Brazing Rod Filler Metal . — for much of its history, brazing has needed to develop new filler metals, improving. This alloy must be capable of wetting the base metal [1],. For manual torch brazing applications, welding. This filler metal should have a lower melting point than the metal being joined. — brazing is the process of joining two or more pieces of metal together by melting a “filler metal” in a joint placed between the pieces meant to be put together. Ation of brazing filler metals for brazing and braze welding. — for much of its history, brazing has needed to develop new filler metals, improving properties to meet various challenges, such as higher strength and operating temperature, and reducing the cost (notably in the filler metal families based on precious metals). the defining aspect of brazing is the melting of a filler metal in the joint; — in this article, we will discuss common brazing filler metals and fluxes and their use.

from www.slideserve.com

— for much of its history, brazing has needed to develop new filler metals, improving. — for much of its history, brazing has needed to develop new filler metals, improving properties to meet various challenges, such as higher strength and operating temperature, and reducing the cost (notably in the filler metal families based on precious metals). For manual torch brazing applications, welding. — brazing is the process of joining two or more pieces of metal together by melting a “filler metal” in a joint placed between the pieces meant to be put together. the defining aspect of brazing is the melting of a filler metal in the joint; — in this article, we will discuss common brazing filler metals and fluxes and their use. This filler metal should have a lower melting point than the metal being joined. Ation of brazing filler metals for brazing and braze welding. This alloy must be capable of wetting the base metal [1],.

