Rack Pinion Drive System . The rack and pinion gear system consists of several essential components that work together to enable smooth and efficient motion transfer. A rack and pinion drive system consists of a rack (or a “linear gear”) and a pinion (or “circular gear”). A rack pinion gear drive is a fundamental mechanical system used to convert rotary motion into linear motion. By using hardened and ground tooth flanks, low backlash and pitch error can be achieved; The rack is a long, straight bar with teeth on one side, while the pinion gear is a small wheel with corresponding teeth. Rack and pinions can also achieve precise positioning and repeatability. Zero backlash can be achieved. The teeth of a rack and pinion drive can be straight or helical, although. The main components include the rack, pinion gear, bearings, and housing. Unlike traditional actuators, the rack and pinion design excels in providing precise positioning and quick response times, ideal for.

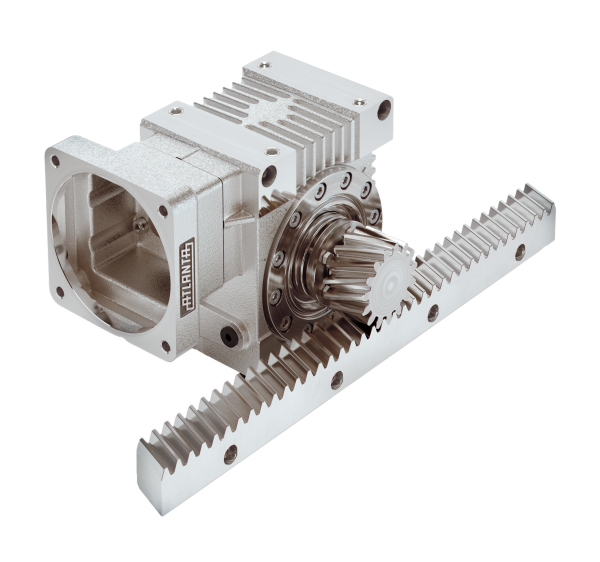

from www.atlantadrives.com

The teeth of a rack and pinion drive can be straight or helical, although. The rack is a long, straight bar with teeth on one side, while the pinion gear is a small wheel with corresponding teeth. Unlike traditional actuators, the rack and pinion design excels in providing precise positioning and quick response times, ideal for. A rack pinion gear drive is a fundamental mechanical system used to convert rotary motion into linear motion. Zero backlash can be achieved. A rack and pinion drive system consists of a rack (or a “linear gear”) and a pinion (or “circular gear”). The main components include the rack, pinion gear, bearings, and housing. By using hardened and ground tooth flanks, low backlash and pitch error can be achieved; Rack and pinions can also achieve precise positioning and repeatability. The rack and pinion gear system consists of several essential components that work together to enable smooth and efficient motion transfer.

ATLANTA Drive Systems, Inc. Rack & Pinion Drive Systems

Rack Pinion Drive System Zero backlash can be achieved. By using hardened and ground tooth flanks, low backlash and pitch error can be achieved; The rack and pinion gear system consists of several essential components that work together to enable smooth and efficient motion transfer. Zero backlash can be achieved. A rack and pinion drive system consists of a rack (or a “linear gear”) and a pinion (or “circular gear”). The main components include the rack, pinion gear, bearings, and housing. The rack is a long, straight bar with teeth on one side, while the pinion gear is a small wheel with corresponding teeth. Unlike traditional actuators, the rack and pinion design excels in providing precise positioning and quick response times, ideal for. Rack and pinions can also achieve precise positioning and repeatability. A rack pinion gear drive is a fundamental mechanical system used to convert rotary motion into linear motion. The teeth of a rack and pinion drive can be straight or helical, although.

From www.stoeber.de

Rack and pinion drives » STOBER Drive Technology Rack Pinion Drive System The teeth of a rack and pinion drive can be straight or helical, although. Unlike traditional actuators, the rack and pinion design excels in providing precise positioning and quick response times, ideal for. Zero backlash can be achieved. A rack pinion gear drive is a fundamental mechanical system used to convert rotary motion into linear motion. By using hardened and. Rack Pinion Drive System.

From www.researchgate.net

Sideways motion of the rack and pinion gear Download Scientific Diagram Rack Pinion Drive System The rack is a long, straight bar with teeth on one side, while the pinion gear is a small wheel with corresponding teeth. Zero backlash can be achieved. The main components include the rack, pinion gear, bearings, and housing. By using hardened and ground tooth flanks, low backlash and pitch error can be achieved; Unlike traditional actuators, the rack and. Rack Pinion Drive System.

From classicautoadvisors.com

Steering System Basics Rack & Pinion vs Recirculating Ball Rack Pinion Drive System A rack pinion gear drive is a fundamental mechanical system used to convert rotary motion into linear motion. The rack and pinion gear system consists of several essential components that work together to enable smooth and efficient motion transfer. Rack and pinions can also achieve precise positioning and repeatability. Zero backlash can be achieved. Unlike traditional actuators, the rack and. Rack Pinion Drive System.

