Shaper In Metalworking . They have a cutter mounted on a. Shapers are machine tools that are designed to remove large amounts of material from a metal workpiece. The shaper machine is a reciprocating type of machine used for producing horizontal, vertical or flat surfaces. Following are different shaper machine operations such as machining horizontal, vertical, angular, irregular surfaces, cutting slots, keyways. Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and while moving forward. In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind of metal. Shaper machines are commonly used to shape metal surfaces, and create slots, keyways, dovetails, and gear teeth in machine parts. Shaping is a process of machining a flat surface which may be horizontal, vertical, inclined, concave, or convex using a reciprocating single.

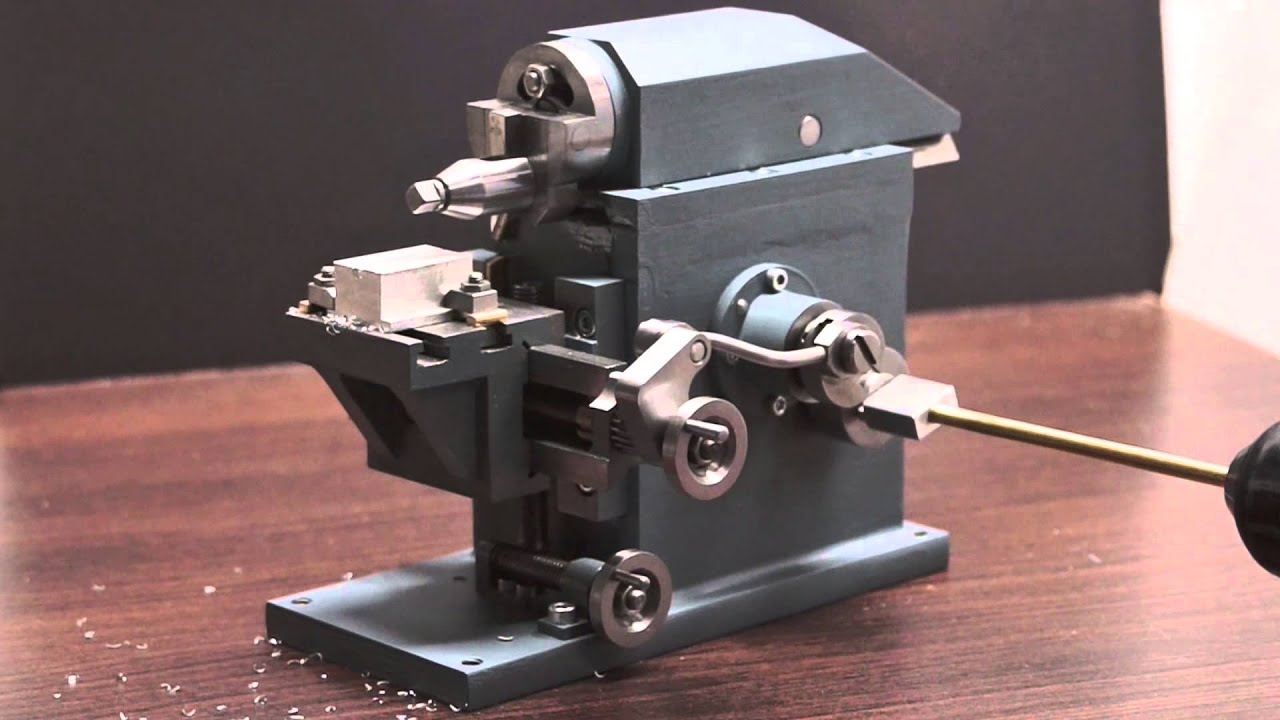

from www.youtube.com

Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and while moving forward. Shaping is a process of machining a flat surface which may be horizontal, vertical, inclined, concave, or convex using a reciprocating single. They have a cutter mounted on a. Following are different shaper machine operations such as machining horizontal, vertical, angular, irregular surfaces, cutting slots, keyways. Shapers are machine tools that are designed to remove large amounts of material from a metal workpiece. Shaper machines are commonly used to shape metal surfaces, and create slots, keyways, dovetails, and gear teeth in machine parts. The shaper machine is a reciprocating type of machine used for producing horizontal, vertical or flat surfaces. In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind of metal.

