference fits can be used to hold parts together. This is one of the most preferred fastening methods for applications that require a lasting bond and perfect alignment. Parts made of lustran abs, san and centrex polymers can be solvent bonded using similar procedures and different solvents. Press fits are great for adapting to many situations, aligning parts, and. Press Fit For Plastic Parts.

From www.mscdirect.com

EZ LOK Press Fit Threaded Inserts; Product Type Flanged; Material Press Fit For Plastic Parts Plastic press fitting provides a simple, fast and economical means for parts assembly. Press fits are great for adapting to many situations, aligning parts, and forming lasting bonds between components. The parts to be entered will. This is one of the most preferred fastening methods for applications that require a lasting bond and perfect alignment. Parts made of lustran abs,. Press Fit For Plastic Parts.

From www.smlease.com

How to Design Snap Fit Joints in Plastic Parts SMLease Design Press Fit For Plastic Parts Press fits are great for adapting to many situations, aligning parts, and forming lasting bonds between components. Parts made of lustran abs, san and centrex polymers can be solvent bonded using similar procedures and different solvents. Press fit assembly is an exact manufacturing process that involves joining two or more metal components by creating an interference fit. The parts to. Press Fit For Plastic Parts.

From www.arptech.com.au

3D Printing Design Ideas for Snap Fit Joint Clips ArpTechBlog Press Fit For Plastic Parts Press fit assembly is an exact manufacturing process that involves joining two or more metal components by creating an interference fit. So, what are the key aspects of press fits, and are they right for your application? Press fits can be used with similar or dissimilar materials and can eliminate screws, metal. The parts to be entered will. Simple interference. Press Fit For Plastic Parts.

From medium.com

Engineering Guidelines to Designing Plastic Parts for Injection Molding Press Fit For Plastic Parts Press fits are great for adapting to many situations, aligning parts, and forming lasting bonds between components. Press fits can be used with similar or dissimilar materials and can eliminate screws, metal. In mechanical engineering, tolerance press fit is the permissible deviation from the assigned dimensions or nominal size. Press fit assembly is an exact manufacturing process that involves joining. Press Fit For Plastic Parts.

From th.misumi-ec.com

No.000100 Plastic Case Pressfit Fixture inCAD Library MISUMI Press Fit For Plastic Parts Parts made of lustran abs, san and centrex polymers can be solvent bonded using similar procedures and different solvents. The parts to be entered will. This is one of the most preferred fastening methods for applications that require a lasting bond and perfect alignment. Simple interference fits can be used to hold parts together. So, what are the key aspects. Press Fit For Plastic Parts.

From www.youtube.com

Plastic Parts Design What Is Snap Fit? YouTube Press Fit For Plastic Parts Press fit assembly is an exact manufacturing process that involves joining two or more metal components by creating an interference fit. In mechanical engineering, tolerance press fit is the permissible deviation from the assigned dimensions or nominal size. Parts made of lustran abs, san and centrex polymers can be solvent bonded using similar procedures and different solvents. Simple interference fits. Press Fit For Plastic Parts.

From www.assemblymag.com

Best Practices for PressFit Assembly 20170914 Assembly Magazine Press Fit For Plastic Parts This is one of the most preferred fastening methods for applications that require a lasting bond and perfect alignment. Simple interference fits can be used to hold parts together. The parts to be entered will. Press fits can be used with similar or dissimilar materials and can eliminate screws, metal. Plastic press fitting provides a simple, fast and economical means. Press Fit For Plastic Parts.

From www.uic.com

PressFit Technology A Great Fit for Today’s Modern Electronics Press Fit For Plastic Parts So, what are the key aspects of press fits, and are they right for your application? Press fits are great for adapting to many situations, aligning parts, and forming lasting bonds between components. In mechanical engineering, tolerance press fit is the permissible deviation from the assigned dimensions or nominal size. The parts to be entered will. Parts made of lustran. Press Fit For Plastic Parts.

From www.indiamart.com

White Press Fit Plastic Wall Gitti, Dimension/Size 32 To 63 Mm, Size Press Fit For Plastic Parts Simple interference fits can be used to hold parts together. Parts made of lustran abs, san and centrex polymers can be solvent bonded using similar procedures and different solvents. So, what are the key aspects of press fits, and are they right for your application? Plastic press fitting provides a simple, fast and economical means for parts assembly. This is. Press Fit For Plastic Parts.

