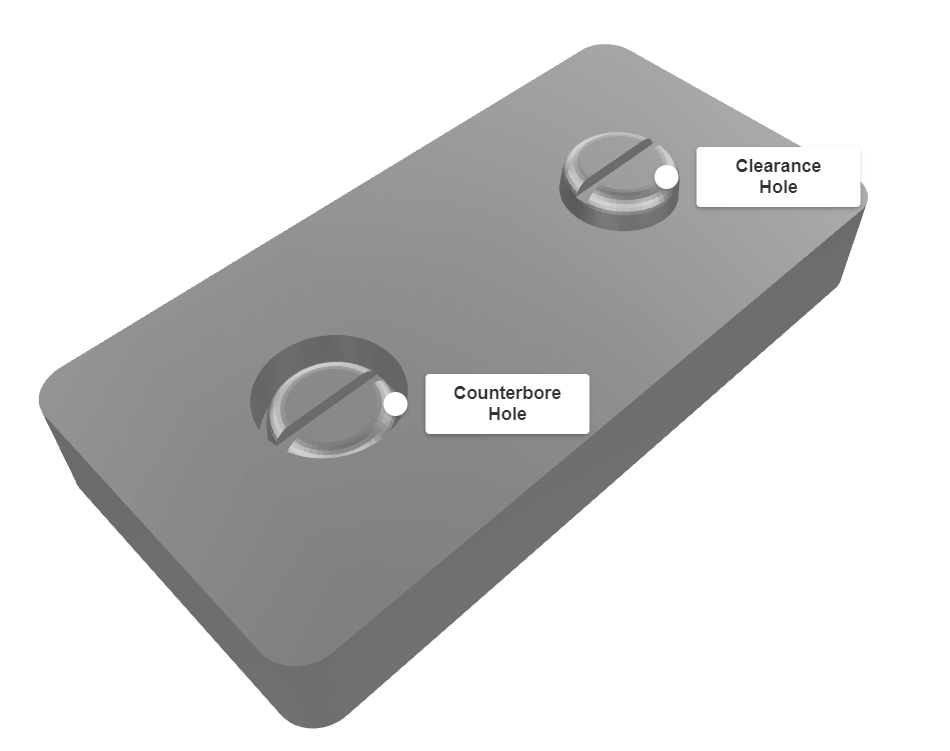

What Would Be The Advantage Of A Counterbore Over A Drilled Hole . This process ensures that the head of a bolt or screw sits flush with the surface of the material, providing a larger surface area for the fastener and a cleaner finish. A counterbore hole is a flat, recessed mounting surface cut into a material at the entrance of a drilled hole primarily to. If the hole is created by a process called ‘boring’ or by a tool with a zero tip angle, the. The counterbore serves to provide a recessed and flat surface for mating parts, and typically, socket head cap screws are used with counterbores. The counterbore makes a flate bottom hole and is best for handling the square shoulder of a bolt or screw. Which is better for pcbs? Understanding the key differences between counterbore and countersink holes is imperative in knowing when one should be used over the other in the pcb assembly process. Together, counterbores and counter sinks allow fasteners to be securely attached while maintaining a clean and flush appearance on the material’s surface. It provides a cleaner look as the fastener’s head can hide with a plug. Which method you use often depends on the material you’re drilling into. A counterbore is a cylindrical hole, with a flat bottom that is larger than and coaxial to another cylindrical hole below it. It offers a strong hold since fasteners sit flush with the material, easily distributing the load on a larger area. For a drilled hole, the shape of the bottom of the hole will be determined by the drill tip angle.

from engineersbible.com

The counterbore serves to provide a recessed and flat surface for mating parts, and typically, socket head cap screws are used with counterbores. For a drilled hole, the shape of the bottom of the hole will be determined by the drill tip angle. A counterbore hole is a flat, recessed mounting surface cut into a material at the entrance of a drilled hole primarily to. This process ensures that the head of a bolt or screw sits flush with the surface of the material, providing a larger surface area for the fastener and a cleaner finish. Together, counterbores and counter sinks allow fasteners to be securely attached while maintaining a clean and flush appearance on the material’s surface. Which method you use often depends on the material you’re drilling into. If the hole is created by a process called ‘boring’ or by a tool with a zero tip angle, the. A counterbore is a cylindrical hole, with a flat bottom that is larger than and coaxial to another cylindrical hole below it. It provides a cleaner look as the fastener’s head can hide with a plug. It offers a strong hold since fasteners sit flush with the material, easily distributing the load on a larger area.

