Crankshaft Milling Journal . The milling process generally removes 4 mm to 5 mm of. In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway fixture,. One of the initial machining processes of the crankshaft is to mill away the extra iron or steel of the pin journals and main journals. One of the most important measurements to maintain when machining a crankshaft is the journal diameter. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding.

from www.heller.biz

In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway fixture,. The milling process generally removes 4 mm to 5 mm of. One of the initial machining processes of the crankshaft is to mill away the extra iron or steel of the pin journals and main journals. One of the most important measurements to maintain when machining a crankshaft is the journal diameter. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding.

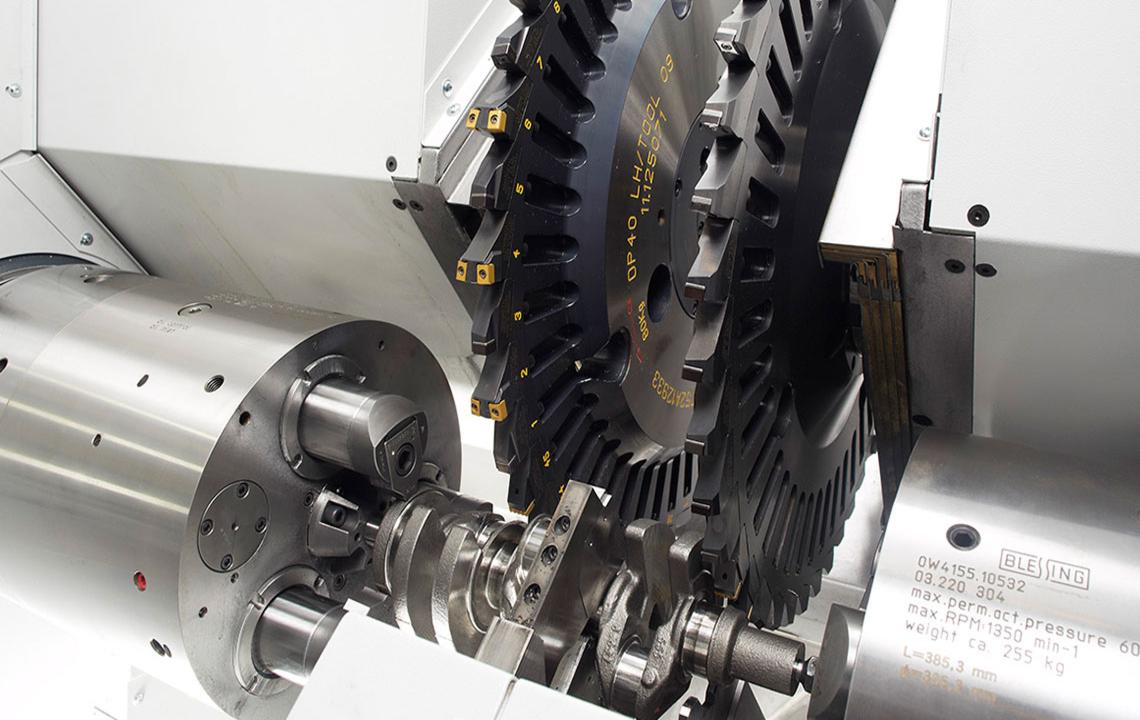

Crankshaft/camshaft production systems RFK/DRZ/MCC 15/RFN HELLER

Crankshaft Milling Journal The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. One of the initial machining processes of the crankshaft is to mill away the extra iron or steel of the pin journals and main journals. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. The milling process generally removes 4 mm to 5 mm of. In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway fixture,. One of the most important measurements to maintain when machining a crankshaft is the journal diameter. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding.

From www.crankshaftgrinding.co.uk

Crankshaft Machining Crankshaft Milling Journal The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. One of the initial machining processes of the crankshaft is to mill away the extra iron or steel of the pin journals and main journals. In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway. Crankshaft Milling Journal.

From www.heller.biz

Crankshaft/camshaft production systems RFK/DRZ/MCC 15/RFN HELLER Crankshaft Milling Journal The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. One of the initial machining processes of the crankshaft is to mill away the extra iron or steel of the pin journals and main journals. In this paper,. Crankshaft Milling Journal.

From www.cosentinoengineering.com

Machining the Crankshaft Connecting Rod Journals Cosentino Engineering Crankshaft Milling Journal The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. The milling process generally removes 4 mm to 5 mm of. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. In this paper, through the typical crankshaft parts machining process analysis and the design of a special. Crankshaft Milling Journal.

From www.pontiacdiy.com

Pontiac V8 Crankshaft Performance Guide Crankshaft Milling Journal In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway fixture,. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. One of the most important measurements to maintain when machining a crankshaft is the journal diameter. One of the initial machining processes of the. Crankshaft Milling Journal.