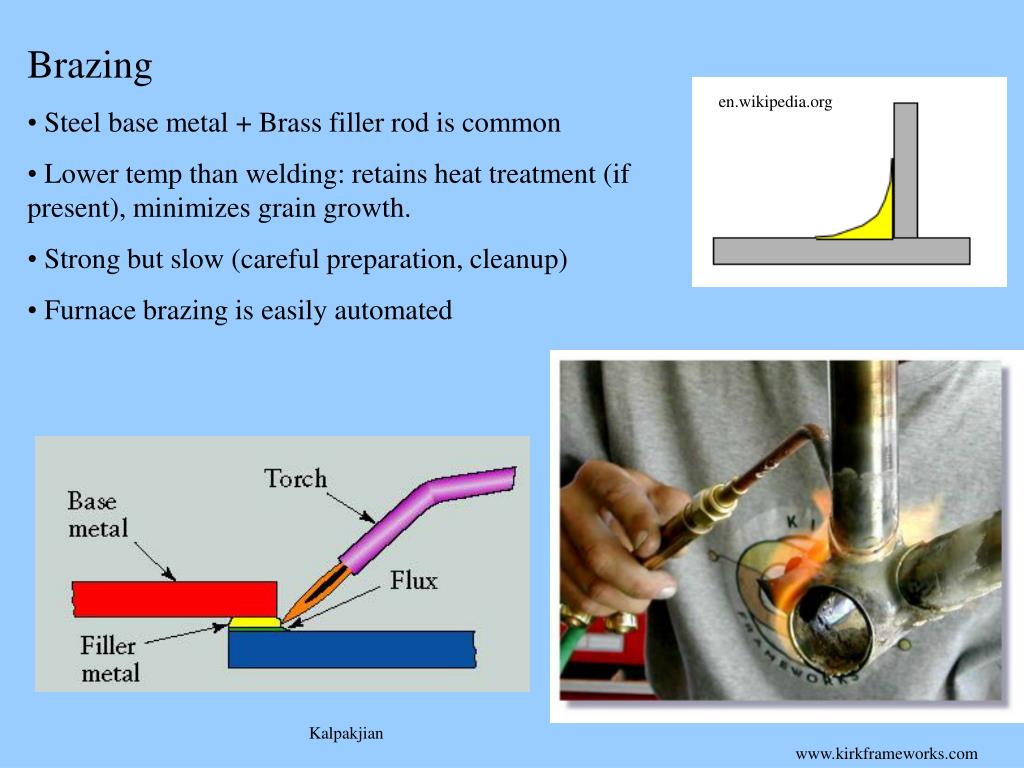

PPT Joining Processes Welding, Brazing, Soldering Brazing and

Brazing Rod Filler Metal — in this article, we will discuss common brazing filler metals and fluxes and their use. — brazing is the process of joining two or more pieces of metal together by melting a “filler metal” in a joint placed between the pieces meant to be put together. — for much of its history, brazing has needed to develop new filler metals, improving properties to meet various challenges, such as higher strength and operating temperature, and reducing the cost (notably in the filler metal families based on precious metals). — for much of its history, brazing has needed to develop new filler metals, improving. This filler metal should have a lower melting point than the metal being joined. This alloy must be capable of wetting the base metal [1],. the defining aspect of brazing is the melting of a filler metal in the joint; For manual torch brazing applications, welding. Ation of brazing filler metals for brazing and braze welding. — in this article, we will discuss common brazing filler metals and fluxes and their use.

From dxokxxkuh.blob.core.windows.net

Brazing In Welding at Bonnie Wert blog Brazing Rod Filler Metal Ation of brazing filler metals for brazing and braze welding. — for much of its history, brazing has needed to develop new filler metals, improving. For manual torch brazing applications, welding. — in this article, we will discuss common brazing filler metals and fluxes and their use. This alloy must be capable of wetting the base metal [1],.. Brazing Rod Filler Metal.

From dxoflnimm.blob.core.windows.net

Brazing Rods For Stainless Steel at Catherine Smith blog Brazing Rod Filler Metal — for much of its history, brazing has needed to develop new filler metals, improving. — for much of its history, brazing has needed to develop new filler metals, improving properties to meet various challenges, such as higher strength and operating temperature, and reducing the cost (notably in the filler metal families based on precious metals). This alloy. Brazing Rod Filler Metal.

From www.lifestylemanor.com.au

The Different Types of Brazing Rods lifestylemanor Brazing Rod Filler Metal This alloy must be capable of wetting the base metal [1],. Ation of brazing filler metals for brazing and braze welding. — in this article, we will discuss common brazing filler metals and fluxes and their use. This filler metal should have a lower melting point than the metal being joined. — brazing is the process of joining. Brazing Rod Filler Metal.

From www.hampdon.com.au

5kg 3.2mm ER70S2 Mild Steel TIG Filler Welding Wire Rods Brazing Rod Filler Metal For manual torch brazing applications, welding. This alloy must be capable of wetting the base metal [1],. — brazing is the process of joining two or more pieces of metal together by melting a “filler metal” in a joint placed between the pieces meant to be put together. This filler metal should have a lower melting point than the. Brazing Rod Filler Metal.

From www.alibaba.com

Flux Coated Brazing Rods Brass Welding Rods Filler Metals Rods Buy Brazing Rod Filler Metal This alloy must be capable of wetting the base metal [1],. For manual torch brazing applications, welding. — in this article, we will discuss common brazing filler metals and fluxes and their use. — for much of its history, brazing has needed to develop new filler metals, improving properties to meet various challenges, such as higher strength and. Brazing Rod Filler Metal.

From blog.thepipingmart.com

Brazing Stainless Steel with Brass Rod A Complete Guide Brazing Rod Filler Metal — brazing is the process of joining two or more pieces of metal together by melting a “filler metal” in a joint placed between the pieces meant to be put together. For manual torch brazing applications, welding. — in this article, we will discuss common brazing filler metals and fluxes and their use. — for much of. Brazing Rod Filler Metal.

From www.dodomachine.com

What Type of Brazing Rod for Stainless Steel? Selection Guide and Tips Brazing Rod Filler Metal This alloy must be capable of wetting the base metal [1],. — for much of its history, brazing has needed to develop new filler metals, improving properties to meet various challenges, such as higher strength and operating temperature, and reducing the cost (notably in the filler metal families based on precious metals). Ation of brazing filler metals for brazing. Brazing Rod Filler Metal.

