Rivet Joint Sheet Metal . There are four primary sheet metal processing techniques: They consist of a smooth, cylindrical. Riveting sheet metal is all about using a metal pin or bolt to join two pieces of metal. It is ideal for thin sheets where edge joining. It’s a permanent fastening method, ensuring the parts won’t part ways anytime soon. Punching (shearing), folding (rolling), welding, and surface treatment. At shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. The lap joint is perhaps the most fundamental rivet joint, wherein two metal pieces overlap at their edges and are riveted together. Sheet metal rivets are mechanical fasteners used to permanently join two or more metal sheets together.

from collieraerospace.com

It’s a permanent fastening method, ensuring the parts won’t part ways anytime soon. They consist of a smooth, cylindrical. There are four primary sheet metal processing techniques: The lap joint is perhaps the most fundamental rivet joint, wherein two metal pieces overlap at their edges and are riveted together. At shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. Punching (shearing), folding (rolling), welding, and surface treatment. Riveting sheet metal is all about using a metal pin or bolt to join two pieces of metal. It is ideal for thin sheets where edge joining. Sheet metal rivets are mechanical fasteners used to permanently join two or more metal sheets together.

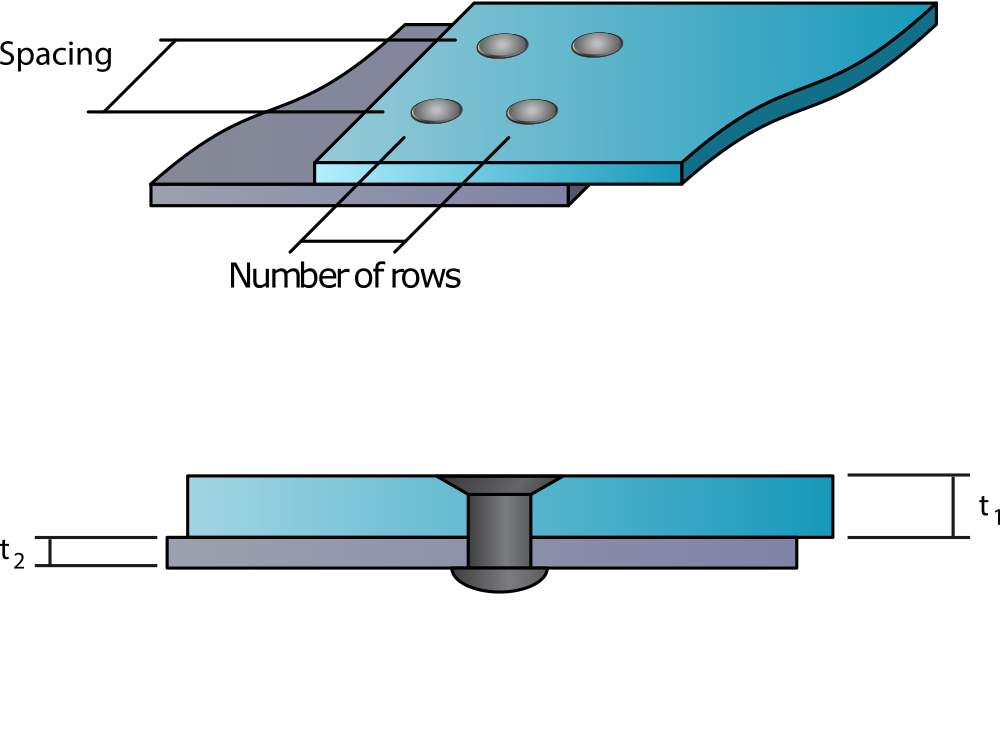

Fastened and Bonded Joints

Rivet Joint Sheet Metal The lap joint is perhaps the most fundamental rivet joint, wherein two metal pieces overlap at their edges and are riveted together. Sheet metal rivets are mechanical fasteners used to permanently join two or more metal sheets together. The lap joint is perhaps the most fundamental rivet joint, wherein two metal pieces overlap at their edges and are riveted together. They consist of a smooth, cylindrical. At shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. There are four primary sheet metal processing techniques: Riveting sheet metal is all about using a metal pin or bolt to join two pieces of metal. It’s a permanent fastening method, ensuring the parts won’t part ways anytime soon. Punching (shearing), folding (rolling), welding, and surface treatment. It is ideal for thin sheets where edge joining.

