Stretch Out Length Formula . How to calculate the value of material shrinkage. Obtain the properties of the bend (bend radius, angle, and method used). This is the amount of material that needs to be added to the total length of the sheet metal to account for the bend. 8.calculate the circumference of the cylinder to determine the stretch out length of the pattern. The diameter here is 1. Essentially, you should calculate the centerline arc: To develop the blank flat length for a cylinder rolled from sheet or plate is quite simple: Sheet metal flat length = length a +. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as. With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet. When a sheet metal part is bent, it physically gets bigger. Total bend deduction in sheet metal parts can be calculated by using the following formula: Use the formula c = πd.

from raisemymarks.com

Obtain the properties of the bend (bend radius, angle, and method used). The final formed dimensions will be greater than the sum total of the outside dimensions of the part as. When a sheet metal part is bent, it physically gets bigger. Sheet metal flat length = length a +. With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet. To develop the blank flat length for a cylinder rolled from sheet or plate is quite simple: Essentially, you should calculate the centerline arc: How to calculate the value of material shrinkage. The diameter here is 1. This is the amount of material that needs to be added to the total length of the sheet metal to account for the bend.

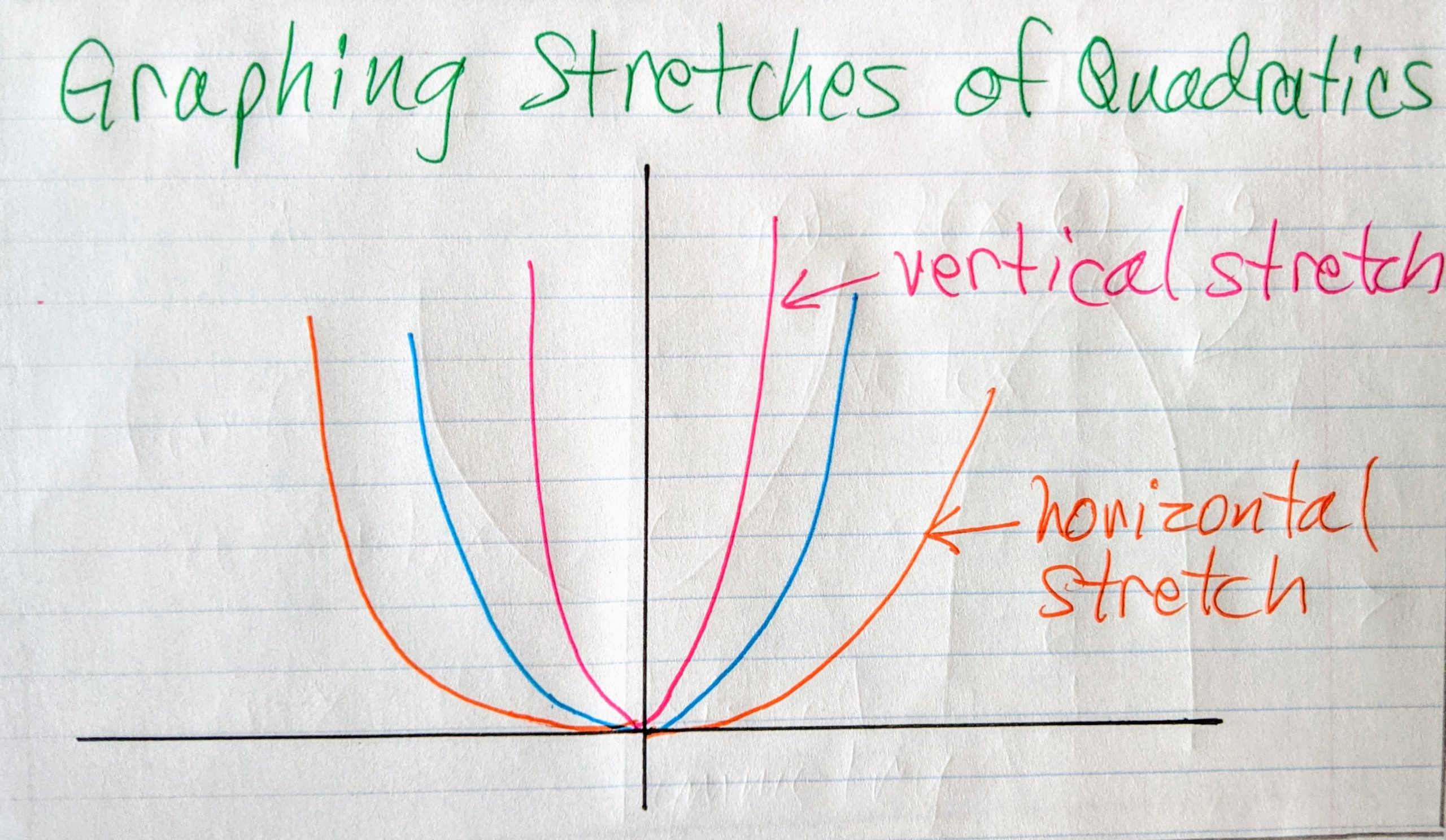

Graphing stretches of Quadratics Math Worksheets & Math Videos Ottawa

Stretch Out Length Formula This is the amount of material that needs to be added to the total length of the sheet metal to account for the bend. Total bend deduction in sheet metal parts can be calculated by using the following formula: With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as. The diameter here is 1. Essentially, you should calculate the centerline arc: Sheet metal flat length = length a +. 8.calculate the circumference of the cylinder to determine the stretch out length of the pattern. How to calculate the value of material shrinkage. This is the amount of material that needs to be added to the total length of the sheet metal to account for the bend. When a sheet metal part is bent, it physically gets bigger. To develop the blank flat length for a cylinder rolled from sheet or plate is quite simple: Use the formula c = πd. Obtain the properties of the bend (bend radius, angle, and method used).

From izwztkcdhv.blogspot.com

How To Find Vertical Stretch How do you calculate horizontal shift Stretch Out Length Formula How to calculate the value of material shrinkage. 8.calculate the circumference of the cylinder to determine the stretch out length of the pattern. With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet. Use the formula c = πd. The final formed dimensions will be greater than the sum total of the outside. Stretch Out Length Formula.

From www.youtube.com

Example Determine the Length of a Side of a Right Triangle Using a Stretch Out Length Formula Essentially, you should calculate the centerline arc: Sheet metal flat length = length a +. 8.calculate the circumference of the cylinder to determine the stretch out length of the pattern. The diameter here is 1. Obtain the properties of the bend (bend radius, angle, and method used). To develop the blank flat length for a cylinder rolled from sheet or. Stretch Out Length Formula.

From www.mashupmath.com

