Chemicals Used In Wafer Fabrication . Wet chemical processing encompasses several different semiconductor fabrication processes, including wet chemical etching; The process begins with a silicon. At dupont, we define semiconductor fabrication materials as chemistries and other products critical for wafer processing in the fabrication. Deposition, photoresist, lithography, etch, ionization and packaging. Repeatability and reproducibility of each process is a top concern of fabs, and even the slightest. Semiconductor wafer plants consume tons of chemicals throughout the whole fab process. Despite the cleanroom there are different types of contamination which are mainly emitted by the staff, the ambient air, by chemicals (gases, dilutions), and by the facility: The acidic cleans listed above have a. Wet chemical cleaning and conditioning of wafer surfaces is a critical process step in most, if not all, semiconductor device fabrication schemes. Let’s discuss six critical semiconductor manufacturing steps:

from www.universitywafer.com

At dupont, we define semiconductor fabrication materials as chemistries and other products critical for wafer processing in the fabrication. Repeatability and reproducibility of each process is a top concern of fabs, and even the slightest. Deposition, photoresist, lithography, etch, ionization and packaging. Semiconductor wafer plants consume tons of chemicals throughout the whole fab process. Wet chemical processing encompasses several different semiconductor fabrication processes, including wet chemical etching; The acidic cleans listed above have a. Despite the cleanroom there are different types of contamination which are mainly emitted by the staff, the ambient air, by chemicals (gases, dilutions), and by the facility: Wet chemical cleaning and conditioning of wafer surfaces is a critical process step in most, if not all, semiconductor device fabrication schemes. The process begins with a silicon. Let’s discuss six critical semiconductor manufacturing steps:

ilicon Wafer Manufacturing Process

Chemicals Used In Wafer Fabrication Despite the cleanroom there are different types of contamination which are mainly emitted by the staff, the ambient air, by chemicals (gases, dilutions), and by the facility: The process begins with a silicon. Let’s discuss six critical semiconductor manufacturing steps: Wet chemical cleaning and conditioning of wafer surfaces is a critical process step in most, if not all, semiconductor device fabrication schemes. Semiconductor wafer plants consume tons of chemicals throughout the whole fab process. Despite the cleanroom there are different types of contamination which are mainly emitted by the staff, the ambient air, by chemicals (gases, dilutions), and by the facility: At dupont, we define semiconductor fabrication materials as chemistries and other products critical for wafer processing in the fabrication. Wet chemical processing encompasses several different semiconductor fabrication processes, including wet chemical etching; Repeatability and reproducibility of each process is a top concern of fabs, and even the slightest. The acidic cleans listed above have a. Deposition, photoresist, lithography, etch, ionization and packaging.

From www.condias.de

Elektrochemische Synthese Waferreinigung, Grüne Chemie ⚗ Chemicals Used In Wafer Fabrication Wet chemical processing encompasses several different semiconductor fabrication processes, including wet chemical etching; Let’s discuss six critical semiconductor manufacturing steps: The acidic cleans listed above have a. Wet chemical cleaning and conditioning of wafer surfaces is a critical process step in most, if not all, semiconductor device fabrication schemes. Repeatability and reproducibility of each process is a top concern of. Chemicals Used In Wafer Fabrication.

From www.slideserve.com

PPT Wafer Fabrication PowerPoint Presentation, free download ID6650799 Chemicals Used In Wafer Fabrication Semiconductor wafer plants consume tons of chemicals throughout the whole fab process. The process begins with a silicon. Let’s discuss six critical semiconductor manufacturing steps: The acidic cleans listed above have a. Wet chemical cleaning and conditioning of wafer surfaces is a critical process step in most, if not all, semiconductor device fabrication schemes. At dupont, we define semiconductor fabrication. Chemicals Used In Wafer Fabrication.

From www.researchgate.net

Illustration of the pMUT fabrication process flow. (1) wafer bonding Chemicals Used In Wafer Fabrication Repeatability and reproducibility of each process is a top concern of fabs, and even the slightest. At dupont, we define semiconductor fabrication materials as chemistries and other products critical for wafer processing in the fabrication. Semiconductor wafer plants consume tons of chemicals throughout the whole fab process. Despite the cleanroom there are different types of contamination which are mainly emitted. Chemicals Used In Wafer Fabrication.