Model of a horizontal Metal Shaper YouTube

Shaper In Metalworking Following are different shaper machine operations such as machining horizontal, vertical, angular, irregular surfaces, cutting slots, keyways. In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind of metal. The shaper machine is a reciprocating type of machine used for producing horizontal, vertical or flat surfaces. Shapers are machine tools that are designed to remove large amounts of material from a metal workpiece. Following are different shaper machine operations such as machining horizontal, vertical, angular, irregular surfaces, cutting slots, keyways. They have a cutter mounted on a. Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and while moving forward. Shaping is a process of machining a flat surface which may be horizontal, vertical, inclined, concave, or convex using a reciprocating single. Shaper machines are commonly used to shape metal surfaces, and create slots, keyways, dovetails, and gear teeth in machine parts.

From www.pinterest.com

South Bend Metal Shaper Metal working tools, Machine tools, Machine shop Shaper In Metalworking The shaper machine is a reciprocating type of machine used for producing horizontal, vertical or flat surfaces. They have a cutter mounted on a. Shaping is a process of machining a flat surface which may be horizontal, vertical, inclined, concave, or convex using a reciprocating single. In setting up a mechanically operated shaper, the length of cut (in inches) is. Shaper In Metalworking.

From www.elitemetaltools.com

Jet JWS25X JET Shaper 3HP 1PH Elite Metal Tools Shaper In Metalworking In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind of metal. Shapers are machine tools that are designed to remove large amounts of material from a metal workpiece. The shaper machine is a reciprocating type of machine used for producing. Shaper In Metalworking.

From www.pinterest.ca

Acto 6 Hand Metal Shaper Plans Machinery Plans Shaper, Metal Shaper In Metalworking The shaper machine is a reciprocating type of machine used for producing horizontal, vertical or flat surfaces. Shaping is a process of machining a flat surface which may be horizontal, vertical, inclined, concave, or convex using a reciprocating single. Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and. Shaper In Metalworking.

From www.pinterest.es

Atlas Shaper Machinist tools, Lathe tools, Machine tools Shaper In Metalworking Following are different shaper machine operations such as machining horizontal, vertical, angular, irregular surfaces, cutting slots, keyways. Shapers are machine tools that are designed to remove large amounts of material from a metal workpiece. Shaper machines are commonly used to shape metal surfaces, and create slots, keyways, dovetails, and gear teeth in machine parts. Shaping is a process of machining. Shaper In Metalworking.

From www.proshaper.com

Pro Shaper Sheet Metal LLC Shaper In Metalworking Shaping is a process of machining a flat surface which may be horizontal, vertical, inclined, concave, or convex using a reciprocating single. In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind of metal. Shapers are machine tools that are designed. Shaper In Metalworking.

From lzmachine.en.made-in-china.com

B635A Horizontal Small high precision planer Metal mini Shaper Machine Shaper In Metalworking Shaping is a process of machining a flat surface which may be horizontal, vertical, inclined, concave, or convex using a reciprocating single. Shapers are machine tools that are designed to remove large amounts of material from a metal workpiece. Shaper machines are commonly used to shape metal surfaces, and create slots, keyways, dovetails, and gear teeth in machine parts. The. Shaper In Metalworking.

From www.lathes.co.uk

Royal & Viveroy Shaper Shaper In Metalworking Shaper machines are commonly used to shape metal surfaces, and create slots, keyways, dovetails, and gear teeth in machine parts. The shaper machine is a reciprocating type of machine used for producing horizontal, vertical or flat surfaces. In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute). Shaper In Metalworking.

From www.youtube.com

Metal shaper project pedestal grinder tool rest YouTube Shaper In Metalworking Shapers are machine tools that are designed to remove large amounts of material from a metal workpiece. Following are different shaper machine operations such as machining horizontal, vertical, angular, irregular surfaces, cutting slots, keyways. The shaper machine is a reciprocating type of machine used for producing horizontal, vertical or flat surfaces. Shaping is a process of machining a flat surface. Shaper In Metalworking.

From www.pinterest.com

Atlas Shaper Milling machine, Shaper, Metal working Shaper In Metalworking Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and while moving forward. The shaper machine is a reciprocating type of machine used for producing horizontal, vertical or flat surfaces. Shapers are machine tools that are designed to remove large amounts of material from a metal workpiece. Shaper machines. Shaper In Metalworking.

From www.theengineerspost.com

Shaper Machine Types of Shaper Machines [Full & Easy Guide] Shaper In Metalworking Following are different shaper machine operations such as machining horizontal, vertical, angular, irregular surfaces, cutting slots, keyways. The shaper machine is a reciprocating type of machine used for producing horizontal, vertical or flat surfaces. Shaping is a process of machining a flat surface which may be horizontal, vertical, inclined, concave, or convex using a reciprocating single. In setting up a. Shaper In Metalworking.

