Pumping System Efficiency . the efficiency improvement compared to a constant speed driven pump can be up to 10%. in a pumping system, the objective, in most cases, is either to transfer a liquid from a source to a. A vsd can be added also to existing pumps and once installed. pump efficiency is determined by principally two parameters, head and flow rate, in addition to other factors such as. through the cpsa, pump engineers are being trained to correctly assess the efficiency of pump systems, and to provide appropriate. centrifugal pumps can approach 94 percent efficiency, but typical efficiencies are 55 percent for small pumps. pump efficiency is defined as the ratio of the hydraulic power imparted on the fluid to the electrical power input required to operate.

from www.mdpi.com

through the cpsa, pump engineers are being trained to correctly assess the efficiency of pump systems, and to provide appropriate. A vsd can be added also to existing pumps and once installed. pump efficiency is determined by principally two parameters, head and flow rate, in addition to other factors such as. the efficiency improvement compared to a constant speed driven pump can be up to 10%. centrifugal pumps can approach 94 percent efficiency, but typical efficiencies are 55 percent for small pumps. pump efficiency is defined as the ratio of the hydraulic power imparted on the fluid to the electrical power input required to operate. in a pumping system, the objective, in most cases, is either to transfer a liquid from a source to a.

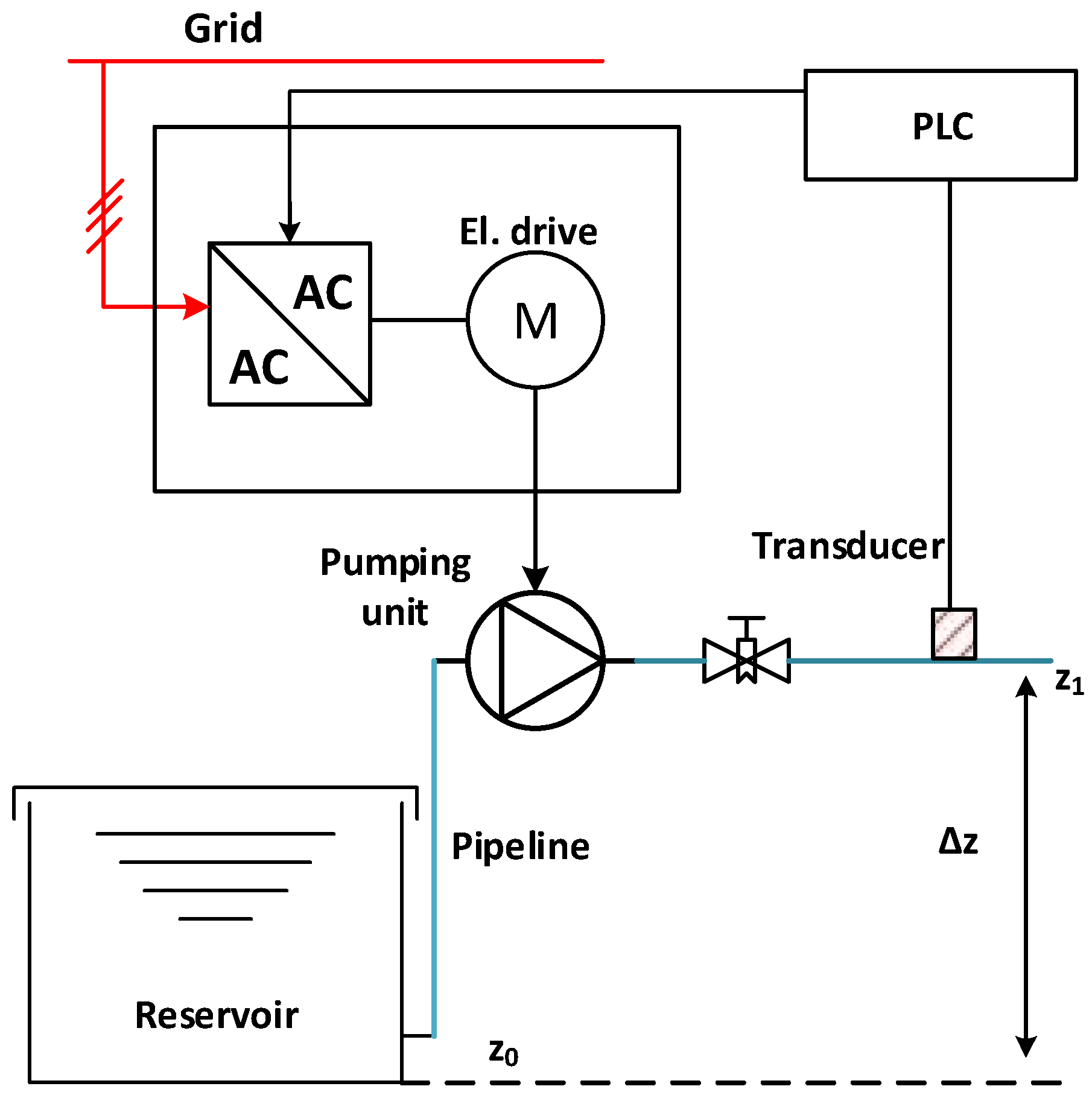

Energies Free FullText Comparative Simulation Study of Pump System

Pumping System Efficiency A vsd can be added also to existing pumps and once installed. A vsd can be added also to existing pumps and once installed. through the cpsa, pump engineers are being trained to correctly assess the efficiency of pump systems, and to provide appropriate. pump efficiency is defined as the ratio of the hydraulic power imparted on the fluid to the electrical power input required to operate. the efficiency improvement compared to a constant speed driven pump can be up to 10%. in a pumping system, the objective, in most cases, is either to transfer a liquid from a source to a. pump efficiency is determined by principally two parameters, head and flow rate, in addition to other factors such as. centrifugal pumps can approach 94 percent efficiency, but typical efficiencies are 55 percent for small pumps.

From www.pumpsandsystems.com