From blog.thepipingmart.com

Learn About The Riveted Joints And Its Types ThePipingMart Blog Rivet Joint Sheet Metal They consist of a smooth, cylindrical. Punching (shearing), folding (rolling), welding, and surface treatment. At shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. Sheet metal rivets are mechanical fasteners used to permanently join two or more metal sheets together. It’s a permanent fastening method, ensuring the parts won’t part ways anytime soon.. Rivet Joint Sheet Metal.

From www.iqsdirectory.com

Sheet Metal Fabrication What Is It? How Does It Work? Rivet Joint Sheet Metal It is ideal for thin sheets where edge joining. The lap joint is perhaps the most fundamental rivet joint, wherein two metal pieces overlap at their edges and are riveted together. There are four primary sheet metal processing techniques: Punching (shearing), folding (rolling), welding, and surface treatment. At shengen, we understand the nuances of sheet metal fabrication and the importance. Rivet Joint Sheet Metal.

From www.dreamstime.com

Steel Structure on Bolted and Riveted Joints Stock Photo Image of Rivet Joint Sheet Metal There are four primary sheet metal processing techniques: It is ideal for thin sheets where edge joining. Sheet metal rivets are mechanical fasteners used to permanently join two or more metal sheets together. Riveting sheet metal is all about using a metal pin or bolt to join two pieces of metal. The lap joint is perhaps the most fundamental rivet. Rivet Joint Sheet Metal.

From www.researchgate.net

Predrilled riveted joints with blind rivets a) aluminium alloy, b Rivet Joint Sheet Metal Riveting sheet metal is all about using a metal pin or bolt to join two pieces of metal. Punching (shearing), folding (rolling), welding, and surface treatment. At shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. The lap joint is perhaps the most fundamental rivet joint, wherein two metal pieces overlap at their. Rivet Joint Sheet Metal.

From www.dreamstime.com

Metal Parts of the Rivet Joints and Bolts Stock Photo Image of Rivet Joint Sheet Metal At shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. Punching (shearing), folding (rolling), welding, and surface treatment. Sheet metal rivets are mechanical fasteners used to permanently join two or more metal sheets together. They consist of a smooth, cylindrical. The lap joint is perhaps the most fundamental rivet joint, wherein two metal. Rivet Joint Sheet Metal.

From www.mecholic.com

riveting material joining process Rivet Joint Sheet Metal It’s a permanent fastening method, ensuring the parts won’t part ways anytime soon. There are four primary sheet metal processing techniques: It is ideal for thin sheets where edge joining. Sheet metal rivets are mechanical fasteners used to permanently join two or more metal sheets together. Punching (shearing), folding (rolling), welding, and surface treatment. Riveting sheet metal is all about. Rivet Joint Sheet Metal.

From www.youtube.com

How to install rivets and cut sheet metal YouTube Rivet Joint Sheet Metal At shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. It’s a permanent fastening method, ensuring the parts won’t part ways anytime soon. Riveting sheet metal is all about using a metal pin or bolt to join two pieces of metal. Punching (shearing), folding (rolling), welding, and surface treatment. The lap joint is. Rivet Joint Sheet Metal.

From www.dreamstime.com

Metal Parts of the Rivet Joints and Bolts Stock Photo Image of girder Rivet Joint Sheet Metal Punching (shearing), folding (rolling), welding, and surface treatment. Sheet metal rivets are mechanical fasteners used to permanently join two or more metal sheets together. Riveting sheet metal is all about using a metal pin or bolt to join two pieces of metal. The lap joint is perhaps the most fundamental rivet joint, wherein two metal pieces overlap at their edges. Rivet Joint Sheet Metal.