From www.youtube.com

metal shaper in action YouTube Shaper In Metalworking Shapers are machine tools that are designed to remove large amounts of material from a metal workpiece. The shaper machine is a reciprocating type of machine used for producing horizontal, vertical or flat surfaces. Following are different shaper machine operations such as machining horizontal, vertical, angular, irregular surfaces, cutting slots, keyways. They have a cutter mounted on a. Shaper machines. Shaper In Metalworking.

From www.lathes.co.uk

Cowell Handoperated Shaper Shaper In Metalworking Shapers are machine tools that are designed to remove large amounts of material from a metal workpiece. The shaper machine is a reciprocating type of machine used for producing horizontal, vertical or flat surfaces. Shaper machines are commonly used to shape metal surfaces, and create slots, keyways, dovetails, and gear teeth in machine parts. Following are different shaper machine operations. Shaper In Metalworking.

From guidebytips.com

Shaper Machine Different Types of Shaper Machine [A Detailed Guide] Shaper In Metalworking Shaper machines are commonly used to shape metal surfaces, and create slots, keyways, dovetails, and gear teeth in machine parts. The shaper machine is a reciprocating type of machine used for producing horizontal, vertical or flat surfaces. Following are different shaper machine operations such as machining horizontal, vertical, angular, irregular surfaces, cutting slots, keyways. In setting up a mechanically operated. Shaper In Metalworking.

From www.youtube.com

Boxford 8 inch Shaper Quick look YouTube Shaper In Metalworking They have a cutter mounted on a. Shapers are machine tools that are designed to remove large amounts of material from a metal workpiece. In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind of metal. Following are different shaper machine. Shaper In Metalworking.

From www.youtube.com

Rhodes metal shaper YouTube Shaper In Metalworking Shaper machines are commonly used to shape metal surfaces, and create slots, keyways, dovetails, and gear teeth in machine parts. In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind of metal. Shaper machine is a production machine in which the. Shaper In Metalworking.

From grabcad.com

Free CAD Designs, Files & 3D Models The GrabCAD Community Library Shaper In Metalworking Following are different shaper machine operations such as machining horizontal, vertical, angular, irregular surfaces, cutting slots, keyways. Shapers are machine tools that are designed to remove large amounts of material from a metal workpiece. Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and while moving forward. In setting. Shaper In Metalworking.

From www.linquip.com

Shaper Machine A Full Explanatory Guide for Buyers Linquip Shaper In Metalworking The shaper machine is a reciprocating type of machine used for producing horizontal, vertical or flat surfaces. They have a cutter mounted on a. Shapers are machine tools that are designed to remove large amounts of material from a metal workpiece. Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is. Shaper In Metalworking.

From www.pinterest.se

Metal shaper PLANS (Acto Super 8) Shaper, Metal working machines Shaper In Metalworking The shaper machine is a reciprocating type of machine used for producing horizontal, vertical or flat surfaces. Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and while moving forward. Shaper machines are commonly used to shape metal surfaces, and create slots, keyways, dovetails, and gear teeth in machine. Shaper In Metalworking.

From www.youtube.com

Model of a horizontal Metal Shaper YouTube Shaper In Metalworking In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind of metal. Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and while moving forward. The shaper machine is a. Shaper In Metalworking.

From www.youtube.com

model metal cutting shaper metal shaper. YouTube Shaper In Metalworking They have a cutter mounted on a. Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and while moving forward. In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind. Shaper In Metalworking.

From mudar-m.com

Exploring the World of Gear Shapers in Metalworking MUDARM Shaper In Metalworking Shaping is a process of machining a flat surface which may be horizontal, vertical, inclined, concave, or convex using a reciprocating single. Shaper machines are commonly used to shape metal surfaces, and create slots, keyways, dovetails, and gear teeth in machine parts. In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting. Shaper In Metalworking.

From www.lzcncmachine.com

B635 Metal Shaper Machine CNC Hydraulic Shaper, Slotting Machine Shaper In Metalworking In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind of metal. Shaper machines are commonly used to shape metal surfaces, and create slots, keyways, dovetails, and gear teeth in machine parts. Shapers are machine tools that are designed to remove. Shaper In Metalworking.

From www.cnclathe-machine.com

High Precision Horizontal Planer Shaper Machine Metal Shaping Machine Tool Shaper In Metalworking They have a cutter mounted on a. Shapers are machine tools that are designed to remove large amounts of material from a metal workpiece. Following are different shaper machine operations such as machining horizontal, vertical, angular, irregular surfaces, cutting slots, keyways. The shaper machine is a reciprocating type of machine used for producing horizontal, vertical or flat surfaces. Shaper machine. Shaper In Metalworking.