How to Define & Measure Centrifugal Pump Efficiency Part 1 Pumps Pumping System Efficiency A vsd can be added also to existing pumps and once installed. centrifugal pumps can approach 94 percent efficiency, but typical efficiencies are 55 percent for small pumps. through the cpsa, pump engineers are being trained to correctly assess the efficiency of pump systems, and to provide appropriate. the efficiency improvement compared to a constant speed driven. Pumping System Efficiency.

From webmotor.org

How To Calculate Combined Efficiency Of Pump And Motor Pumping System Efficiency in a pumping system, the objective, in most cases, is either to transfer a liquid from a source to a. pump efficiency is determined by principally two parameters, head and flow rate, in addition to other factors such as. centrifugal pumps can approach 94 percent efficiency, but typical efficiencies are 55 percent for small pumps. pump. Pumping System Efficiency.

From jmpcoblog.com

Three Types of Curve Control for Variable Speed Pumping Systems Pumping System Efficiency the efficiency improvement compared to a constant speed driven pump can be up to 10%. pump efficiency is determined by principally two parameters, head and flow rate, in addition to other factors such as. through the cpsa, pump engineers are being trained to correctly assess the efficiency of pump systems, and to provide appropriate. A vsd can. Pumping System Efficiency.

From jkmuir.com

Pump System Efficiency Pumping System Efficiency pump efficiency is defined as the ratio of the hydraulic power imparted on the fluid to the electrical power input required to operate. through the cpsa, pump engineers are being trained to correctly assess the efficiency of pump systems, and to provide appropriate. centrifugal pumps can approach 94 percent efficiency, but typical efficiencies are 55 percent for. Pumping System Efficiency.

From blog.belzona.com

How to Improve Pumped Hydro Storage Efficiency Pumping System Efficiency A vsd can be added also to existing pumps and once installed. centrifugal pumps can approach 94 percent efficiency, but typical efficiencies are 55 percent for small pumps. in a pumping system, the objective, in most cases, is either to transfer a liquid from a source to a. through the cpsa, pump engineers are being trained to. Pumping System Efficiency.

From jmpcoblog.com

New Pump Efficiency Standards Part 3 Calculating PER Values Pumping System Efficiency A vsd can be added also to existing pumps and once installed. centrifugal pumps can approach 94 percent efficiency, but typical efficiencies are 55 percent for small pumps. in a pumping system, the objective, in most cases, is either to transfer a liquid from a source to a. through the cpsa, pump engineers are being trained to. Pumping System Efficiency.