From www.pinterest.com

snap fitting in product design Google Search Plastic design Press Fit For Plastic Parts Press fit assembly is an exact manufacturing process that involves joining two or more metal components by creating an interference fit. So, what are the key aspects of press fits, and are they right for your application? In mechanical engineering, tolerance press fit is the permissible deviation from the assigned dimensions or nominal size. Simple interference fits can be used. Press Fit For Plastic Parts.

From www.fictiv.com

Too Tight or Perfect Fit? When to Use Press Fits in Your Assemblies Press Fit For Plastic Parts Plastic press fitting provides a simple, fast and economical means for parts assembly. This is one of the most preferred fastening methods for applications that require a lasting bond and perfect alignment. Press fits can be used with similar or dissimilar materials and can eliminate screws, metal. So, what are the key aspects of press fits, and are they right. Press Fit For Plastic Parts.

From www.youtube.com

Plastic Sleeve Bearing PressFitted Simulation In Solidworks 2019 YouTube Press Fit For Plastic Parts Press fits can be used with similar or dissimilar materials and can eliminate screws, metal. In mechanical engineering, tolerance press fit is the permissible deviation from the assigned dimensions or nominal size. The parts to be entered will. Plastic press fitting provides a simple, fast and economical means for parts assembly. Press fits are great for adapting to many situations,. Press Fit For Plastic Parts.

From www.pinterest.com

Snap Fits Best Practices in 2021 Plastic design, Mechanical design Press Fit For Plastic Parts So, what are the key aspects of press fits, and are they right for your application? In mechanical engineering, tolerance press fit is the permissible deviation from the assigned dimensions or nominal size. Plastic press fitting provides a simple, fast and economical means for parts assembly. Press fits are great for adapting to many situations, aligning parts, and forming lasting. Press Fit For Plastic Parts.

From makezine.com

Tips for 3D Printing PressFit Parts — Make Press Fit For Plastic Parts This is one of the most preferred fastening methods for applications that require a lasting bond and perfect alignment. In mechanical engineering, tolerance press fit is the permissible deviation from the assigned dimensions or nominal size. Simple interference fits can be used to hold parts together. Press fits can be used with similar or dissimilar materials and can eliminate screws,. Press Fit For Plastic Parts.

From www.multi-circuit-boards.eu

PressFit technology Multi Circuit Boards Press Fit For Plastic Parts In mechanical engineering, tolerance press fit is the permissible deviation from the assigned dimensions or nominal size. Press fits are great for adapting to many situations, aligning parts, and forming lasting bonds between components. The parts to be entered will. Press fit assembly is an exact manufacturing process that involves joining two or more metal components by creating an interference. Press Fit For Plastic Parts.

From www.assemblymag.com

Best Practices for PressFit Assembly 20170914 Assembly Magazine Press Fit For Plastic Parts This is one of the most preferred fastening methods for applications that require a lasting bond and perfect alignment. Plastic press fitting provides a simple, fast and economical means for parts assembly. Press fits are great for adapting to many situations, aligning parts, and forming lasting bonds between components. Simple interference fits can be used to hold parts together. Press. Press Fit For Plastic Parts.

From www.fictiv.com

How to Design Snap Fit Components Fictiv Press Fit For Plastic Parts This is one of the most preferred fastening methods for applications that require a lasting bond and perfect alignment. Plastic press fitting provides a simple, fast and economical means for parts assembly. Parts made of lustran abs, san and centrex polymers can be solvent bonded using similar procedures and different solvents. Press fit assembly is an exact manufacturing process that. Press Fit For Plastic Parts.

From www.pemnet.com

Four Ways To Tackle Threaded Inserts For Plastics PEM Press Fit For Plastic Parts Parts made of lustran abs, san and centrex polymers can be solvent bonded using similar procedures and different solvents. In mechanical engineering, tolerance press fit is the permissible deviation from the assigned dimensions or nominal size. Simple interference fits can be used to hold parts together. The parts to be entered will. Press fits can be used with similar or. Press Fit For Plastic Parts.

From www.smlease.com

Plastic Design Archives SMLease Design Press Fit For Plastic Parts Parts made of lustran abs, san and centrex polymers can be solvent bonded using similar procedures and different solvents. Simple interference fits can be used to hold parts together. Press fits are great for adapting to many situations, aligning parts, and forming lasting bonds between components. This is one of the most preferred fastening methods for applications that require a. Press Fit For Plastic Parts.

From www.icomold.com

Plastic Part Design Guidelines Press Fit For Plastic Parts So, what are the key aspects of press fits, and are they right for your application? Plastic press fitting provides a simple, fast and economical means for parts assembly. Parts made of lustran abs, san and centrex polymers can be solvent bonded using similar procedures and different solvents. Press fits can be used with similar or dissimilar materials and can. Press Fit For Plastic Parts.