Counterbore Hole Size for Pan Head (ISO 7045) The Engineer's Bible

What Would Be The Advantage Of A Counterbore Over A Drilled Hole It offers a strong hold since fasteners sit flush with the material, easily distributing the load on a larger area. If the hole is created by a process called ‘boring’ or by a tool with a zero tip angle, the. This process ensures that the head of a bolt or screw sits flush with the surface of the material, providing a larger surface area for the fastener and a cleaner finish. Which is better for pcbs? For a drilled hole, the shape of the bottom of the hole will be determined by the drill tip angle. A counterbore hole is a flat, recessed mounting surface cut into a material at the entrance of a drilled hole primarily to. Which method you use often depends on the material you’re drilling into. It provides a cleaner look as the fastener’s head can hide with a plug. A counterbore is a cylindrical hole, with a flat bottom that is larger than and coaxial to another cylindrical hole below it. It offers a strong hold since fasteners sit flush with the material, easily distributing the load on a larger area. Together, counterbores and counter sinks allow fasteners to be securely attached while maintaining a clean and flush appearance on the material’s surface. Understanding the key differences between counterbore and countersink holes is imperative in knowing when one should be used over the other in the pcb assembly process. The counterbore makes a flate bottom hole and is best for handling the square shoulder of a bolt or screw. The counterbore serves to provide a recessed and flat surface for mating parts, and typically, socket head cap screws are used with counterbores.

From www.youtube.com

68 Draw Counterbore Hole (AutoCAD Tutorial) YouTube What Would Be The Advantage Of A Counterbore Over A Drilled Hole Together, counterbores and counter sinks allow fasteners to be securely attached while maintaining a clean and flush appearance on the material’s surface. Which method you use often depends on the material you’re drilling into. The counterbore makes a flate bottom hole and is best for handling the square shoulder of a bolt or screw. It provides a cleaner look as. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From www.youtube.com

Creo Hole (Tap, Clearnce, Drilled, Counterbore, CounterSink) YouTube What Would Be The Advantage Of A Counterbore Over A Drilled Hole Which method you use often depends on the material you’re drilling into. Understanding the key differences between counterbore and countersink holes is imperative in knowing when one should be used over the other in the pcb assembly process. The counterbore serves to provide a recessed and flat surface for mating parts, and typically, socket head cap screws are used with. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From www.slideshare.net

Engineering Drawing Chapter 11 thread fastener What Would Be The Advantage Of A Counterbore Over A Drilled Hole The counterbore serves to provide a recessed and flat surface for mating parts, and typically, socket head cap screws are used with counterbores. It offers a strong hold since fasteners sit flush with the material, easily distributing the load on a larger area. A counterbore is a cylindrical hole, with a flat bottom that is larger than and coaxial to. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From www.gdandtbasics.com

Counterbore GD&T Basics What Would Be The Advantage Of A Counterbore Over A Drilled Hole Which method you use often depends on the material you’re drilling into. The counterbore makes a flate bottom hole and is best for handling the square shoulder of a bolt or screw. For a drilled hole, the shape of the bottom of the hole will be determined by the drill tip angle. If the hole is created by a process. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From sendcutsend.com

The Benefits of Countersinking SendCutSend What Would Be The Advantage Of A Counterbore Over A Drilled Hole If the hole is created by a process called ‘boring’ or by a tool with a zero tip angle, the. Which method you use often depends on the material you’re drilling into. Which is better for pcbs? A counterbore is a cylindrical hole, with a flat bottom that is larger than and coaxial to another cylindrical hole below it. It. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From linghunt.com

Linghunt CUSTOM THREAD GUIDE What Would Be The Advantage Of A Counterbore Over A Drilled Hole A counterbore is a cylindrical hole, with a flat bottom that is larger than and coaxial to another cylindrical hole below it. If the hole is created by a process called ‘boring’ or by a tool with a zero tip angle, the. Together, counterbores and counter sinks allow fasteners to be securely attached while maintaining a clean and flush appearance. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From www.cnccookbook.com

