Lathe Threading Tools . Adjust the tool angle to match the thread pitch and size. Choose from our selection of threading tools, including lathe tools, indexable lathe tools, and more. To thread on a metal lathe, you need to start by selecting the appropriate threading tool and setting the speed of the lathe. Position the cutting tool so that it is perpendicular to the workpiece surface and aligned with the desired thread start point. The thread is cut by moving the tool along the length of the material in a. In stock and ready to ship. A sharp tool is paramount to the threading process. Use a thread gauge to accurately determine the. Once you have chosen the tool and set the right speed, you can begin by engaging the threading tool with the workpiece and cutting the thread. Constructed of a carbide tip brazed onto a ground steel shank, these tools are more wear. Solid carbide internal threading lathe tools. Dull tools can cause damage to the workpiece and create a poor thread. Solutions include laydown threading inserts, top notch™. Ensure that the tool angle is correct to avoid damaging the thread.

from www.mccrone.com

Choose from our selection of threading tools, including lathe tools, indexable lathe tools, and more. A sharp tool is paramount to the threading process. Use a thread gauge to accurately determine the. Ensure that the tool angle is correct to avoid damaging the thread. The thread is cut by moving the tool along the length of the material in a. Adjust the tool angle to match the thread pitch and size. Dull tools can cause damage to the workpiece and create a poor thread. Constructed of a carbide tip brazed onto a ground steel shank, these tools are more wear. Solutions include laydown threading inserts, top notch™. Once you have chosen the tool and set the right speed, you can begin by engaging the threading tool with the workpiece and cutting the thread.

