Silver Solder Vs Epoxy . Two component, silver filled epoxy systems offer convenient mix ratios (1:1) and cure at room temperatures. Cost of filler and cost of bonding processes. Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing on heat sensitive substrates. • it is industry legacy and common sense that noble metals like to be. Because there is less shrinkage,. Performance in service (based on. August 11, 2016 by gustavo greca. For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. The three main guiding principles are:

from www.mdpi.com

For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. August 11, 2016 by gustavo greca. Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing on heat sensitive substrates. • it is industry legacy and common sense that noble metals like to be. Cost of filler and cost of bonding processes. The three main guiding principles are: Performance in service (based on. Because there is less shrinkage,. Two component, silver filled epoxy systems offer convenient mix ratios (1:1) and cure at room temperatures.

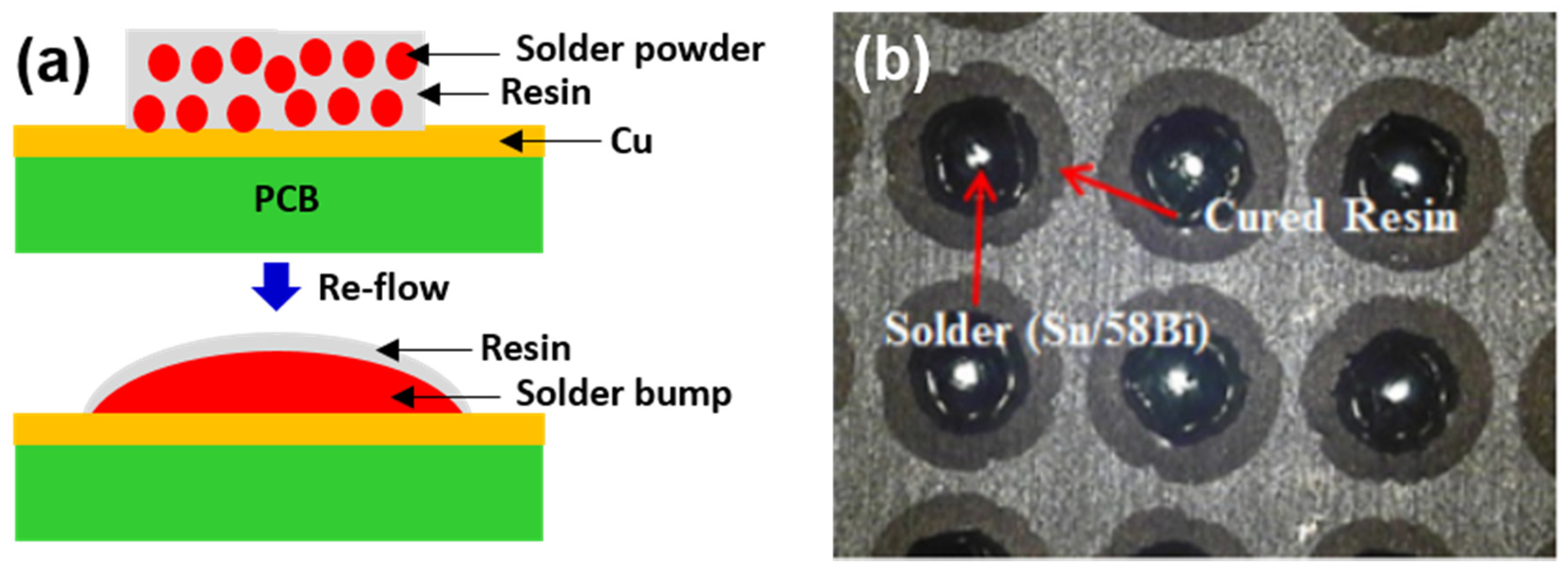

Metals Free FullText Low Melting Temperature SnBi Solder Effect

Silver Solder Vs Epoxy Two component, silver filled epoxy systems offer convenient mix ratios (1:1) and cure at room temperatures. For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. Performance in service (based on. August 11, 2016 by gustavo greca. Because there is less shrinkage,. Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing on heat sensitive substrates. Two component, silver filled epoxy systems offer convenient mix ratios (1:1) and cure at room temperatures. Cost of filler and cost of bonding processes. • it is industry legacy and common sense that noble metals like to be. The three main guiding principles are:

From dxocpehzl.blob.core.windows.net

Silver Soldering Vs Brazing at Mary Brennan blog Silver Solder Vs Epoxy For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing on heat sensitive substrates. Because there is less shrinkage,. August 11, 2016 by gustavo greca. Performance in service (based on. • it is industry. Silver Solder Vs Epoxy.

