Marine Diesel Engine Crankshaft Material . There are two primary types of crankshafts used in ship engines: Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. There are two main types of crankshafts used in ship engines: The bed plate provides the rigid seating of the crankshaft, which is absolutely essential for satisfactory. We can classify the common marine engine crankshaft into the following three types: Forged crankshafts are made from a solid piece. Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. Construction materials for marine diesel engines: As a result, engine manufacturers developed fully built crankshafts. Crankshafts on large engines can weigh as much as 300 tonnes and are difficult to build as a single piece.

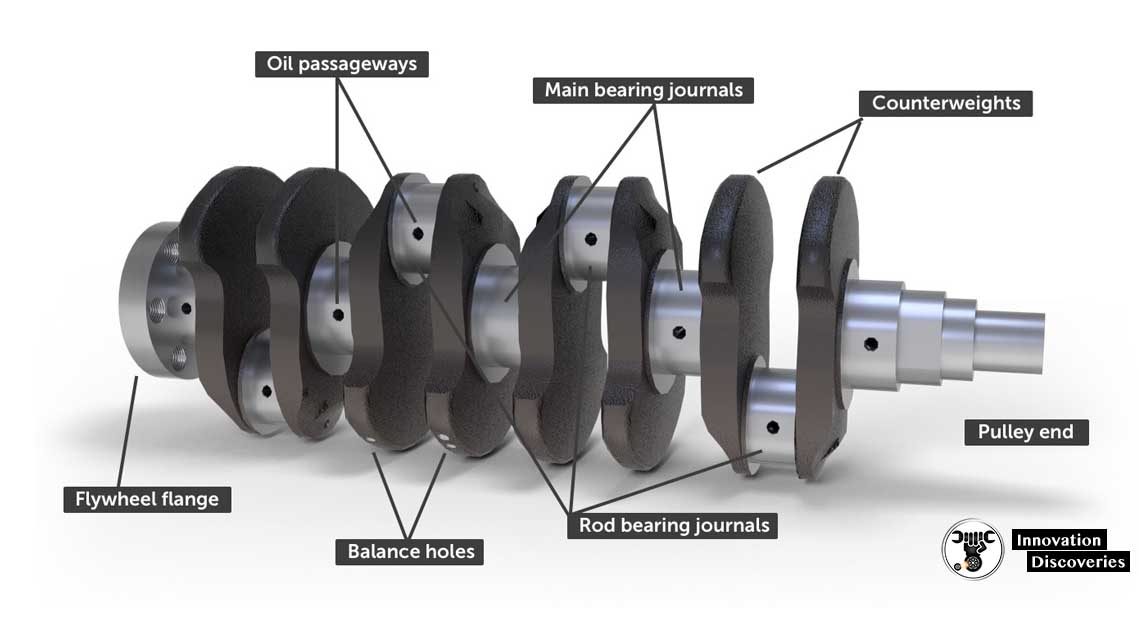

from innovationdiscoveries.space

Forged crankshafts are made from a solid piece. Crankshafts on large engines can weigh as much as 300 tonnes and are difficult to build as a single piece. There are two main types of crankshafts used in ship engines: We can classify the common marine engine crankshaft into the following three types: Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. There are two primary types of crankshafts used in ship engines: As a result, engine manufacturers developed fully built crankshafts. The bed plate provides the rigid seating of the crankshaft, which is absolutely essential for satisfactory. Construction materials for marine diesel engines: Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify.

Difference Between Crankshaft And Camshaft

Marine Diesel Engine Crankshaft Material Crankshafts on large engines can weigh as much as 300 tonnes and are difficult to build as a single piece. As a result, engine manufacturers developed fully built crankshafts. Forged crankshafts are made from a solid piece. Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. There are two primary types of crankshafts used in ship engines: There are two main types of crankshafts used in ship engines: Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. Construction materials for marine diesel engines: The bed plate provides the rigid seating of the crankshaft, which is absolutely essential for satisfactory. We can classify the common marine engine crankshaft into the following three types: Crankshafts on large engines can weigh as much as 300 tonnes and are difficult to build as a single piece.

From circuitenginecarlos101.z22.web.core.windows.net

Diagram Of A Crankshaft Marine Diesel Engine Crankshaft Material There are two primary types of crankshafts used in ship engines: Crankshafts on large engines can weigh as much as 300 tonnes and are difficult to build as a single piece. We can classify the common marine engine crankshaft into the following three types: Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and. Marine Diesel Engine Crankshaft Material.

From csscservice.com

Crankshaft Repair on Site Knowledge Center CSSCSERVICE Marine Diesel Engine Crankshaft Material Crankshafts on large engines can weigh as much as 300 tonnes and are difficult to build as a single piece. As a result, engine manufacturers developed fully built crankshafts. Forged crankshafts are made from a solid piece. Construction materials for marine diesel engines: The bed plate provides the rigid seating of the crankshaft, which is absolutely essential for satisfactory. There. Marine Diesel Engine Crankshaft Material.

