Thermoplastic Design Meaning . Thermoplastic is a type of plastic material that becomes soft when heated and hard when cooled. Thermoplastic, also known as a thermosoftening plastic, is a type of polymer which becomes soft when heated and hardens upon cooling. Check out a few examples. Learn its properties, applications, advantages, & disadvantages. A thermoplastic is a polymer that softens when heated and solidifies when cooled, allowing it to be molded and reshaped multiple times without. A thermoplastic is a class of polymer that can be softened through heating and then processed using methods such as extrusion, injection moulding, thermoforming and blow moulding. Thermoplastics are a class of materials that, by reaching a glass transition temperature, can be remolded repeatedly [135]. Compare & contrast thermoset vs. Manufacturers use thermoplastics for many things because they are incredibly easy to mold and.

from www.mdpi.com

Manufacturers use thermoplastics for many things because they are incredibly easy to mold and. Learn its properties, applications, advantages, & disadvantages. Compare & contrast thermoset vs. A thermoplastic is a polymer that softens when heated and solidifies when cooled, allowing it to be molded and reshaped multiple times without. Thermoplastic, also known as a thermosoftening plastic, is a type of polymer which becomes soft when heated and hardens upon cooling. A thermoplastic is a class of polymer that can be softened through heating and then processed using methods such as extrusion, injection moulding, thermoforming and blow moulding. Check out a few examples. Thermoplastic is a type of plastic material that becomes soft when heated and hard when cooled. Thermoplastics are a class of materials that, by reaching a glass transition temperature, can be remolded repeatedly [135].

