Electro Etching Voltage . Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic fluids. Electrolytic etching describes a metalworking technique in which the surface of a metal object is etched by submerging it in an. The electrical current is directly proportional to the voltage set on the power supply: But how does this process compare with other marking methods? The electrochemical etching process relies on the use of an electrolyte solution and a voltage applied between the electrodes. Electrolytic processes, using electricity, have the advantage of not producing waste, such as gas bubbles which with traditional acid etching can block the bite, nor does it produce sediment. Especially when preparing to etch and for troubleshooting, understanding ohm’s law will help tremendously. Ohm’s law shows how voltage (v), current (i) and. You will need a varible power source preferably with a voltage output which can be varied, that supplies direct current (dc) up to 3 to 5 amps at least with a voltage of about 5 volts,. Increasing the voltage increases the current.

from mantavya.com

Increasing the voltage increases the current. Electrolytic etching describes a metalworking technique in which the surface of a metal object is etched by submerging it in an. Electrolytic processes, using electricity, have the advantage of not producing waste, such as gas bubbles which with traditional acid etching can block the bite, nor does it produce sediment. You will need a varible power source preferably with a voltage output which can be varied, that supplies direct current (dc) up to 3 to 5 amps at least with a voltage of about 5 volts,. Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic fluids. Especially when preparing to etch and for troubleshooting, understanding ohm’s law will help tremendously. Ohm’s law shows how voltage (v), current (i) and. But how does this process compare with other marking methods? The electrical current is directly proportional to the voltage set on the power supply: The electrochemical etching process relies on the use of an electrolyte solution and a voltage applied between the electrodes.