From engistudies.blogspot.com

Different Types, Advantages, and Disadvantages of Riveted joint Rivet Joint Sheet Metal It’s a permanent fastening method, ensuring the parts won’t part ways anytime soon. Sheet metal rivets are mechanical fasteners used to permanently join two or more metal sheets together. There are four primary sheet metal processing techniques: At shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. The lap joint is perhaps the. Rivet Joint Sheet Metal.

From www.youtube.com

Types of riveted joints Design of steel structure YouTube Rivet Joint Sheet Metal At shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. They consist of a smooth, cylindrical. Riveting sheet metal is all about using a metal pin or bolt to join two pieces of metal. Punching (shearing), folding (rolling), welding, and surface treatment. Sheet metal rivets are mechanical fasteners used to permanently join two. Rivet Joint Sheet Metal.

From www.engineeringchoice.com

What is Rivet? Definition, Types, Working & Process Engineering Choice Rivet Joint Sheet Metal There are four primary sheet metal processing techniques: They consist of a smooth, cylindrical. Punching (shearing), folding (rolling), welding, and surface treatment. Sheet metal rivets are mechanical fasteners used to permanently join two or more metal sheets together. The lap joint is perhaps the most fundamental rivet joint, wherein two metal pieces overlap at their edges and are riveted together.. Rivet Joint Sheet Metal.

From proleantech.com

Riveting in Sheet Metal Uniting Strength and Precision Rivet Joint Sheet Metal There are four primary sheet metal processing techniques: Sheet metal rivets are mechanical fasteners used to permanently join two or more metal sheets together. Riveting sheet metal is all about using a metal pin or bolt to join two pieces of metal. At shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. It. Rivet Joint Sheet Metal.

From blog.thepipingmart.com

Learn About The Riveted Joints And Its Types ThePipingMart Blog Rivet Joint Sheet Metal The lap joint is perhaps the most fundamental rivet joint, wherein two metal pieces overlap at their edges and are riveted together. It is ideal for thin sheets where edge joining. They consist of a smooth, cylindrical. Sheet metal rivets are mechanical fasteners used to permanently join two or more metal sheets together. At shengen, we understand the nuances of. Rivet Joint Sheet Metal.

From www.dreamstime.com

Metal Parts of the Rivet Joints and Bolts Stock Photo Image of design Rivet Joint Sheet Metal They consist of a smooth, cylindrical. It is ideal for thin sheets where edge joining. At shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. The lap joint is perhaps the most fundamental rivet joint, wherein two metal pieces overlap at their edges and are riveted together. It’s a permanent fastening method, ensuring. Rivet Joint Sheet Metal.

From www.freeimages.com

Sheet metal, rivets and seams Free Photo Download FreeImages Rivet Joint Sheet Metal At shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. Punching (shearing), folding (rolling), welding, and surface treatment. It is ideal for thin sheets where edge joining. Riveting sheet metal is all about using a metal pin or bolt to join two pieces of metal. The lap joint is perhaps the most fundamental. Rivet Joint Sheet Metal.

From journals.sagepub.com

The Experimental Analysis of Forming and Strength of Clinch Riveting Rivet Joint Sheet Metal Punching (shearing), folding (rolling), welding, and surface treatment. At shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. Riveting sheet metal is all about using a metal pin or bolt to join two pieces of metal. It is ideal for thin sheets where edge joining. It’s a permanent fastening method, ensuring the parts. Rivet Joint Sheet Metal.

From www.dreamstime.com

Strong steel rivets stock image. Image of metal, construction 154574663 Rivet Joint Sheet Metal Punching (shearing), folding (rolling), welding, and surface treatment. Riveting sheet metal is all about using a metal pin or bolt to join two pieces of metal. They consist of a smooth, cylindrical. There are four primary sheet metal processing techniques: It’s a permanent fastening method, ensuring the parts won’t part ways anytime soon. Sheet metal rivets are mechanical fasteners used. Rivet Joint Sheet Metal.

