Wire Rope Sheave Friction Coefficient . The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with 6 × 36, 28 mm and 35 mm diameter, iwrc (independent wire rope. In this paper, friction and wear tests between the transmission wire rope and sheave under different sliding velocities (from 0.8 m/s to 1.6 m/s) were carried out using a homemade test rig. Wear leads to performance degradation of the wire rope and seriously threatens its service reliability. The relationship of coefficient of friction with its contact surface can be expressed as: T 1 = tension applied on one side of the surface t 2 =. The material of the steel wires was low I am currently pulling a load with a wire rope that is moved through a system of sheaves, but had to replace a smaller wire rope. The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with 6 × 36, 28 mm and 35 mm. Ultimate wire rope strength indicate dramatic improvements in the endurance life of wire rope when used with cast nylatron® gsm pa6.

from www.mdpi.com

The relationship of coefficient of friction with its contact surface can be expressed as: Ultimate wire rope strength indicate dramatic improvements in the endurance life of wire rope when used with cast nylatron® gsm pa6. T 1 = tension applied on one side of the surface t 2 =. In this paper, friction and wear tests between the transmission wire rope and sheave under different sliding velocities (from 0.8 m/s to 1.6 m/s) were carried out using a homemade test rig. I am currently pulling a load with a wire rope that is moved through a system of sheaves, but had to replace a smaller wire rope. Wear leads to performance degradation of the wire rope and seriously threatens its service reliability. The material of the steel wires was low The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with 6 × 36, 28 mm and 35 mm. The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with 6 × 36, 28 mm and 35 mm diameter, iwrc (independent wire rope.

Machines Free FullText Laboratory Device Detecting Tensile Forces

Wire Rope Sheave Friction Coefficient Wear leads to performance degradation of the wire rope and seriously threatens its service reliability. T 1 = tension applied on one side of the surface t 2 =. The material of the steel wires was low The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with 6 × 36, 28 mm and 35 mm diameter, iwrc (independent wire rope. Ultimate wire rope strength indicate dramatic improvements in the endurance life of wire rope when used with cast nylatron® gsm pa6. The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with 6 × 36, 28 mm and 35 mm. I am currently pulling a load with a wire rope that is moved through a system of sheaves, but had to replace a smaller wire rope. Wear leads to performance degradation of the wire rope and seriously threatens its service reliability. The relationship of coefficient of friction with its contact surface can be expressed as: In this paper, friction and wear tests between the transmission wire rope and sheave under different sliding velocities (from 0.8 m/s to 1.6 m/s) were carried out using a homemade test rig.

From www.mdpi.com

Machines Free FullText Laboratory Device Detecting Tensile Forces Wire Rope Sheave Friction Coefficient The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with 6 × 36, 28 mm and 35 mm. T 1 = tension applied on one side of the surface t 2 =. Wear leads to performance degradation of the wire rope and seriously threatens its service reliability. The material of the steel wires. Wire Rope Sheave Friction Coefficient.

From www.mdpi.com

Machines Free FullText Laboratory Device Detecting Tensile Forces Wire Rope Sheave Friction Coefficient The relationship of coefficient of friction with its contact surface can be expressed as: I am currently pulling a load with a wire rope that is moved through a system of sheaves, but had to replace a smaller wire rope. T 1 = tension applied on one side of the surface t 2 =. The frictional behaviour of heavily loaded. Wire Rope Sheave Friction Coefficient.

From www.researchgate.net

Rope guide mechanism and the sheaves along with their degrees of Wire Rope Sheave Friction Coefficient In this paper, friction and wear tests between the transmission wire rope and sheave under different sliding velocities (from 0.8 m/s to 1.6 m/s) were carried out using a homemade test rig. I am currently pulling a load with a wire rope that is moved through a system of sheaves, but had to replace a smaller wire rope. The relationship. Wire Rope Sheave Friction Coefficient.