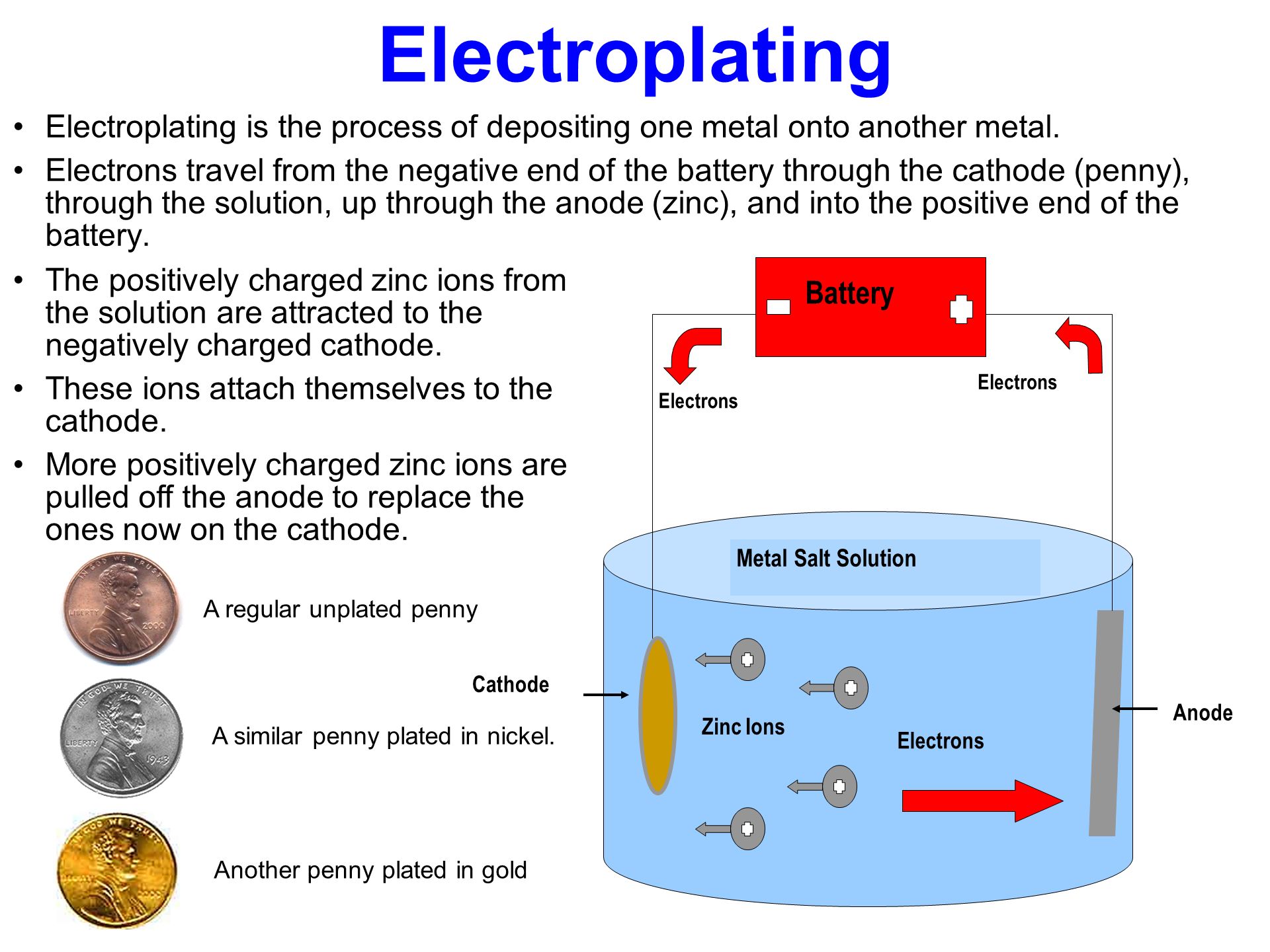

What Is Electroplating & How does it work 2021 Guide Mantavya

Electro Etching Voltage The electrochemical etching process relies on the use of an electrolyte solution and a voltage applied between the electrodes. Ohm’s law shows how voltage (v), current (i) and. The electrical current is directly proportional to the voltage set on the power supply: Increasing the voltage increases the current. Electrolytic processes, using electricity, have the advantage of not producing waste, such as gas bubbles which with traditional acid etching can block the bite, nor does it produce sediment. But how does this process compare with other marking methods? You will need a varible power source preferably with a voltage output which can be varied, that supplies direct current (dc) up to 3 to 5 amps at least with a voltage of about 5 volts,. The electrochemical etching process relies on the use of an electrolyte solution and a voltage applied between the electrodes. Electrolytic etching describes a metalworking technique in which the surface of a metal object is etched by submerging it in an. Especially when preparing to etch and for troubleshooting, understanding ohm’s law will help tremendously. Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic fluids.

From www.researchgate.net

Schematic representation of the setup for electrochemical etching of Electro Etching Voltage Increasing the voltage increases the current. Electrolytic etching describes a metalworking technique in which the surface of a metal object is etched by submerging it in an. You will need a varible power source preferably with a voltage output which can be varied, that supplies direct current (dc) up to 3 to 5 amps at least with a voltage of. Electro Etching Voltage.

From www.voxelinnovations.com

Electropolishing vs. Electrochemical Machining Electro Etching Voltage Electrolytic processes, using electricity, have the advantage of not producing waste, such as gas bubbles which with traditional acid etching can block the bite, nor does it produce sediment. Especially when preparing to etch and for troubleshooting, understanding ohm’s law will help tremendously. Ohm’s law shows how voltage (v), current (i) and. You will need a varible power source preferably. Electro Etching Voltage.

From www.researchgate.net

The typical relation between current density versus voltage for Electro Etching Voltage Ohm’s law shows how voltage (v), current (i) and. The electrochemical etching process relies on the use of an electrolyte solution and a voltage applied between the electrodes. The electrical current is directly proportional to the voltage set on the power supply: Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of. Electro Etching Voltage.

From mantavya.com

What Is Electroplating & How does it work 2021 Guide Mantavya Electro Etching Voltage The electrochemical etching process relies on the use of an electrolyte solution and a voltage applied between the electrodes. You will need a varible power source preferably with a voltage output which can be varied, that supplies direct current (dc) up to 3 to 5 amps at least with a voltage of about 5 volts,. Ohm’s law shows how voltage. Electro Etching Voltage.