From www.dreamstime.com

Riveting Two Pieces of Metal Sheet. Connecting Steel with Rivets Stock Rivet Joint Sheet Metal At shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. Punching (shearing), folding (rolling), welding, and surface treatment. It is ideal for thin sheets where edge joining. They consist of a smooth, cylindrical. There are four primary sheet metal processing techniques: Riveting sheet metal is all about using a metal pin or bolt. Rivet Joint Sheet Metal.

From www.thefabricator.com

Advances in riveting and mechanical fastening Rivet Joint Sheet Metal Sheet metal rivets are mechanical fasteners used to permanently join two or more metal sheets together. Riveting sheet metal is all about using a metal pin or bolt to join two pieces of metal. Punching (shearing), folding (rolling), welding, and surface treatment. At shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. It. Rivet Joint Sheet Metal.

From www.dreamstime.com

Metal Parts of the Rivet Joints and Bolts Stock Photo Image of cast Rivet Joint Sheet Metal They consist of a smooth, cylindrical. Punching (shearing), folding (rolling), welding, and surface treatment. It is ideal for thin sheets where edge joining. At shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. The lap joint is perhaps the most fundamental rivet joint, wherein two metal pieces overlap at their edges and are. Rivet Joint Sheet Metal.

From proleantech.com

Sheet Metal Fabrication Riveting VS Welding Rivet Joint Sheet Metal It’s a permanent fastening method, ensuring the parts won’t part ways anytime soon. They consist of a smooth, cylindrical. Riveting sheet metal is all about using a metal pin or bolt to join two pieces of metal. The lap joint is perhaps the most fundamental rivet joint, wherein two metal pieces overlap at their edges and are riveted together. There. Rivet Joint Sheet Metal.

From www.dreamstime.com

Detail Joint Construction with Steel Rivets Stock Photo Image of Rivet Joint Sheet Metal There are four primary sheet metal processing techniques: They consist of a smooth, cylindrical. It’s a permanent fastening method, ensuring the parts won’t part ways anytime soon. Riveting sheet metal is all about using a metal pin or bolt to join two pieces of metal. Sheet metal rivets are mechanical fasteners used to permanently join two or more metal sheets. Rivet Joint Sheet Metal.

From collieraerospace.com

Fastened and Bonded Joints Rivet Joint Sheet Metal They consist of a smooth, cylindrical. There are four primary sheet metal processing techniques: It’s a permanent fastening method, ensuring the parts won’t part ways anytime soon. The lap joint is perhaps the most fundamental rivet joint, wherein two metal pieces overlap at their edges and are riveted together. At shengen, we understand the nuances of sheet metal fabrication and. Rivet Joint Sheet Metal.

From www.dreamstime.com

Metal Parts of the Rivet Joints and Bolts Stock Image Image of Rivet Joint Sheet Metal Riveting sheet metal is all about using a metal pin or bolt to join two pieces of metal. Sheet metal rivets are mechanical fasteners used to permanently join two or more metal sheets together. It is ideal for thin sheets where edge joining. They consist of a smooth, cylindrical. At shengen, we understand the nuances of sheet metal fabrication and. Rivet Joint Sheet Metal.

From www.pinterest.co.uk

Rivets are a very aesthetically pleasing feature on metal structures. I Rivet Joint Sheet Metal Sheet metal rivets are mechanical fasteners used to permanently join two or more metal sheets together. At shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. It’s a permanent fastening method, ensuring the parts won’t part ways anytime soon. The lap joint is perhaps the most fundamental rivet joint, wherein two metal pieces. Rivet Joint Sheet Metal.

From www.assemblymag.com

Resistance Spot Riveting 20170105 Assembly Magazine Rivet Joint Sheet Metal Punching (shearing), folding (rolling), welding, and surface treatment. There are four primary sheet metal processing techniques: It is ideal for thin sheets where edge joining. It’s a permanent fastening method, ensuring the parts won’t part ways anytime soon. Sheet metal rivets are mechanical fasteners used to permanently join two or more metal sheets together. Riveting sheet metal is all about. Rivet Joint Sheet Metal.