Using the Arc Length Formula and Sector Area Formula Complete Guide Stretch Out Length Formula How to calculate the value of material shrinkage. Sheet metal flat length = length a +. To develop the blank flat length for a cylinder rolled from sheet or plate is quite simple: When a sheet metal part is bent, it physically gets bigger. The final formed dimensions will be greater than the sum total of the outside dimensions of. Stretch Out Length Formula.

From printableshirubichanaf.z21.web.core.windows.net

Volume Formulas Sheet Stretch Out Length Formula With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet. Use the formula c = πd. This is the amount of material that needs to be added to the total length of the sheet metal to account for the bend. To develop the blank flat length for a cylinder rolled from sheet or. Stretch Out Length Formula.

From gioireddt.blob.core.windows.net

Diagonal Of Square And Rectangle Length at James Green blog Stretch Out Length Formula When a sheet metal part is bent, it physically gets bigger. Use the formula c = πd. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as. This is the amount of material that needs to be added to the total length of the sheet metal to account for the bend.. Stretch Out Length Formula.

From www.youtube.com

Function Transformations Horizontal and Vertical Stretches and Stretch Out Length Formula Sheet metal flat length = length a +. Use the formula c = πd. Total bend deduction in sheet metal parts can be calculated by using the following formula: Essentially, you should calculate the centerline arc: 8.calculate the circumference of the cylinder to determine the stretch out length of the pattern. When a sheet metal part is bent, it physically. Stretch Out Length Formula.

From www.youtube.com

Determine the stretch in each spring for equilibrium of the 2kg block Stretch Out Length Formula Use the formula c = πd. With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet. Total bend deduction in sheet metal parts can be calculated by using the following formula: To develop the blank flat length for a cylinder rolled from sheet or plate is quite simple: Obtain the properties of the. Stretch Out Length Formula.

From quizinterworks.z21.web.core.windows.net

How To Predict Bond Length Stretch Out Length Formula Essentially, you should calculate the centerline arc: Obtain the properties of the bend (bend radius, angle, and method used). Total bend deduction in sheet metal parts can be calculated by using the following formula: This is the amount of material that needs to be added to the total length of the sheet metal to account for the bend. 8.calculate the. Stretch Out Length Formula.

From lessonschooloverjumped.z5.web.core.windows.net

Arc Length And Sector Area Formulas Stretch Out Length Formula Essentially, you should calculate the centerline arc: This is the amount of material that needs to be added to the total length of the sheet metal to account for the bend. How to calculate the value of material shrinkage. Use the formula c = πd. 8.calculate the circumference of the cylinder to determine the stretch out length of the pattern.. Stretch Out Length Formula.

From www.pinterest.com

Heron’s Formula Area of a Triangle Knowing Lengths of 3 Sides Stretch Out Length Formula The diameter here is 1. Total bend deduction in sheet metal parts can be calculated by using the following formula: Use the formula c = πd. 8.calculate the circumference of the cylinder to determine the stretch out length of the pattern. With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet. To develop. Stretch Out Length Formula.