From spectrographic.co.uk

Electro Etching System Spectrographic Ltd Electro Etching Voltage Ohm’s law shows how voltage (v), current (i) and. Increasing the voltage increases the current. Especially when preparing to etch and for troubleshooting, understanding ohm’s law will help tremendously. But how does this process compare with other marking methods? Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and. Electro Etching Voltage.

From www.mdpi.com

Materials Free FullText Rapid Fabrication of HighAspectRatio Electro Etching Voltage The electrochemical etching process relies on the use of an electrolyte solution and a voltage applied between the electrodes. The electrical current is directly proportional to the voltage set on the power supply: Especially when preparing to etch and for troubleshooting, understanding ohm’s law will help tremendously. Ohm’s law shows how voltage (v), current (i) and. Electrochemical marking is a. Electro Etching Voltage.

From www.researchgate.net

Influence of etching voltage V etch and etching current density J Electro Etching Voltage You will need a varible power source preferably with a voltage output which can be varied, that supplies direct current (dc) up to 3 to 5 amps at least with a voltage of about 5 volts,. Ohm’s law shows how voltage (v), current (i) and. Electrolytic etching describes a metalworking technique in which the surface of a metal object is. Electro Etching Voltage.

From www.youtube.com

Electro Etch Metal at Home Easy Electrolysis & Etching YouTube Electro Etching Voltage You will need a varible power source preferably with a voltage output which can be varied, that supplies direct current (dc) up to 3 to 5 amps at least with a voltage of about 5 volts,. Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic fluids.. Electro Etching Voltage.

From www.researchgate.net

Basic schematic of electrochemical etching method Download Scientific Electro Etching Voltage Electrolytic etching describes a metalworking technique in which the surface of a metal object is etched by submerging it in an. Ohm’s law shows how voltage (v), current (i) and. Especially when preparing to etch and for troubleshooting, understanding ohm’s law will help tremendously. Increasing the voltage increases the current. The electrochemical etching process relies on the use of an. Electro Etching Voltage.

From www.researchgate.net

Schematic of the electrochemical etching setup and the voltage bias Electro Etching Voltage Electrolytic etching describes a metalworking technique in which the surface of a metal object is etched by submerging it in an. Electrolytic processes, using electricity, have the advantage of not producing waste, such as gas bubbles which with traditional acid etching can block the bite, nor does it produce sediment. Especially when preparing to etch and for troubleshooting, understanding ohm’s. Electro Etching Voltage.

From www.slideserve.com

PPT Reactive Ion Etching PowerPoint Presentation ID1250115 Electro Etching Voltage But how does this process compare with other marking methods? You will need a varible power source preferably with a voltage output which can be varied, that supplies direct current (dc) up to 3 to 5 amps at least with a voltage of about 5 volts,. Electrolytic etching describes a metalworking technique in which the surface of a metal object. Electro Etching Voltage.

From www.youtube.com

Electro Etching Preparation & Tutorial Kernowcraft YouTube Electro Etching Voltage Increasing the voltage increases the current. Electrolytic etching describes a metalworking technique in which the surface of a metal object is etched by submerging it in an. Ohm’s law shows how voltage (v), current (i) and. You will need a varible power source preferably with a voltage output which can be varied, that supplies direct current (dc) up to 3. Electro Etching Voltage.

From www.researchgate.net

Schematic of the electrochemical etching setup and the voltage bias Electro Etching Voltage Increasing the voltage increases the current. Electrolytic processes, using electricity, have the advantage of not producing waste, such as gas bubbles which with traditional acid etching can block the bite, nor does it produce sediment. Especially when preparing to etch and for troubleshooting, understanding ohm’s law will help tremendously. Electrochemical marking is a process by which conductive metal surfaces are. Electro Etching Voltage.

From www.researchgate.net

(a) Electroetching method and the applications (b) V2CT x synthesized Electro Etching Voltage But how does this process compare with other marking methods? Electrolytic etching describes a metalworking technique in which the surface of a metal object is etched by submerging it in an. The electrochemical etching process relies on the use of an electrolyte solution and a voltage applied between the electrodes. Increasing the voltage increases the current. The electrical current is. Electro Etching Voltage.