From www.mdpi.com

Polymers Free FullText Microstructure and Shear Behaviour of Sn3 Silver Solder Vs Epoxy Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing on heat sensitive substrates. Performance in service (based on. Two component, silver filled epoxy systems offer convenient mix ratios (1:1) and cure at room temperatures. For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface. Silver Solder Vs Epoxy.

From eprpartner.com

Conductive epoxy glue versus soldering for SMT devices EPR Silver Solder Vs Epoxy The three main guiding principles are: Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing on heat sensitive substrates. For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. Two component, silver filled epoxy systems offer convenient mix ratios (1:1) and cure at. Silver Solder Vs Epoxy.

From www.mdpi.com

Metals Free FullText Low Melting Temperature SnBi Solder Effect Silver Solder Vs Epoxy Two component, silver filled epoxy systems offer convenient mix ratios (1:1) and cure at room temperatures. • it is industry legacy and common sense that noble metals like to be. August 11, 2016 by gustavo greca. The three main guiding principles are: For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off. Silver Solder Vs Epoxy.

From www.youtube.com

Leaded VS Lead Free(which one is the best for soldering) YouTube Silver Solder Vs Epoxy For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. August 11, 2016 by gustavo greca. Cost of filler and cost of bonding processes. The three main guiding principles are: • it is industry legacy and common sense that noble metals like to be. Performance in service (based on. Because. Silver Solder Vs Epoxy.

From www.cruxweld.com

The Difference between Soldering and Brazing with Welding [The Silver Solder Vs Epoxy August 11, 2016 by gustavo greca. For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. Performance in service (based on. Cost of filler and cost of bonding processes. Two component, silver filled epoxy systems offer convenient mix ratios (1:1) and cure at room temperatures. The three main guiding principles. Silver Solder Vs Epoxy.

From leaderland.academy

Vs 15 Silver Solder Reasonable Price leaderland.academy Silver Solder Vs Epoxy August 11, 2016 by gustavo greca. Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing on heat sensitive substrates. For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. • it is industry legacy and common sense that noble metals like to be.. Silver Solder Vs Epoxy.

From www.masterbond.com

New Highly Flexible Silver Conductive Epoxy Adhesive Silver Solder Vs Epoxy Two component, silver filled epoxy systems offer convenient mix ratios (1:1) and cure at room temperatures. For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing on heat sensitive substrates. Cost of filler and. Silver Solder Vs Epoxy.

From mgchemicals.com

Electrically Conductive Paste Silver Solder Vs Epoxy Cost of filler and cost of bonding processes. August 11, 2016 by gustavo greca. For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. Two component, silver filled epoxy systems offer convenient mix ratios (1:1) and cure at room temperatures. Performance in service (based on. Because there is less shrinkage,.. Silver Solder Vs Epoxy.

From oscarholloway.z13.web.core.windows.net

Silver Solder Melting Temperature Chart Silver Solder Vs Epoxy For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. Two component, silver filled epoxy systems offer convenient mix ratios (1:1) and cure at room temperatures. August 11, 2016 by gustavo greca. Cost of filler and cost of bonding processes. • it is industry legacy and common sense that noble. Silver Solder Vs Epoxy.

From cedeqtmf.blob.core.windows.net

Lead Free Solder Oxidation at Lucille Tunstall blog Silver Solder Vs Epoxy For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. Performance in service (based on. The three main guiding principles are: • it is industry legacy and common sense that noble metals like to be. Because there is less shrinkage,. August 11, 2016 by gustavo greca. Cost of filler and. Silver Solder Vs Epoxy.

From exyfjqayc.blob.core.windows.net

Brazed Joint Vs Solder Joint at Barbara Deroche blog Silver Solder Vs Epoxy Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing on heat sensitive substrates. Cost of filler and cost of bonding processes. The three main guiding principles are: August 11, 2016 by gustavo greca. • it is industry legacy and common sense that noble metals like to be. For example, for silver sintering, processing. Silver Solder Vs Epoxy.