From www.amazon.co.uk

ruthex® threaded insert M5 (50 pieces) RXM5x9.5 Brass Threaded Press Fit For Plastic Parts In mechanical engineering, tolerance press fit is the permissible deviation from the assigned dimensions or nominal size. Press fits can be used with similar or dissimilar materials and can eliminate screws, metal. Plastic press fitting provides a simple, fast and economical means for parts assembly. So, what are the key aspects of press fits, and are they right for your. Press Fit For Plastic Parts.

From www.rutlandplastics.co.uk

Design For Assembly 1 Rutland Plastics Press Fit For Plastic Parts In mechanical engineering, tolerance press fit is the permissible deviation from the assigned dimensions or nominal size. The parts to be entered will. Press fits can be used with similar or dissimilar materials and can eliminate screws, metal. Parts made of lustran abs, san and centrex polymers can be solvent bonded using similar procedures and different solvents. This is one. Press Fit For Plastic Parts.

From www.rutlandplastics.co.uk

Design For Assembly 1 Rutland Plastics Press Fit For Plastic Parts Press fits can be used with similar or dissimilar materials and can eliminate screws, metal. Plastic press fitting provides a simple, fast and economical means for parts assembly. In mechanical engineering, tolerance press fit is the permissible deviation from the assigned dimensions or nominal size. Press fit assembly is an exact manufacturing process that involves joining two or more metal. Press Fit For Plastic Parts.

From www.eenewseurope.com

Pressfit PCB pins for platedthrough holes Press Fit For Plastic Parts In mechanical engineering, tolerance press fit is the permissible deviation from the assigned dimensions or nominal size. Simple interference fits can be used to hold parts together. This is one of the most preferred fastening methods for applications that require a lasting bond and perfect alignment. Parts made of lustran abs, san and centrex polymers can be solvent bonded using. Press Fit For Plastic Parts.

From www.hubs.com

CAD modeling 3 Snap fits Protolabs Network Press Fit For Plastic Parts Plastic press fitting provides a simple, fast and economical means for parts assembly. Press fit assembly is an exact manufacturing process that involves joining two or more metal components by creating an interference fit. Parts made of lustran abs, san and centrex polymers can be solvent bonded using similar procedures and different solvents. Press fits are great for adapting to. Press Fit For Plastic Parts.

From www.kemalmfg.com

The Ultimate Guide to Snap Fit Designs Types and Best Practices Kemal Press Fit For Plastic Parts Plastic press fitting provides a simple, fast and economical means for parts assembly. This is one of the most preferred fastening methods for applications that require a lasting bond and perfect alignment. So, what are the key aspects of press fits, and are they right for your application? Press fits are great for adapting to many situations, aligning parts, and. Press Fit For Plastic Parts.

From www.multipipe.co.uk

A Beginner’s Guide to PressFit Blog Multipipe Press Fit For Plastic Parts So, what are the key aspects of press fits, and are they right for your application? Press fits are great for adapting to many situations, aligning parts, and forming lasting bonds between components. The parts to be entered will. Parts made of lustran abs, san and centrex polymers can be solvent bonded using similar procedures and different solvents. Plastic press. Press Fit For Plastic Parts.

From in.pinterest.com

How to design Snapfit Joints for 3D Printing 3D Hubs 3d printing Press Fit For Plastic Parts Press fit assembly is an exact manufacturing process that involves joining two or more metal components by creating an interference fit. Simple interference fits can be used to hold parts together. Press fits are great for adapting to many situations, aligning parts, and forming lasting bonds between components. So, what are the key aspects of press fits, and are they. Press Fit For Plastic Parts.

From www.pcb-hero.com

What is a PressFit Hole PCB ? PCB HERO Press Fit For Plastic Parts The parts to be entered will. Plastic press fitting provides a simple, fast and economical means for parts assembly. So, what are the key aspects of press fits, and are they right for your application? This is one of the most preferred fastening methods for applications that require a lasting bond and perfect alignment. Press fits are great for adapting. Press Fit For Plastic Parts.

From formlabs.com

How to Design 3D Printed Snap Fit Enclosures Press Fit For Plastic Parts Parts made of lustran abs, san and centrex polymers can be solvent bonded using similar procedures and different solvents. This is one of the most preferred fastening methods for applications that require a lasting bond and perfect alignment. Press fit assembly is an exact manufacturing process that involves joining two or more metal components by creating an interference fit. In. Press Fit For Plastic Parts.