Holemaking Tools for CNC [ Easy Guide ] What Would Be The Advantage Of A Counterbore Over A Drilled Hole Which is better for pcbs? For a drilled hole, the shape of the bottom of the hole will be determined by the drill tip angle. It offers a strong hold since fasteners sit flush with the material, easily distributing the load on a larger area. Understanding the key differences between counterbore and countersink holes is imperative in knowing when one. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From www.slideserve.com

PPT Chapter 10 cont. PowerPoint Presentation, free download ID1984589 What Would Be The Advantage Of A Counterbore Over A Drilled Hole The counterbore serves to provide a recessed and flat surface for mating parts, and typically, socket head cap screws are used with counterbores. Understanding the key differences between counterbore and countersink holes is imperative in knowing when one should be used over the other in the pcb assembly process. Which method you use often depends on the material you’re drilling. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From www.7pcb.com

The Difference Between Counterbore and Countersink Holes What Would Be The Advantage Of A Counterbore Over A Drilled Hole Understanding the key differences between counterbore and countersink holes is imperative in knowing when one should be used over the other in the pcb assembly process. A counterbore is a cylindrical hole, with a flat bottom that is larger than and coaxial to another cylindrical hole below it. A counterbore hole is a flat, recessed mounting surface cut into a. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From engineersbible.com

Counterbore Hole Size for Socket Head (ANSI Inch) The Engineer's Bible What Would Be The Advantage Of A Counterbore Over A Drilled Hole Which is better for pcbs? This process ensures that the head of a bolt or screw sits flush with the surface of the material, providing a larger surface area for the fastener and a cleaner finish. It provides a cleaner look as the fastener’s head can hide with a plug. A counterbore hole is a flat, recessed mounting surface cut. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From www.madearia.com

Spotface Vs. Counterbore in Machining Parts What Would Be The Advantage Of A Counterbore Over A Drilled Hole For a drilled hole, the shape of the bottom of the hole will be determined by the drill tip angle. This process ensures that the head of a bolt or screw sits flush with the surface of the material, providing a larger surface area for the fastener and a cleaner finish. Which is better for pcbs? A counterbore is a. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From www.xometry.com

Spotface vs. Counterbore Holes in Machining Differences and Uses Xometry What Would Be The Advantage Of A Counterbore Over A Drilled Hole A counterbore hole is a flat, recessed mounting surface cut into a material at the entrance of a drilled hole primarily to. It offers a strong hold since fasteners sit flush with the material, easily distributing the load on a larger area. A counterbore is a cylindrical hole, with a flat bottom that is larger than and coaxial to another. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From www.slideserve.com

PPT ADVANCED MECHANICAL DRAFTING PowerPoint Presentation, free What Would Be The Advantage Of A Counterbore Over A Drilled Hole Together, counterbores and counter sinks allow fasteners to be securely attached while maintaining a clean and flush appearance on the material’s surface. It offers a strong hold since fasteners sit flush with the material, easily distributing the load on a larger area. If the hole is created by a process called ‘boring’ or by a tool with a zero tip. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From engineersbible.com

Types of Holes The Complete Guide The Engineer's Bible What Would Be The Advantage Of A Counterbore Over A Drilled Hole Understanding the key differences between counterbore and countersink holes is imperative in knowing when one should be used over the other in the pcb assembly process. A counterbore is a cylindrical hole, with a flat bottom that is larger than and coaxial to another cylindrical hole below it. The counterbore makes a flate bottom hole and is best for handling. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From www.theengineeringknowledge.com

What is Countersink vs. Counterbore Holes in Machining The What Would Be The Advantage Of A Counterbore Over A Drilled Hole Which is better for pcbs? A counterbore hole is a flat, recessed mounting surface cut into a material at the entrance of a drilled hole primarily to. Together, counterbores and counter sinks allow fasteners to be securely attached while maintaining a clean and flush appearance on the material’s surface. Which method you use often depends on the material you’re drilling. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From www.youtube.com