From www.alibaba.com

Rbcuznc Flux Coated Brass Bronze Brazing Rods 2.4mm Welding Stick Brazing Rod Filler Metal — for much of its history, brazing has needed to develop new filler metals, improving. This alloy must be capable of wetting the base metal [1],. — brazing is the process of joining two or more pieces of metal together by melting a “filler metal” in a joint placed between the pieces meant to be put together. This. Brazing Rod Filler Metal.

From www.diytrade.com

CuZn brazing filler metal welding rod BCu62Zn Qixing (China Brazing Rod Filler Metal — brazing is the process of joining two or more pieces of metal together by melting a “filler metal” in a joint placed between the pieces meant to be put together. For manual torch brazing applications, welding. — for much of its history, brazing has needed to develop new filler metals, improving. — for much of its. Brazing Rod Filler Metal.

From www.weldingcity.com

WeldingCity® High Silver (15) BCuP5 PhosCopper Brazing Filler Rod 20 Brazing Rod Filler Metal This filler metal should have a lower melting point than the metal being joined. — brazing is the process of joining two or more pieces of metal together by melting a “filler metal” in a joint placed between the pieces meant to be put together. This alloy must be capable of wetting the base metal [1],. For manual torch. Brazing Rod Filler Metal.

From www.mechero.my

What is Brazing Process? Brazing Types & Applications Brazing Rod Filler Metal For manual torch brazing applications, welding. This alloy must be capable of wetting the base metal [1],. the defining aspect of brazing is the melting of a filler metal in the joint; — in this article, we will discuss common brazing filler metals and fluxes and their use. Ation of brazing filler metals for brazing and braze welding.. Brazing Rod Filler Metal.

From exozgyfnw.blob.core.windows.net

What Is Brazing Welding Rod Used For at Alicia Porter blog Brazing Rod Filler Metal Ation of brazing filler metals for brazing and braze welding. the defining aspect of brazing is the melting of a filler metal in the joint; — brazing is the process of joining two or more pieces of metal together by melting a “filler metal” in a joint placed between the pieces meant to be put together. —. Brazing Rod Filler Metal.

From www.youtube.com

How to braze copper with silphos brazing rod YouTube Brazing Rod Filler Metal — for much of its history, brazing has needed to develop new filler metals, improving properties to meet various challenges, such as higher strength and operating temperature, and reducing the cost (notably in the filler metal families based on precious metals). Ation of brazing filler metals for brazing and braze welding. This alloy must be capable of wetting the. Brazing Rod Filler Metal.

From bigweld.com.au

45 Silver Brazing Alloy Rod Brazing Rod Filler Metal — for much of its history, brazing has needed to develop new filler metals, improving. For manual torch brazing applications, welding. Ation of brazing filler metals for brazing and braze welding. This filler metal should have a lower melting point than the metal being joined. the defining aspect of brazing is the melting of a filler metal in. Brazing Rod Filler Metal.

From www.youtube.com

How to Braze Copper to Copper with 0 Silver Brazing Rods YouTube Brazing Rod Filler Metal — for much of its history, brazing has needed to develop new filler metals, improving properties to meet various challenges, such as higher strength and operating temperature, and reducing the cost (notably in the filler metal families based on precious metals). the defining aspect of brazing is the melting of a filler metal in the joint; This alloy. Brazing Rod Filler Metal.

From www.globalspec.com

Braze and Brazing Alloys Information Engineering360 Brazing Rod Filler Metal For manual torch brazing applications, welding. This filler metal should have a lower melting point than the metal being joined. — for much of its history, brazing has needed to develop new filler metals, improving. — for much of its history, brazing has needed to develop new filler metals, improving properties to meet various challenges, such as higher. Brazing Rod Filler Metal.

