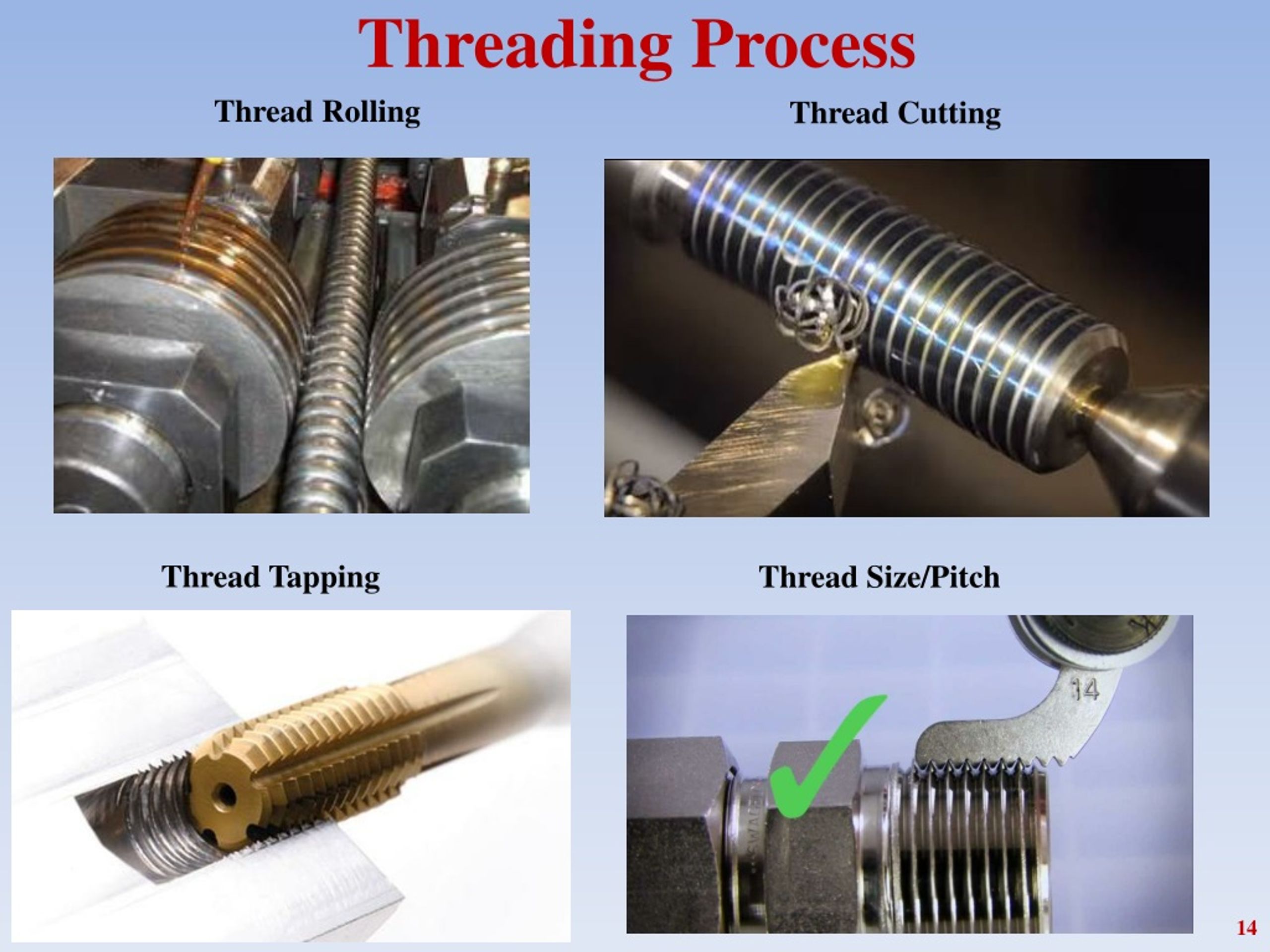

Threading (Manufacturing) . the thread defines the geometry of a thread and includes component diameters (major, pitch and minor diameter), thread profile angle, pitch, radii. Generally, it refers to the method of. threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. the major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread. The method is used to create both internal threads (threads cut into the surface of a bore or hole) and external threads (threads cut around a rod, cylinder, or shaft). a solid grasp of thread types, their parameters, and application is pivotal for engineers. Let’s take a closer look at these methods. to cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. As always, clear communication and diligent verification are paramount in ensuring successful, functional, and durable threaded connections in any manufacturing endeavor.