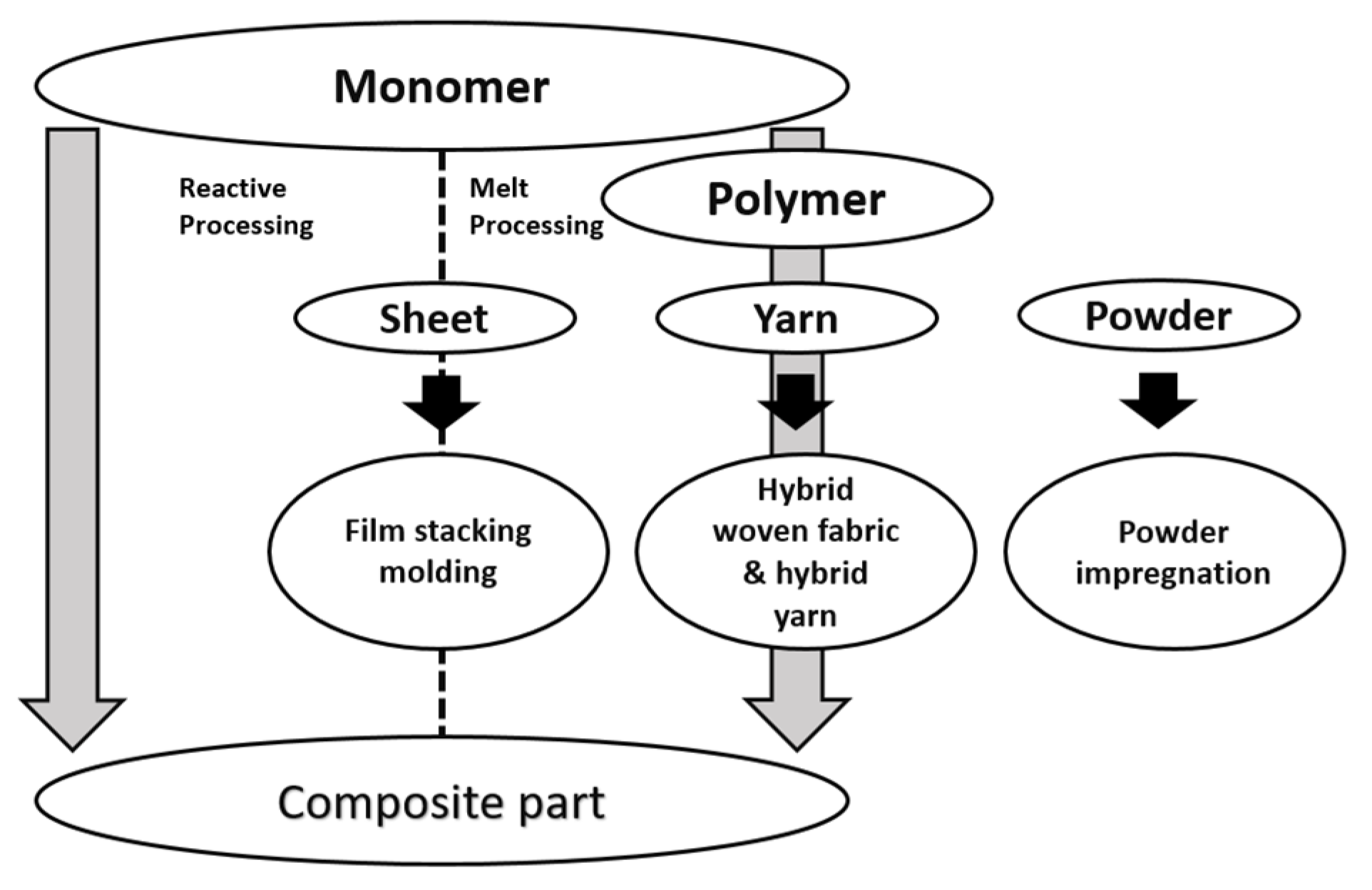

Polymers Free FullText Different Production Processes for

Thermoplastic Design Meaning Check out a few examples. Check out a few examples. Learn its properties, applications, advantages, & disadvantages. A thermoplastic is a class of polymer that can be softened through heating and then processed using methods such as extrusion, injection moulding, thermoforming and blow moulding. A thermoplastic is a polymer that softens when heated and solidifies when cooled, allowing it to be molded and reshaped multiple times without. Thermoplastic is a type of plastic material that becomes soft when heated and hard when cooled. Manufacturers use thermoplastics for many things because they are incredibly easy to mold and. Thermoplastic, also known as a thermosoftening plastic, is a type of polymer which becomes soft when heated and hardens upon cooling. Compare & contrast thermoset vs. Thermoplastics are a class of materials that, by reaching a glass transition temperature, can be remolded repeatedly [135].

From www.slideserve.com

PPT Group 6 Presentation Chapter 7, 8, and 9 PowerPoint Presentation Thermoplastic Design Meaning Check out a few examples. A thermoplastic is a polymer that softens when heated and solidifies when cooled, allowing it to be molded and reshaped multiple times without. A thermoplastic is a class of polymer that can be softened through heating and then processed using methods such as extrusion, injection moulding, thermoforming and blow moulding. Thermoplastic is a type of. Thermoplastic Design Meaning.

From www.sportsandsafetysurfaces.co.uk

Thermoplastic Playground Line Marking Design Sports and Safety Surfaces Thermoplastic Design Meaning Learn its properties, applications, advantages, & disadvantages. Compare & contrast thermoset vs. Thermoplastics are a class of materials that, by reaching a glass transition temperature, can be remolded repeatedly [135]. A thermoplastic is a class of polymer that can be softened through heating and then processed using methods such as extrusion, injection moulding, thermoforming and blow moulding. Manufacturers use thermoplastics. Thermoplastic Design Meaning.

From www.desertcart.in

Buy ENERLITES Elite Series Screwless Decorator Wall Plate Child Safe Thermoplastic Design Meaning Thermoplastics are a class of materials that, by reaching a glass transition temperature, can be remolded repeatedly [135]. A thermoplastic is a class of polymer that can be softened through heating and then processed using methods such as extrusion, injection moulding, thermoforming and blow moulding. Learn its properties, applications, advantages, & disadvantages. Compare & contrast thermoset vs. Thermoplastic, also known. Thermoplastic Design Meaning.