From www.youtube.com

Physics4.1.2.2 Comparing the spring constant of springs using a force Stretch Out Length Formula 8.calculate the circumference of the cylinder to determine the stretch out length of the pattern. When a sheet metal part is bent, it physically gets bigger. To develop the blank flat length for a cylinder rolled from sheet or plate is quite simple: Essentially, you should calculate the centerline arc: This is the amount of material that needs to be. Stretch Out Length Formula.

From www.youtube.com

Ex Identify Horizontal and Vertical Stretches and Compressions Stretch Out Length Formula Total bend deduction in sheet metal parts can be calculated by using the following formula: This is the amount of material that needs to be added to the total length of the sheet metal to account for the bend. To develop the blank flat length for a cylinder rolled from sheet or plate is quite simple: The diameter here is. Stretch Out Length Formula.

From www.reddit.com

HELP math with calculator r/Sat Stretch Out Length Formula The diameter here is 1. Sheet metal flat length = length a +. To develop the blank flat length for a cylinder rolled from sheet or plate is quite simple: How to calculate the value of material shrinkage. 8.calculate the circumference of the cylinder to determine the stretch out length of the pattern. This is the amount of material that. Stretch Out Length Formula.

From printablelibhofmann.z21.web.core.windows.net

Solving Special Right Triangles Worksheet Stretch Out Length Formula Sheet metal flat length = length a +. Essentially, you should calculate the centerline arc: 8.calculate the circumference of the cylinder to determine the stretch out length of the pattern. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as. Total bend deduction in sheet metal parts can be calculated by. Stretch Out Length Formula.

From learningtechnologyofficial.com

How To Calculate Length Of Chord For Circle Construction Encyclopedia Stretch Out Length Formula Sheet metal flat length = length a +. Use the formula c = πd. When a sheet metal part is bent, it physically gets bigger. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as. The diameter here is 1. Essentially, you should calculate the centerline arc: Total bend deduction in. Stretch Out Length Formula.

From www.youtube.com

Midpoint and Length of Line Segment Formula YouTube Stretch Out Length Formula How to calculate the value of material shrinkage. Use the formula c = πd. 8.calculate the circumference of the cylinder to determine the stretch out length of the pattern. Total bend deduction in sheet metal parts can be calculated by using the following formula: Obtain the properties of the bend (bend radius, angle, and method used). The diameter here is. Stretch Out Length Formula.

From ar.inspiredpencil.com

Geometry Formulas Circles Stretch Out Length Formula Sheet metal flat length = length a +. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as. Total bend deduction in sheet metal parts can be calculated by using the following formula: How to calculate the value of material shrinkage. This is the amount of material that needs to be. Stretch Out Length Formula.

From www.youtube.com

Ex Function Notation for Horizontal and Vertical Stretches and Stretch Out Length Formula Use the formula c = πd. With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet. How to calculate the value of material shrinkage. Essentially, you should calculate the centerline arc: This is the amount of material that needs to be added to the total length of the sheet metal to account for. Stretch Out Length Formula.

From dbdalrymplesibships.z21.web.core.windows.net

Formula For The Area Of A Scalene Triangle Stretch Out Length Formula With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet. Sheet metal flat length = length a +. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as. Use the formula c = πd. Total bend deduction in sheet metal parts can be calculated. Stretch Out Length Formula.

From printablefullfolia.z13.web.core.windows.net

Arc Length And Sector Area Formulas Stretch Out Length Formula 8.calculate the circumference of the cylinder to determine the stretch out length of the pattern. Obtain the properties of the bend (bend radius, angle, and method used). Use the formula c = πd. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as. This is the amount of material that needs. Stretch Out Length Formula.

From raisemymarks.com

Graphing stretches of Quadratics Math Worksheets & Math Videos Ottawa Stretch Out Length Formula 8.calculate the circumference of the cylinder to determine the stretch out length of the pattern. Sheet metal flat length = length a +. The diameter here is 1. Obtain the properties of the bend (bend radius, angle, and method used). How to calculate the value of material shrinkage. With this free online tool we quickly get the sheet metal bend. Stretch Out Length Formula.

From animalia-life.club

Isosceles Triangle Side Lengths Stretch Out Length Formula To develop the blank flat length for a cylinder rolled from sheet or plate is quite simple: The final formed dimensions will be greater than the sum total of the outside dimensions of the part as. With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet. 8.calculate the circumference of the cylinder to. Stretch Out Length Formula.

From www.youtube.com

Arc Length Theorem YouTube Stretch Out Length Formula This is the amount of material that needs to be added to the total length of the sheet metal to account for the bend. Obtain the properties of the bend (bend radius, angle, and method used). Essentially, you should calculate the centerline arc: Sheet metal flat length = length a +. To develop the blank flat length for a cylinder. Stretch Out Length Formula.