from www.slideserve.com

The method is used to create both internal threads (threads cut into the surface of a bore or hole) and external threads (threads cut around a rod, cylinder, or shaft). the thread defines the geometry of a thread and includes component diameters (major, pitch and minor diameter), thread profile angle, pitch, radii. a solid grasp of thread types, their parameters, and application is pivotal for engineers. the major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread. to cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. Generally, it refers to the method of. As always, clear communication and diligent verification are paramount in ensuring successful, functional, and durable threaded connections in any manufacturing endeavor. threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. Let’s take a closer look at these methods.

PPT Topics PowerPoint Presentation, free download ID345512

Threading (Manufacturing) to cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. As always, clear communication and diligent verification are paramount in ensuring successful, functional, and durable threaded connections in any manufacturing endeavor. Let’s take a closer look at these methods. to cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. Generally, it refers to the method of. a solid grasp of thread types, their parameters, and application is pivotal for engineers. the thread defines the geometry of a thread and includes component diameters (major, pitch and minor diameter), thread profile angle, pitch, radii. The method is used to create both internal threads (threads cut into the surface of a bore or hole) and external threads (threads cut around a rod, cylinder, or shaft). threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. the major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread.

From fyorndsoo.blob.core.windows.net

Sewing Thread Manufacturing Process at Joanna Lee blog Threading (Manufacturing) Generally, it refers to the method of. to cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. the thread defines the geometry of a thread and includes component. Threading (Manufacturing).

From www.clarkengineering.net

Thread Manufacturing Services Clark Engineering Threading (Manufacturing) Generally, it refers to the method of. the major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread. The method is used to create both internal threads (threads cut into the surface of a bore or hole) and external threads (threads cut around a rod, cylinder, or shaft). Let’s take a closer look at these. Threading (Manufacturing).

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Threading (Manufacturing) the major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread. threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. Let’s take a closer look at these methods. the thread defines the geometry of a thread and includes component diameters (major, pitch and minor diameter), thread. Threading (Manufacturing).

From gmtindustries.net

Pipe Threading Machine GMT Industries Limited Threading (Manufacturing) Generally, it refers to the method of. the thread defines the geometry of a thread and includes component diameters (major, pitch and minor diameter), thread profile angle, pitch, radii. threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. Let’s take a closer look at these methods. The method is used to. Threading (Manufacturing).

From proleantech.com

CNC Threading Process in Manufacturing A Comprehensive Guide CNC Threading (Manufacturing) a solid grasp of thread types, their parameters, and application is pivotal for engineers. to cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. Let’s take a closer. Threading (Manufacturing).

From www.dreamstime.com

Detail of Thread Factory Production Line Stock Photo Image of Threading (Manufacturing) a solid grasp of thread types, their parameters, and application is pivotal for engineers. Let’s take a closer look at these methods. to cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. the thread defines the geometry of a thread and includes component diameters. Threading (Manufacturing).

From www.cpc-fasteners.com

THREADING MANUFACTURING Threading (Manufacturing) a solid grasp of thread types, their parameters, and application is pivotal for engineers. Let’s take a closer look at these methods. The method is used to create both internal threads (threads cut into the surface of a bore or hole) and external threads (threads cut around a rod, cylinder, or shaft). to cut a correct thread on. Threading (Manufacturing).

From www.dreamstime.com

Detail of Thread Factory Production Line Stock Photo Image of Threading (Manufacturing) the major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread. Let’s take a closer look at these methods. threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. The method is used to create both internal threads (threads cut into the surface of a bore or hole). Threading (Manufacturing).

From www.youtube.com

Shot of an automatic machine manufacturing thread Indian Stock Threading (Manufacturing) Generally, it refers to the method of. to cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. the major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread. a solid grasp of thread types, their parameters, and application is pivotal. Threading (Manufacturing).

From www.youtube.com

BDN How is a screw made? Pinch Pointing, Threading Manufacturing Threading (Manufacturing) the major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread. The method is used to create both internal threads (threads cut into the surface of a bore or hole) and external threads (threads cut around a rod, cylinder, or shaft). a solid grasp of thread types, their parameters, and application is pivotal for. Threading (Manufacturing).