From www.youtube.com

S8E1 Low Voltage Electro Etching Tools 1080p YouTube Electro Etching Voltage Increasing the voltage increases the current. The electrochemical etching process relies on the use of an electrolyte solution and a voltage applied between the electrodes. The electrical current is directly proportional to the voltage set on the power supply: Electrolytic etching describes a metalworking technique in which the surface of a metal object is etched by submerging it in an.. Electro Etching Voltage.

From www.mdpi.com

Applied Sciences Free FullText Deep Electrochemical Etching of Electro Etching Voltage Increasing the voltage increases the current. Electrolytic processes, using electricity, have the advantage of not producing waste, such as gas bubbles which with traditional acid etching can block the bite, nor does it produce sediment. Especially when preparing to etch and for troubleshooting, understanding ohm’s law will help tremendously. The electrochemical etching process relies on the use of an electrolyte. Electro Etching Voltage.

From www.researchgate.net

The current density versus voltage curve for electrochemical etching Electro Etching Voltage Electrolytic etching describes a metalworking technique in which the surface of a metal object is etched by submerging it in an. The electrical current is directly proportional to the voltage set on the power supply: You will need a varible power source preferably with a voltage output which can be varied, that supplies direct current (dc) up to 3 to. Electro Etching Voltage.

From www.researchgate.net

The experimental configuration of the selective electrochemical etching Electro Etching Voltage The electrical current is directly proportional to the voltage set on the power supply: Ohm’s law shows how voltage (v), current (i) and. You will need a varible power source preferably with a voltage output which can be varied, that supplies direct current (dc) up to 3 to 5 amps at least with a voltage of about 5 volts,. The. Electro Etching Voltage.

From www.youtube.com

ElectroEtching Metal How to use DC to etch metal & AC to mark metal Electro Etching Voltage Electrolytic processes, using electricity, have the advantage of not producing waste, such as gas bubbles which with traditional acid etching can block the bite, nor does it produce sediment. The electrical current is directly proportional to the voltage set on the power supply: But how does this process compare with other marking methods? You will need a varible power source. Electro Etching Voltage.

From www.youtube.com

Electro Etching with 2 9v batteries YouTube Electro Etching Voltage The electrical current is directly proportional to the voltage set on the power supply: Ohm’s law shows how voltage (v), current (i) and. Especially when preparing to etch and for troubleshooting, understanding ohm’s law will help tremendously. Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic. Electro Etching Voltage.

From www.researchgate.net

Schematic of the electrochemical etching setup and the voltage bias Electro Etching Voltage But how does this process compare with other marking methods? Ohm’s law shows how voltage (v), current (i) and. You will need a varible power source preferably with a voltage output which can be varied, that supplies direct current (dc) up to 3 to 5 amps at least with a voltage of about 5 volts,. Electrolytic etching describes a metalworking. Electro Etching Voltage.

From silhouetteuk.blogspot.com

Silhouette UK Two techniques for Etching Sterling Silver Electro Etching Voltage Electrolytic processes, using electricity, have the advantage of not producing waste, such as gas bubbles which with traditional acid etching can block the bite, nor does it produce sediment. Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic fluids. The electrochemical etching process relies on the. Electro Etching Voltage.

From ebsd.com

Electrolyte Polishing & Etching for EBSD Sample Preparation Oxford Electro Etching Voltage But how does this process compare with other marking methods? You will need a varible power source preferably with a voltage output which can be varied, that supplies direct current (dc) up to 3 to 5 amps at least with a voltage of about 5 volts,. Electrochemical marking is a process by which conductive metal surfaces are marked and labeled. Electro Etching Voltage.

From www.slideserve.com

PPT Electrochemical Wet Etching of Silver STM Tips PowerPoint Electro Etching Voltage Electrolytic etching describes a metalworking technique in which the surface of a metal object is etched by submerging it in an. But how does this process compare with other marking methods? Ohm’s law shows how voltage (v), current (i) and. The electrical current is directly proportional to the voltage set on the power supply: Electrochemical marking is a process by. Electro Etching Voltage.