From www.slideserve.com

PPT Rack And Pinion Drive System PPT PowerPoint Presentation, free Rack Pinion Drive System Zero backlash can be achieved. The teeth of a rack and pinion drive can be straight or helical, although. The rack and pinion gear system consists of several essential components that work together to enable smooth and efficient motion transfer. By using hardened and ground tooth flanks, low backlash and pitch error can be achieved; The rack is a long,. Rack Pinion Drive System.

From trends.directindustry.com

Linear Gear Rack Lift Drives Lifgo linear for long stroke distances Rack Pinion Drive System By using hardened and ground tooth flanks, low backlash and pitch error can be achieved; Rack and pinions can also achieve precise positioning and repeatability. The rack is a long, straight bar with teeth on one side, while the pinion gear is a small wheel with corresponding teeth. Zero backlash can be achieved. A rack and pinion drive system consists. Rack Pinion Drive System.

From www.howacarworks.com

How the steering system works How a Car Works Rack Pinion Drive System Rack and pinions can also achieve precise positioning and repeatability. Zero backlash can be achieved. The teeth of a rack and pinion drive can be straight or helical, although. A rack pinion gear drive is a fundamental mechanical system used to convert rotary motion into linear motion. The main components include the rack, pinion gear, bearings, and housing. The rack. Rack Pinion Drive System.

From www.engineeringchoice.com

What is Rack and Pinion? Definition and Application Engineering Choice Rack Pinion Drive System The teeth of a rack and pinion drive can be straight or helical, although. The main components include the rack, pinion gear, bearings, and housing. Zero backlash can be achieved. By using hardened and ground tooth flanks, low backlash and pitch error can be achieved; The rack is a long, straight bar with teeth on one side, while the pinion. Rack Pinion Drive System.

From www.pnpdrive.com

High Precision Rack and Pinion Reducer System 22 Rack Pinion Drive System A rack pinion gear drive is a fundamental mechanical system used to convert rotary motion into linear motion. The rack and pinion gear system consists of several essential components that work together to enable smooth and efficient motion transfer. A rack and pinion drive system consists of a rack (or a “linear gear”) and a pinion (or “circular gear”). The. Rack Pinion Drive System.

From www.designworldonline.com

What are rackandpinion sets? Technical summary Rack Pinion Drive System The rack and pinion gear system consists of several essential components that work together to enable smooth and efficient motion transfer. The main components include the rack, pinion gear, bearings, and housing. The rack is a long, straight bar with teeth on one side, while the pinion gear is a small wheel with corresponding teeth. Unlike traditional actuators, the rack. Rack Pinion Drive System.

From www.finelineautomation.com

Rack and Pinion Drive Fine Line Automation Rack Pinion Drive System Unlike traditional actuators, the rack and pinion design excels in providing precise positioning and quick response times, ideal for. Zero backlash can be achieved. By using hardened and ground tooth flanks, low backlash and pitch error can be achieved; The main components include the rack, pinion gear, bearings, and housing. A rack and pinion drive system consists of a rack. Rack Pinion Drive System.

From www.apexdyna.nl

Linear drives 8 advantages of rack and pinion by Apex Dynamics Rack Pinion Drive System Unlike traditional actuators, the rack and pinion design excels in providing precise positioning and quick response times, ideal for. A rack and pinion drive system consists of a rack (or a “linear gear”) and a pinion (or “circular gear”). A rack pinion gear drive is a fundamental mechanical system used to convert rotary motion into linear motion. By using hardened. Rack Pinion Drive System.

From catalog.orientalmotor.com

LM4F40AZMC1, HighTransportable Mass Rack and Pinion System (100 mm Rack Pinion Drive System By using hardened and ground tooth flanks, low backlash and pitch error can be achieved; The rack is a long, straight bar with teeth on one side, while the pinion gear is a small wheel with corresponding teeth. A rack and pinion drive system consists of a rack (or a “linear gear”) and a pinion (or “circular gear”). Unlike traditional. Rack Pinion Drive System.

From www.machinedesigning.com

Vertical Linear Motion With Rack&Pinion 1 Machine Designing Rack Pinion Drive System A rack pinion gear drive is a fundamental mechanical system used to convert rotary motion into linear motion. The main components include the rack, pinion gear, bearings, and housing. Unlike traditional actuators, the rack and pinion design excels in providing precise positioning and quick response times, ideal for. The rack is a long, straight bar with teeth on one side,. Rack Pinion Drive System.