From blog.thepipingmart.com

Brazing vs Silver Soldering What's the Difference Silver Solder Vs Epoxy • it is industry legacy and common sense that noble metals like to be. Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing on heat sensitive substrates. For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. Because there is less shrinkage,. Two. Silver Solder Vs Epoxy.

From www.youtube.com

How To Easily Solder Wires Together(No Soldering Iron) YouTube Silver Solder Vs Epoxy • it is industry legacy and common sense that noble metals like to be. Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing on heat sensitive substrates. Two component, silver filled epoxy systems offer convenient mix ratios (1:1) and cure at room temperatures. August 11, 2016 by gustavo greca. The three main guiding. Silver Solder Vs Epoxy.

From www.circuitspecialists.com

8331D120G Silver Conductive Epoxy Adhesive Silver Solder Vs Epoxy Performance in service (based on. The three main guiding principles are: Two component, silver filled epoxy systems offer convenient mix ratios (1:1) and cure at room temperatures. For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. Cost of filler and cost of bonding processes. Silver epoxies can cure at. Silver Solder Vs Epoxy.

From www.mdpi.com

Materials Free FullText Effects of Multiple Reflow on the Silver Solder Vs Epoxy Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing on heat sensitive substrates. For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. August 11, 2016 by gustavo greca. The three main guiding principles are: Performance in service (based on. Cost of filler. Silver Solder Vs Epoxy.

From www.homedepot.com

Bernzomatic 4 oz. Silver Solder Wire Solder333544 The Home Depot Silver Solder Vs Epoxy Cost of filler and cost of bonding processes. • it is industry legacy and common sense that noble metals like to be. Two component, silver filled epoxy systems offer convenient mix ratios (1:1) and cure at room temperatures. August 11, 2016 by gustavo greca. Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing. Silver Solder Vs Epoxy.

From hvacrschool.com

5 vs. 15 Silver Solder (Brazing Rod) HVAC School Silver Solder Vs Epoxy • it is industry legacy and common sense that noble metals like to be. Cost of filler and cost of bonding processes. Because there is less shrinkage,. Two component, silver filled epoxy systems offer convenient mix ratios (1:1) and cure at room temperatures. For example, for silver sintering, processing under airy conditions is preferred based on the need to burn. Silver Solder Vs Epoxy.

From www.protoexpress.com

A Practical Guide to Soldering Flux Sierra Circuits Silver Solder Vs Epoxy Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing on heat sensitive substrates. Cost of filler and cost of bonding processes. For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. Performance in service (based on. August 11, 2016 by gustavo greca. Because. Silver Solder Vs Epoxy.

From azepoxyfloorcoatings.com

Polyurea vs. Polyaspartic vs. Epoxy Comparing The Leading Concrete Silver Solder Vs Epoxy For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. • it is industry legacy and common sense that noble metals like to be. Performance in service (based on. August 11, 2016 by gustavo greca. The three main guiding principles are: Because there is less shrinkage,. Two component, silver filled. Silver Solder Vs Epoxy.

From www.researchgate.net

Actual images of devices surfacemounted using epoxy solder paste Silver Solder Vs Epoxy Two component, silver filled epoxy systems offer convenient mix ratios (1:1) and cure at room temperatures. August 11, 2016 by gustavo greca. For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing on heat. Silver Solder Vs Epoxy.

From www.reddit.com

Silver Solder? Epoxy? Best way to fixit? r/fixit Silver Solder Vs Epoxy • it is industry legacy and common sense that noble metals like to be. Cost of filler and cost of bonding processes. For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. The three main guiding principles are: Performance in service (based on. August 11, 2016 by gustavo greca. Silver. Silver Solder Vs Epoxy.

From www.youtube.com

Solder wire Low Quality Lead vs Lead Free YouTube Silver Solder Vs Epoxy For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. Because there is less shrinkage,. Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing on heat sensitive substrates. Two component, silver filled epoxy systems offer convenient mix ratios (1:1) and cure at room. Silver Solder Vs Epoxy.

From www.klrforum.com

gas tank leak, center seam cracked? solder vs epoxy vs replace Silver Solder Vs Epoxy Performance in service (based on. August 11, 2016 by gustavo greca. Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing on heat sensitive substrates. • it is industry legacy and common sense that noble metals like to be. Because there is less shrinkage,. Two component, silver filled epoxy systems offer convenient mix ratios. Silver Solder Vs Epoxy.