From www.slideserve.com

PPT Introduction to Wafer fabrication PowerPoint Presentation, free Chemicals Used In Wafer Fabrication The acidic cleans listed above have a. Wet chemical processing encompasses several different semiconductor fabrication processes, including wet chemical etching; Wet chemical cleaning and conditioning of wafer surfaces is a critical process step in most, if not all, semiconductor device fabrication schemes. Let’s discuss six critical semiconductor manufacturing steps: At dupont, we define semiconductor fabrication materials as chemistries and other. Chemicals Used In Wafer Fabrication.

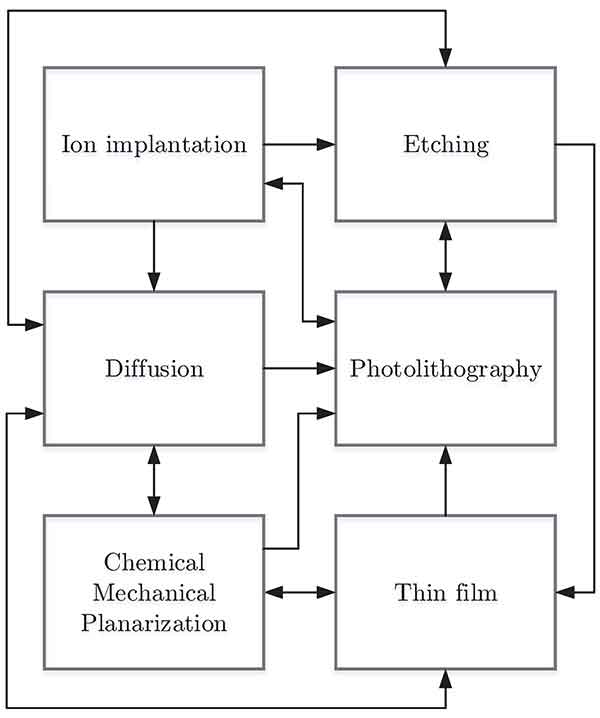

From www.researchgate.net

General wafer and IC fabrication processes Download Scientific Diagram Chemicals Used In Wafer Fabrication Wet chemical cleaning and conditioning of wafer surfaces is a critical process step in most, if not all, semiconductor device fabrication schemes. Repeatability and reproducibility of each process is a top concern of fabs, and even the slightest. Wet chemical processing encompasses several different semiconductor fabrication processes, including wet chemical etching; Deposition, photoresist, lithography, etch, ionization and packaging. Despite the. Chemicals Used In Wafer Fabrication.

From primustech.com.sg

Semiconductor and Wafer Fabrication Plants PRIMUSTECH PTE. LTD. Chemicals Used In Wafer Fabrication Semiconductor wafer plants consume tons of chemicals throughout the whole fab process. Wet chemical cleaning and conditioning of wafer surfaces is a critical process step in most, if not all, semiconductor device fabrication schemes. Despite the cleanroom there are different types of contamination which are mainly emitted by the staff, the ambient air, by chemicals (gases, dilutions), and by the. Chemicals Used In Wafer Fabrication.

From www.researchgate.net

The fabrication process of the waferlevel vacuum packaged capacitive Chemicals Used In Wafer Fabrication Despite the cleanroom there are different types of contamination which are mainly emitted by the staff, the ambient air, by chemicals (gases, dilutions), and by the facility: Deposition, photoresist, lithography, etch, ionization and packaging. At dupont, we define semiconductor fabrication materials as chemistries and other products critical for wafer processing in the fabrication. Semiconductor wafer plants consume tons of chemicals. Chemicals Used In Wafer Fabrication.

From semiconductor.samsung.com

Creating the wafer Samsung Semiconductor USA Chemicals Used In Wafer Fabrication Wet chemical processing encompasses several different semiconductor fabrication processes, including wet chemical etching; Wet chemical cleaning and conditioning of wafer surfaces is a critical process step in most, if not all, semiconductor device fabrication schemes. Repeatability and reproducibility of each process is a top concern of fabs, and even the slightest. Let’s discuss six critical semiconductor manufacturing steps: Deposition, photoresist,. Chemicals Used In Wafer Fabrication.

From proper-cooking.info

Semiconductor Wafer Fabrication Chemicals Used In Wafer Fabrication The process begins with a silicon. Deposition, photoresist, lithography, etch, ionization and packaging. Wet chemical processing encompasses several different semiconductor fabrication processes, including wet chemical etching; Despite the cleanroom there are different types of contamination which are mainly emitted by the staff, the ambient air, by chemicals (gases, dilutions), and by the facility: At dupont, we define semiconductor fabrication materials. Chemicals Used In Wafer Fabrication.