From www.gibbsmachinery.com

6.4 Litre Crankshaft Machining Line Gibbs Machinery Company Crankshaft Milling Journal One of the most important measurements to maintain when machining a crankshaft is the journal diameter. The milling process generally removes 4 mm to 5 mm of. In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway fixture,. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining. Crankshaft Milling Journal.

From www.inter-motion.com

multijournalcrankshaftafter4 InterMotion Crankshaft Milling Journal The milling process generally removes 4 mm to 5 mm of. One of the initial machining processes of the crankshaft is to mill away the extra iron or steel of the pin journals and main journals. In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway fixture,. The traditional crankshaft machining. Crankshaft Milling Journal.

From www.enginelabs.com

Video CNC Crankshaft Machining Combines Speed And Precision Crankshaft Milling Journal In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway fixture,. The milling process generally removes 4 mm to 5 mm of. One of the initial machining processes of the crankshaft is to mill away the extra iron or steel of the pin journals and main journals. The traditional crankshaft machining. Crankshaft Milling Journal.

From www.crankshaftgrinding.co.uk

Shaft Journal Repair Crankshaft Milling Journal In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway fixture,. One of the initial machining processes of the crankshaft is to mill away the extra iron or steel of the pin journals and main journals. The milling process generally removes 4 mm to 5 mm of. The traditional crankshaft machining. Crankshaft Milling Journal.

From www.crankshaftgrinding.co.uk

Crankshaft Machining Crankshaft Milling Journal One of the most important measurements to maintain when machining a crankshaft is the journal diameter. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. The milling process generally removes 4 mm to 5 mm of. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. In. Crankshaft Milling Journal.

From www.corvetteactioncenter.com

Ruthless Pursuit of Power The Mystique of the C6 Corvette LS7 Engine Crankshaft Milling Journal In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway fixture,. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. The milling process generally removes 4 mm to 5 mm of. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining. Crankshaft Milling Journal.

From www.youtube.com

Offset Grinding Crankshaft YouTube Crankshaft Milling Journal The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. One of the most important measurements to maintain when machining a crankshaft is the journal diameter. In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway fixture,. The milling process generally removes 4 mm to. Crankshaft Milling Journal.

From www.youtube.com

Great way to crankshaft machining with CNC machine. Excellent CNC Crankshaft Milling Journal One of the initial machining processes of the crankshaft is to mill away the extra iron or steel of the pin journals and main journals. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. The milling process. Crankshaft Milling Journal.

From www.youtube.com

Crankshaft Main Bearing Journal Measurements YouTube Crankshaft Milling Journal One of the most important measurements to maintain when machining a crankshaft is the journal diameter. In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway fixture,. One of the initial machining processes of the crankshaft is to mill away the extra iron or steel of the pin journals and main. Crankshaft Milling Journal.

From exocyebyz.blob.core.windows.net

What Is The Function Of A Crankshaft In A Car at Anna Nosal blog Crankshaft Milling Journal The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. One of the most important measurements to maintain when machining a crankshaft is the journal diameter. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. In this paper, through the typical crankshaft parts machining process analysis and. Crankshaft Milling Journal.

From www.cosentinoengineering.com

Machining the Crankshaft Connecting Rod Journals Cosentino Engineering Crankshaft Milling Journal The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway fixture,. One of the initial machining processes of the crankshaft is to mill away the extra iron or steel of the pin journals and main. Crankshaft Milling Journal.

From mechanicaljungle.com

What Is Crankshaft Machining? Crankshaft Machining Method of Crankshaft Milling Journal The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. One of the initial machining processes of the crankshaft is to mill away the extra iron or steel of the pin journals and main journals. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. The milling process. Crankshaft Milling Journal.

From motormission.com

CrankshaftMainJournalCrack09172020.jpg Motor Mission Machine Crankshaft Milling Journal The milling process generally removes 4 mm to 5 mm of. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. One of the most important measurements to maintain when machining a crankshaft is the journal diameter. One of the initial machining processes of the crankshaft is to mill away the extra iron or. Crankshaft Milling Journal.

From www.youtube.com

Welding a crankshaft rod journal. YouTube Crankshaft Milling Journal The milling process generally removes 4 mm to 5 mm of. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. One of the initial machining processes of the crankshaft is to mill away the extra iron or steel of the pin journals and main journals. One of the most important measurements to maintain. Crankshaft Milling Journal.

From www.crankshaftgrinding.co.uk

Crankshaft Machining Crankshaft Milling Journal The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. The milling process generally removes 4 mm to 5 mm of. One of the most important measurements to maintain when machining a crankshaft is the journal diameter. In. Crankshaft Milling Journal.