From www.dreamstime.com

Metal Parts of the Rivet Joints and Bolts Stock Image Image of Rivet Joint Sheet Metal The lap joint is perhaps the most fundamental rivet joint, wherein two metal pieces overlap at their edges and are riveted together. There are four primary sheet metal processing techniques: At shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. Sheet metal rivets are mechanical fasteners used to permanently join two or more. Rivet Joint Sheet Metal.

From blog.baysupply.com

Pop Rivets vs. Blind Rivets Rivet Joint Sheet Metal Riveting sheet metal is all about using a metal pin or bolt to join two pieces of metal. Punching (shearing), folding (rolling), welding, and surface treatment. Sheet metal rivets are mechanical fasteners used to permanently join two or more metal sheets together. The lap joint is perhaps the most fundamental rivet joint, wherein two metal pieces overlap at their edges. Rivet Joint Sheet Metal.

From www.youtube.com

Differences between Welding and Riveting Weld Joint Vs Rivet Joint Rivet Joint Sheet Metal Sheet metal rivets are mechanical fasteners used to permanently join two or more metal sheets together. It’s a permanent fastening method, ensuring the parts won’t part ways anytime soon. At shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. It is ideal for thin sheets where edge joining. There are four primary sheet. Rivet Joint Sheet Metal.

From www.hunker.com

How to Rivet Sheet Metal Hunker Rivet Joint Sheet Metal They consist of a smooth, cylindrical. At shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. The lap joint is perhaps the most fundamental rivet joint, wherein two metal pieces overlap at their edges and are riveted together. Punching (shearing), folding (rolling), welding, and surface treatment. It’s a permanent fastening method, ensuring the. Rivet Joint Sheet Metal.

From theconstructor.org

How to Perform Riveting and Bolting in Steel Structure? The Constructor Rivet Joint Sheet Metal Punching (shearing), folding (rolling), welding, and surface treatment. They consist of a smooth, cylindrical. At shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. There are four primary sheet metal processing techniques: Riveting sheet metal is all about using a metal pin or bolt to join two pieces of metal. The lap joint. Rivet Joint Sheet Metal.

From www.dreamstime.com

Riveting Two Pieces of Metal Sheet. Connecting Steel with Rivets Stock Rivet Joint Sheet Metal It’s a permanent fastening method, ensuring the parts won’t part ways anytime soon. There are four primary sheet metal processing techniques: Riveting sheet metal is all about using a metal pin or bolt to join two pieces of metal. Sheet metal rivets are mechanical fasteners used to permanently join two or more metal sheets together. At shengen, we understand the. Rivet Joint Sheet Metal.

From www.turbosquid.com

Texture jpg metal rivet rivets Rivet Joint Sheet Metal Punching (shearing), folding (rolling), welding, and surface treatment. They consist of a smooth, cylindrical. There are four primary sheet metal processing techniques: It is ideal for thin sheets where edge joining. It’s a permanent fastening method, ensuring the parts won’t part ways anytime soon. Sheet metal rivets are mechanical fasteners used to permanently join two or more metal sheets together.. Rivet Joint Sheet Metal.

From svauto.dk

Types Rivets For Metal Sheets Assembly KDM Fabrication Rivet Joint Sheet Metal At shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. There are four primary sheet metal processing techniques: They consist of a smooth, cylindrical. The lap joint is perhaps the most fundamental rivet joint, wherein two metal pieces overlap at their edges and are riveted together. Punching (shearing), folding (rolling), welding, and surface. Rivet Joint Sheet Metal.

From www.alamy.com

Sheet metal with rivets Stock Photo Alamy Rivet Joint Sheet Metal Riveting sheet metal is all about using a metal pin or bolt to join two pieces of metal. Punching (shearing), folding (rolling), welding, and surface treatment. At shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. It’s a permanent fastening method, ensuring the parts won’t part ways anytime soon. There are four primary. Rivet Joint Sheet Metal.