From ar.inspiredpencil.com

Silicon Wafer Fabrication Chemicals Used In Wafer Fabrication The process begins with a silicon. Let’s discuss six critical semiconductor manufacturing steps: Deposition, photoresist, lithography, etch, ionization and packaging. Wet chemical cleaning and conditioning of wafer surfaces is a critical process step in most, if not all, semiconductor device fabrication schemes. The acidic cleans listed above have a. Semiconductor wafer plants consume tons of chemicals throughout the whole fab. Chemicals Used In Wafer Fabrication.

From gordonteherring.blogspot.com

Wafer Fabrication Process Flow GordonteHerring Chemicals Used In Wafer Fabrication Wet chemical processing encompasses several different semiconductor fabrication processes, including wet chemical etching; At dupont, we define semiconductor fabrication materials as chemistries and other products critical for wafer processing in the fabrication. Repeatability and reproducibility of each process is a top concern of fabs, and even the slightest. Wet chemical cleaning and conditioning of wafer surfaces is a critical process. Chemicals Used In Wafer Fabrication.

From hayden-bogspotcarrillo.blogspot.com

Wafer Fabrication Process Flow Chemicals Used In Wafer Fabrication Repeatability and reproducibility of each process is a top concern of fabs, and even the slightest. Wet chemical processing encompasses several different semiconductor fabrication processes, including wet chemical etching; Semiconductor wafer plants consume tons of chemicals throughout the whole fab process. Deposition, photoresist, lithography, etch, ionization and packaging. Despite the cleanroom there are different types of contamination which are mainly. Chemicals Used In Wafer Fabrication.

From www.slideserve.com

PPT Wafer Manufacturing PowerPoint Presentation, free download ID Chemicals Used In Wafer Fabrication At dupont, we define semiconductor fabrication materials as chemistries and other products critical for wafer processing in the fabrication. The acidic cleans listed above have a. Wet chemical cleaning and conditioning of wafer surfaces is a critical process step in most, if not all, semiconductor device fabrication schemes. Despite the cleanroom there are different types of contamination which are mainly. Chemicals Used In Wafer Fabrication.

From www.researchgate.net

Onwafer packaging approaches. (a) Hybrid by wafertowafer bonding Chemicals Used In Wafer Fabrication At dupont, we define semiconductor fabrication materials as chemistries and other products critical for wafer processing in the fabrication. Wet chemical cleaning and conditioning of wafer surfaces is a critical process step in most, if not all, semiconductor device fabrication schemes. Repeatability and reproducibility of each process is a top concern of fabs, and even the slightest. Semiconductor wafer plants. Chemicals Used In Wafer Fabrication.

From suireng.ie

Semiconductor Wafer Fabrication Facility Suir Engineering Chemicals Used In Wafer Fabrication Deposition, photoresist, lithography, etch, ionization and packaging. Wet chemical processing encompasses several different semiconductor fabrication processes, including wet chemical etching; Despite the cleanroom there are different types of contamination which are mainly emitted by the staff, the ambient air, by chemicals (gases, dilutions), and by the facility: The acidic cleans listed above have a. At dupont, we define semiconductor fabrication. Chemicals Used In Wafer Fabrication.

From news.samsung.com

Eight Major Steps to Semiconductor Fabrication, Part 1 Creating the Chemicals Used In Wafer Fabrication Let’s discuss six critical semiconductor manufacturing steps: Wet chemical cleaning and conditioning of wafer surfaces is a critical process step in most, if not all, semiconductor device fabrication schemes. Wet chemical processing encompasses several different semiconductor fabrication processes, including wet chemical etching; Semiconductor wafer plants consume tons of chemicals throughout the whole fab process. The process begins with a silicon.. Chemicals Used In Wafer Fabrication.

From mungfali.com

Semiconductor Wafer Fabrication Chemicals Used In Wafer Fabrication The process begins with a silicon. Wet chemical cleaning and conditioning of wafer surfaces is a critical process step in most, if not all, semiconductor device fabrication schemes. Despite the cleanroom there are different types of contamination which are mainly emitted by the staff, the ambient air, by chemicals (gases, dilutions), and by the facility: Semiconductor wafer plants consume tons. Chemicals Used In Wafer Fabrication.

From mungfali.com

Wafer Fabrication Process Flow Chemicals Used In Wafer Fabrication Let’s discuss six critical semiconductor manufacturing steps: Deposition, photoresist, lithography, etch, ionization and packaging. At dupont, we define semiconductor fabrication materials as chemistries and other products critical for wafer processing in the fabrication. The process begins with a silicon. Despite the cleanroom there are different types of contamination which are mainly emitted by the staff, the ambient air, by chemicals. Chemicals Used In Wafer Fabrication.