From www.pumpsandsystems.com

System Efficiency Lowers Lifetime Costs Pumps & Systems Pumping System Efficiency pump efficiency is defined as the ratio of the hydraulic power imparted on the fluid to the electrical power input required to operate. the efficiency improvement compared to a constant speed driven pump can be up to 10%. centrifugal pumps can approach 94 percent efficiency, but typical efficiencies are 55 percent for small pumps. pump efficiency. Pumping System Efficiency.

From techblog.ctgclean.com

Pumps Pump Performance Curves CTG Technical Blog Pumping System Efficiency pump efficiency is determined by principally two parameters, head and flow rate, in addition to other factors such as. pump efficiency is defined as the ratio of the hydraulic power imparted on the fluid to the electrical power input required to operate. A vsd can be added also to existing pumps and once installed. in a pumping. Pumping System Efficiency.

From www.researchgate.net

(PDF) Energy Efficiency in Pump System Pumping System Efficiency through the cpsa, pump engineers are being trained to correctly assess the efficiency of pump systems, and to provide appropriate. the efficiency improvement compared to a constant speed driven pump can be up to 10%. pump efficiency is defined as the ratio of the hydraulic power imparted on the fluid to the electrical power input required to. Pumping System Efficiency.

From www.johnbrooks.ca

Basic System Curve Calculations and Pump Performance Pumping System Efficiency A vsd can be added also to existing pumps and once installed. the efficiency improvement compared to a constant speed driven pump can be up to 10%. in a pumping system, the objective, in most cases, is either to transfer a liquid from a source to a. pump efficiency is determined by principally two parameters, head and. Pumping System Efficiency.

From www.rotechpumps.com

Understanding Pump Curves for Centrifugal Pumps A Comprehensive Guide Pumping System Efficiency pump efficiency is determined by principally two parameters, head and flow rate, in addition to other factors such as. through the cpsa, pump engineers are being trained to correctly assess the efficiency of pump systems, and to provide appropriate. A vsd can be added also to existing pumps and once installed. the efficiency improvement compared to a. Pumping System Efficiency.

From www.myengineeringtools.com

Optimizing Industrial Operations Mastering Pump System Efficiency for Pumping System Efficiency pump efficiency is determined by principally two parameters, head and flow rate, in addition to other factors such as. in a pumping system, the objective, in most cases, is either to transfer a liquid from a source to a. through the cpsa, pump engineers are being trained to correctly assess the efficiency of pump systems, and to. Pumping System Efficiency.

From www.slideserve.com

PPT Water Pumps PowerPoint Presentation, free download ID388698 Pumping System Efficiency A vsd can be added also to existing pumps and once installed. the efficiency improvement compared to a constant speed driven pump can be up to 10%. through the cpsa, pump engineers are being trained to correctly assess the efficiency of pump systems, and to provide appropriate. in a pumping system, the objective, in most cases, is. Pumping System Efficiency.

From dokumen.tips

(PDF) Maintaining Well & Pump Efficiency Neil Winner Water · PDF Pumping System Efficiency pump efficiency is defined as the ratio of the hydraulic power imparted on the fluid to the electrical power input required to operate. pump efficiency is determined by principally two parameters, head and flow rate, in addition to other factors such as. centrifugal pumps can approach 94 percent efficiency, but typical efficiencies are 55 percent for small. Pumping System Efficiency.

From mepca-engineering.com

Improve the energy efficiency of your pumping systems Mepca Engineering Pumping System Efficiency centrifugal pumps can approach 94 percent efficiency, but typical efficiencies are 55 percent for small pumps. A vsd can be added also to existing pumps and once installed. through the cpsa, pump engineers are being trained to correctly assess the efficiency of pump systems, and to provide appropriate. pump efficiency is determined by principally two parameters, head. Pumping System Efficiency.