From hxetluafw.blob.core.windows.net

Crankshaft Deflection In Marine Diesel Engines at Ching Johnson blog Marine Diesel Engine Crankshaft Material Construction materials for marine diesel engines: As a result, engine manufacturers developed fully built crankshafts. We can classify the common marine engine crankshaft into the following three types: Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. The bed plate provides the rigid seating of the crankshaft,. Marine Diesel Engine Crankshaft Material.

From www.goltens.com

Large Engine Crankshaft Replacement Goltens Marine Diesel Engine Crankshaft Material As a result, engine manufacturers developed fully built crankshafts. Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. There are two primary types of crankshafts used in ship engines: We can classify the common marine engine crankshaft into the following three types: Forged crankshafts are made from a solid piece. Crankshafts on. Marine Diesel Engine Crankshaft Material.

From www.otomotifstudi.com

Representation of a Crankshaft and its Important Components, Engine Marine Diesel Engine Crankshaft Material Forged crankshafts are made from a solid piece. Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. We can classify the common marine engine crankshaft into the following three types: Construction materials for marine diesel engines: As a result, engine manufacturers developed fully built crankshafts. Crankshafts on. Marine Diesel Engine Crankshaft Material.

From innovationdiscoveries.space

Difference Between Crankshaft And Camshaft Marine Diesel Engine Crankshaft Material Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. There are two primary types of crankshafts used in ship engines: As a result, engine manufacturers developed fully built crankshafts. Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. The. Marine Diesel Engine Crankshaft Material.

From www.alibaba.com

6isde Marine Diesel Engine Crankshaft 5301009 4934862 3974538 Buy Marine Diesel Engine Crankshaft Material The bed plate provides the rigid seating of the crankshaft, which is absolutely essential for satisfactory. Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. There are two main types of crankshafts used in ship engines: Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and. Marine Diesel Engine Crankshaft Material.

From noah-marineservices.com

Crankshaft Damage in Diesel Engines Detection and Repair Noah Marine Marine Diesel Engine Crankshaft Material There are two primary types of crankshafts used in ship engines: Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. Construction materials for marine diesel engines: Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. There are two main. Marine Diesel Engine Crankshaft Material.

From dieselcrankshaft.en.made-in-china.com

Weichai Diesel Engine Parts Cw6200/Cw8200 Marine Engine Crankshaft Marine Diesel Engine Crankshaft Material The bed plate provides the rigid seating of the crankshaft, which is absolutely essential for satisfactory. Forged crankshafts are made from a solid piece. Construction materials for marine diesel engines: There are two primary types of crankshafts used in ship engines: There are two main types of crankshafts used in ship engines: We can classify the common marine engine crankshaft. Marine Diesel Engine Crankshaft Material.

From mechanicstips.blogspot.com

Crankshaft of Ship Engine MechanicsTips Marine Diesel Engine Crankshaft Material There are two main types of crankshafts used in ship engines: We can classify the common marine engine crankshaft into the following three types: Forged crankshafts are made from a solid piece. Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. There are two primary types of crankshafts used in ship engines:. Marine Diesel Engine Crankshaft Material.

From innovationdiscoveries.space

Materials for Marine Diesel Engines Marine Diesel Engine Crankshaft Material Forged crankshafts are made from a solid piece. The bed plate provides the rigid seating of the crankshaft, which is absolutely essential for satisfactory. Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. Construction materials for marine diesel engines: Crankshafts on large engines can weigh as much as 300 tonnes and are. Marine Diesel Engine Crankshaft Material.

From marinerspointpro.com

Crankshaft Types, Parts, Function, Sensor, Images Marinerspoint Pro Marine Diesel Engine Crankshaft Material As a result, engine manufacturers developed fully built crankshafts. We can classify the common marine engine crankshaft into the following three types: The bed plate provides the rigid seating of the crankshaft, which is absolutely essential for satisfactory. There are two primary types of crankshafts used in ship engines: Construction materials for marine diesel engines: Cast crankshafts, on the other. Marine Diesel Engine Crankshaft Material.

From www.indiamart.com

Marine Diesel Engine Crankshaft 2 MAN B&W9L58/648L58/647L58/64 Marine Diesel Engine Crankshaft Material As a result, engine manufacturers developed fully built crankshafts. Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. There are two primary types of crankshafts used in ship engines: Crankshafts on large engines can weigh as much as 300 tonnes and are difficult to build as a. Marine Diesel Engine Crankshaft Material.