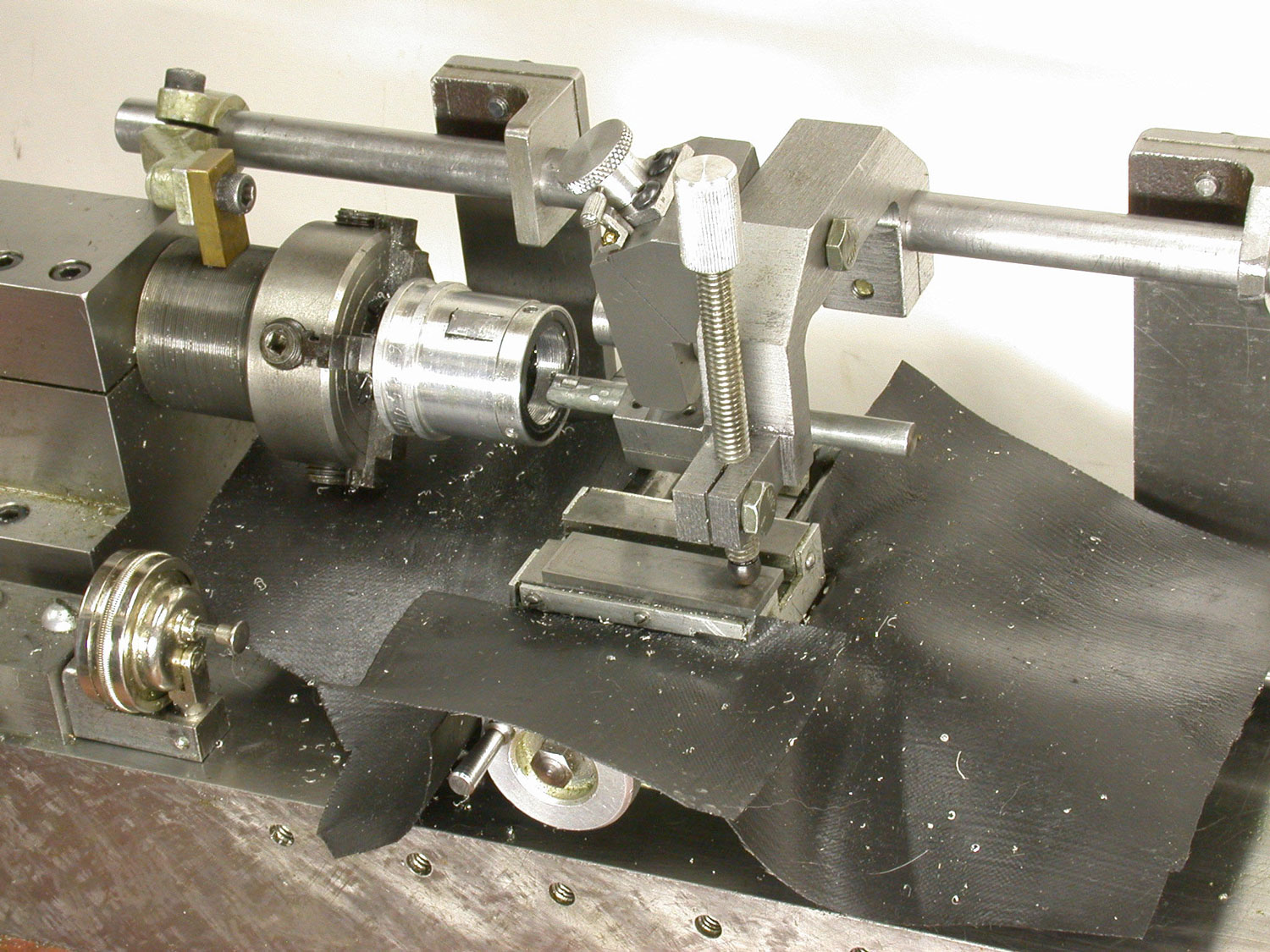

An Adjustable Threading Feed Attachment for a Lathe Without Metric

Lathe Threading Tools Solid carbide internal threading lathe tools. Position the cutting tool so that it is perpendicular to the workpiece surface and aligned with the desired thread start point. Use a thread gauge to accurately determine the. Once you have chosen the tool and set the right speed, you can begin by engaging the threading tool with the workpiece and cutting the thread. Solutions include laydown threading inserts, top notch™. Adjust the tool angle to match the thread pitch and size. The thread is cut by moving the tool along the length of the material in a. Dull tools can cause damage to the workpiece and create a poor thread. Constructed of a carbide tip brazed onto a ground steel shank, these tools are more wear. A sharp tool is paramount to the threading process. Choose from our selection of threading tools, including lathe tools, indexable lathe tools, and more. Ensure that the tool angle is correct to avoid damaging the thread. To thread on a metal lathe, you need to start by selecting the appropriate threading tool and setting the speed of the lathe. Solid carbide internal threading lathe tools. In stock and ready to ship.

From www.youtube.com

Cutting Internal Threads on the Metal Lathe Threading a Custom Nova Lathe Threading Tools To thread on a metal lathe, you need to start by selecting the appropriate threading tool and setting the speed of the lathe. Solutions include laydown threading inserts, top notch™. Choose from our selection of threading tools, including lathe tools, indexable lathe tools, and more. Position the cutting tool so that it is perpendicular to the workpiece surface and aligned. Lathe Threading Tools.

From

Lathe Threading Tools Dull tools can cause damage to the workpiece and create a poor thread. Ensure that the tool angle is correct to avoid damaging the thread. Position the cutting tool so that it is perpendicular to the workpiece surface and aligned with the desired thread start point. Once you have chosen the tool and set the right speed, you can begin. Lathe Threading Tools.

From

Lathe Threading Tools To thread on a metal lathe, you need to start by selecting the appropriate threading tool and setting the speed of the lathe. Dull tools can cause damage to the workpiece and create a poor thread. In stock and ready to ship. A sharp tool is paramount to the threading process. Adjust the tool angle to match the thread pitch. Lathe Threading Tools.

From www.youtube.com

Threading on a lathe YouTube Lathe Threading Tools Solid carbide internal threading lathe tools. The thread is cut by moving the tool along the length of the material in a. Adjust the tool angle to match the thread pitch and size. Constructed of a carbide tip brazed onto a ground steel shank, these tools are more wear. Position the cutting tool so that it is perpendicular to the. Lathe Threading Tools.