From www.youtube.com

Thermoplastic resin Meaning YouTube Thermoplastic Design Meaning Thermoplastic is a type of plastic material that becomes soft when heated and hard when cooled. A thermoplastic is a class of polymer that can be softened through heating and then processed using methods such as extrusion, injection moulding, thermoforming and blow moulding. Thermoplastics are a class of materials that, by reaching a glass transition temperature, can be remolded repeatedly. Thermoplastic Design Meaning.

From www.mdpi.com

Applied Sciences Free FullText Continuous FiberReinforced Thermoplastic Design Meaning Learn its properties, applications, advantages, & disadvantages. A thermoplastic is a polymer that softens when heated and solidifies when cooled, allowing it to be molded and reshaped multiple times without. Thermoplastics are a class of materials that, by reaching a glass transition temperature, can be remolded repeatedly [135]. Manufacturers use thermoplastics for many things because they are incredibly easy to. Thermoplastic Design Meaning.

From www.echosupply.com

Basics of Thermoplastics Echo Supply Thermoplastic Design Meaning Compare & contrast thermoset vs. A thermoplastic is a polymer that softens when heated and solidifies when cooled, allowing it to be molded and reshaped multiple times without. Check out a few examples. Thermoplastic, also known as a thermosoftening plastic, is a type of polymer which becomes soft when heated and hardens upon cooling. Learn its properties, applications, advantages, &. Thermoplastic Design Meaning.

From pubs.acs.org

Design of Thermoplastic Polyurethanes with Conferred Antibacterial Thermoplastic Design Meaning Learn its properties, applications, advantages, & disadvantages. Thermoplastic is a type of plastic material that becomes soft when heated and hard when cooled. Compare & contrast thermoset vs. A thermoplastic is a class of polymer that can be softened through heating and then processed using methods such as extrusion, injection moulding, thermoforming and blow moulding. Check out a few examples.. Thermoplastic Design Meaning.

From www.youtube.com

Designing with Thermoplastics Fluid Handling YouTube Thermoplastic Design Meaning Check out a few examples. Thermoplastic, also known as a thermosoftening plastic, is a type of polymer which becomes soft when heated and hardens upon cooling. Thermoplastic is a type of plastic material that becomes soft when heated and hard when cooled. Learn its properties, applications, advantages, & disadvantages. A thermoplastic is a polymer that softens when heated and solidifies. Thermoplastic Design Meaning.

From www.porticos.net

ThermoplasticPolymer Porticos Product Design & Development Thermoplastic Design Meaning Compare & contrast thermoset vs. A thermoplastic is a class of polymer that can be softened through heating and then processed using methods such as extrusion, injection moulding, thermoforming and blow moulding. Check out a few examples. Thermoplastic is a type of plastic material that becomes soft when heated and hard when cooled. Manufacturers use thermoplastics for many things because. Thermoplastic Design Meaning.

From www.mdpi.com

Metals Free FullText Mechanical Properties of ThermoplasticBased Thermoplastic Design Meaning Check out a few examples. Thermoplastic, also known as a thermosoftening plastic, is a type of polymer which becomes soft when heated and hardens upon cooling. A thermoplastic is a class of polymer that can be softened through heating and then processed using methods such as extrusion, injection moulding, thermoforming and blow moulding. Compare & contrast thermoset vs. Thermoplastics are. Thermoplastic Design Meaning.

From www.liuguitang.org

B What Are The Differences Between Thermoplastics And Thermosetting Thermoplastic Design Meaning Manufacturers use thermoplastics for many things because they are incredibly easy to mold and. Thermoplastics are a class of materials that, by reaching a glass transition temperature, can be remolded repeatedly [135]. A thermoplastic is a polymer that softens when heated and solidifies when cooled, allowing it to be molded and reshaped multiple times without. Thermoplastic, also known as a. Thermoplastic Design Meaning.