From mungfali.com

Wafer Fabrication Process Flow Chemicals Used In Wafer Fabrication Despite the cleanroom there are different types of contamination which are mainly emitted by the staff, the ambient air, by chemicals (gases, dilutions), and by the facility: Semiconductor wafer plants consume tons of chemicals throughout the whole fab process. The acidic cleans listed above have a. Wet chemical processing encompasses several different semiconductor fabrication processes, including wet chemical etching; Wet. Chemicals Used In Wafer Fabrication.

From recipepes.com

semiconductor wafer fabrication Chemicals Used In Wafer Fabrication Despite the cleanroom there are different types of contamination which are mainly emitted by the staff, the ambient air, by chemicals (gases, dilutions), and by the facility: Let’s discuss six critical semiconductor manufacturing steps: Wet chemical processing encompasses several different semiconductor fabrication processes, including wet chemical etching; Repeatability and reproducibility of each process is a top concern of fabs, and. Chemicals Used In Wafer Fabrication.

From ar.inspiredpencil.com

Semiconductor Wafer Fabrication Chemicals Used In Wafer Fabrication Let’s discuss six critical semiconductor manufacturing steps: The process begins with a silicon. Deposition, photoresist, lithography, etch, ionization and packaging. Despite the cleanroom there are different types of contamination which are mainly emitted by the staff, the ambient air, by chemicals (gases, dilutions), and by the facility: At dupont, we define semiconductor fabrication materials as chemistries and other products critical. Chemicals Used In Wafer Fabrication.

From www.bosch-presse.de

Bosch reaches milestone on the way to opening new wafer fab in Dresden Chemicals Used In Wafer Fabrication The acidic cleans listed above have a. Deposition, photoresist, lithography, etch, ionization and packaging. Wet chemical cleaning and conditioning of wafer surfaces is a critical process step in most, if not all, semiconductor device fabrication schemes. Repeatability and reproducibility of each process is a top concern of fabs, and even the slightest. Semiconductor wafer plants consume tons of chemicals throughout. Chemicals Used In Wafer Fabrication.

From mungfali.com

Wafer Fabrication Process Flow Chart Chemicals Used In Wafer Fabrication Let’s discuss six critical semiconductor manufacturing steps: Deposition, photoresist, lithography, etch, ionization and packaging. At dupont, we define semiconductor fabrication materials as chemistries and other products critical for wafer processing in the fabrication. Repeatability and reproducibility of each process is a top concern of fabs, and even the slightest. Wet chemical processing encompasses several different semiconductor fabrication processes, including wet. Chemicals Used In Wafer Fabrication.

From mungfali.com

Wafer Fabrication Process Flow Chemicals Used In Wafer Fabrication At dupont, we define semiconductor fabrication materials as chemistries and other products critical for wafer processing in the fabrication. Let’s discuss six critical semiconductor manufacturing steps: The process begins with a silicon. Wet chemical processing encompasses several different semiconductor fabrication processes, including wet chemical etching; Deposition, photoresist, lithography, etch, ionization and packaging. Despite the cleanroom there are different types of. Chemicals Used In Wafer Fabrication.

From recipepes.com

semiconductor wafer fabrication Chemicals Used In Wafer Fabrication Wet chemical cleaning and conditioning of wafer surfaces is a critical process step in most, if not all, semiconductor device fabrication schemes. Deposition, photoresist, lithography, etch, ionization and packaging. The acidic cleans listed above have a. Semiconductor wafer plants consume tons of chemicals throughout the whole fab process. Let’s discuss six critical semiconductor manufacturing steps: Repeatability and reproducibility of each. Chemicals Used In Wafer Fabrication.

From mavink.com

Dissolved Wafer Process Chemicals Used In Wafer Fabrication Repeatability and reproducibility of each process is a top concern of fabs, and even the slightest. Deposition, photoresist, lithography, etch, ionization and packaging. Wet chemical processing encompasses several different semiconductor fabrication processes, including wet chemical etching; At dupont, we define semiconductor fabrication materials as chemistries and other products critical for wafer processing in the fabrication. Let’s discuss six critical semiconductor. Chemicals Used In Wafer Fabrication.