From www.mdpi.com

Coatings Free FullText Determination of the Coefficient of Wire Rope Sheave Friction Coefficient Ultimate wire rope strength indicate dramatic improvements in the endurance life of wire rope when used with cast nylatron® gsm pa6. Wear leads to performance degradation of the wire rope and seriously threatens its service reliability. T 1 = tension applied on one side of the surface t 2 =. The relationship of coefficient of friction with its contact surface. Wire Rope Sheave Friction Coefficient.

From www.mdpi.com

Machines Free FullText Laboratory Device Detecting Tensile Forces Wire Rope Sheave Friction Coefficient In this paper, friction and wear tests between the transmission wire rope and sheave under different sliding velocities (from 0.8 m/s to 1.6 m/s) were carried out using a homemade test rig. Ultimate wire rope strength indicate dramatic improvements in the endurance life of wire rope when used with cast nylatron® gsm pa6. T 1 = tension applied on one. Wire Rope Sheave Friction Coefficient.

From www.researchgate.net

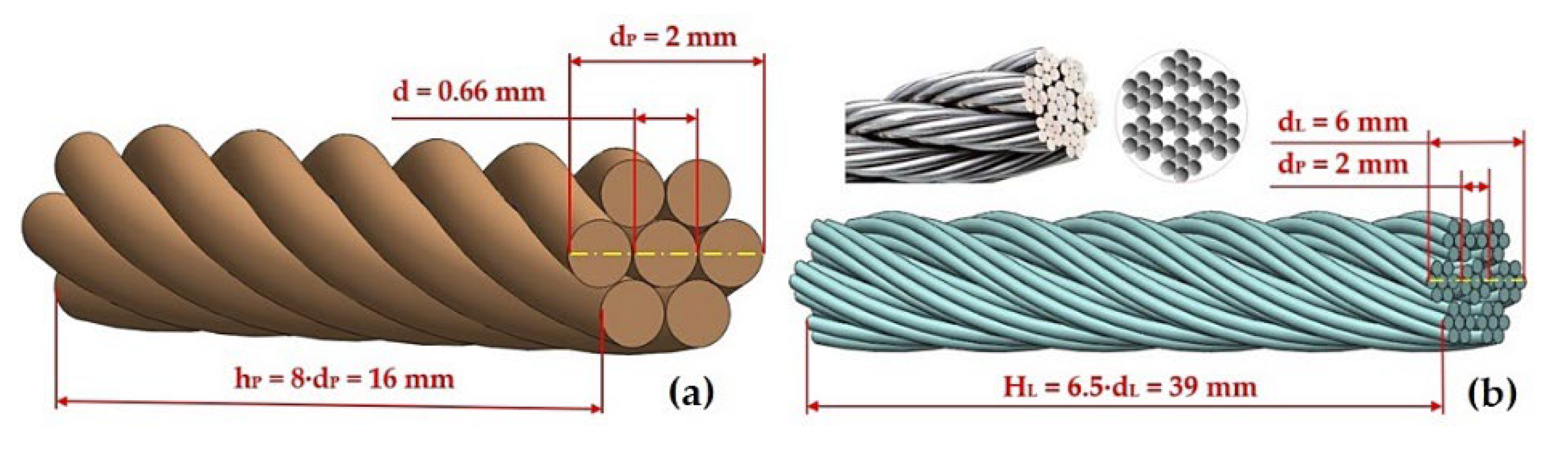

6×19+FC wire rope sample. (a) wire rope; (b) cross section. Download Wire Rope Sheave Friction Coefficient The material of the steel wires was low The relationship of coefficient of friction with its contact surface can be expressed as: The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with 6 × 36, 28 mm and 35 mm. The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves. Wire Rope Sheave Friction Coefficient.

From www.mdpi.com

Materials Free FullText Sliding Friction and Wear Characteristics Wire Rope Sheave Friction Coefficient In this paper, friction and wear tests between the transmission wire rope and sheave under different sliding velocities (from 0.8 m/s to 1.6 m/s) were carried out using a homemade test rig. Wear leads to performance degradation of the wire rope and seriously threatens its service reliability. The material of the steel wires was low Ultimate wire rope strength indicate. Wire Rope Sheave Friction Coefficient.