From www.cnc-parts.net

Everything to Know About CNC Rack and Pinion Parts cncparts Rack Pinion Drive System The rack and pinion gear system consists of several essential components that work together to enable smooth and efficient motion transfer. Unlike traditional actuators, the rack and pinion design excels in providing precise positioning and quick response times, ideal for. The teeth of a rack and pinion drive can be straight or helical, although. Zero backlash can be achieved. The. Rack Pinion Drive System.

From www.arcracing.com

1411 Rack & Pinion (vertical) ARC Racing Rack Pinion Drive System A rack pinion gear drive is a fundamental mechanical system used to convert rotary motion into linear motion. A rack and pinion drive system consists of a rack (or a “linear gear”) and a pinion (or “circular gear”). By using hardened and ground tooth flanks, low backlash and pitch error can be achieved; The main components include the rack, pinion. Rack Pinion Drive System.

From www.linearmotiontips.com

How to size a rackandpinion system for a precision motion axis Rack Pinion Drive System The rack is a long, straight bar with teeth on one side, while the pinion gear is a small wheel with corresponding teeth. The rack and pinion gear system consists of several essential components that work together to enable smooth and efficient motion transfer. The main components include the rack, pinion gear, bearings, and housing. By using hardened and ground. Rack Pinion Drive System.

From www.onallcylinders.com

Rack and Pinion Revisited A Basic Guide to Rack and Pinion Steering Rack Pinion Drive System Unlike traditional actuators, the rack and pinion design excels in providing precise positioning and quick response times, ideal for. The teeth of a rack and pinion drive can be straight or helical, although. By using hardened and ground tooth flanks, low backlash and pitch error can be achieved; The rack is a long, straight bar with teeth on one side,. Rack Pinion Drive System.

From www.linearmotiontips.com

How to size a rackandpinion system for a precision motion axis Rack Pinion Drive System The main components include the rack, pinion gear, bearings, and housing. The teeth of a rack and pinion drive can be straight or helical, although. A rack and pinion drive system consists of a rack (or a “linear gear”) and a pinion (or “circular gear”). Unlike traditional actuators, the rack and pinion design excels in providing precise positioning and quick. Rack Pinion Drive System.

From www.drivesweb.com

Robust, highprecision rack and pinion gears Rack Pinion Drive System By using hardened and ground tooth flanks, low backlash and pitch error can be achieved; The rack and pinion gear system consists of several essential components that work together to enable smooth and efficient motion transfer. A rack pinion gear drive is a fundamental mechanical system used to convert rotary motion into linear motion. The teeth of a rack and. Rack Pinion Drive System.

From www.youtube.com

Rack and Pinion Steering Gearbox Mechanism Working Explained with Rack Pinion Drive System By using hardened and ground tooth flanks, low backlash and pitch error can be achieved; A rack and pinion drive system consists of a rack (or a “linear gear”) and a pinion (or “circular gear”). The rack and pinion gear system consists of several essential components that work together to enable smooth and efficient motion transfer. Zero backlash can be. Rack Pinion Drive System.

From www.youtube.com

ATLANTA ZTRS HighForce Rack & Pinion Drive Systems Overview YouTube Rack Pinion Drive System The rack is a long, straight bar with teeth on one side, while the pinion gear is a small wheel with corresponding teeth. By using hardened and ground tooth flanks, low backlash and pitch error can be achieved; Zero backlash can be achieved. A rack and pinion drive system consists of a rack (or a “linear gear”) and a pinion. Rack Pinion Drive System.

From www.apexdyna.nl

Calculating rack and pinion, how do you do that? Rack Pinion Drive System Unlike traditional actuators, the rack and pinion design excels in providing precise positioning and quick response times, ideal for. A rack and pinion drive system consists of a rack (or a “linear gear”) and a pinion (or “circular gear”). The rack and pinion gear system consists of several essential components that work together to enable smooth and efficient motion transfer.. Rack Pinion Drive System.

From www.engineernewsnetwork.com

Drive system solutions for rack and pinion applications Engineer News Rack Pinion Drive System Rack and pinions can also achieve precise positioning and repeatability. Unlike traditional actuators, the rack and pinion design excels in providing precise positioning and quick response times, ideal for. The main components include the rack, pinion gear, bearings, and housing. By using hardened and ground tooth flanks, low backlash and pitch error can be achieved; A rack pinion gear drive. Rack Pinion Drive System.

From www.pressebox.com

Rackandpinion systems Maximum precision, dynamics and durability Rack Pinion Drive System By using hardened and ground tooth flanks, low backlash and pitch error can be achieved; A rack and pinion drive system consists of a rack (or a “linear gear”) and a pinion (or “circular gear”). Zero backlash can be achieved. The rack is a long, straight bar with teeth on one side, while the pinion gear is a small wheel. Rack Pinion Drive System.