From www.researchgate.net

Examples of (a) thermoplastics and (b) thermosetting plastics Thermoplastic Design Meaning Thermoplastic, also known as a thermosoftening plastic, is a type of polymer which becomes soft when heated and hardens upon cooling. Thermoplastic is a type of plastic material that becomes soft when heated and hard when cooled. Check out a few examples. Compare & contrast thermoset vs. A thermoplastic is a class of polymer that can be softened through heating. Thermoplastic Design Meaning.

From www.essentracomponents.com

The future of injection moulding Essentra Components UK Thermoplastic Design Meaning Thermoplastic is a type of plastic material that becomes soft when heated and hard when cooled. Compare & contrast thermoset vs. Learn its properties, applications, advantages, & disadvantages. Thermoplastic, also known as a thermosoftening plastic, is a type of polymer which becomes soft when heated and hardens upon cooling. Thermoplastics are a class of materials that, by reaching a glass. Thermoplastic Design Meaning.

From www.youtube.com

Thermoplastics and Thermosetting Plastics Meaning, difference, uses Thermoplastic Design Meaning Thermoplastic is a type of plastic material that becomes soft when heated and hard when cooled. Check out a few examples. Thermoplastic, also known as a thermosoftening plastic, is a type of polymer which becomes soft when heated and hardens upon cooling. Thermoplastics are a class of materials that, by reaching a glass transition temperature, can be remolded repeatedly [135].. Thermoplastic Design Meaning.

From www.productiveplastics.com

What is Thermoforming? Plastic Thermoforming Explained Productive Thermoplastic Design Meaning A thermoplastic is a polymer that softens when heated and solidifies when cooled, allowing it to be molded and reshaped multiple times without. A thermoplastic is a class of polymer that can be softened through heating and then processed using methods such as extrusion, injection moulding, thermoforming and blow moulding. Learn its properties, applications, advantages, & disadvantages. Thermoplastics are a. Thermoplastic Design Meaning.

From dokumen.tips

(PPTX) Thermoplastics Introduction,classification,Processing Thermoplastic Design Meaning A thermoplastic is a polymer that softens when heated and solidifies when cooled, allowing it to be molded and reshaped multiple times without. Check out a few examples. Manufacturers use thermoplastics for many things because they are incredibly easy to mold and. Thermoplastics are a class of materials that, by reaching a glass transition temperature, can be remolded repeatedly [135].. Thermoplastic Design Meaning.

From www.youtube.com

Thermoplastic Meaning YouTube Thermoplastic Design Meaning Manufacturers use thermoplastics for many things because they are incredibly easy to mold and. A thermoplastic is a polymer that softens when heated and solidifies when cooled, allowing it to be molded and reshaped multiple times without. Thermoplastic is a type of plastic material that becomes soft when heated and hard when cooled. Thermoplastic, also known as a thermosoftening plastic,. Thermoplastic Design Meaning.

From www.youtube.com

3 Thermoplastic & Thermoset Polymers' Key Attributes YouTube Thermoplastic Design Meaning Thermoplastic is a type of plastic material that becomes soft when heated and hard when cooled. Thermoplastics are a class of materials that, by reaching a glass transition temperature, can be remolded repeatedly [135]. A thermoplastic is a polymer that softens when heated and solidifies when cooled, allowing it to be molded and reshaped multiple times without. Check out a. Thermoplastic Design Meaning.

From www.youtube.com

Thermoplastic resin Meaning YouTube Thermoplastic Design Meaning Compare & contrast thermoset vs. Thermoplastic, also known as a thermosoftening plastic, is a type of polymer which becomes soft when heated and hardens upon cooling. Learn its properties, applications, advantages, & disadvantages. A thermoplastic is a polymer that softens when heated and solidifies when cooled, allowing it to be molded and reshaped multiple times without. Thermoplastics are a class. Thermoplastic Design Meaning.