From www.samselsupply.com

HOWTO Order Wire Rope Sheaves Wire Rope Sheave Friction Coefficient The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with 6 × 36, 28 mm and 35 mm diameter, iwrc (independent wire rope. The relationship of coefficient of friction with its contact surface can be expressed as: In this paper, friction and wear tests between the transmission wire rope and sheave under different. Wire Rope Sheave Friction Coefficient.

From dokumen.tips

(PDF) Wire Rope Sheave Friction Effects ppi · PDF fileWire Rope Wire Rope Sheave Friction Coefficient T 1 = tension applied on one side of the surface t 2 =. I am currently pulling a load with a wire rope that is moved through a system of sheaves, but had to replace a smaller wire rope. The material of the steel wires was low Wear leads to performance degradation of the wire rope and seriously threatens. Wire Rope Sheave Friction Coefficient.

From mepsystems.com.sg

MORDEC WIRE ROPE SHEAVE GAUGE MEP Deck Solutions Wire Rope Sheave Friction Coefficient The relationship of coefficient of friction with its contact surface can be expressed as: T 1 = tension applied on one side of the surface t 2 =. Wear leads to performance degradation of the wire rope and seriously threatens its service reliability. The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with. Wire Rope Sheave Friction Coefficient.

From www.semanticscholar.org

Figure 1 from Frictional performance of wire and fibre ropes bent over Wire Rope Sheave Friction Coefficient Ultimate wire rope strength indicate dramatic improvements in the endurance life of wire rope when used with cast nylatron® gsm pa6. In this paper, friction and wear tests between the transmission wire rope and sheave under different sliding velocities (from 0.8 m/s to 1.6 m/s) were carried out using a homemade test rig. The frictional behaviour of heavily loaded wire. Wire Rope Sheave Friction Coefficient.

From www.researchgate.net

(PDF) Laboratory Device Detecting Tensile Forces in the Rope and Wire Rope Sheave Friction Coefficient The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with 6 × 36, 28 mm and 35 mm diameter, iwrc (independent wire rope. I am currently pulling a load with a wire rope that is moved through a system of sheaves, but had to replace a smaller wire rope. Wear leads to performance. Wire Rope Sheave Friction Coefficient.

From www.mdpi.com

Machines Free FullText Laboratory Device Detecting Tensile Forces Wire Rope Sheave Friction Coefficient The relationship of coefficient of friction with its contact surface can be expressed as: I am currently pulling a load with a wire rope that is moved through a system of sheaves, but had to replace a smaller wire rope. The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with 6 × 36,. Wire Rope Sheave Friction Coefficient.

From exypoylsr.blob.core.windows.net

Wire Rope Sheave Efficiency at Howard Valente blog Wire Rope Sheave Friction Coefficient T 1 = tension applied on one side of the surface t 2 =. The material of the steel wires was low Ultimate wire rope strength indicate dramatic improvements in the endurance life of wire rope when used with cast nylatron® gsm pa6. Wear leads to performance degradation of the wire rope and seriously threatens its service reliability. The frictional. Wire Rope Sheave Friction Coefficient.

From www.researchgate.net

(PDF) Influence of friction coefficient on mechanical properties of Wire Rope Sheave Friction Coefficient The material of the steel wires was low The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with 6 × 36, 28 mm and 35 mm. The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with 6 × 36, 28 mm and 35 mm diameter, iwrc. Wire Rope Sheave Friction Coefficient.

From www.mdpi.com

Materials Free FullText Sliding Friction and Wear Characteristics Wire Rope Sheave Friction Coefficient Wear leads to performance degradation of the wire rope and seriously threatens its service reliability. The material of the steel wires was low Ultimate wire rope strength indicate dramatic improvements in the endurance life of wire rope when used with cast nylatron® gsm pa6. The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated. Wire Rope Sheave Friction Coefficient.