From by-digital-designs.netlify.app

Rack And Pinion Design Calculations Pdf at Design Rack Pinion Drive System Zero backlash can be achieved. A rack and pinion drive system consists of a rack (or a “linear gear”) and a pinion (or “circular gear”). The rack and pinion gear system consists of several essential components that work together to enable smooth and efficient motion transfer. By using hardened and ground tooth flanks, low backlash and pitch error can be. Rack Pinion Drive System.

From www.finelineautomation.com

Rack and Pinion Drive Fine Line Automation Rack Pinion Drive System The teeth of a rack and pinion drive can be straight or helical, although. Zero backlash can be achieved. The rack and pinion gear system consists of several essential components that work together to enable smooth and efficient motion transfer. A rack pinion gear drive is a fundamental mechanical system used to convert rotary motion into linear motion. By using. Rack Pinion Drive System.

From grabcad.com

Free CAD Designs, Files & 3D Models The GrabCAD Community Library Rack Pinion Drive System The rack and pinion gear system consists of several essential components that work together to enable smooth and efficient motion transfer. The main components include the rack, pinion gear, bearings, and housing. A rack pinion gear drive is a fundamental mechanical system used to convert rotary motion into linear motion. A rack and pinion drive system consists of a rack. Rack Pinion Drive System.

From www.shopsabre.com

The truth about rack and pinion drive systems in CNC ShopSabre CNC Rack Pinion Drive System A rack and pinion drive system consists of a rack (or a “linear gear”) and a pinion (or “circular gear”). The rack and pinion gear system consists of several essential components that work together to enable smooth and efficient motion transfer. Rack and pinions can also achieve precise positioning and repeatability. Zero backlash can be achieved. Unlike traditional actuators, the. Rack Pinion Drive System.

From support.lci1.com

2 x 2 Electric Slide System Lippert Customer Care Center Rack Pinion Drive System The teeth of a rack and pinion drive can be straight or helical, although. The rack is a long, straight bar with teeth on one side, while the pinion gear is a small wheel with corresponding teeth. Rack and pinions can also achieve precise positioning and repeatability. The rack and pinion gear system consists of several essential components that work. Rack Pinion Drive System.

From www.mdpi.com

JMMP Free FullText Effect of Rack and Pinion Feed Drive Control Rack Pinion Drive System Zero backlash can be achieved. A rack and pinion drive system consists of a rack (or a “linear gear”) and a pinion (or “circular gear”). Rack and pinions can also achieve precise positioning and repeatability. The rack is a long, straight bar with teeth on one side, while the pinion gear is a small wheel with corresponding teeth. By using. Rack Pinion Drive System.

From www.youtube.com

STOBER Rack and Pinion Overview YouTube Rack Pinion Drive System Rack and pinions can also achieve precise positioning and repeatability. By using hardened and ground tooth flanks, low backlash and pitch error can be achieved; Zero backlash can be achieved. The rack and pinion gear system consists of several essential components that work together to enable smooth and efficient motion transfer. A rack pinion gear drive is a fundamental mechanical. Rack Pinion Drive System.

From www.atlantadrives.com

ATLANTA Drive Systems, Inc. Rack & Pinion Drive Systems Rack Pinion Drive System By using hardened and ground tooth flanks, low backlash and pitch error can be achieved; Rack and pinions can also achieve precise positioning and repeatability. The teeth of a rack and pinion drive can be straight or helical, although. A rack pinion gear drive is a fundamental mechanical system used to convert rotary motion into linear motion. The rack and. Rack Pinion Drive System.

From www.directindustry.com

Rack and pinion drive lean SL® double LEANTECHNIK AG Rack Pinion Drive System Zero backlash can be achieved. Unlike traditional actuators, the rack and pinion design excels in providing precise positioning and quick response times, ideal for. Rack and pinions can also achieve precise positioning and repeatability. A rack pinion gear drive is a fundamental mechanical system used to convert rotary motion into linear motion. The main components include the rack, pinion gear,. Rack Pinion Drive System.

From www.avidcnc.com

PRO Rack and Pinion Drive, NEMA 23 Avid CNC Rack Pinion Drive System The rack is a long, straight bar with teeth on one side, while the pinion gear is a small wheel with corresponding teeth. A rack pinion gear drive is a fundamental mechanical system used to convert rotary motion into linear motion. Unlike traditional actuators, the rack and pinion design excels in providing precise positioning and quick response times, ideal for.. Rack Pinion Drive System.

From www.uskoreahotlink.com

High Precision Gearbox and Zero Backlash Rack Pinion Rack Pinion Drive System The rack and pinion gear system consists of several essential components that work together to enable smooth and efficient motion transfer. By using hardened and ground tooth flanks, low backlash and pitch error can be achieved; Zero backlash can be achieved. The rack is a long, straight bar with teeth on one side, while the pinion gear is a small. Rack Pinion Drive System.