From

Lathe Threading Tools A sharp tool is paramount to the threading process. In stock and ready to ship. Adjust the tool angle to match the thread pitch and size. Ensure that the tool angle is correct to avoid damaging the thread. Once you have chosen the tool and set the right speed, you can begin by engaging the threading tool with the workpiece. Lathe Threading Tools.

From engineeringlearn.com

14 Types of Lathe Cutting Tools and Their Uses Guide Lathe Threading Tools A sharp tool is paramount to the threading process. Dull tools can cause damage to the workpiece and create a poor thread. Use a thread gauge to accurately determine the. Solutions include laydown threading inserts, top notch™. In stock and ready to ship. Once you have chosen the tool and set the right speed, you can begin by engaging the. Lathe Threading Tools.

From

Lathe Threading Tools Constructed of a carbide tip brazed onto a ground steel shank, these tools are more wear. Dull tools can cause damage to the workpiece and create a poor thread. A sharp tool is paramount to the threading process. Ensure that the tool angle is correct to avoid damaging the thread. Position the cutting tool so that it is perpendicular to. Lathe Threading Tools.

From

Lathe Threading Tools Position the cutting tool so that it is perpendicular to the workpiece surface and aligned with the desired thread start point. Solid carbide internal threading lathe tools. Adjust the tool angle to match the thread pitch and size. A sharp tool is paramount to the threading process. Constructed of a carbide tip brazed onto a ground steel shank, these tools. Lathe Threading Tools.

From chainheadway.com

CNC Threading Tools Supplier Chain Headway Lathe Threading Tools Position the cutting tool so that it is perpendicular to the workpiece surface and aligned with the desired thread start point. Solid carbide internal threading lathe tools. Constructed of a carbide tip brazed onto a ground steel shank, these tools are more wear. To thread on a metal lathe, you need to start by selecting the appropriate threading tool and. Lathe Threading Tools.

From

Lathe Threading Tools The thread is cut by moving the tool along the length of the material in a. In stock and ready to ship. Dull tools can cause damage to the workpiece and create a poor thread. To thread on a metal lathe, you need to start by selecting the appropriate threading tool and setting the speed of the lathe. Once you. Lathe Threading Tools.

From

Lathe Threading Tools Once you have chosen the tool and set the right speed, you can begin by engaging the threading tool with the workpiece and cutting the thread. Choose from our selection of threading tools, including lathe tools, indexable lathe tools, and more. Constructed of a carbide tip brazed onto a ground steel shank, these tools are more wear. The thread is. Lathe Threading Tools.

From imagetou.com

Manual Turning On A Lathe Image to u Lathe Threading Tools Position the cutting tool so that it is perpendicular to the workpiece surface and aligned with the desired thread start point. Dull tools can cause damage to the workpiece and create a poor thread. Choose from our selection of threading tools, including lathe tools, indexable lathe tools, and more. Constructed of a carbide tip brazed onto a ground steel shank,. Lathe Threading Tools.

From

Lathe Threading Tools Choose from our selection of threading tools, including lathe tools, indexable lathe tools, and more. Ensure that the tool angle is correct to avoid damaging the thread. In stock and ready to ship. Solutions include laydown threading inserts, top notch™. Constructed of a carbide tip brazed onto a ground steel shank, these tools are more wear. Adjust the tool angle. Lathe Threading Tools.

From

Lathe Threading Tools To thread on a metal lathe, you need to start by selecting the appropriate threading tool and setting the speed of the lathe. Choose from our selection of threading tools, including lathe tools, indexable lathe tools, and more. In stock and ready to ship. Ensure that the tool angle is correct to avoid damaging the thread. Once you have chosen. Lathe Threading Tools.