From www.mdpi.com

Machines Free FullText Laboratory Device Detecting Tensile Forces Wire Rope Sheave Friction Coefficient I am currently pulling a load with a wire rope that is moved through a system of sheaves, but had to replace a smaller wire rope. The relationship of coefficient of friction with its contact surface can be expressed as: Ultimate wire rope strength indicate dramatic improvements in the endurance life of wire rope when used with cast nylatron® gsm. Wire Rope Sheave Friction Coefficient.

From www.mdpi.com

Machines Free FullText Laboratory Device Detecting Tensile Forces Wire Rope Sheave Friction Coefficient The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with 6 × 36, 28 mm and 35 mm. In this paper, friction and wear tests between the transmission wire rope and sheave under different sliding velocities (from 0.8 m/s to 1.6 m/s) were carried out using a homemade test rig. T 1 =. Wire Rope Sheave Friction Coefficient.

From rentlgh.ca

Using The Coefficient of Friction to Calculate Frictional Force LGH Wire Rope Sheave Friction Coefficient In this paper, friction and wear tests between the transmission wire rope and sheave under different sliding velocities (from 0.8 m/s to 1.6 m/s) were carried out using a homemade test rig. The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with 6 × 36, 28 mm and 35 mm diameter, iwrc (independent. Wire Rope Sheave Friction Coefficient.

From www.mdpi.com

Machines Free FullText Laboratory Device Detecting Tensile Forces Wire Rope Sheave Friction Coefficient Wear leads to performance degradation of the wire rope and seriously threatens its service reliability. The relationship of coefficient of friction with its contact surface can be expressed as: I am currently pulling a load with a wire rope that is moved through a system of sheaves, but had to replace a smaller wire rope. T 1 = tension applied. Wire Rope Sheave Friction Coefficient.

From roperescuetraining.com

Rope Rescue Raising Friction Wire Rope Sheave Friction Coefficient The relationship of coefficient of friction with its contact surface can be expressed as: T 1 = tension applied on one side of the surface t 2 =. In this paper, friction and wear tests between the transmission wire rope and sheave under different sliding velocities (from 0.8 m/s to 1.6 m/s) were carried out using a homemade test rig.. Wire Rope Sheave Friction Coefficient.

From www.mdpi.com

Machines Free FullText Laboratory Device Detecting Tensile Forces Wire Rope Sheave Friction Coefficient The relationship of coefficient of friction with its contact surface can be expressed as: The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with 6 × 36, 28 mm and 35 mm diameter, iwrc (independent wire rope. I am currently pulling a load with a wire rope that is moved through a system. Wire Rope Sheave Friction Coefficient.

From www.cmcpro.com

Analyzing a Rope System Theoretical vs. Actual Mechanical Advantage Wire Rope Sheave Friction Coefficient The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with 6 × 36, 28 mm and 35 mm diameter, iwrc (independent wire rope. I am currently pulling a load with a wire rope that is moved through a system of sheaves, but had to replace a smaller wire rope. In this paper, friction. Wire Rope Sheave Friction Coefficient.

From www.researchgate.net

(PDF) Frictional performance of wire and fibre ropes bent over sheaves Wire Rope Sheave Friction Coefficient The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with 6 × 36, 28 mm and 35 mm diameter, iwrc (independent wire rope. Ultimate wire rope strength indicate dramatic improvements in the endurance life of wire rope when used with cast nylatron® gsm pa6. The frictional behaviour of heavily loaded wire ropes bent. Wire Rope Sheave Friction Coefficient.

From www.mdpi.com

Materials Free FullText Sliding Friction and Wear Characteristics Wire Rope Sheave Friction Coefficient The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with 6 × 36, 28 mm and 35 mm diameter, iwrc (independent wire rope. T 1 = tension applied on one side of the surface t 2 =. In this paper, friction and wear tests between the transmission wire rope and sheave under different. Wire Rope Sheave Friction Coefficient.

From suncorstainless.com

Stainless Steel Sheaves Selection and Use Suncor Stainless Wire Rope Sheave Friction Coefficient Wear leads to performance degradation of the wire rope and seriously threatens its service reliability. The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with 6 × 36, 28 mm and 35 mm. The material of the steel wires was low In this paper, friction and wear tests between the transmission wire rope. Wire Rope Sheave Friction Coefficient.