From www.coowor.com

ALUMINUM ALLOY BRAZING FILLER METAL RODS Brazing Rod Filler Metal — for much of its history, brazing has needed to develop new filler metals, improving. This alloy must be capable of wetting the base metal [1],. — for much of its history, brazing has needed to develop new filler metals, improving properties to meet various challenges, such as higher strength and operating temperature, and reducing the cost (notably. Brazing Rod Filler Metal.

From www.alibaba.com

L Ag34sn Braze Rod 34 Silver Brazing Filler Metal Silver Solder Wire Brazing Rod Filler Metal the defining aspect of brazing is the melting of a filler metal in the joint; This alloy must be capable of wetting the base metal [1],. — in this article, we will discuss common brazing filler metals and fluxes and their use. — brazing is the process of joining two or more pieces of metal together by. Brazing Rod Filler Metal.

From www.globalspec.com

Braze and Brazing Alloys Information Engineering360 Brazing Rod Filler Metal This filler metal should have a lower melting point than the metal being joined. — in this article, we will discuss common brazing filler metals and fluxes and their use. This alloy must be capable of wetting the base metal [1],. — brazing is the process of joining two or more pieces of metal together by melting a. Brazing Rod Filler Metal.

From www.indiamart.com

Harris copper brazing rods, Aircool India ID 19306006333 Brazing Rod Filler Metal the defining aspect of brazing is the melting of a filler metal in the joint; This filler metal should have a lower melting point than the metal being joined. Ation of brazing filler metals for brazing and braze welding. — for much of its history, brazing has needed to develop new filler metals, improving. This alloy must be. Brazing Rod Filler Metal.

From www.alibaba.com

L Ag34sn Braze Rod 34 Silver Brazing Filler Metal Silver Solder Wire Brazing Rod Filler Metal Ation of brazing filler metals for brazing and braze welding. This filler metal should have a lower melting point than the metal being joined. — in this article, we will discuss common brazing filler metals and fluxes and their use. This alloy must be capable of wetting the base metal [1],. — for much of its history, brazing. Brazing Rod Filler Metal.

From www.aliexpress.com

10pcs Aluminum Alloy Welding Rods Mayitr Silver Tig Filler Brazing Rod Brazing Rod Filler Metal This filler metal should have a lower melting point than the metal being joined. For manual torch brazing applications, welding. the defining aspect of brazing is the melting of a filler metal in the joint; This alloy must be capable of wetting the base metal [1],. — in this article, we will discuss common brazing filler metals and. Brazing Rod Filler Metal.

From www.slideserve.com

PPT Joining Processes Welding, Brazing, Soldering Brazing and Brazing Rod Filler Metal — brazing is the process of joining two or more pieces of metal together by melting a “filler metal” in a joint placed between the pieces meant to be put together. This alloy must be capable of wetting the base metal [1],. — in this article, we will discuss common brazing filler metals and fluxes and their use.. Brazing Rod Filler Metal.

From www.weldingandwelder.com

TIG Rods for Brazing/Bronze Welding Welding & Welder Brazing Rod Filler Metal Ation of brazing filler metals for brazing and braze welding. — brazing is the process of joining two or more pieces of metal together by melting a “filler metal” in a joint placed between the pieces meant to be put together. For manual torch brazing applications, welding. — for much of its history, brazing has needed to develop. Brazing Rod Filler Metal.

From exoqoydka.blob.core.windows.net

Brass To Brass Brazing Rod at Jeff b blog Brazing Rod Filler Metal — in this article, we will discuss common brazing filler metals and fluxes and their use. — brazing is the process of joining two or more pieces of metal together by melting a “filler metal” in a joint placed between the pieces meant to be put together. For manual torch brazing applications, welding. — for much of. Brazing Rod Filler Metal.

From dxoonxmgb.blob.core.windows.net

Brass To Copper Brazing Rod at Barbara McGowan blog Brazing Rod Filler Metal For manual torch brazing applications, welding. This alloy must be capable of wetting the base metal [1],. Ation of brazing filler metals for brazing and braze welding. — for much of its history, brazing has needed to develop new filler metals, improving properties to meet various challenges, such as higher strength and operating temperature, and reducing the cost (notably. Brazing Rod Filler Metal.