From www.youtube.com

Thread manufacturing process YouTube Threading (Manufacturing) the thread defines the geometry of a thread and includes component diameters (major, pitch and minor diameter), thread profile angle, pitch, radii. The method is used to create both internal threads (threads cut into the surface of a bore or hole) and external threads (threads cut around a rod, cylinder, or shaft). the major threading methods used in. Threading (Manufacturing).

From pecm.co.uk

Custom made threading tools for non standard threads and applications Threading (Manufacturing) Generally, it refers to the method of. Let’s take a closer look at these methods. the thread defines the geometry of a thread and includes component diameters (major, pitch and minor diameter), thread profile angle, pitch, radii. threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. a solid grasp of. Threading (Manufacturing).

From www.threadingmachines.co.in

Automatic Bolt Threading Machine Supplier, Manufacturing Unit in India Threading (Manufacturing) Generally, it refers to the method of. As always, clear communication and diligent verification are paramount in ensuring successful, functional, and durable threaded connections in any manufacturing endeavor. Let’s take a closer look at these methods. the major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread. threading holds a critical position in manufacturing. Threading (Manufacturing).

From www.rolledthreads.com

How Does the Thread Rolling Process Work? Threading (Manufacturing) a solid grasp of thread types, their parameters, and application is pivotal for engineers. to cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. Let’s take a closer look at these methods. threading holds a critical position in manufacturing due to its broad versatility. Threading (Manufacturing).

From jbcmachine.com

Threading Services JBC Machine, Inc. Threading (Manufacturing) to cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. The method is used to create both internal threads (threads cut into the surface of a bore or hole) and external threads (threads cut around a rod, cylinder, or shaft). Generally, it refers to the method. Threading (Manufacturing).

From www.cpc-fasteners.com

THREADING MANUFACTURING Threading (Manufacturing) As always, clear communication and diligent verification are paramount in ensuring successful, functional, and durable threaded connections in any manufacturing endeavor. Generally, it refers to the method of. a solid grasp of thread types, their parameters, and application is pivotal for engineers. to cut a correct thread on the lathe, it is necessary first to make calculations so. Threading (Manufacturing).

From www.youtube.com

Threading_Custom Manufacturing YouTube Threading (Manufacturing) the major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread. a solid grasp of thread types, their parameters, and application is pivotal for engineers. The method is used to create both internal threads (threads cut into the surface of a bore or hole) and external threads (threads cut around a rod, cylinder, or. Threading (Manufacturing).

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Threading (Manufacturing) Generally, it refers to the method of. threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. a solid grasp of thread types, their parameters, and application is pivotal for engineers. The method is used to create both internal threads (threads cut into the surface of a bore or hole) and external. Threading (Manufacturing).

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Threading (Manufacturing) Generally, it refers to the method of. threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. the major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread. a solid grasp of thread types, their parameters, and application is pivotal for engineers. As always, clear communication and. Threading (Manufacturing).

From cnpipetool.en.made-in-china.com

Threading Manufacturing Machine China Electric Pipe Threading Machine Threading (Manufacturing) to cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. the major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread. Let’s take a closer look at these methods. a solid grasp of thread types, their parameters, and application is. Threading (Manufacturing).

From www.cpc-fasteners.com

THREADING MANUFACTURING Threading (Manufacturing) to cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. The method is used to create both internal threads (threads cut into the surface of a bore or hole). Threading (Manufacturing).

From www.slideserve.com

PPT Topics PowerPoint Presentation, free download ID345512 Threading (Manufacturing) a solid grasp of thread types, their parameters, and application is pivotal for engineers. to cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. the major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread. Generally, it refers to the. Threading (Manufacturing).

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Threading (Manufacturing) the thread defines the geometry of a thread and includes component diameters (major, pitch and minor diameter), thread profile angle, pitch, radii. to cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. the major threading methods used in manufacturing include tapping, threading with dies,. Threading (Manufacturing).

From www.edthread.com

Polyester — Eddington Thread Manufacturing Threading (Manufacturing) to cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. Let’s take a closer look at these methods. the major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread. As always, clear communication and diligent verification are paramount in ensuring successful,. Threading (Manufacturing).