How to Drill a Counterbore Hole for Allen Cap Screw YouTube What Would Be The Advantage Of A Counterbore Over A Drilled Hole A counterbore is a cylindrical hole, with a flat bottom that is larger than and coaxial to another cylindrical hole below it. It offers a strong hold since fasteners sit flush with the material, easily distributing the load on a larger area. This process ensures that the head of a bolt or screw sits flush with the surface of the. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From www.theengineeringknowledge.com

What is Countersink vs. Counterbore Holes in Machining The What Would Be The Advantage Of A Counterbore Over A Drilled Hole If the hole is created by a process called ‘boring’ or by a tool with a zero tip angle, the. Understanding the key differences between counterbore and countersink holes is imperative in knowing when one should be used over the other in the pcb assembly process. Together, counterbores and counter sinks allow fasteners to be securely attached while maintaining a. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From dxoqscgne.blob.core.windows.net

M6 Counterbore Depth at Martha Perrin blog What Would Be The Advantage Of A Counterbore Over A Drilled Hole The counterbore makes a flate bottom hole and is best for handling the square shoulder of a bolt or screw. It provides a cleaner look as the fastener’s head can hide with a plug. Which is better for pcbs? This process ensures that the head of a bolt or screw sits flush with the surface of the material, providing a. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From www.slideserve.com

PPT Holes PowerPoint Presentation, free download ID2107959 What Would Be The Advantage Of A Counterbore Over A Drilled Hole The counterbore makes a flate bottom hole and is best for handling the square shoulder of a bolt or screw. This process ensures that the head of a bolt or screw sits flush with the surface of the material, providing a larger surface area for the fastener and a cleaner finish. It provides a cleaner look as the fastener’s head. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From www.gdandtbasics.com

Counterbore GD&T Basics What Would Be The Advantage Of A Counterbore Over A Drilled Hole It provides a cleaner look as the fastener’s head can hide with a plug. A counterbore is a cylindrical hole, with a flat bottom that is larger than and coaxial to another cylindrical hole below it. This process ensures that the head of a bolt or screw sits flush with the surface of the material, providing a larger surface area. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From www.youtube.com

Making Counterbore Slot with SOLIDWORKS Hole Wizard YouTube What Would Be The Advantage Of A Counterbore Over A Drilled Hole Understanding the key differences between counterbore and countersink holes is imperative in knowing when one should be used over the other in the pcb assembly process. It provides a cleaner look as the fastener’s head can hide with a plug. It offers a strong hold since fasteners sit flush with the material, easily distributing the load on a larger area.. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From slidetodoc.com

Holes and Hole Notes Introduction to Engineering Design What Would Be The Advantage Of A Counterbore Over A Drilled Hole Which method you use often depends on the material you’re drilling into. It offers a strong hold since fasteners sit flush with the material, easily distributing the load on a larger area. Together, counterbores and counter sinks allow fasteners to be securely attached while maintaining a clean and flush appearance on the material’s surface. A counterbore hole is a flat,. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From dobemy.com

Countersunk Holes vs. Counterbore Holes What's the Difference?DOBEMY What Would Be The Advantage Of A Counterbore Over A Drilled Hole This process ensures that the head of a bolt or screw sits flush with the surface of the material, providing a larger surface area for the fastener and a cleaner finish. It offers a strong hold since fasteners sit flush with the material, easily distributing the load on a larger area. If the hole is created by a process called. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From slideplayer.com

Drills & Drill Press Ops. ppt download What Would Be The Advantage Of A Counterbore Over A Drilled Hole For a drilled hole, the shape of the bottom of the hole will be determined by the drill tip angle. A counterbore hole is a flat, recessed mounting surface cut into a material at the entrance of a drilled hole primarily to. A counterbore is a cylindrical hole, with a flat bottom that is larger than and coaxial to another. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From engineersbible.com

Counterbore Hole Size for Pan Head (ISO 7045) The Engineer's Bible What Would Be The Advantage Of A Counterbore Over A Drilled Hole A counterbore is a cylindrical hole, with a flat bottom that is larger than and coaxial to another cylindrical hole below it. This process ensures that the head of a bolt or screw sits flush with the surface of the material, providing a larger surface area for the fastener and a cleaner finish. Understanding the key differences between counterbore and. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From www.finepowertools.com