From fyopwakbp.blob.core.windows.net

How To Find The Angle Of A Right Triangle Formula at Denise Green blog Stretch Out Length Formula Essentially, you should calculate the centerline arc: Total bend deduction in sheet metal parts can be calculated by using the following formula: Use the formula c = πd. Sheet metal flat length = length a +. How to calculate the value of material shrinkage. 8.calculate the circumference of the cylinder to determine the stretch out length of the pattern. The. Stretch Out Length Formula.

From www.youtube.com

How To Calculate Length Of Chord For Circle Learning Technology YouTube Stretch Out Length Formula The final formed dimensions will be greater than the sum total of the outside dimensions of the part as. This is the amount of material that needs to be added to the total length of the sheet metal to account for the bend. Use the formula c = πd. Sheet metal flat length = length a +. 8.calculate the circumference. Stretch Out Length Formula.

From www.youtube.com

Ex Find the Work Required to Stretch a Spring (Integration App) YouTube Stretch Out Length Formula Sheet metal flat length = length a +. With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet. To develop the blank flat length for a cylinder rolled from sheet or plate is quite simple: When a sheet metal part is bent, it physically gets bigger. The diameter here is 1. 8.calculate the. Stretch Out Length Formula.

From ar.inspiredpencil.com

Arc Length Formula Stretch Out Length Formula The diameter here is 1. Use the formula c = πd. Total bend deduction in sheet metal parts can be calculated by using the following formula: When a sheet metal part is bent, it physically gets bigger. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as. How to calculate the. Stretch Out Length Formula.

From mathmonks.com

Hypotenuse of a Triangle Definition, Formulas Stretch Out Length Formula Essentially, you should calculate the centerline arc: The final formed dimensions will be greater than the sum total of the outside dimensions of the part as. To develop the blank flat length for a cylinder rolled from sheet or plate is quite simple: Sheet metal flat length = length a +. Use the formula c = πd. The diameter here. Stretch Out Length Formula.

From fitdentistcouple.com

Importance and Benefits of Stretching A Quick Guide Change Makers Stretch Out Length Formula How to calculate the value of material shrinkage. Obtain the properties of the bend (bend radius, angle, and method used). With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet. The diameter here is 1. The final formed dimensions will be greater than the sum total of the outside dimensions of the part. Stretch Out Length Formula.

From learningnumerolin1.z21.web.core.windows.net

Calculate The Wave Number Of A Wave Stretch Out Length Formula This is the amount of material that needs to be added to the total length of the sheet metal to account for the bend. Obtain the properties of the bend (bend radius, angle, and method used). To develop the blank flat length for a cylinder rolled from sheet or plate is quite simple: How to calculate the value of material. Stretch Out Length Formula.

From www.dailycivil.com

How To Calculate Bend Deduction Length Of Bar Stretch Out Length Formula The diameter here is 1. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as. Obtain the properties of the bend (bend radius, angle, and method used). Use the formula c = πd. Total bend deduction in sheet metal parts can be calculated by using the following formula: 8.calculate the circumference. Stretch Out Length Formula.

From owlcation.com

How to Calculate Arc Length of a Circle, Segment and Sector Area Stretch Out Length Formula 8.calculate the circumference of the cylinder to determine the stretch out length of the pattern. The diameter here is 1. With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet. Use the formula c = πd. The final formed dimensions will be greater than the sum total of the outside dimensions of the. Stretch Out Length Formula.

From www.emathinstruction.com

Vertical Stretching and Compressing of Functions eMATHinstruction Stretch Out Length Formula 8.calculate the circumference of the cylinder to determine the stretch out length of the pattern. How to calculate the value of material shrinkage. Sheet metal flat length = length a +. Use the formula c = πd. When a sheet metal part is bent, it physically gets bigger. With this free online tool we quickly get the sheet metal bend. Stretch Out Length Formula.

From gioaekslg.blob.core.windows.net

Arc Length Calculator For Circle at Glenn Judkins blog Stretch Out Length Formula How to calculate the value of material shrinkage. Sheet metal flat length = length a +. Obtain the properties of the bend (bend radius, angle, and method used). 8.calculate the circumference of the cylinder to determine the stretch out length of the pattern. The diameter here is 1. Total bend deduction in sheet metal parts can be calculated by using. Stretch Out Length Formula.

From www.slideserve.com

PPT Lec 23, Ch.16, pp.692708 Horizontal alignment (objectives Stretch Out Length Formula How to calculate the value of material shrinkage. The diameter here is 1. Obtain the properties of the bend (bend radius, angle, and method used). The final formed dimensions will be greater than the sum total of the outside dimensions of the part as. When a sheet metal part is bent, it physically gets bigger. Total bend deduction in sheet. Stretch Out Length Formula.