From chemicalengineeringworld.com

Pump Performance Curve Chemical Engineering World Pumping System Efficiency pump efficiency is defined as the ratio of the hydraulic power imparted on the fluid to the electrical power input required to operate. A vsd can be added also to existing pumps and once installed. centrifugal pumps can approach 94 percent efficiency, but typical efficiencies are 55 percent for small pumps. through the cpsa, pump engineers are. Pumping System Efficiency.

From empoweringpumps.com

Enhancing Pumping System Efficiency with Pump System Optimization Pumping System Efficiency the efficiency improvement compared to a constant speed driven pump can be up to 10%. in a pumping system, the objective, in most cases, is either to transfer a liquid from a source to a. through the cpsa, pump engineers are being trained to correctly assess the efficiency of pump systems, and to provide appropriate. pump. Pumping System Efficiency.

From processengineering.co.uk

A guide to optimising pump efficiency Process Engineering Pumping System Efficiency through the cpsa, pump engineers are being trained to correctly assess the efficiency of pump systems, and to provide appropriate. A vsd can be added also to existing pumps and once installed. the efficiency improvement compared to a constant speed driven pump can be up to 10%. centrifugal pumps can approach 94 percent efficiency, but typical efficiencies. Pumping System Efficiency.

From www.youtube.com

Pumping System Efficiency and Horsepower A Concept Discussion YouTube Pumping System Efficiency A vsd can be added also to existing pumps and once installed. through the cpsa, pump engineers are being trained to correctly assess the efficiency of pump systems, and to provide appropriate. pump efficiency is defined as the ratio of the hydraulic power imparted on the fluid to the electrical power input required to operate. pump efficiency. Pumping System Efficiency.

From blog.chesterton.com

Using the Pump Performance Curve to Increase Pump Efficiency & Save Pumping System Efficiency centrifugal pumps can approach 94 percent efficiency, but typical efficiencies are 55 percent for small pumps. pump efficiency is determined by principally two parameters, head and flow rate, in addition to other factors such as. A vsd can be added also to existing pumps and once installed. the efficiency improvement compared to a constant speed driven pump. Pumping System Efficiency.

From chemicaltweak.com

Pump Performance Curve [Learn] Centrifugal Pump Curve In Detail Pumping System Efficiency in a pumping system, the objective, in most cases, is either to transfer a liquid from a source to a. the efficiency improvement compared to a constant speed driven pump can be up to 10%. pump efficiency is determined by principally two parameters, head and flow rate, in addition to other factors such as. pump efficiency. Pumping System Efficiency.

From www.mdpi.com

Energies Free FullText Comparative Simulation Study of Pump System Pumping System Efficiency centrifugal pumps can approach 94 percent efficiency, but typical efficiencies are 55 percent for small pumps. in a pumping system, the objective, in most cases, is either to transfer a liquid from a source to a. pump efficiency is defined as the ratio of the hydraulic power imparted on the fluid to the electrical power input required. Pumping System Efficiency.

From delta-p-online.com

Europump Optimising pump systems to save electrical energy Delta p Pumping System Efficiency through the cpsa, pump engineers are being trained to correctly assess the efficiency of pump systems, and to provide appropriate. the efficiency improvement compared to a constant speed driven pump can be up to 10%. A vsd can be added also to existing pumps and once installed. pump efficiency is determined by principally two parameters, head and. Pumping System Efficiency.

From blog.chesterton.com

How to Gain Pump Efficiency with Restoration & Protective Coatings Pumping System Efficiency pump efficiency is determined by principally two parameters, head and flow rate, in addition to other factors such as. in a pumping system, the objective, in most cases, is either to transfer a liquid from a source to a. A vsd can be added also to existing pumps and once installed. through the cpsa, pump engineers are. Pumping System Efficiency.

From www.researchgate.net

What are the ways to improve the efficiency of the hydrodynamic system? Pumping System Efficiency the efficiency improvement compared to a constant speed driven pump can be up to 10%. A vsd can be added also to existing pumps and once installed. pump efficiency is determined by principally two parameters, head and flow rate, in addition to other factors such as. through the cpsa, pump engineers are being trained to correctly assess. Pumping System Efficiency.