From www.ship-research.com

Stress prediction of marine diesel engine crankshaft based on digital Marine Diesel Engine Crankshaft Material There are two main types of crankshafts used in ship engines: Crankshafts on large engines can weigh as much as 300 tonnes and are difficult to build as a single piece. The bed plate provides the rigid seating of the crankshaft, which is absolutely essential for satisfactory. There are two primary types of crankshafts used in ship engines: Construction materials. Marine Diesel Engine Crankshaft Material.

From innovationdiscoveries.space

Materials for Marine Diesel Engines Marine Diesel Engine Crankshaft Material There are two primary types of crankshafts used in ship engines: There are two main types of crankshafts used in ship engines: Construction materials for marine diesel engines: Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. Forged crankshafts are made from a solid piece. Crankshafts on large engines can weigh as. Marine Diesel Engine Crankshaft Material.

From www.scientific.net

Finite Element Analysis of Small Marine Diesel Engine Crankshaft Marine Diesel Engine Crankshaft Material As a result, engine manufacturers developed fully built crankshafts. There are two main types of crankshafts used in ship engines: We can classify the common marine engine crankshaft into the following three types: Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. The bed plate provides the rigid seating of the crankshaft,. Marine Diesel Engine Crankshaft Material.

From marinerspointpro.com

Crankshaft Types, Parts, Function, Sensor, Images Marinerspoint Pro Marine Diesel Engine Crankshaft Material The bed plate provides the rigid seating of the crankshaft, which is absolutely essential for satisfactory. Crankshafts on large engines can weigh as much as 300 tonnes and are difficult to build as a single piece. We can classify the common marine engine crankshaft into the following three types: As a result, engine manufacturers developed fully built crankshafts. Forged crankshafts. Marine Diesel Engine Crankshaft Material.

From sinotrukhowo.cn

How To Maintain Crankshaft Parts 100Genuine Factory Price Marine Diesel Engine Crankshaft Material Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. We can classify the common marine engine crankshaft into the following three types: As a result, engine manufacturers developed fully built crankshafts. There are two main types of crankshafts used in ship engines: Crankshafts on large engines can weigh as much as 300. Marine Diesel Engine Crankshaft Material.

From fixwiringhospital.z21.web.core.windows.net

Parts Of A Piston Labeled Marine Diesel Engine Crankshaft Material The bed plate provides the rigid seating of the crankshaft, which is absolutely essential for satisfactory. There are two main types of crankshafts used in ship engines: Crankshafts on large engines can weigh as much as 300 tonnes and are difficult to build as a single piece. Construction materials for marine diesel engines: There are two primary types of crankshafts. Marine Diesel Engine Crankshaft Material.

From www.dieselenginespare-parts.com

3418898 Marine Diesel Engine Crankshaft Cast Iron Crankshaft 6 Cylinder Marine Diesel Engine Crankshaft Material Construction materials for marine diesel engines: Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. We can classify the common marine engine crankshaft into the following three types: Forged crankshafts are made from a solid piece. There are two primary types of crankshafts used in ship engines:. Marine Diesel Engine Crankshaft Material.

From www.marineinsight.com

Reasons for Failure and Misalignment of Crankshaft in Marine Engines Marine Diesel Engine Crankshaft Material There are two main types of crankshafts used in ship engines: Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. Forged crankshafts are made from a solid piece. There are two primary types of crankshafts used in ship engines: Construction materials for marine diesel engines: Cast crankshafts, on the other hand, are. Marine Diesel Engine Crankshaft Material.

From dragonbeeotch4sschematic.z21.web.core.windows.net

Engine Cylindrs Diagram Marine Diesel Engine Crankshaft Material Construction materials for marine diesel engines: Crankshafts on large engines can weigh as much as 300 tonnes and are difficult to build as a single piece. There are two main types of crankshafts used in ship engines: Forged crankshafts are made from a solid piece. There are two primary types of crankshafts used in ship engines: As a result, engine. Marine Diesel Engine Crankshaft Material.

From www.dieselenginespare-parts.com

3418898 Marine Diesel Engine Crankshaft Cast Iron Crankshaft 6 Cylinder Marine Diesel Engine Crankshaft Material Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. Crankshafts on large engines can weigh as much as 300 tonnes and are difficult to build as a single piece. There are two main types of crankshafts used in ship engines: Forged crankshafts are made by heating a. Marine Diesel Engine Crankshaft Material.

From marinersgalaxy.com

Crankshaft Types, Stress and Deflections marinersgalaxy Marine Diesel Engine Crankshaft Material We can classify the common marine engine crankshaft into the following three types: As a result, engine manufacturers developed fully built crankshafts. Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and. Marine Diesel Engine Crankshaft Material.