From www.slideserve.com

PPT Materials PowerPoint Presentation, free download ID1851949 Thermoplastic Design Meaning Thermoplastic, also known as a thermosoftening plastic, is a type of polymer which becomes soft when heated and hardens upon cooling. Check out a few examples. A thermoplastic is a polymer that softens when heated and solidifies when cooled, allowing it to be molded and reshaped multiple times without. A thermoplastic is a class of polymer that can be softened. Thermoplastic Design Meaning.

From www.polymermolding.com

Thermoplastics Their Properties and Common Uses Thermoplastic Design Meaning Thermoplastic is a type of plastic material that becomes soft when heated and hard when cooled. Manufacturers use thermoplastics for many things because they are incredibly easy to mold and. Thermoplastics are a class of materials that, by reaching a glass transition temperature, can be remolded repeatedly [135]. Check out a few examples. Thermoplastic, also known as a thermosoftening plastic,. Thermoplastic Design Meaning.

From studylib.net

An Engineer`s Guide to Specify the Right Thermoplastic Thermoplastic Design Meaning Manufacturers use thermoplastics for many things because they are incredibly easy to mold and. Compare & contrast thermoset vs. Learn its properties, applications, advantages, & disadvantages. A thermoplastic is a polymer that softens when heated and solidifies when cooled, allowing it to be molded and reshaped multiple times without. Thermoplastics are a class of materials that, by reaching a glass. Thermoplastic Design Meaning.

From krusetraining.com

Torsten's Training Tip Polymer Materials Overview Kruse Training Thermoplastic Design Meaning Thermoplastics are a class of materials that, by reaching a glass transition temperature, can be remolded repeatedly [135]. Thermoplastic is a type of plastic material that becomes soft when heated and hard when cooled. Learn its properties, applications, advantages, & disadvantages. Compare & contrast thermoset vs. A thermoplastic is a polymer that softens when heated and solidifies when cooled, allowing. Thermoplastic Design Meaning.

From www.linkedin.com

THERMOPLASTICS & THERMOSET Thermoplastic Design Meaning Compare & contrast thermoset vs. Thermoplastics are a class of materials that, by reaching a glass transition temperature, can be remolded repeatedly [135]. Thermoplastic, also known as a thermosoftening plastic, is a type of polymer which becomes soft when heated and hardens upon cooling. Manufacturers use thermoplastics for many things because they are incredibly easy to mold and. A thermoplastic. Thermoplastic Design Meaning.

From www.slideserve.com

PPT Understanding the Basics of Plastic Materials and the IAPD Thermoplastic Design Meaning Thermoplastic is a type of plastic material that becomes soft when heated and hard when cooled. A thermoplastic is a class of polymer that can be softened through heating and then processed using methods such as extrusion, injection moulding, thermoforming and blow moulding. A thermoplastic is a polymer that softens when heated and solidifies when cooled, allowing it to be. Thermoplastic Design Meaning.

From www.researchgate.net

Schematic representation of the thermoplastic process applied to Thermoplastic Design Meaning Thermoplastic is a type of plastic material that becomes soft when heated and hard when cooled. Manufacturers use thermoplastics for many things because they are incredibly easy to mold and. Learn its properties, applications, advantages, & disadvantages. Thermoplastics are a class of materials that, by reaching a glass transition temperature, can be remolded repeatedly [135]. Thermoplastic, also known as a. Thermoplastic Design Meaning.

From www.eirecomposites.com

Demonstration of Thermoplastic Composites Thermoplastic Design Meaning A thermoplastic is a polymer that softens when heated and solidifies when cooled, allowing it to be molded and reshaped multiple times without. Thermoplastic, also known as a thermosoftening plastic, is a type of polymer which becomes soft when heated and hardens upon cooling. Thermoplastics are a class of materials that, by reaching a glass transition temperature, can be remolded. Thermoplastic Design Meaning.