From www.dreamstime.com

Closeup Process of Metal Machining by Threading Stock Photo Image of Threading (Manufacturing) the thread defines the geometry of a thread and includes component diameters (major, pitch and minor diameter), thread profile angle, pitch, radii. a solid grasp of thread types, their parameters, and application is pivotal for engineers. As always, clear communication and diligent verification are paramount in ensuring successful, functional, and durable threaded connections in any manufacturing endeavor. . Threading (Manufacturing).

From www.dreamstime.com

Detail of Thread Factory Production Line Stock Photo Image of bobbin Threading (Manufacturing) a solid grasp of thread types, their parameters, and application is pivotal for engineers. Let’s take a closer look at these methods. As always, clear communication and diligent verification are paramount in ensuring successful, functional, and durable threaded connections in any manufacturing endeavor. to cut a correct thread on the lathe, it is necessary first to make calculations. Threading (Manufacturing).

From www.dreamstime.com

18,697 Thread Making Stock Photos Free & RoyaltyFree Stock Photos Threading (Manufacturing) Generally, it refers to the method of. As always, clear communication and diligent verification are paramount in ensuring successful, functional, and durable threaded connections in any manufacturing endeavor. the major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread. threading holds a critical position in manufacturing due to its broad versatility and applicability across. Threading (Manufacturing).

From www.omsos.com

Technology Connection OMS Oilfield Services Oilfield Manufacturing Threading (Manufacturing) to cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. Let’s take a closer look at these methods. threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. The method is used to create both internal threads (threads cut. Threading (Manufacturing).

From www.bbprice.co.uk

Threading Machine Screw Threading B.B. Price Threading (Manufacturing) the major threading methods used in manufacturing include tapping, threading with dies, thread milling, thread. As always, clear communication and diligent verification are paramount in ensuring successful, functional, and durable threaded connections in any manufacturing endeavor. threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. to cut a correct thread. Threading (Manufacturing).

From www.scribd.com

Thread manufacturing process ppt Screw Metalworking Threading (Manufacturing) to cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. As always, clear communication and diligent verification are paramount in ensuring successful, functional, and durable threaded connections in any manufacturing endeavor. threading holds a critical position in manufacturing due to its broad versatility and applicability. Threading (Manufacturing).

From vesciomfg.com

Thread Cutting & Grinding Vescio Manufacturing Threading (Manufacturing) the thread defines the geometry of a thread and includes component diameters (major, pitch and minor diameter), thread profile angle, pitch, radii. to cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. a solid grasp of thread types, their parameters, and application is pivotal. Threading (Manufacturing).

From www.youtube.com

How Thread Is Made Thread Production Line Thread Factory YouTube Threading (Manufacturing) a solid grasp of thread types, their parameters, and application is pivotal for engineers. threading holds a critical position in manufacturing due to its broad versatility and applicability across industries. Generally, it refers to the method of. As always, clear communication and diligent verification are paramount in ensuring successful, functional, and durable threaded connections in any manufacturing endeavor.. Threading (Manufacturing).

From nxrev.com

Top 3 Benefits of Digital Thread in Manufacturing Creo, Windchill Threading (Manufacturing) the thread defines the geometry of a thread and includes component diameters (major, pitch and minor diameter), thread profile angle, pitch, radii. As always, clear communication and diligent verification are paramount in ensuring successful, functional, and durable threaded connections in any manufacturing endeavor. The method is used to create both internal threads (threads cut into the surface of a. Threading (Manufacturing).

From www.morebooks.de

Threading (Manufacturing), 9786200973160, 6200973164 ,9786200973160 Threading (Manufacturing) the thread defines the geometry of a thread and includes component diameters (major, pitch and minor diameter), thread profile angle, pitch, radii. The method is used to create both internal threads (threads cut into the surface of a bore or hole) and external threads (threads cut around a rod, cylinder, or shaft). threading holds a critical position in. Threading (Manufacturing).

From www.dreamstime.com

Production Of Threads In A Textile Factory Stock Image Image of Threading (Manufacturing) the thread defines the geometry of a thread and includes component diameters (major, pitch and minor diameter), thread profile angle, pitch, radii. As always, clear communication and diligent verification are paramount in ensuring successful, functional, and durable threaded connections in any manufacturing endeavor. The method is used to create both internal threads (threads cut into the surface of a. Threading (Manufacturing).