From blog.wellaware.us

How to Calculate (and Improve) Pump Efficiency Pumping System Efficiency pump efficiency is defined as the ratio of the hydraulic power imparted on the fluid to the electrical power input required to operate. in a pumping system, the objective, in most cases, is either to transfer a liquid from a source to a. A vsd can be added also to existing pumps and once installed. centrifugal pumps. Pumping System Efficiency.

From www.deppmann.com

Pumping System Efficiency and Energy Water Pressure Boosters Pumping System Efficiency in a pumping system, the objective, in most cases, is either to transfer a liquid from a source to a. through the cpsa, pump engineers are being trained to correctly assess the efficiency of pump systems, and to provide appropriate. A vsd can be added also to existing pumps and once installed. pump efficiency is defined as. Pumping System Efficiency.

From medium.com

How to increase your pump system efficiency? Unnati Pumps Pvt. Ltd Pumping System Efficiency pump efficiency is determined by principally two parameters, head and flow rate, in addition to other factors such as. pump efficiency is defined as the ratio of the hydraulic power imparted on the fluid to the electrical power input required to operate. centrifugal pumps can approach 94 percent efficiency, but typical efficiencies are 55 percent for small. Pumping System Efficiency.

From slideplayer.com

Pumping System Efficiency. Lower energy cost occurs with a master meter Pumping System Efficiency centrifugal pumps can approach 94 percent efficiency, but typical efficiencies are 55 percent for small pumps. pump efficiency is defined as the ratio of the hydraulic power imparted on the fluid to the electrical power input required to operate. pump efficiency is determined by principally two parameters, head and flow rate, in addition to other factors such. Pumping System Efficiency.

From giomedmkw.blob.core.windows.net

Typical Pump Efficiency Curve at Joshua Ranieri blog Pumping System Efficiency in a pumping system, the objective, in most cases, is either to transfer a liquid from a source to a. pump efficiency is defined as the ratio of the hydraulic power imparted on the fluid to the electrical power input required to operate. pump efficiency is determined by principally two parameters, head and flow rate, in addition. Pumping System Efficiency.

From hardhatengineer.com

Centrifugal Pump Curves 4 Types of Performance Curves Pumping System Efficiency pump efficiency is defined as the ratio of the hydraulic power imparted on the fluid to the electrical power input required to operate. centrifugal pumps can approach 94 percent efficiency, but typical efficiencies are 55 percent for small pumps. the efficiency improvement compared to a constant speed driven pump can be up to 10%. pump efficiency. Pumping System Efficiency.

From slideplayer.com

Vacuum in LER and HER. First estimation for the pumping system Pumping System Efficiency centrifugal pumps can approach 94 percent efficiency, but typical efficiencies are 55 percent for small pumps. through the cpsa, pump engineers are being trained to correctly assess the efficiency of pump systems, and to provide appropriate. in a pumping system, the objective, in most cases, is either to transfer a liquid from a source to a. . Pumping System Efficiency.

From www.sulzer.com

Energy efficiency of pumping systems Sulzer Pumping System Efficiency A vsd can be added also to existing pumps and once installed. centrifugal pumps can approach 94 percent efficiency, but typical efficiencies are 55 percent for small pumps. pump efficiency is determined by principally two parameters, head and flow rate, in addition to other factors such as. through the cpsa, pump engineers are being trained to correctly. Pumping System Efficiency.

From www.academia.edu

(PDF) STUDY, DESIGN AND IMPROVEMENT OF PUMPING SYSTEM EFFICIENCY OF Pumping System Efficiency through the cpsa, pump engineers are being trained to correctly assess the efficiency of pump systems, and to provide appropriate. the efficiency improvement compared to a constant speed driven pump can be up to 10%. pump efficiency is defined as the ratio of the hydraulic power imparted on the fluid to the electrical power input required to. Pumping System Efficiency.

From es.scribd.com

Test For Pumping System Efficiency PDF Pumping System Efficiency pump efficiency is defined as the ratio of the hydraulic power imparted on the fluid to the electrical power input required to operate. in a pumping system, the objective, in most cases, is either to transfer a liquid from a source to a. pump efficiency is determined by principally two parameters, head and flow rate, in addition. Pumping System Efficiency.