From www.texplas.com

Texas Plastic Technologies Thermoplastic Materials Guide Thermoplastic Design Meaning Thermoplastic, also known as a thermosoftening plastic, is a type of polymer which becomes soft when heated and hardens upon cooling. Learn its properties, applications, advantages, & disadvantages. Thermoplastics are a class of materials that, by reaching a glass transition temperature, can be remolded repeatedly [135]. A thermoplastic is a polymer that softens when heated and solidifies when cooled, allowing. Thermoplastic Design Meaning.

From www.theengineeringknowledge.com

Blog Page 25 of 108 The Engineering Knowledge Thermoplastic Design Meaning Manufacturers use thermoplastics for many things because they are incredibly easy to mold and. Check out a few examples. Thermoplastics are a class of materials that, by reaching a glass transition temperature, can be remolded repeatedly [135]. Thermoplastic is a type of plastic material that becomes soft when heated and hard when cooled. Learn its properties, applications, advantages, & disadvantages.. Thermoplastic Design Meaning.

From pri-plastics.com

Understanding Thermoforming Plastics Resources Inc. Thermoplastic Design Meaning Check out a few examples. Compare & contrast thermoset vs. Learn its properties, applications, advantages, & disadvantages. Thermoplastic, also known as a thermosoftening plastic, is a type of polymer which becomes soft when heated and hardens upon cooling. Thermoplastics are a class of materials that, by reaching a glass transition temperature, can be remolded repeatedly [135]. A thermoplastic is a. Thermoplastic Design Meaning.

From www.mdpi.com

Polymers Free FullText Different Production Processes for Thermoplastic Design Meaning Thermoplastic, also known as a thermosoftening plastic, is a type of polymer which becomes soft when heated and hardens upon cooling. Compare & contrast thermoset vs. Thermoplastics are a class of materials that, by reaching a glass transition temperature, can be remolded repeatedly [135]. A thermoplastic is a polymer that softens when heated and solidifies when cooled, allowing it to. Thermoplastic Design Meaning.

From www.petervaldivia.com

Fabrication of Plastics Tecnología ESO en Ingles Thermoplastic Design Meaning Thermoplastics are a class of materials that, by reaching a glass transition temperature, can be remolded repeatedly [135]. Manufacturers use thermoplastics for many things because they are incredibly easy to mold and. Thermoplastic is a type of plastic material that becomes soft when heated and hard when cooled. Compare & contrast thermoset vs. Thermoplastic, also known as a thermosoftening plastic,. Thermoplastic Design Meaning.

From www.iqsdirectory.com

Thermoplastic Molding Process, Types, Materials, and Applications Thermoplastic Design Meaning Manufacturers use thermoplastics for many things because they are incredibly easy to mold and. Thermoplastic, also known as a thermosoftening plastic, is a type of polymer which becomes soft when heated and hardens upon cooling. Compare & contrast thermoset vs. Thermoplastic is a type of plastic material that becomes soft when heated and hard when cooled. A thermoplastic is a. Thermoplastic Design Meaning.

From www.findoutaboutplastics.com

Find out about.......Plastics, Polymer Engineering and Leadership Thermoplastic Design Meaning A thermoplastic is a class of polymer that can be softened through heating and then processed using methods such as extrusion, injection moulding, thermoforming and blow moulding. A thermoplastic is a polymer that softens when heated and solidifies when cooled, allowing it to be molded and reshaped multiple times without. Thermoplastics are a class of materials that, by reaching a. Thermoplastic Design Meaning.

From joiavwpnt.blob.core.windows.net

Is Pet 1 Plastic Reusable at Brian Irish blog Thermoplastic Design Meaning Compare & contrast thermoset vs. A thermoplastic is a polymer that softens when heated and solidifies when cooled, allowing it to be molded and reshaped multiple times without. Thermoplastics are a class of materials that, by reaching a glass transition temperature, can be remolded repeatedly [135]. A thermoplastic is a class of polymer that can be softened through heating and. Thermoplastic Design Meaning.