From moto2-usa.blogspot.com

The Hypermono! Machining the Crankshaft Connecting Rod Journals Crankshaft Milling Journal In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway fixture,. The milling process generally removes 4 mm to 5 mm of. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining. Crankshaft Milling Journal.

From www.youtube.com

Crankshaft Rod & Main Journal Measurement YouTube Crankshaft Milling Journal In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway fixture,. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. One of the initial machining processes of the crankshaft is to mill away the extra iron or steel of the pin journals and main. Crankshaft Milling Journal.

From abujehadauto.com

عمود الكرنك.. ما هو؟ ومتى يتلف؟ وما أهم وظائفه في حركة الدوران؟ Crankshaft Milling Journal One of the most important measurements to maintain when machining a crankshaft is the journal diameter. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. One of the initial machining processes of the crankshaft is to mill away the extra iron or steel of the pin journals and main journals. The milling process. Crankshaft Milling Journal.

From www.cosentinoengineering.com

Machining the Crankshaft Connecting Rod Journals Cosentino Engineering Crankshaft Milling Journal The milling process generally removes 4 mm to 5 mm of. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway fixture,. One of the initial machining processes of the crankshaft is to mill away. Crankshaft Milling Journal.

From www.youtube.com

Crankshaft main journal and connecting rod journal measurements YouTube Crankshaft Milling Journal One of the initial machining processes of the crankshaft is to mill away the extra iron or steel of the pin journals and main journals. In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway fixture,. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final. Crankshaft Milling Journal.

From www.pinterest.com

29 best images about Special chucks on Pinterest Welding process Crankshaft Milling Journal The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway fixture,. One of the most important measurements to maintain when machining a crankshaft is the journal diameter. One of the initial machining processes of the. Crankshaft Milling Journal.

From esslingeracing.com

94mm Crank w/ 50mm Rod Journals Cranks We start with a brand Crankshaft Milling Journal The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway fixture,. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. The milling process generally removes 4 mm to. Crankshaft Milling Journal.

From motormission.com

CrankshaftRodJournalCrack09172020.jpg Motor Mission Machine and Crankshaft Milling Journal The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway fixture,. One of the initial machining processes of the crankshaft is to mill away the extra iron or steel of the pin journals and main. Crankshaft Milling Journal.

From www.heller.biz

Crankshaft/camshaft production systems RFK/DRZ/MCC 15/RFN HELLER Crankshaft Milling Journal One of the initial machining processes of the crankshaft is to mill away the extra iron or steel of the pin journals and main journals. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. One of the. Crankshaft Milling Journal.

From www.crankshaftgrinding.co.uk

Crankshaft Machining Crankshaft Milling Journal One of the most important measurements to maintain when machining a crankshaft is the journal diameter. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway fixture,. The traditional crankshaft machining process involved turning a. Crankshaft Milling Journal.

From www.inplace.com

Crankshaft Machining & Repair InPlace Machining Company Crankshaft Milling Journal The milling process generally removes 4 mm to 5 mm of. One of the most important measurements to maintain when machining a crankshaft is the journal diameter. One of the initial machining processes of the crankshaft is to mill away the extra iron or steel of the pin journals and main journals. In this paper, through the typical crankshaft parts. Crankshaft Milling Journal.

From metal-crankshaft.com

Crankshaft Drilling Crankshaft Machining Service Nazhen Crankshaft Milling Journal One of the initial machining processes of the crankshaft is to mill away the extra iron or steel of the pin journals and main journals. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. One of the most important measurements to maintain when machining a crankshaft is the journal diameter. The milling process. Crankshaft Milling Journal.

From www.youtube.com

Crankshaft Pin Milling on a Heller Milling & Turning Centre YouTube Crankshaft Milling Journal In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway fixture,. The milling process generally removes 4 mm to 5 mm of. One of the most important measurements to maintain when machining a crankshaft is the journal diameter. One of the initial machining processes of the crankshaft is to mill away. Crankshaft Milling Journal.

From www.inter-motion.com

multijournalcrankshaftafter3 InterMotion Crankshaft Milling Journal The milling process generally removes 4 mm to 5 mm of. In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway fixture,. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. One of the initial machining processes of the crankshaft is to mill away. Crankshaft Milling Journal.

From metal-crankshaft.com

Crankshaft Drilling Crankshaft Machining Service Nazhen Crankshaft Milling Journal One of the initial machining processes of the crankshaft is to mill away the extra iron or steel of the pin journals and main journals. In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway fixture,. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final. Crankshaft Milling Journal.

From pauter.com

Crankshafts Pauter Crankshaft Milling Journal One of the initial machining processes of the crankshaft is to mill away the extra iron or steel of the pin journals and main journals. The traditional crankshaft machining process involved turning a crankshaft and bearing journal machining and final grinding. In this paper, through the typical crankshaft parts machining process analysis and the design of a special milling keyway. Crankshaft Milling Journal.