From www.reddit.com

The open crankcase and crankshaft of a WärtsiläSulzer 12 cylinder Marine Diesel Engine Crankshaft Material There are two main types of crankshafts used in ship engines: Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. The bed plate provides the rigid seating of the crankshaft, which is absolutely essential for satisfactory. Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and. Marine Diesel Engine Crankshaft Material.

From lver.hippy.jp

Crankshaft 買換応援 lver.hippy.jp Marine Diesel Engine Crankshaft Material As a result, engine manufacturers developed fully built crankshafts. There are two main types of crankshafts used in ship engines: There are two primary types of crankshafts used in ship engines: Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. Crankshafts on large engines can weigh as. Marine Diesel Engine Crankshaft Material.

From mirmarine.net

Crankshaft procedures for Inspection and Calibration MirMarine Marine Diesel Engine Crankshaft Material Construction materials for marine diesel engines: As a result, engine manufacturers developed fully built crankshafts. There are two primary types of crankshafts used in ship engines: We can classify the common marine engine crankshaft into the following three types: The bed plate provides the rigid seating of the crankshaft, which is absolutely essential for satisfactory. Cast crankshafts, on the other. Marine Diesel Engine Crankshaft Material.

From www.youtube.com

CRANK SHAFT CRANK THROWN CRANK WEB FUNCTION OF CRANK SHAFT Marine Diesel Engine Crankshaft Material Crankshafts on large engines can weigh as much as 300 tonnes and are difficult to build as a single piece. We can classify the common marine engine crankshaft into the following three types: Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. The bed plate provides the rigid seating of the crankshaft,. Marine Diesel Engine Crankshaft Material.

From studiousguy.com

Crankshaft Types, Functions & Examples StudiousGuy Marine Diesel Engine Crankshaft Material Forged crankshafts are made from a solid piece. We can classify the common marine engine crankshaft into the following three types: The bed plate provides the rigid seating of the crankshaft, which is absolutely essential for satisfactory. Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify. Construction. Marine Diesel Engine Crankshaft Material.

From www.tradeindia.com

Crankshaft For Diesel Engine at Best Price in Bhavnagar Malwi Marine Marine Diesel Engine Crankshaft Material Construction materials for marine diesel engines: We can classify the common marine engine crankshaft into the following three types: Crankshafts on large engines can weigh as much as 300 tonnes and are difficult to build as a single piece. Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and. Marine Diesel Engine Crankshaft Material.

From cgtpoleemploiara.fr

24 Valves ITM VQ35DE Eng Code Engine Crankshaft Main Bearing SetDOHC Marine Diesel Engine Crankshaft Material Forged crankshafts are made from a solid piece. The bed plate provides the rigid seating of the crankshaft, which is absolutely essential for satisfactory. There are two primary types of crankshafts used in ship engines: Construction materials for marine diesel engines: We can classify the common marine engine crankshaft into the following three types: Cast crankshafts, on the other hand,. Marine Diesel Engine Crankshaft Material.

From workshopfixoharaepos.z21.web.core.windows.net

Engine Piston Diagram Marine Diesel Engine Crankshaft Material We can classify the common marine engine crankshaft into the following three types: As a result, engine manufacturers developed fully built crankshafts. The bed plate provides the rigid seating of the crankshaft, which is absolutely essential for satisfactory. Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and allowing it to cool and solidify.. Marine Diesel Engine Crankshaft Material.

From dieselcrankshaft.en.made-in-china.com

Weichai Crankshaft/W8170 Engine Parts/Marine Diesel Engine Crankshaft Marine Diesel Engine Crankshaft Material Forged crankshafts are made by heating a solid piece of metal and then hammering it into shape. The bed plate provides the rigid seating of the crankshaft, which is absolutely essential for satisfactory. There are two primary types of crankshafts used in ship engines: Cast crankshafts, on the other hand, are created by pouring molten metal into a mold and. Marine Diesel Engine Crankshaft Material.

From eureka.patsnap.com

Marine diesel engine crankshaft casting method Eureka Patsnap Marine Diesel Engine Crankshaft Material Construction materials for marine diesel engines: Crankshafts on large engines can weigh as much as 300 tonnes and are difficult to build as a single piece. As a result, engine manufacturers developed fully built crankshafts. There are two main types of crankshafts used in ship engines: Forged crankshafts are made by heating a solid piece of metal and then hammering. Marine Diesel Engine Crankshaft Material.

From www.scribd.com

Crank Shaft & Its Deflection Measurement Engines Diesel Engine Marine Diesel Engine Crankshaft Material There are two main types of crankshafts used in ship engines: As a result, engine manufacturers developed fully built crankshafts. Crankshafts on large engines can weigh as much as 300 tonnes and are difficult to build as a single piece. The bed plate provides the rigid seating of the crankshaft, which is absolutely essential for satisfactory. Construction materials for marine. Marine Diesel Engine Crankshaft Material.