From www.youtube.com

Threading Step 5 (Setting Lathe Speed) YouTube Lathe Threading Tools To thread on a metal lathe, you need to start by selecting the appropriate threading tool and setting the speed of the lathe. Use a thread gauge to accurately determine the. Dull tools can cause damage to the workpiece and create a poor thread. In stock and ready to ship. Once you have chosen the tool and set the right. Lathe Threading Tools.

From

Lathe Threading Tools Ensure that the tool angle is correct to avoid damaging the thread. Dull tools can cause damage to the workpiece and create a poor thread. Solid carbide internal threading lathe tools. Once you have chosen the tool and set the right speed, you can begin by engaging the threading tool with the workpiece and cutting the thread. Choose from our. Lathe Threading Tools.

From

Lathe Threading Tools Use a thread gauge to accurately determine the. To thread on a metal lathe, you need to start by selecting the appropriate threading tool and setting the speed of the lathe. A sharp tool is paramount to the threading process. Choose from our selection of threading tools, including lathe tools, indexable lathe tools, and more. Solutions include laydown threading inserts,. Lathe Threading Tools.

From www.youtube.com

HOW TO THREAD ON LATHE MACHINE. EXTERNAL AND INTERNAL THREADS YouTube Lathe Threading Tools Choose from our selection of threading tools, including lathe tools, indexable lathe tools, and more. Adjust the tool angle to match the thread pitch and size. Use a thread gauge to accurately determine the. Dull tools can cause damage to the workpiece and create a poor thread. Solid carbide internal threading lathe tools. A sharp tool is paramount to the. Lathe Threading Tools.

From www.youtube.com

Threading With a Die on the Lathe YouTube Lathe Threading Tools Solutions include laydown threading inserts, top notch™. Dull tools can cause damage to the workpiece and create a poor thread. Solid carbide internal threading lathe tools. Ensure that the tool angle is correct to avoid damaging the thread. A sharp tool is paramount to the threading process. Position the cutting tool so that it is perpendicular to the workpiece surface. Lathe Threading Tools.

From

Lathe Threading Tools The thread is cut by moving the tool along the length of the material in a. Solutions include laydown threading inserts, top notch™. In stock and ready to ship. Position the cutting tool so that it is perpendicular to the workpiece surface and aligned with the desired thread start point. Choose from our selection of threading tools, including lathe tools,. Lathe Threading Tools.

From

Lathe Threading Tools Once you have chosen the tool and set the right speed, you can begin by engaging the threading tool with the workpiece and cutting the thread. Constructed of a carbide tip brazed onto a ground steel shank, these tools are more wear. Choose from our selection of threading tools, including lathe tools, indexable lathe tools, and more. Adjust the tool. Lathe Threading Tools.

From

Lathe Threading Tools In stock and ready to ship. Dull tools can cause damage to the workpiece and create a poor thread. Solutions include laydown threading inserts, top notch™. Adjust the tool angle to match the thread pitch and size. Choose from our selection of threading tools, including lathe tools, indexable lathe tools, and more. To thread on a metal lathe, you need. Lathe Threading Tools.

From

Lathe Threading Tools In stock and ready to ship. Position the cutting tool so that it is perpendicular to the workpiece surface and aligned with the desired thread start point. Choose from our selection of threading tools, including lathe tools, indexable lathe tools, and more. Once you have chosen the tool and set the right speed, you can begin by engaging the threading. Lathe Threading Tools.

From

Lathe Threading Tools Once you have chosen the tool and set the right speed, you can begin by engaging the threading tool with the workpiece and cutting the thread. Solutions include laydown threading inserts, top notch™. Solid carbide internal threading lathe tools. Ensure that the tool angle is correct to avoid damaging the thread. In stock and ready to ship. To thread on. Lathe Threading Tools.

From

Lathe Threading Tools The thread is cut by moving the tool along the length of the material in a. Choose from our selection of threading tools, including lathe tools, indexable lathe tools, and more. Position the cutting tool so that it is perpendicular to the workpiece surface and aligned with the desired thread start point. Adjust the tool angle to match the thread. Lathe Threading Tools.