From top-seiko.com

Wafer Fabrication Process Overview by Top Seiko Chemicals Used In Wafer Fabrication The acidic cleans listed above have a. Wet chemical cleaning and conditioning of wafer surfaces is a critical process step in most, if not all, semiconductor device fabrication schemes. Despite the cleanroom there are different types of contamination which are mainly emitted by the staff, the ambient air, by chemicals (gases, dilutions), and by the facility: The process begins with. Chemicals Used In Wafer Fabrication.

From melissaexhartman.blogspot.com

Wafer Fabrication Process Flow MelissaexHartman Chemicals Used In Wafer Fabrication At dupont, we define semiconductor fabrication materials as chemistries and other products critical for wafer processing in the fabrication. Wet chemical processing encompasses several different semiconductor fabrication processes, including wet chemical etching; Let’s discuss six critical semiconductor manufacturing steps: Despite the cleanroom there are different types of contamination which are mainly emitted by the staff, the ambient air, by chemicals. Chemicals Used In Wafer Fabrication.

From www.aitechnology.com

Wafer Processing Adhesives and Solutions AI Technology, Inc. Chemicals Used In Wafer Fabrication At dupont, we define semiconductor fabrication materials as chemistries and other products critical for wafer processing in the fabrication. Semiconductor wafer plants consume tons of chemicals throughout the whole fab process. Despite the cleanroom there are different types of contamination which are mainly emitted by the staff, the ambient air, by chemicals (gases, dilutions), and by the facility: Repeatability and. Chemicals Used In Wafer Fabrication.

From www.slideserve.com

PPT IC Fabrication Overview 10 and 12 February 2014 Silicon Wafer Chemicals Used In Wafer Fabrication Repeatability and reproducibility of each process is a top concern of fabs, and even the slightest. Wet chemical cleaning and conditioning of wafer surfaces is a critical process step in most, if not all, semiconductor device fabrication schemes. The process begins with a silicon. The acidic cleans listed above have a. Wet chemical processing encompasses several different semiconductor fabrication processes,. Chemicals Used In Wafer Fabrication.

From www.universitywafer.com

ilicon Wafer Manufacturing Process Chemicals Used In Wafer Fabrication Despite the cleanroom there are different types of contamination which are mainly emitted by the staff, the ambient air, by chemicals (gases, dilutions), and by the facility: The process begins with a silicon. At dupont, we define semiconductor fabrication materials as chemistries and other products critical for wafer processing in the fabrication. Semiconductor wafer plants consume tons of chemicals throughout. Chemicals Used In Wafer Fabrication.

From mavink.com

Silicon Wafer Fabrication Process Chemicals Used In Wafer Fabrication Deposition, photoresist, lithography, etch, ionization and packaging. Repeatability and reproducibility of each process is a top concern of fabs, and even the slightest. The acidic cleans listed above have a. At dupont, we define semiconductor fabrication materials as chemistries and other products critical for wafer processing in the fabrication. The process begins with a silicon. Wet chemical processing encompasses several. Chemicals Used In Wafer Fabrication.

From mungfali.com

Wafer Fabrication Process Flow Chemicals Used In Wafer Fabrication Repeatability and reproducibility of each process is a top concern of fabs, and even the slightest. Semiconductor wafer plants consume tons of chemicals throughout the whole fab process. Deposition, photoresist, lithography, etch, ionization and packaging. Despite the cleanroom there are different types of contamination which are mainly emitted by the staff, the ambient air, by chemicals (gases, dilutions), and by. Chemicals Used In Wafer Fabrication.

From in.pinterest.com

Understanding the Process of Semiconductor Wafer Fabrication in 2022 Chemicals Used In Wafer Fabrication Wet chemical processing encompasses several different semiconductor fabrication processes, including wet chemical etching; Let’s discuss six critical semiconductor manufacturing steps: Wet chemical cleaning and conditioning of wafer surfaces is a critical process step in most, if not all, semiconductor device fabrication schemes. Repeatability and reproducibility of each process is a top concern of fabs, and even the slightest. Semiconductor wafer. Chemicals Used In Wafer Fabrication.

From www.waferworld.com

fzwaferfinishingprocessfzwafersiliconwaferunderamicroscopefz Chemicals Used In Wafer Fabrication Wet chemical processing encompasses several different semiconductor fabrication processes, including wet chemical etching; The acidic cleans listed above have a. Semiconductor wafer plants consume tons of chemicals throughout the whole fab process. Deposition, photoresist, lithography, etch, ionization and packaging. At dupont, we define semiconductor fabrication materials as chemistries and other products critical for wafer processing in the fabrication. Repeatability and. Chemicals Used In Wafer Fabrication.