From www.pinterest.fr

South Bend Shaper Machine shop projects, Machinist tool box, Metal Shaper In Metalworking The shaper machine is a reciprocating type of machine used for producing horizontal, vertical or flat surfaces. Shaping is a process of machining a flat surface which may be horizontal, vertical, inclined, concave, or convex using a reciprocating single. Shapers are machine tools that are designed to remove large amounts of material from a metal workpiece. They have a cutter. Shaper In Metalworking.

From www.engineeringchoice.com

What Is Shaper Machine? Definition, Parts, Working Shaper In Metalworking Shapers are machine tools that are designed to remove large amounts of material from a metal workpiece. Shaping is a process of machining a flat surface which may be horizontal, vertical, inclined, concave, or convex using a reciprocating single. Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and. Shaper In Metalworking.

From userlibrarybaumgaertner.z19.web.core.windows.net

Manual Metal Shaper Shaper In Metalworking The shaper machine is a reciprocating type of machine used for producing horizontal, vertical or flat surfaces. Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and while moving forward. Shapers are machine tools that are designed to remove large amounts of material from a metal workpiece. Shaping is. Shaper In Metalworking.

From makercise.com

Metal Shaper A Homemade Machine Tool for DIY Metalworking Projects Shaper In Metalworking In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind of metal. Shaping is a process of machining a flat surface which may be horizontal, vertical, inclined, concave, or convex using a reciprocating single. Following are different shaper machine operations such. Shaper In Metalworking.

From www.youtube.com

Metal Shaper tool post project YouTube Shaper In Metalworking Shaping is a process of machining a flat surface which may be horizontal, vertical, inclined, concave, or convex using a reciprocating single. The shaper machine is a reciprocating type of machine used for producing horizontal, vertical or flat surfaces. Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and. Shaper In Metalworking.

From www.youtube.com

Metal Shaper Action MitAMit YouTube Shaper In Metalworking Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and while moving forward. Following are different shaper machine operations such as machining horizontal, vertical, angular, irregular surfaces, cutting slots, keyways. Shaping is a process of machining a flat surface which may be horizontal, vertical, inclined, concave, or convex using. Shaper In Metalworking.

From www.hotrod.com

Basic Techniques To MetalShaping From Home Hot Rod Network Shaper In Metalworking In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind of metal. The shaper machine is a reciprocating type of machine used for producing horizontal, vertical or flat surfaces. Shaper machine is a production machine in which the single point cutting. Shaper In Metalworking.

From www.machineryconsultants.com

Smith & Mills 25″ HD Mechanical Horizontal Shaper Machinery Consultants Shaper In Metalworking The shaper machine is a reciprocating type of machine used for producing horizontal, vertical or flat surfaces. Shapers are machine tools that are designed to remove large amounts of material from a metal workpiece. Shaping is a process of machining a flat surface which may be horizontal, vertical, inclined, concave, or convex using a reciprocating single. In setting up a. Shaper In Metalworking.

From www.youtube.com

Metal Shaper YouTube Shaper In Metalworking The shaper machine is a reciprocating type of machine used for producing horizontal, vertical or flat surfaces. Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and while moving forward. Shaping is a process of machining a flat surface which may be horizontal, vertical, inclined, concave, or convex using. Shaper In Metalworking.

From cncwmt.com

BC6066 Horizontal Metal Planner Shaper Machine for Metal Shaper In Metalworking The shaper machine is a reciprocating type of machine used for producing horizontal, vertical or flat surfaces. Shaping is a process of machining a flat surface which may be horizontal, vertical, inclined, concave, or convex using a reciprocating single. Shapers are machine tools that are designed to remove large amounts of material from a metal workpiece. Shaper machine is a. Shaper In Metalworking.

From www.pinterest.co.uk

Adept Shapers Metal working machines, Metal working, Shapers Shaper In Metalworking They have a cutter mounted on a. In setting up a mechanically operated shaper, the length of cut (in inches) is known, and the cutting speed (in feet per minute) is selected according to the kind of metal. Following are different shaper machine operations such as machining horizontal, vertical, angular, irregular surfaces, cutting slots, keyways. Shaper machines are commonly used. Shaper In Metalworking.

From www.lathes.co.uk

Cowell Handoperated Shaper Shaper In Metalworking They have a cutter mounted on a. Shaping is a process of machining a flat surface which may be horizontal, vertical, inclined, concave, or convex using a reciprocating single. Shaper machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and while moving forward. The shaper machine is a reciprocating type. Shaper In Metalworking.