From www.mccrone.com

An Adjustable Threading Feed Attachment for a Lathe Without Metric Lathe Threading Tools Ensure that the tool angle is correct to avoid damaging the thread. Use a thread gauge to accurately determine the. Dull tools can cause damage to the workpiece and create a poor thread. To thread on a metal lathe, you need to start by selecting the appropriate threading tool and setting the speed of the lathe. Position the cutting tool. Lathe Threading Tools.

From chronos.ltd.uk

Set of 8 SCT Solid HSS Lathe Turning Tools 16 mm Square Lathe Threading Tools Position the cutting tool so that it is perpendicular to the workpiece surface and aligned with the desired thread start point. Constructed of a carbide tip brazed onto a ground steel shank, these tools are more wear. In stock and ready to ship. Dull tools can cause damage to the workpiece and create a poor thread. A sharp tool is. Lathe Threading Tools.

From www.aliexpress.com

MANF Lathe Cutting Tools HSNR0012M11 CNC Lathe Machining Cutter Lathe Threading Tools To thread on a metal lathe, you need to start by selecting the appropriate threading tool and setting the speed of the lathe. Dull tools can cause damage to the workpiece and create a poor thread. Choose from our selection of threading tools, including lathe tools, indexable lathe tools, and more. A sharp tool is paramount to the threading process.. Lathe Threading Tools.

From www.aliexpress.com

Outside diameter thread tool holder SER2020K16 CNC lathe tool holder Lathe Threading Tools Once you have chosen the tool and set the right speed, you can begin by engaging the threading tool with the workpiece and cutting the thread. Choose from our selection of threading tools, including lathe tools, indexable lathe tools, and more. To thread on a metal lathe, you need to start by selecting the appropriate threading tool and setting the. Lathe Threading Tools.

From

Lathe Threading Tools Use a thread gauge to accurately determine the. The thread is cut by moving the tool along the length of the material in a. Adjust the tool angle to match the thread pitch and size. Solid carbide internal threading lathe tools. Once you have chosen the tool and set the right speed, you can begin by engaging the threading tool. Lathe Threading Tools.

From www.youtube.com

Thread milling with Lathe Threading Tool YouTube Lathe Threading Tools Solid carbide internal threading lathe tools. Once you have chosen the tool and set the right speed, you can begin by engaging the threading tool with the workpiece and cutting the thread. Choose from our selection of threading tools, including lathe tools, indexable lathe tools, and more. A sharp tool is paramount to the threading process. The thread is cut. Lathe Threading Tools.

From

Lathe Threading Tools Ensure that the tool angle is correct to avoid damaging the thread. Solid carbide internal threading lathe tools. Choose from our selection of threading tools, including lathe tools, indexable lathe tools, and more. Adjust the tool angle to match the thread pitch and size. Use a thread gauge to accurately determine the. Constructed of a carbide tip brazed onto a. Lathe Threading Tools.

From

Lathe Threading Tools Adjust the tool angle to match the thread pitch and size. Ensure that the tool angle is correct to avoid damaging the thread. Dull tools can cause damage to the workpiece and create a poor thread. Solid carbide internal threading lathe tools. The thread is cut by moving the tool along the length of the material in a. To thread. Lathe Threading Tools.

From www.aliexpress.com

SER1010H11 10x100mm External Threading Tools Lathe Threading Turning Lathe Threading Tools In stock and ready to ship. The thread is cut by moving the tool along the length of the material in a. Ensure that the tool angle is correct to avoid damaging the thread. To thread on a metal lathe, you need to start by selecting the appropriate threading tool and setting the speed of the lathe. A sharp tool. Lathe Threading Tools.

From

Lathe Threading Tools A sharp tool is paramount to the threading process. Solid carbide internal threading lathe tools. Ensure that the tool angle is correct to avoid damaging the thread. To thread on a metal lathe, you need to start by selecting the appropriate threading tool and setting the speed of the lathe. Use a thread gauge to accurately determine the. Solutions include. Lathe Threading Tools.