Counterbore vs Countersink. Differences, Strength & Uses What Would Be The Advantage Of A Counterbore Over A Drilled Hole The counterbore makes a flate bottom hole and is best for handling the square shoulder of a bolt or screw. It provides a cleaner look as the fastener’s head can hide with a plug. If the hole is created by a process called ‘boring’ or by a tool with a zero tip angle, the. Which method you use often depends. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From slideplayer.com

Drills & Drill Press Ops. ppt download What Would Be The Advantage Of A Counterbore Over A Drilled Hole A counterbore is a cylindrical hole, with a flat bottom that is larger than and coaxial to another cylindrical hole below it. This process ensures that the head of a bolt or screw sits flush with the surface of the material, providing a larger surface area for the fastener and a cleaner finish. Together, counterbores and counter sinks allow fasteners. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From www.eng-tips.com

THREADED HOLE WITH COUNTERBORE CALLOUT Aeronautic & Space engineering What Would Be The Advantage Of A Counterbore Over A Drilled Hole This process ensures that the head of a bolt or screw sits flush with the surface of the material, providing a larger surface area for the fastener and a cleaner finish. For a drilled hole, the shape of the bottom of the hole will be determined by the drill tip angle. A counterbore is a cylindrical hole, with a flat. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From www.youtube.com

What are Counterbore and Countersink? PCB Knowledge YouTube What Would Be The Advantage Of A Counterbore Over A Drilled Hole It offers a strong hold since fasteners sit flush with the material, easily distributing the load on a larger area. Understanding the key differences between counterbore and countersink holes is imperative in knowing when one should be used over the other in the pcb assembly process. Together, counterbores and counter sinks allow fasteners to be securely attached while maintaining a. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From www.urbanpro.com

5 Basic Operations Of Lathe Machine UrbanPro What Would Be The Advantage Of A Counterbore Over A Drilled Hole A counterbore hole is a flat, recessed mounting surface cut into a material at the entrance of a drilled hole primarily to. This process ensures that the head of a bolt or screw sits flush with the surface of the material, providing a larger surface area for the fastener and a cleaner finish. It offers a strong hold since fasteners. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From www.ablcircuits.co.uk

PCB Hole Types Counterbore vs Countersink ABL Circuits What Would Be The Advantage Of A Counterbore Over A Drilled Hole It offers a strong hold since fasteners sit flush with the material, easily distributing the load on a larger area. If the hole is created by a process called ‘boring’ or by a tool with a zero tip angle, the. A counterbore hole is a flat, recessed mounting surface cut into a material at the entrance of a drilled hole. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From leadrp.net

Counterbore Vs Countersink Understanding The Differences LEADRP What Would Be The Advantage Of A Counterbore Over A Drilled Hole The counterbore makes a flate bottom hole and is best for handling the square shoulder of a bolt or screw. A counterbore is a cylindrical hole, with a flat bottom that is larger than and coaxial to another cylindrical hole below it. The counterbore serves to provide a recessed and flat surface for mating parts, and typically, socket head cap. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From www.theengineeringknowledge.com

What is Countersink vs. Counterbore Holes in Machining The What Would Be The Advantage Of A Counterbore Over A Drilled Hole It provides a cleaner look as the fastener’s head can hide with a plug. For a drilled hole, the shape of the bottom of the hole will be determined by the drill tip angle. A counterbore hole is a flat, recessed mounting surface cut into a material at the entrance of a drilled hole primarily to. Understanding the key differences. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From www.chegg.com

Solved How many counterbore holes are drilled in this What Would Be The Advantage Of A Counterbore Over A Drilled Hole The counterbore serves to provide a recessed and flat surface for mating parts, and typically, socket head cap screws are used with counterbores. Which is better for pcbs? If the hole is created by a process called ‘boring’ or by a tool with a zero tip angle, the. This process ensures that the head of a bolt or screw sits. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.

From slidetodoc.com

Holes 3 Basic Types Drilled Straight Cylinder Counterbore What Would Be The Advantage Of A Counterbore Over A Drilled Hole The counterbore makes a flate bottom hole and is best for handling the square shoulder of a bolt or screw. Which method you use often depends on the material you’re drilling into. Which is better for pcbs? A counterbore is a cylindrical hole, with a flat bottom that is larger than and coaxial to another cylindrical hole below it. It. What Would Be The Advantage Of A Counterbore Over A Drilled Hole.