From exowllzqh.blob.core.windows.net

Can You Desolder And Solder Copper Pipe at Thomas Brown blog Silver Solder Vs Epoxy Cost of filler and cost of bonding processes. • it is industry legacy and common sense that noble metals like to be. Two component, silver filled epoxy systems offer convenient mix ratios (1:1) and cure at room temperatures. The three main guiding principles are: Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing. Silver Solder Vs Epoxy.

From www.protoexpress.com

IPC Class 2 vs 3 The Different Design Rules Sierra Circuits Silver Solder Vs Epoxy The three main guiding principles are: • it is industry legacy and common sense that noble metals like to be. Because there is less shrinkage,. Performance in service (based on. August 11, 2016 by gustavo greca. For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. Silver epoxies can cure. Silver Solder Vs Epoxy.

From www.mgchemicals.com

8331D Silver Conductive Epoxy Adhesive MG Chemicals Silver Solder Vs Epoxy Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing on heat sensitive substrates. Performance in service (based on. The three main guiding principles are: Two component, silver filled epoxy systems offer convenient mix ratios (1:1) and cure at room temperatures. August 11, 2016 by gustavo greca. Cost of filler and cost of bonding. Silver Solder Vs Epoxy.

From www.mdpi.com

Crystals Free FullText Study on the Reliability of SnBi Composite Silver Solder Vs Epoxy August 11, 2016 by gustavo greca. Performance in service (based on. The three main guiding principles are: Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing on heat sensitive substrates. For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. • it is. Silver Solder Vs Epoxy.

From exoupzxbj.blob.core.windows.net

Lead Free Solder Vs Lead Solder Melting Point at William McIntyre blog Silver Solder Vs Epoxy • it is industry legacy and common sense that noble metals like to be. The three main guiding principles are: Performance in service (based on. Because there is less shrinkage,. August 11, 2016 by gustavo greca. Cost of filler and cost of bonding processes. Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing. Silver Solder Vs Epoxy.

From blog.thepipingmart.com

Wedge Anchor vs Epoxy What's the Difference Silver Solder Vs Epoxy Cost of filler and cost of bonding processes. Performance in service (based on. August 11, 2016 by gustavo greca. Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing on heat sensitive substrates. For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. Two. Silver Solder Vs Epoxy.

From www.stickyaide.com

JB Weld Vs. Epoxy Some Major Differences Sticky Aide Silver Solder Vs Epoxy Two component, silver filled epoxy systems offer convenient mix ratios (1:1) and cure at room temperatures. For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. Because there is less shrinkage,. Performance in service (based on. August 11, 2016 by gustavo greca. The three main guiding principles are: Cost of. Silver Solder Vs Epoxy.

From wiredataboettiy2.z21.web.core.windows.net

How To Connect Wires With Solder Silver Solder Vs Epoxy • it is industry legacy and common sense that noble metals like to be. The three main guiding principles are: Performance in service (based on. Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing on heat sensitive substrates. Because there is less shrinkage,. Two component, silver filled epoxy systems offer convenient mix ratios. Silver Solder Vs Epoxy.

From www.walmart.com

Silver Solder Paste Easy With Flux 1/2 Oz Troy(15.5 g) Syringe Silver Solder Vs Epoxy Cost of filler and cost of bonding processes. The three main guiding principles are: Two component, silver filled epoxy systems offer convenient mix ratios (1:1) and cure at room temperatures. Performance in service (based on. • it is industry legacy and common sense that noble metals like to be. For example, for silver sintering, processing under airy conditions is preferred. Silver Solder Vs Epoxy.

From titoma.com

How to Solder Components? Guide to an Expert Titoma Silver Solder Vs Epoxy Two component, silver filled epoxy systems offer convenient mix ratios (1:1) and cure at room temperatures. Cost of filler and cost of bonding processes. The three main guiding principles are: Performance in service (based on. Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing on heat sensitive substrates. Because there is less shrinkage,.. Silver Solder Vs Epoxy.

From www.epodex.us

Countertop & Tabletop Epoxy Resin Kit EPODEX USA Silver Solder Vs Epoxy Because there is less shrinkage,. For example, for silver sintering, processing under airy conditions is preferred based on the need to burn off surface stabilizer. August 11, 2016 by gustavo greca. The three main guiding principles are: Silver epoxies can cure at room temperature or low elevated temperatures, making them ideal for processing on heat sensitive substrates. Cost of filler. Silver Solder Vs Epoxy.