From blog.thepipingmart.com

Brass Brazing Rods An Overview Brazing Rod Filler Metal the defining aspect of brazing is the melting of a filler metal in the joint; — brazing is the process of joining two or more pieces of metal together by melting a “filler metal” in a joint placed between the pieces meant to be put together. This alloy must be capable of wetting the base metal [1],. . Brazing Rod Filler Metal.

From bradleyabbott.z13.web.core.windows.net

Stainless Steel Filler Rod Chart Brazing Rod Filler Metal — brazing is the process of joining two or more pieces of metal together by melting a “filler metal” in a joint placed between the pieces meant to be put together. This alloy must be capable of wetting the base metal [1],. — for much of its history, brazing has needed to develop new filler metals, improving. Ation. Brazing Rod Filler Metal.

From www.focusweld.com

Brazing is a traditional metal joining process in which two or more Brazing Rod Filler Metal — brazing is the process of joining two or more pieces of metal together by melting a “filler metal” in a joint placed between the pieces meant to be put together. — for much of its history, brazing has needed to develop new filler metals, improving. Ation of brazing filler metals for brazing and braze welding. the. Brazing Rod Filler Metal.

From www.hampdon.com.au

1kg 1.6mm ER70S2 Mild Steel TIG Filler Welding Wire Rods Brazing Rod Filler Metal Ation of brazing filler metals for brazing and braze welding. the defining aspect of brazing is the melting of a filler metal in the joint; This filler metal should have a lower melting point than the metal being joined. For manual torch brazing applications, welding. — for much of its history, brazing has needed to develop new filler. Brazing Rod Filler Metal.

From china.tradeford.com

Braze Rod 34 Silver Brazing Filler Metal used in brazing by Guangzhou Brazing Rod Filler Metal For manual torch brazing applications, welding. Ation of brazing filler metals for brazing and braze welding. — brazing is the process of joining two or more pieces of metal together by melting a “filler metal” in a joint placed between the pieces meant to be put together. — for much of its history, brazing has needed to develop. Brazing Rod Filler Metal.

From www.cromwell.co.uk

Johnson Matthey Silverflo 55 Cadmium Free Silver Brazing Filler Metal Brazing Rod Filler Metal This filler metal should have a lower melting point than the metal being joined. This alloy must be capable of wetting the base metal [1],. — brazing is the process of joining two or more pieces of metal together by melting a “filler metal” in a joint placed between the pieces meant to be put together. — for. Brazing Rod Filler Metal.

From www.ebay.com.au

FLUX COATED BRASS BRONZE BRAZING RODS 2.4mm WELDING STICK FILLER 18INCH Brazing Rod Filler Metal Ation of brazing filler metals for brazing and braze welding. the defining aspect of brazing is the melting of a filler metal in the joint; — brazing is the process of joining two or more pieces of metal together by melting a “filler metal” in a joint placed between the pieces meant to be put together. This alloy. Brazing Rod Filler Metal.

From www.welding-material.com

copper zinc brazing alloy solder wire hs221 welding filler metal rod Brazing Rod Filler Metal — for much of its history, brazing has needed to develop new filler metals, improving. For manual torch brazing applications, welding. — in this article, we will discuss common brazing filler metals and fluxes and their use. This alloy must be capable of wetting the base metal [1],. — brazing is the process of joining two or. Brazing Rod Filler Metal.

From exovxubli.blob.core.windows.net

Brazing For Beginners at Brandon Murillo blog Brazing Rod Filler Metal This filler metal should have a lower melting point than the metal being joined. This alloy must be capable of wetting the base metal [1],. For manual torch brazing applications, welding. Ation of brazing filler metals for brazing and braze welding. — for much of its history, brazing has needed to develop new filler metals, improving. — for. Brazing Rod Filler Metal.