From www.youtube.com

How To ElectroEtch with Salt Water and Aluminium YouTube Electro Etching Voltage You will need a varible power source preferably with a voltage output which can be varied, that supplies direct current (dc) up to 3 to 5 amps at least with a voltage of about 5 volts,. Especially when preparing to etch and for troubleshooting, understanding ohm’s law will help tremendously. The electrical current is directly proportional to the voltage set. Electro Etching Voltage.

From metallographie.shop

Electrolytic etching unit from SchmitzMetallographie, 574,70 Electro Etching Voltage But how does this process compare with other marking methods? You will need a varible power source preferably with a voltage output which can be varied, that supplies direct current (dc) up to 3 to 5 amps at least with a voltage of about 5 volts,. Ohm’s law shows how voltage (v), current (i) and. Increasing the voltage increases the. Electro Etching Voltage.

From www.exploratorium.edu

Electrical Etching Chemistry & Combining Matter Science Activity Electro Etching Voltage Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic fluids. You will need a varible power source preferably with a voltage output which can be varied, that supplies direct current (dc) up to 3 to 5 amps at least with a voltage of about 5 volts,.. Electro Etching Voltage.

From blog.thepipingmart.com

Electropolishing vs Electro Etching What's the Difference Electro Etching Voltage The electrical current is directly proportional to the voltage set on the power supply: Electrolytic processes, using electricity, have the advantage of not producing waste, such as gas bubbles which with traditional acid etching can block the bite, nor does it produce sediment. Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help. Electro Etching Voltage.

From www.metaletching.org

Stainless Steel Etching Companies Services Electro Etching Voltage You will need a varible power source preferably with a voltage output which can be varied, that supplies direct current (dc) up to 3 to 5 amps at least with a voltage of about 5 volts,. Electrolytic processes, using electricity, have the advantage of not producing waste, such as gas bubbles which with traditional acid etching can block the bite,. Electro Etching Voltage.

From www.researchgate.net

Electrochemical etching process. (a) At a beginning step. (b) At an Electro Etching Voltage Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic fluids. But how does this process compare with other marking methods? Electrolytic processes, using electricity, have the advantage of not producing waste, such as gas bubbles which with traditional acid etching can block the bite, nor does. Electro Etching Voltage.

From www.youtube.com

ElectroEtching Tutorial YouTube Electro Etching Voltage Ohm’s law shows how voltage (v), current (i) and. The electrochemical etching process relies on the use of an electrolyte solution and a voltage applied between the electrodes. Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic fluids. Especially when preparing to etch and for troubleshooting,. Electro Etching Voltage.

From www.youtube.com

ELECTROETCHING A TOUCHMARK!!! YouTube Electro Etching Voltage But how does this process compare with other marking methods? Electrolytic processes, using electricity, have the advantage of not producing waste, such as gas bubbles which with traditional acid etching can block the bite, nor does it produce sediment. Electrolytic etching describes a metalworking technique in which the surface of a metal object is etched by submerging it in an.. Electro Etching Voltage.

From www.youtube.com

Initial ElectroEtching Experiments YouTube Electro Etching Voltage Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic fluids. The electrochemical etching process relies on the use of an electrolyte solution and a voltage applied between the electrodes. Electrolytic processes, using electricity, have the advantage of not producing waste, such as gas bubbles which with. Electro Etching Voltage.

From www.youtube.com

How to Build an Electro Chemical Etching Machine Full Guide YouTube Electro Etching Voltage Ohm’s law shows how voltage (v), current (i) and. You will need a varible power source preferably with a voltage output which can be varied, that supplies direct current (dc) up to 3 to 5 amps at least with a voltage of about 5 volts,. Electrolytic processes, using electricity, have the advantage of not producing waste, such as gas bubbles. Electro Etching Voltage.

From www.researchgate.net

The electrochemical etching system. Download Scientific Diagram Electro Etching Voltage Ohm’s law shows how voltage (v), current (i) and. The electrochemical etching process relies on the use of an electrolyte solution and a voltage applied between the electrodes. Electrochemical marking is a process by which conductive metal surfaces are marked and labeled with the help of electrical current and mild electrolytic fluids. Increasing the voltage increases the current. Electrolytic processes,. Electro Etching Voltage.