From www.mdpi.com

Machines Free FullText Laboratory Device Detecting Tensile Forces Wire Rope Sheave Friction Coefficient Wear leads to performance degradation of the wire rope and seriously threatens its service reliability. T 1 = tension applied on one side of the surface t 2 =. I am currently pulling a load with a wire rope that is moved through a system of sheaves, but had to replace a smaller wire rope. The material of the steel. Wire Rope Sheave Friction Coefficient.

From exypoylsr.blob.core.windows.net

Wire Rope Sheave Efficiency at Howard Valente blog Wire Rope Sheave Friction Coefficient The material of the steel wires was low The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with 6 × 36, 28 mm and 35 mm diameter, iwrc (independent wire rope. T 1 = tension applied on one side of the surface t 2 =. In this paper, friction and wear tests between. Wire Rope Sheave Friction Coefficient.

From www.mdpi.com

Machines Free FullText Laboratory Device Detecting Tensile Forces Wire Rope Sheave Friction Coefficient Wear leads to performance degradation of the wire rope and seriously threatens its service reliability. The material of the steel wires was low Ultimate wire rope strength indicate dramatic improvements in the endurance life of wire rope when used with cast nylatron® gsm pa6. The relationship of coefficient of friction with its contact surface can be expressed as: I am. Wire Rope Sheave Friction Coefficient.

From www.mdpi.com

Materials Free FullText Sliding Friction and Wear Characteristics Wire Rope Sheave Friction Coefficient In this paper, friction and wear tests between the transmission wire rope and sheave under different sliding velocities (from 0.8 m/s to 1.6 m/s) were carried out using a homemade test rig. Wear leads to performance degradation of the wire rope and seriously threatens its service reliability. The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves. Wire Rope Sheave Friction Coefficient.

From www.mdpi.com

Machines Free FullText Laboratory Device Detecting Tensile Forces Wire Rope Sheave Friction Coefficient The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with 6 × 36, 28 mm and 35 mm diameter, iwrc (independent wire rope. In this paper, friction and wear tests between the transmission wire rope and sheave under different sliding velocities (from 0.8 m/s to 1.6 m/s) were carried out using a homemade. Wire Rope Sheave Friction Coefficient.

From www.mdpi.com

Materials Free FullText Sliding Friction and Wear Characteristics Wire Rope Sheave Friction Coefficient Wear leads to performance degradation of the wire rope and seriously threatens its service reliability. T 1 = tension applied on one side of the surface t 2 =. I am currently pulling a load with a wire rope that is moved through a system of sheaves, but had to replace a smaller wire rope. The relationship of coefficient of. Wire Rope Sheave Friction Coefficient.

From www.linkedin.com

Analysis and prevention of sliding rope of steel wire rope of multi Wire Rope Sheave Friction Coefficient Wear leads to performance degradation of the wire rope and seriously threatens its service reliability. I am currently pulling a load with a wire rope that is moved through a system of sheaves, but had to replace a smaller wire rope. The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with 6 ×. Wire Rope Sheave Friction Coefficient.

From exypoylsr.blob.core.windows.net

Wire Rope Sheave Efficiency at Howard Valente blog Wire Rope Sheave Friction Coefficient Wear leads to performance degradation of the wire rope and seriously threatens its service reliability. The frictional behaviour of heavily loaded wire ropes bent over relatively small sheaves has been investigated with 6 × 36, 28 mm and 35 mm diameter, iwrc (independent wire rope. I am currently pulling a load with a wire rope that is moved through a. Wire Rope Sheave Friction Coefficient.

From www.researchgate.net

Diagram of multirope friction hoist and hoisting system. Download Wire Rope Sheave Friction Coefficient Wear leads to performance degradation of the wire rope and seriously threatens its service reliability. T 1 = tension applied on one side of the surface t 2 =. The relationship of coefficient of friction with its contact surface can be expressed as: In this paper, friction and wear tests between the transmission wire rope and sheave under different sliding. Wire Rope Sheave Friction Coefficient.